Traction type all-in-one machine integrating forest residue picking, crushing and compression

A residual, traction-type technology, applied in the fields of botanical equipment and methods, plant cultivation, gardening, etc., can solve the problems of crushing or compressing device damage, rough roads, insufficient pickup, etc., and achieves convenient collection and simple device structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the traction-type forest area residue picking, crushing and compressing integrated machine described in this embodiment, it includes traction device 1, picker 3, filter plate 4, baffle plate 5, sealing transmission cylinder 6, front wheel 7. Conveyor belt 8, diesel engine 9, cyclone separator 10, rear wheel 11, crushing box 12, sawtooth type crushing mechanism 14, throwing knife type crushing mechanism 15, frame body 16 and compression device 17;

[0019] The frame body 16 is a triangle on the left and right sides, and the main body of the frame body 16 is a rectangular or trapezoidal box structure with the upper and lower sides. Two front wheels 7 and two rear wheels 7 are installed on the lower side of the frame body 16. Wheels 11, the two front wheels 7 and the two rear wheels 11 are respectively connected by bearings;

[0020] The front end of frame body 16 is provided with pickup 3, and...

specific Embodiment approach 2

[0032] Specific embodiment 2. This embodiment is a further description of the traction-type forest residue picking, crushing and compressing machine described in specific embodiment 1. The frame body 16 includes a steel plate, a box body for installing a diesel engine, and a wheel installation. frame; the diesel engine and the steel plate are bolted, the wheel mounting frame is welded on the lower surface of the steel plate, and the box body for installing the diesel engine is welded on the upper surface of the steel plate.

specific Embodiment approach 3

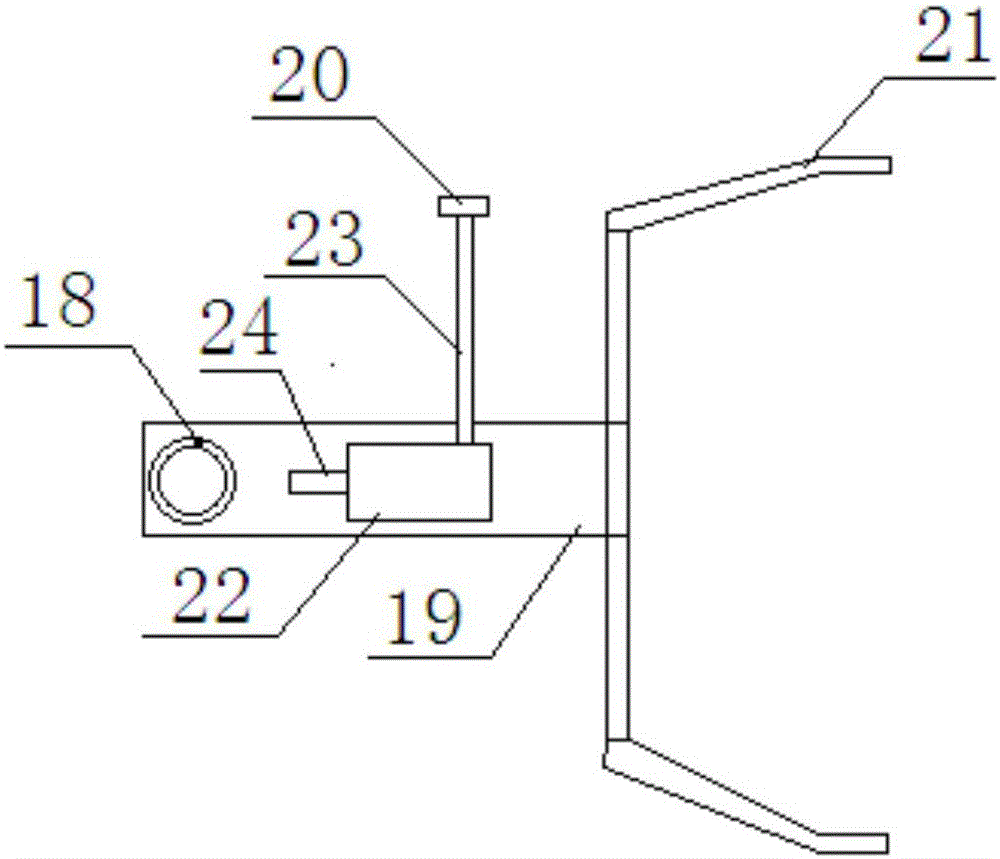

[0033] Specific embodiment three, combine figure 2 This embodiment is described. This embodiment is a further description of the traction-type forest area residue picking, crushing and compression machine described in the first specific embodiment. The traction device 1 includes a traction bracket buckle 18, a traction beam 19 and a walking wheel; the traction bracket buckle 18 is welded on the upper surface of the traction beam 19, and the rear end of the traction beam 19 is connected with two fixing frames 21 through a cross bar, and the two fixing frames 21 are welded on the frame body 16 The front end of the front end, the road wheel is installed on the lower surface of the traction beam 19 through the connecting rod, and the upper surface of the traction beam 19 is also fixed with a cardan shaft 24, and one end of the cardan shaft 24 is connected with the input shaft of the reducer 22, The reducer 22 forms a key fit with the pulley 20 through the power output shaft 23, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com