Automatic grabbing device for injection-molded blades

A grabbing device and automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of excessive labor, high labor intensity, and low production efficiency, and achieve the goal of reducing production costs, reducing labor intensity, and ensuring labor safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

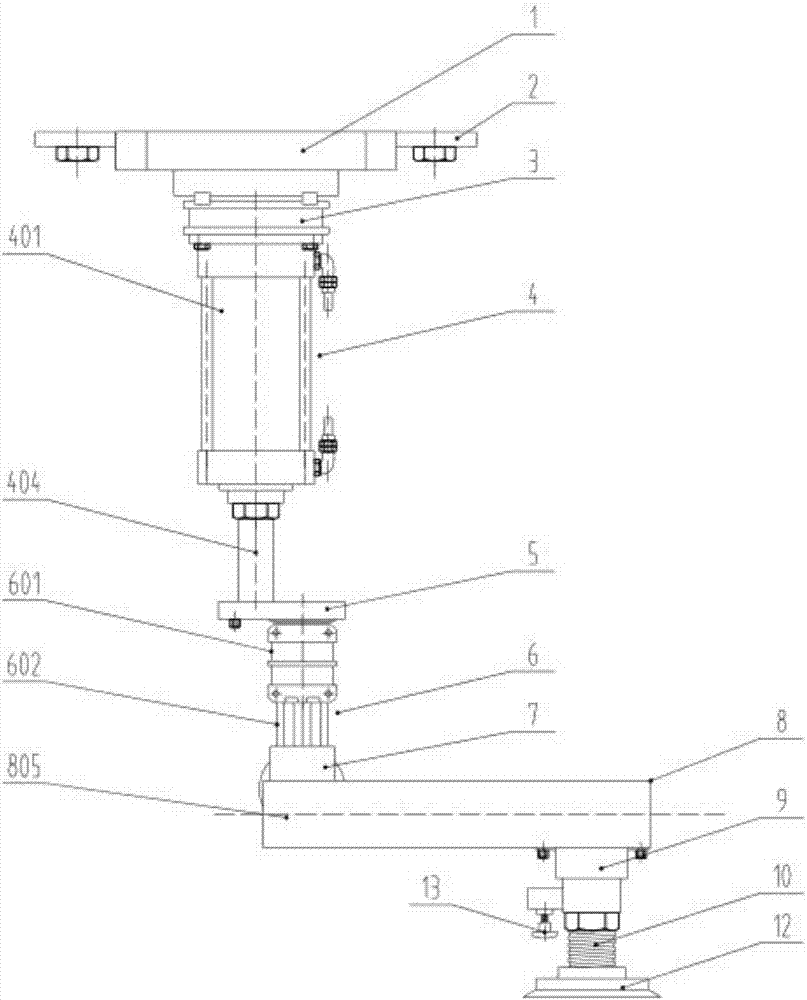

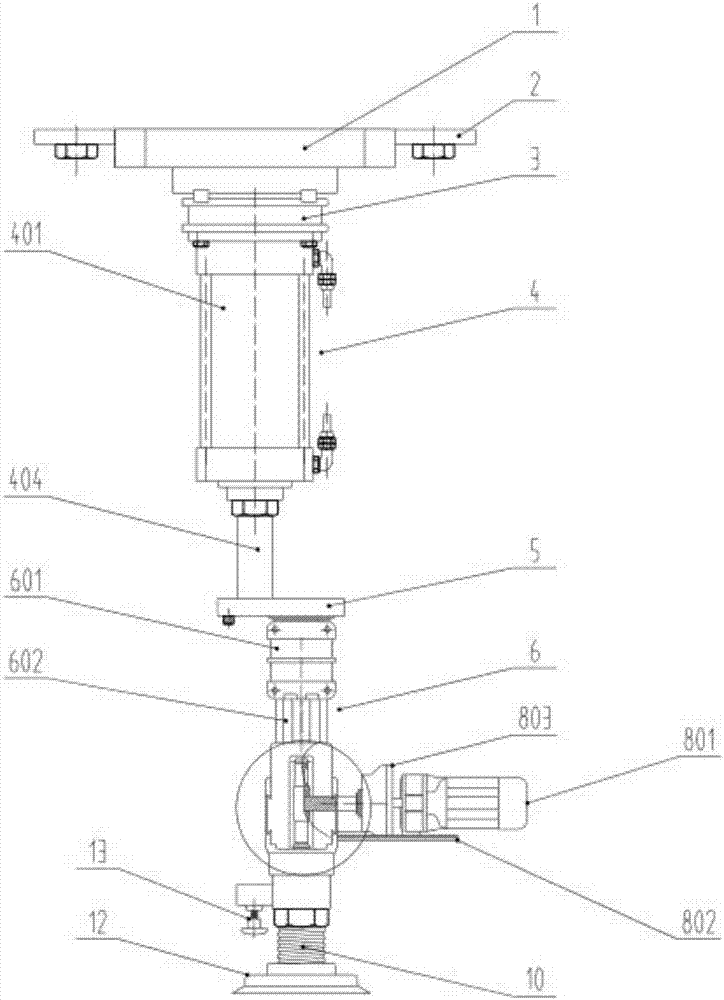

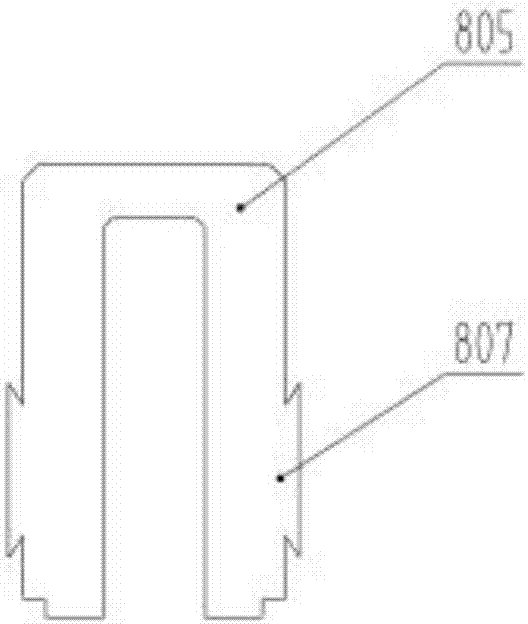

[0023] An automatic grasping device for injection molding blades, comprising a mounting seat 1, a fixed plate 2, a buffer 3, a vertical drive mechanism 4, a connecting plate 5, a rotating mechanism 6, a connecting block I7, a horizontal driving mechanism 8, a connecting block II9, and an outer screw 10. The solenoid valve 11, the suction cup 12 and the fastening bolt 13, characterized in that: the mounting seat 1 is fixedly connected to the fixing plate 2, and the fixing plate 2 is installed on the host or casing, and the mounting seat 1 is perpendicular to The driving mechanism 4 is fixedly connected by a buffer 3, a connecting plate 5 is installed under the vertical driving mechanism 4, and the connecting plate 5 is fixedly connected to the rotating mechanism 6, and the rotating mechanism 6 is movable with the horizontal driving mechanism 8 through the connecting block I7. The horizontal drive mechanism 8 is fixedly connected to the outer screw 13 through a connecting block II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com