Loading and unloading mechanism for small-module bevel gears

A technology of bevel gear and small module, which is applied in the field of small module bevel gear loading and unloading mechanism, which can solve the problems of difficult clamping and slow loading and unloading of products, and achieve the effects of stable and precise movement, stable operation and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

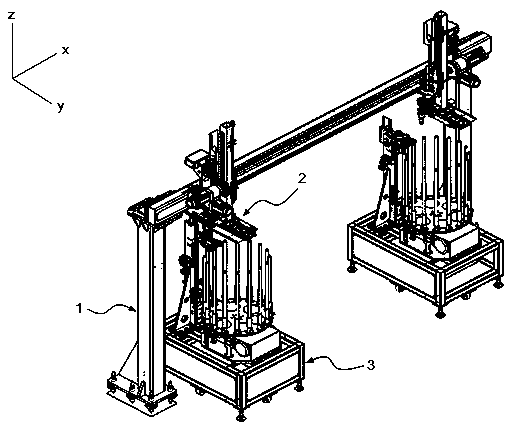

[0046] Specific examples Figure 1 to Figure 14 shown, where in figure 1 The XYZ coordinate direction is defined in , a small modulus bevel gear loading and unloading mechanism, including:

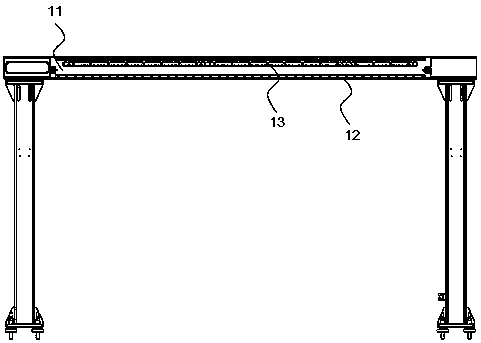

[0047] The gantry truss 1 includes a beam 11, a double guide rail A12 is fixed on one side of the beam 11, and a rack A13 is arranged between the double guide rails A12;

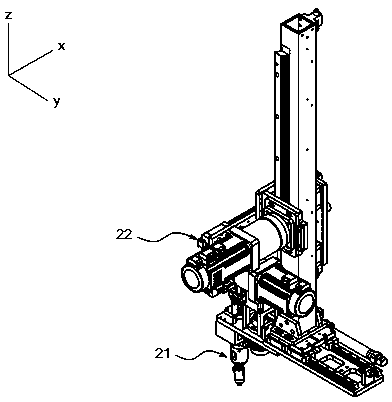

[0048] The feeding mechanism 2 is arranged on the crossbeam 11 and includes the internal expansion fixture 21, the internal expansion fixture 21 realizes the three-dimensional movement of the space through the driving mechanism 22, and the driving mechanism 22 is connected on the double guide rail A12, such as figure 1 shown in;

[0049] The internal expansion fixture 21 includes:

[0050] Expansion sleeve 211, one end of the expansion sleeve 211 is a connecting seat 212, and the other end is a petal-shaped expansion head 213; the expansion sleeve 211 is provided with an expansion core 214, and the free end of the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com