Spring assembly auxiliary loading and unloading tooling

A spring assembly and loading and unloading technology, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problem of loading and unloading tools without a guiding structure, etc., and achieve the effect of saving operation time, improving operation efficiency, and reducing stress and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

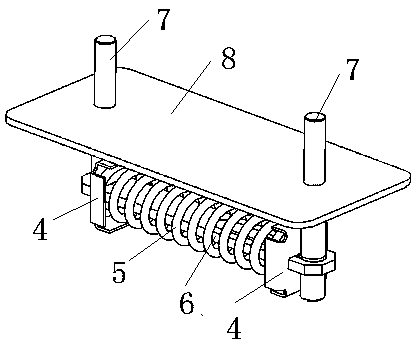

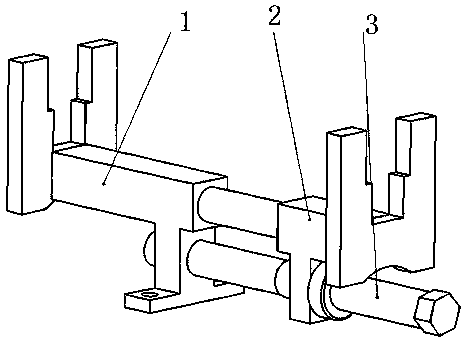

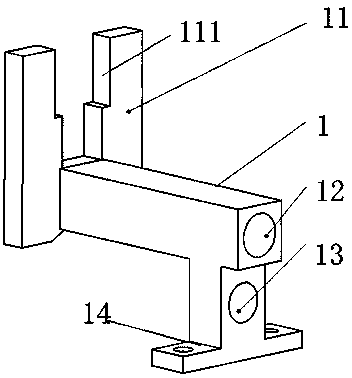

[0022] The specific embodiment of the spring assembly assisting the loading and unloading tool of the present invention, such as Figure 2 to Figure 6 As shown, the auxiliary loading and unloading tooling of the spring assembly can be applied to the loading and unloading of the opening spring and the closing spring as the tension spring, and also can be applied to the loading and unloading of the opening spring and the closing spring as the compression spring. The first base 1 and the second base 2 that are close to and away from each other have a left force application part 11 on the first base 1, a right force application part 21 on the second base 2, and the left force application part 11 and the right force application part 21. A spring assembly is placed between the force applying parts 21 , and the left and right force applying parts apply force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com