Patents

Literature

30results about How to "Ensure labor safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

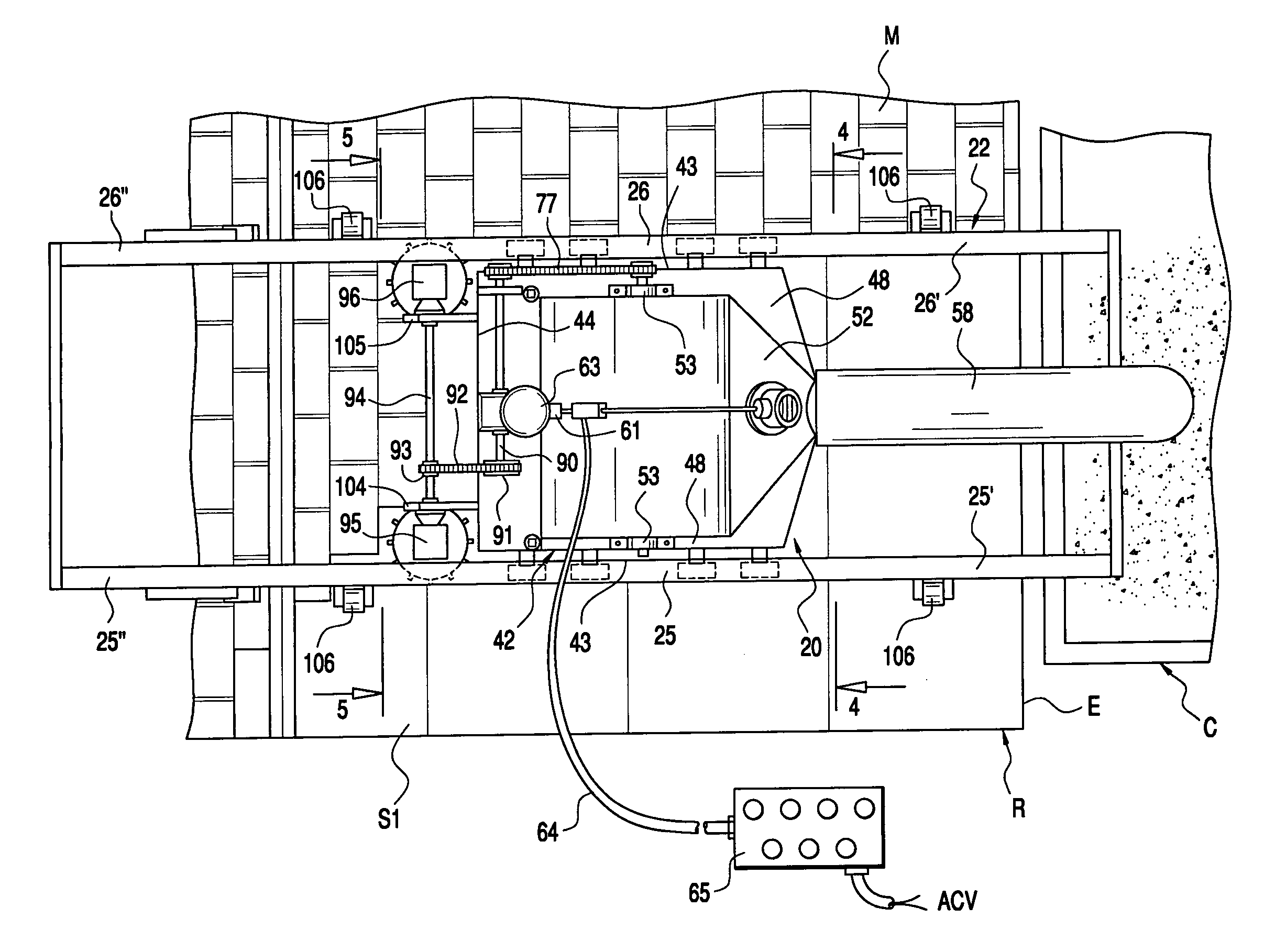

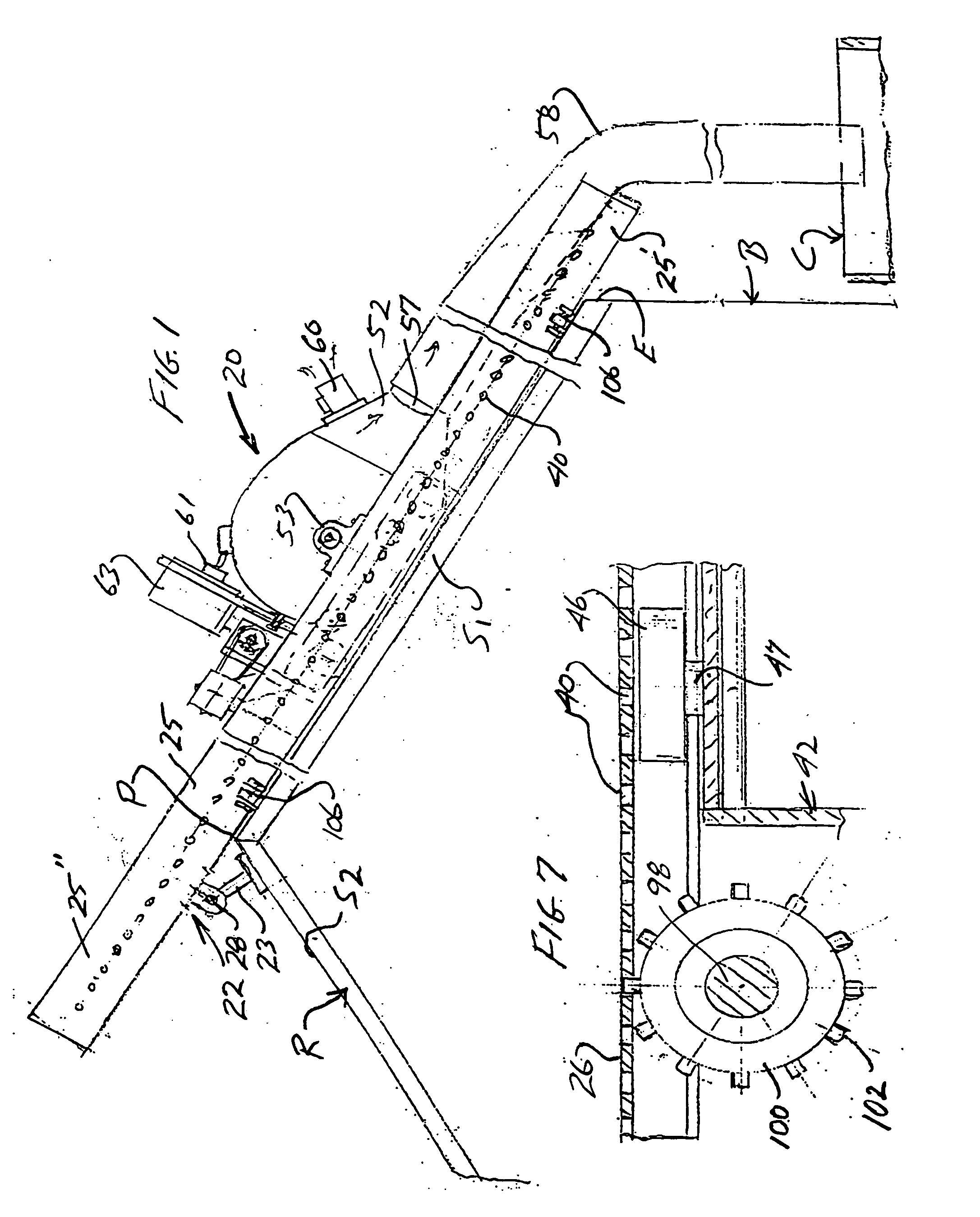

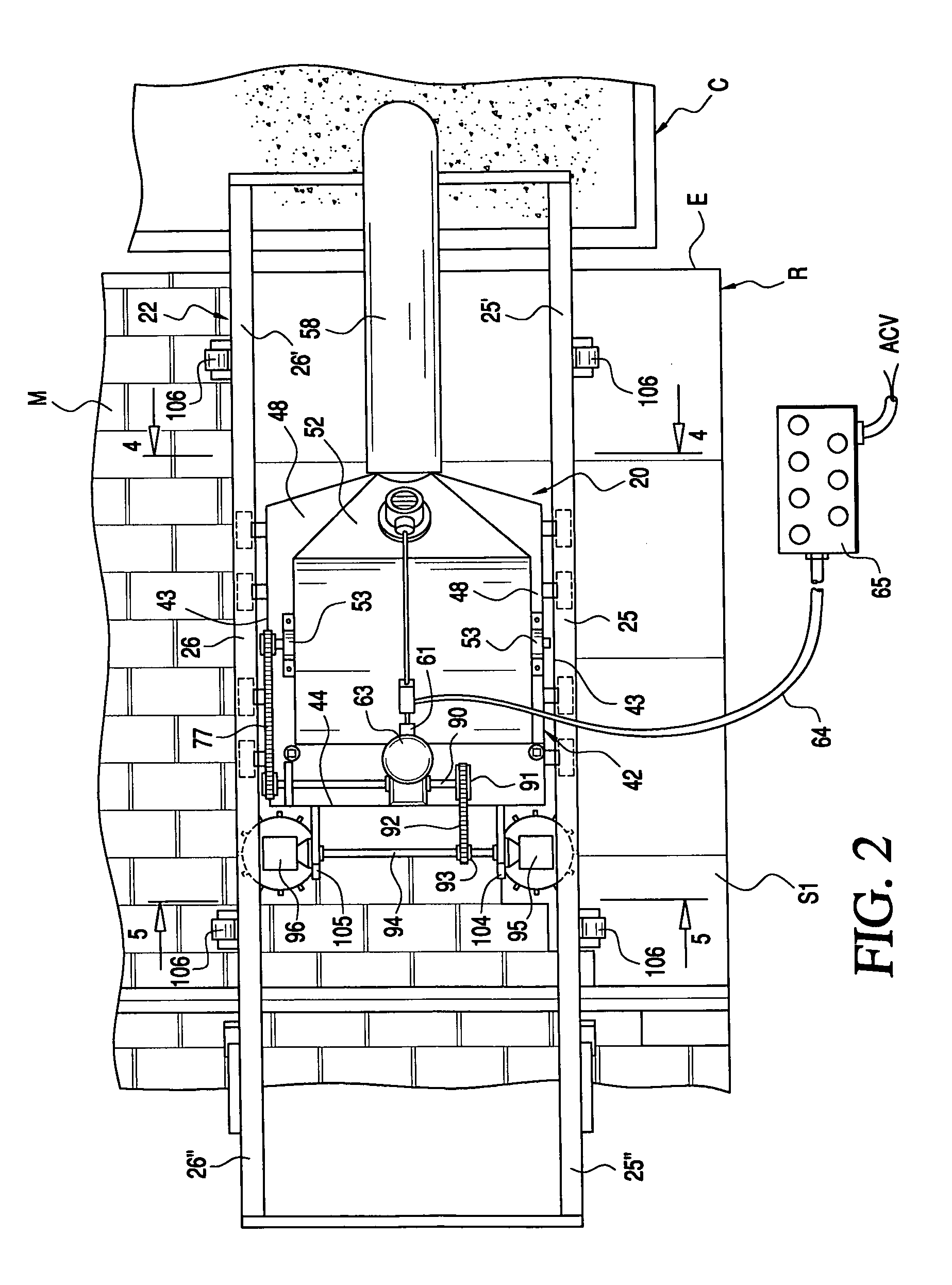

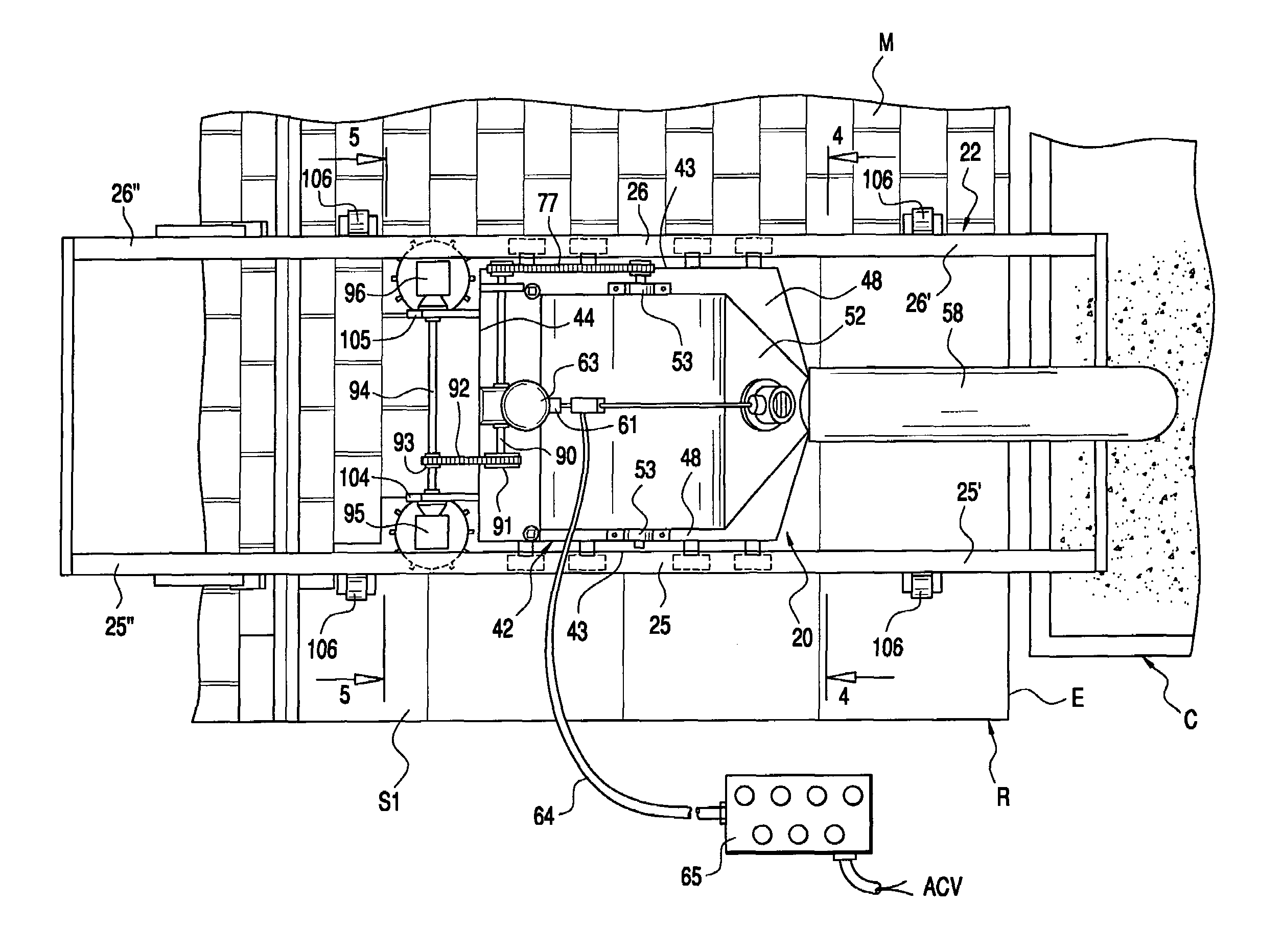

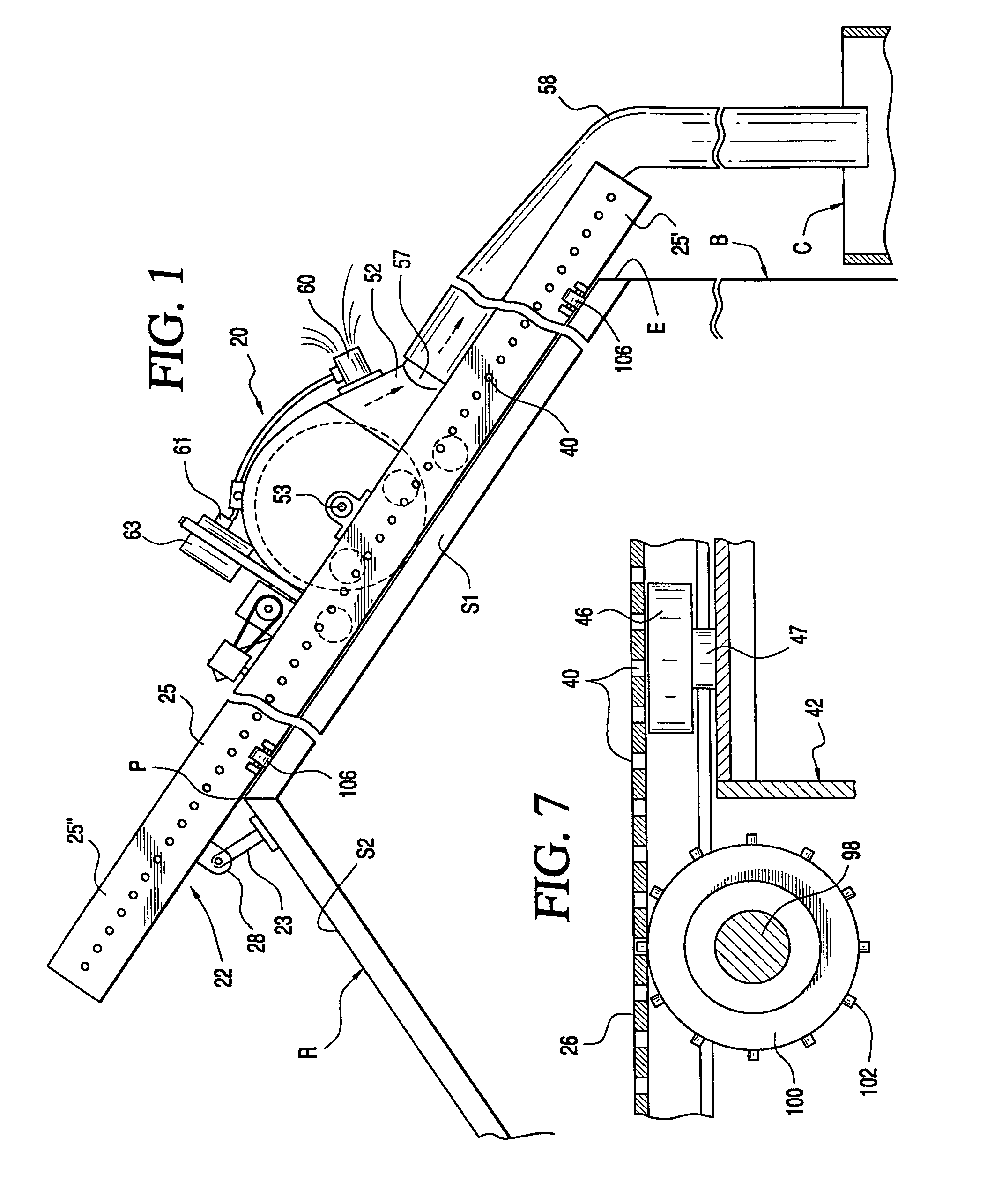

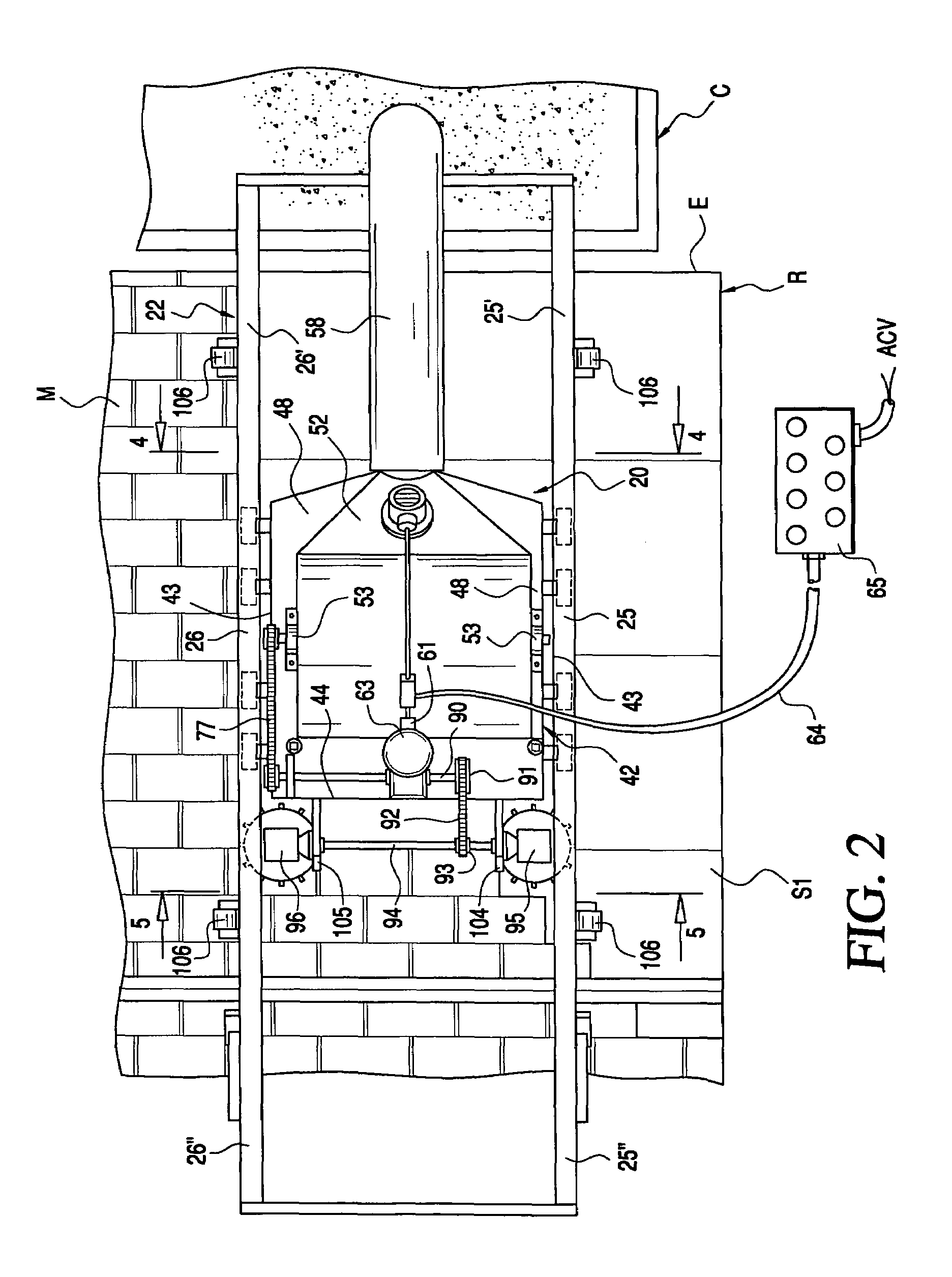

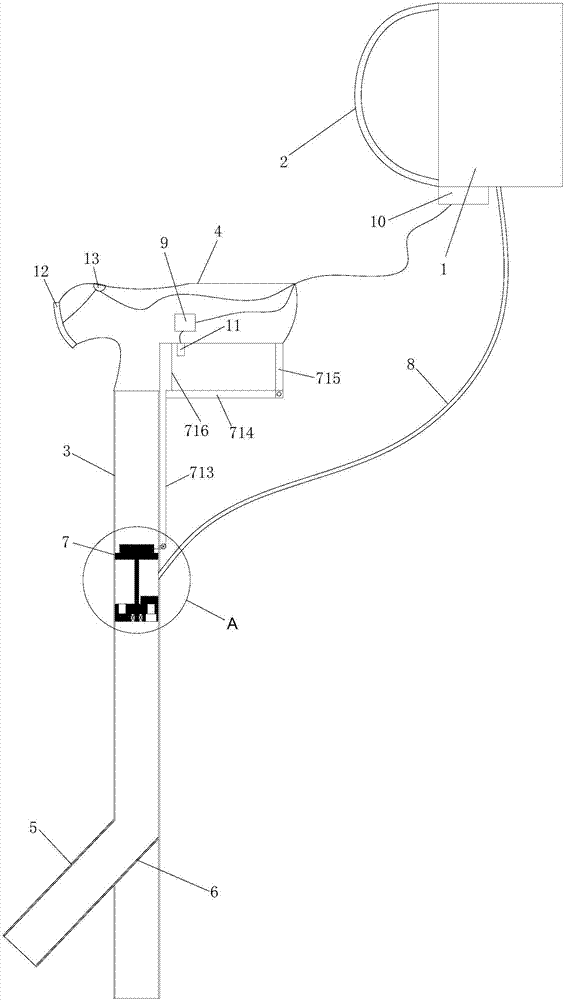

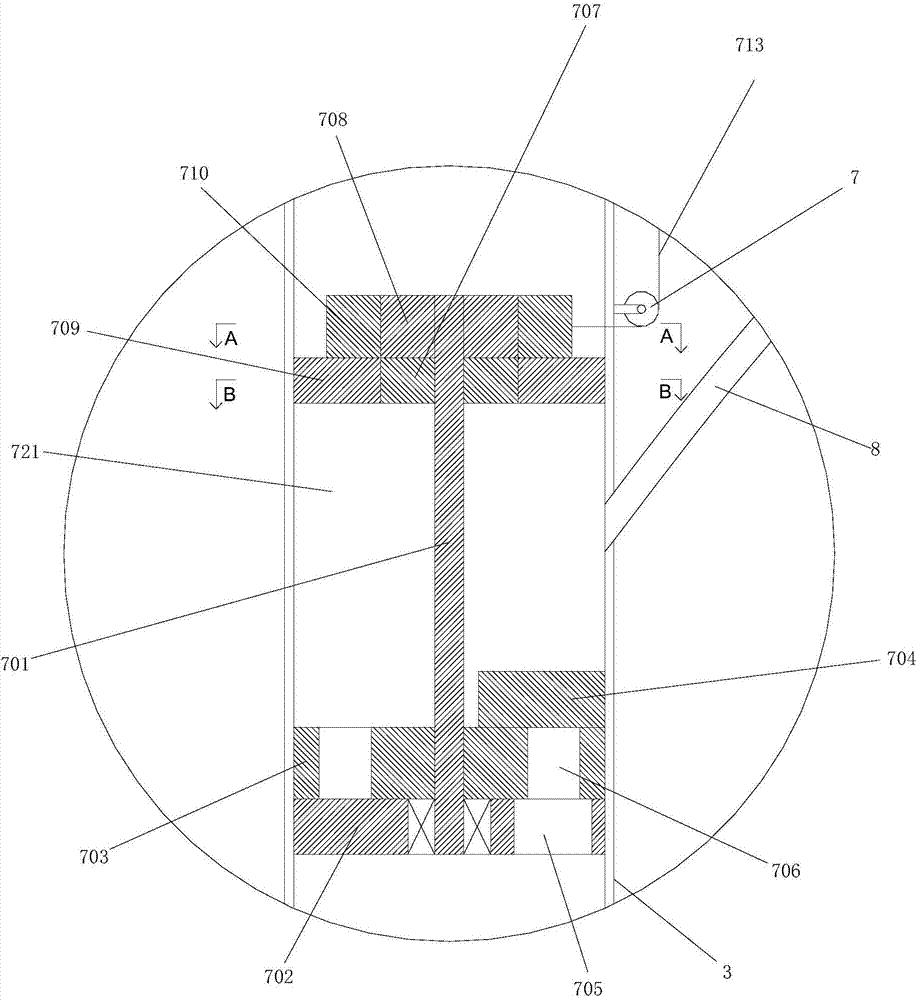

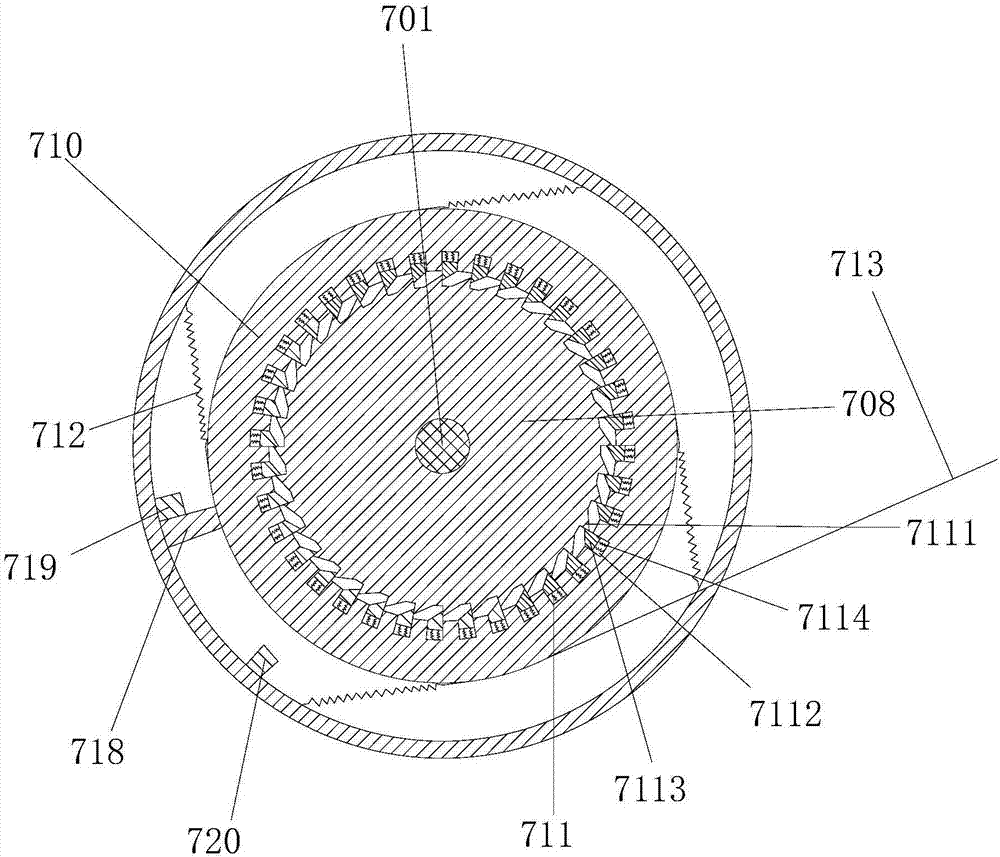

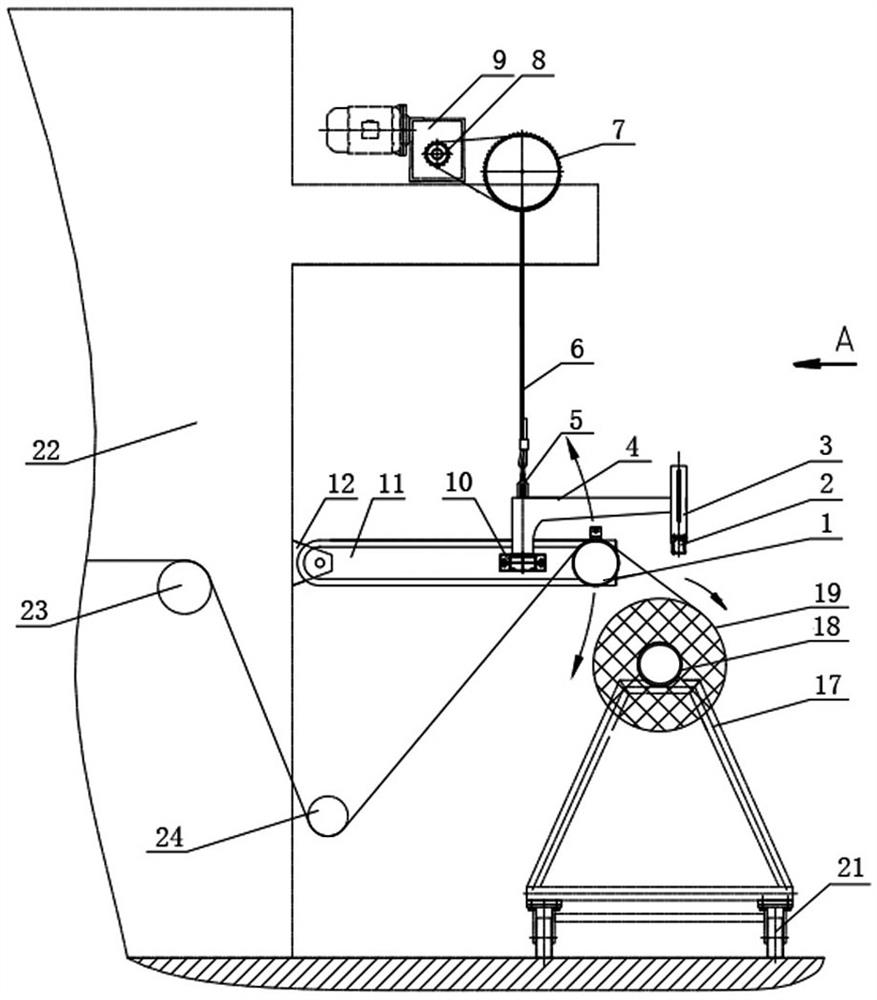

Automated roofing material removal machine and method

ActiveUS20070164597A1Ensure labor safetyQuick serviceRoof toolsMetal working apparatusControl powerMaterial removal

A roofing material removal machine and method for removing roofing materials wherein the machine travels along guide rails mounted on a roof surface and roofing material lifting elements carried by the machine are operated to lift the roofing materials as the machine moves along the guide rails after which the removed materials are conveyed to a collection receptacle. A remote control device may be used to control power to and movement of the machine along the guide rails.

Owner:ARREL TECH

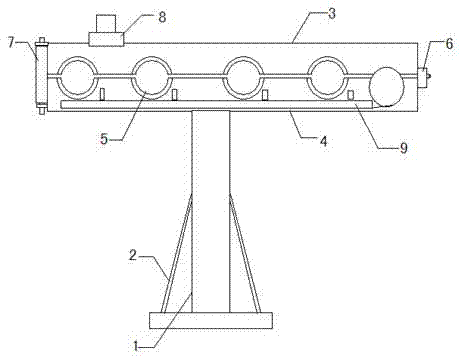

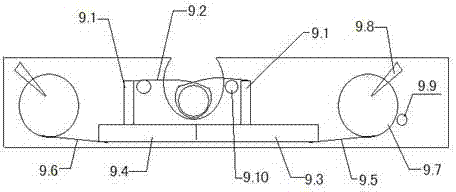

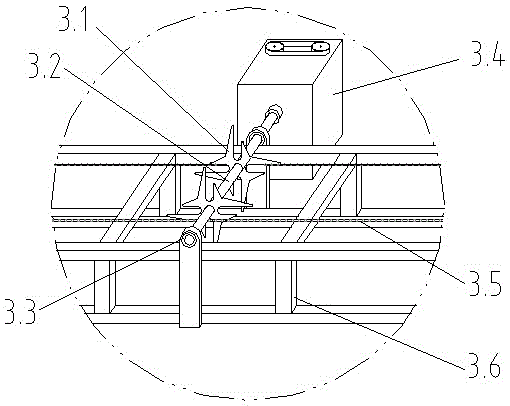

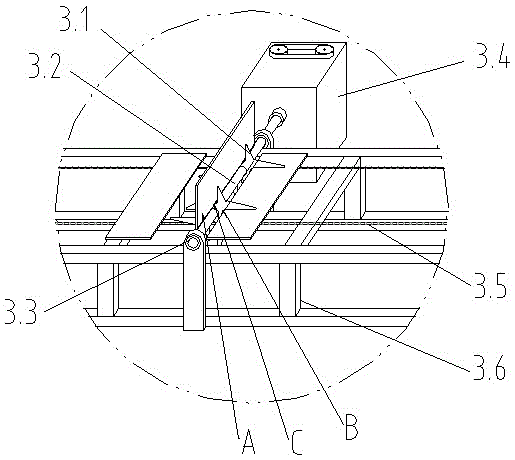

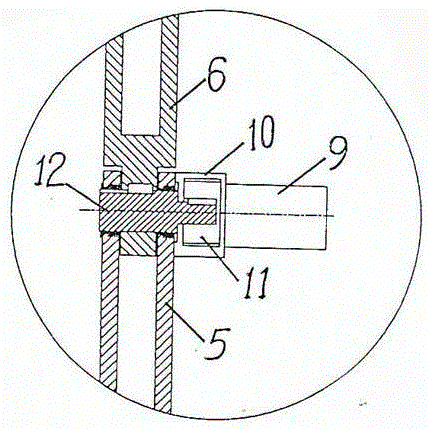

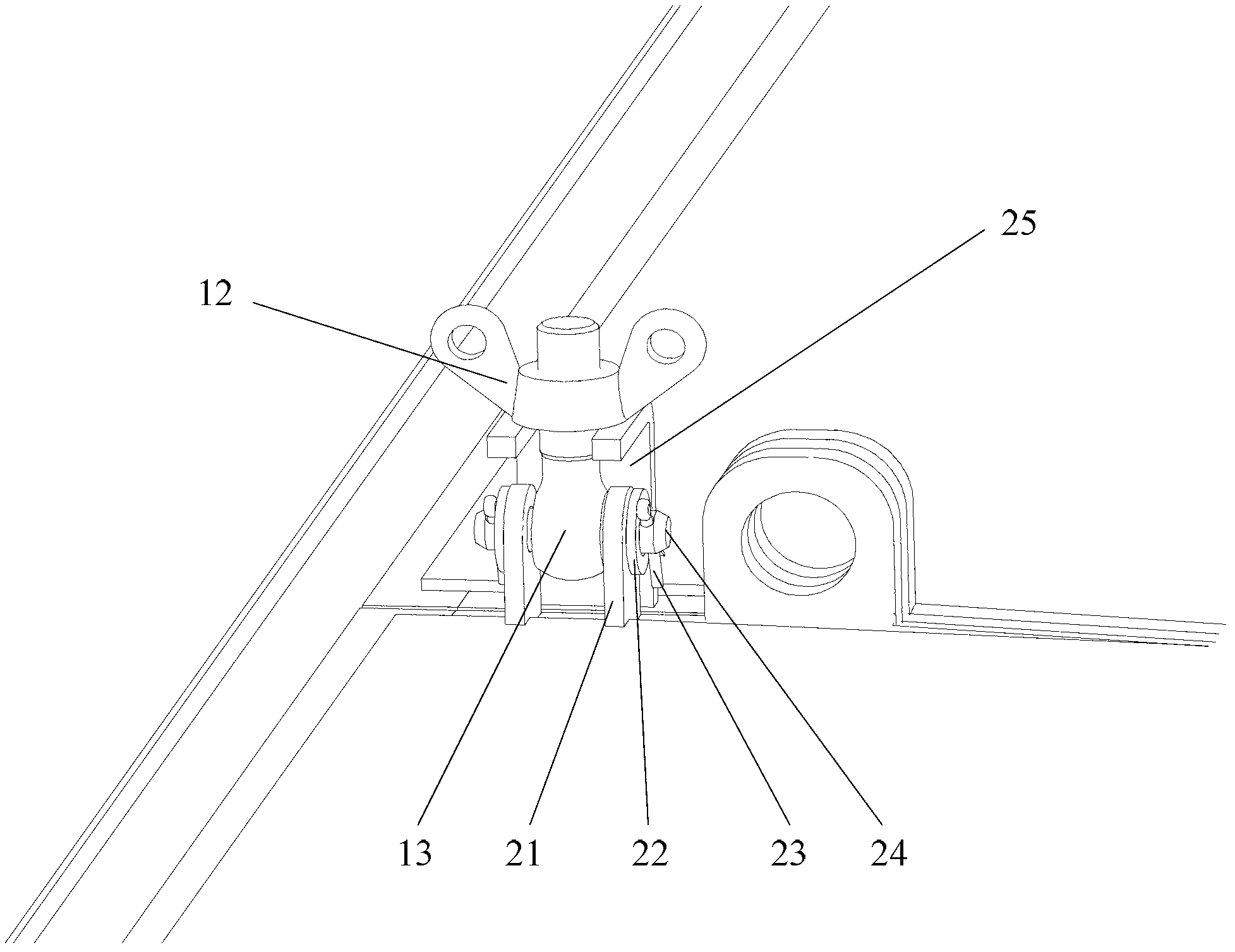

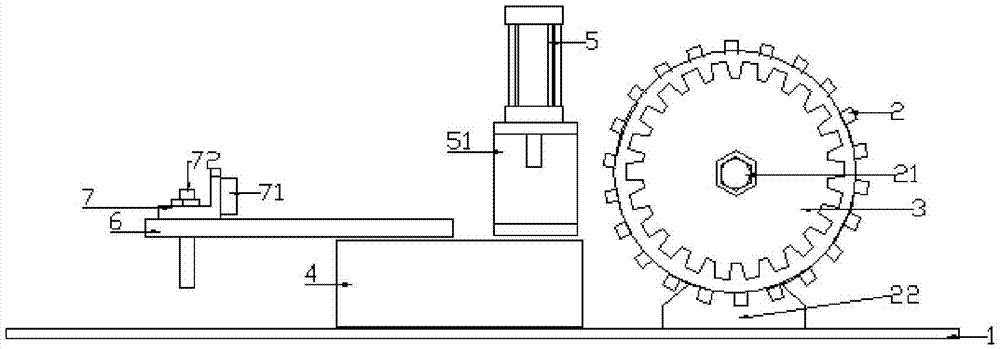

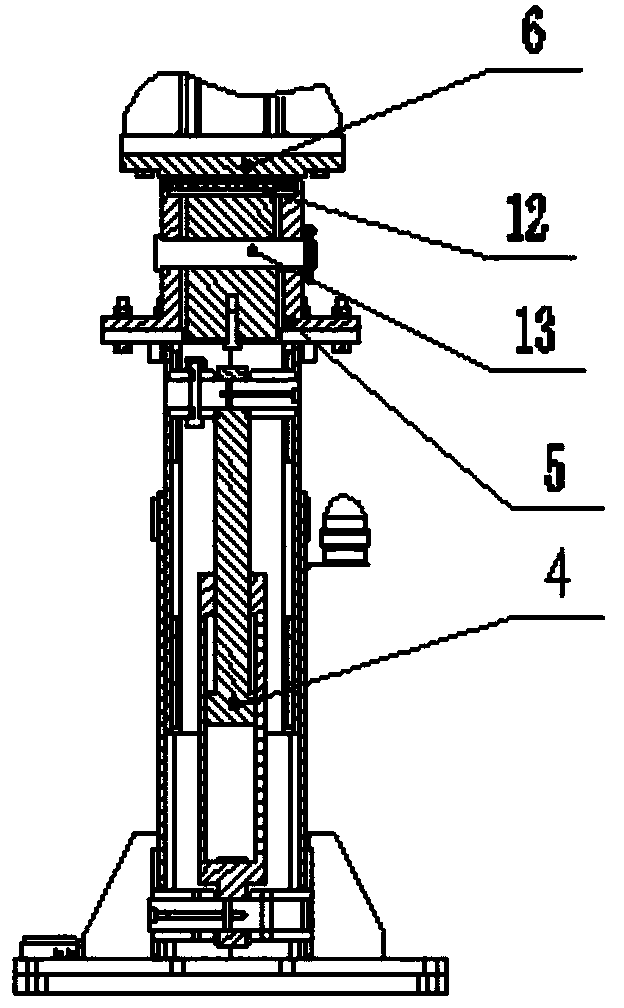

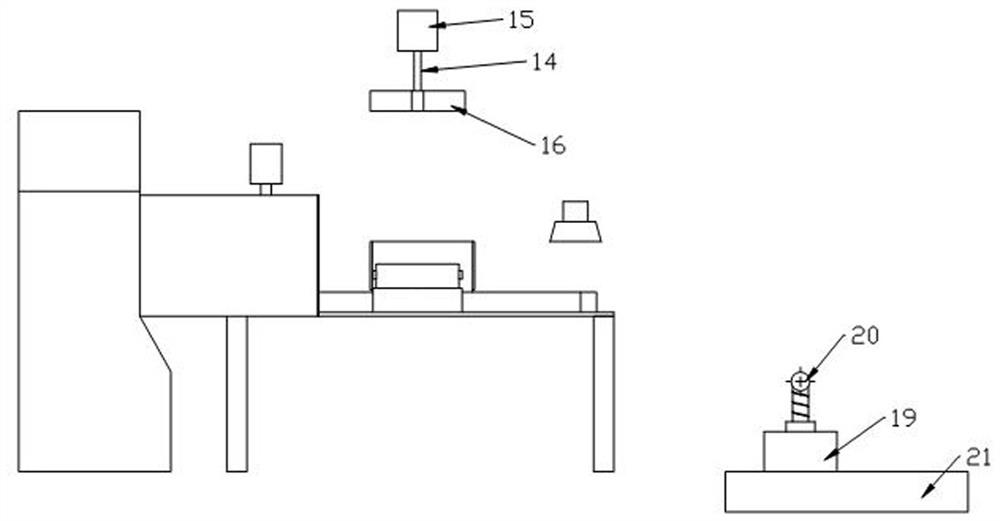

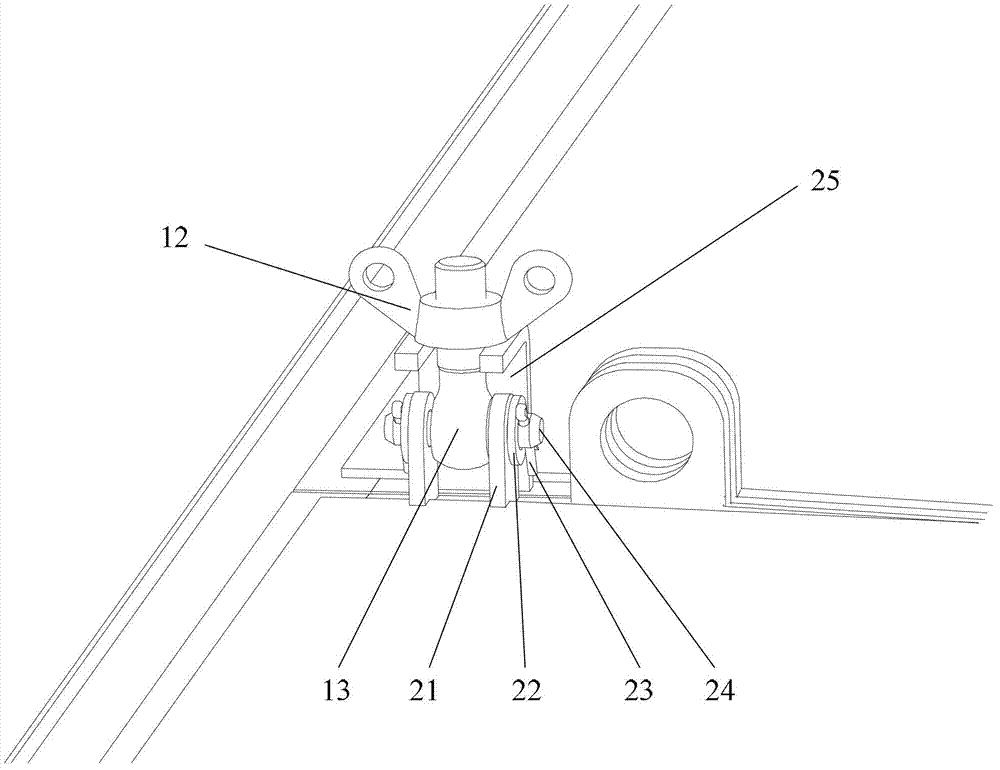

Insulating rod withstand voltage test testing device and locating method

InactiveCN104714154AAchieve clampingImprove accuracyTesting dielectric strengthMeasurement instrument housingTransformerUltimate tensile strength

The invention relates to an insulating rod withstand voltage test testing device and a locating method. According to the technical scheme, the insulating rod withstand voltage test testing device comprises a support rod, clamping sleeves, a hinge and a threaded rod, wherein the bottom of the support rod is provided with side support frames, the top of the support rod is connected with the clamping sleeves, the clamping sleeves comprise an upper clamping sleeve and a lower clamping sleeve, the upper clamping sleeve is connected with one end of the lower clamping sleeve through the hinge in a hinged mode, the upper clamping sleeve is connected with the other end of the lower clamping sleeve through the threaded rod, the upper clamping sleeve and the lower clamping sleeve are provided with semicircular grooves which are mutually matched, insulating rod through holes are formed after the semicircular grooves in the upper clamping sleeve and the lower clamping sleeve are closed, the upper clamping sleeve is provided with a conducting bolt, and a support electrode closer is arranged between every two semicircular grooves. The insulating rod withstand voltage test testing device and the locating method have the advantages that the labor safety of personnel is guaranteed, the installing efficiency is improved, the labor intensity of construction personnel is reduced, the normal operation of a transformer is guaranteed, and normal power supply is supplied.

Owner:STATE GRID CORP OF CHINA +1

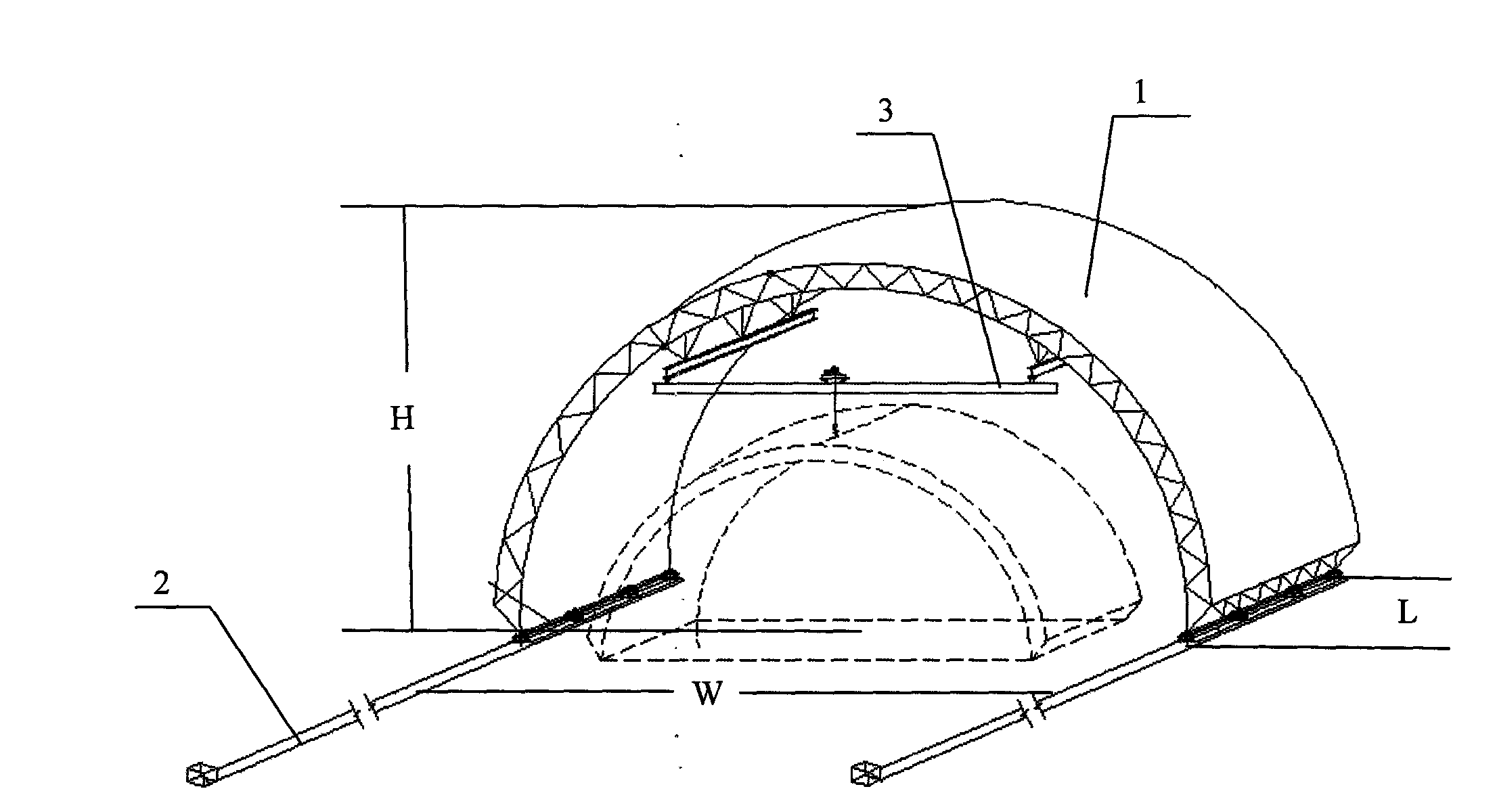

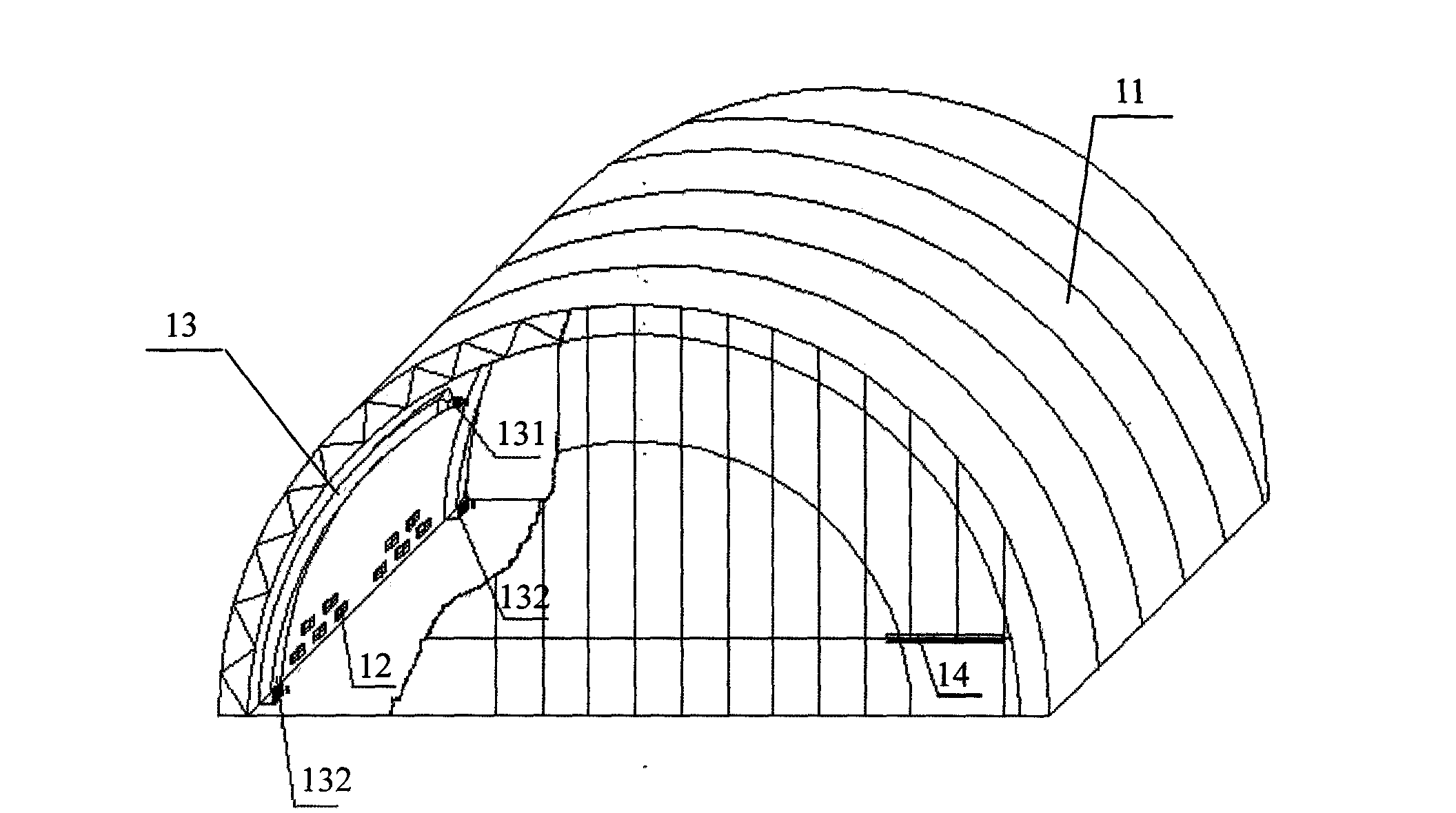

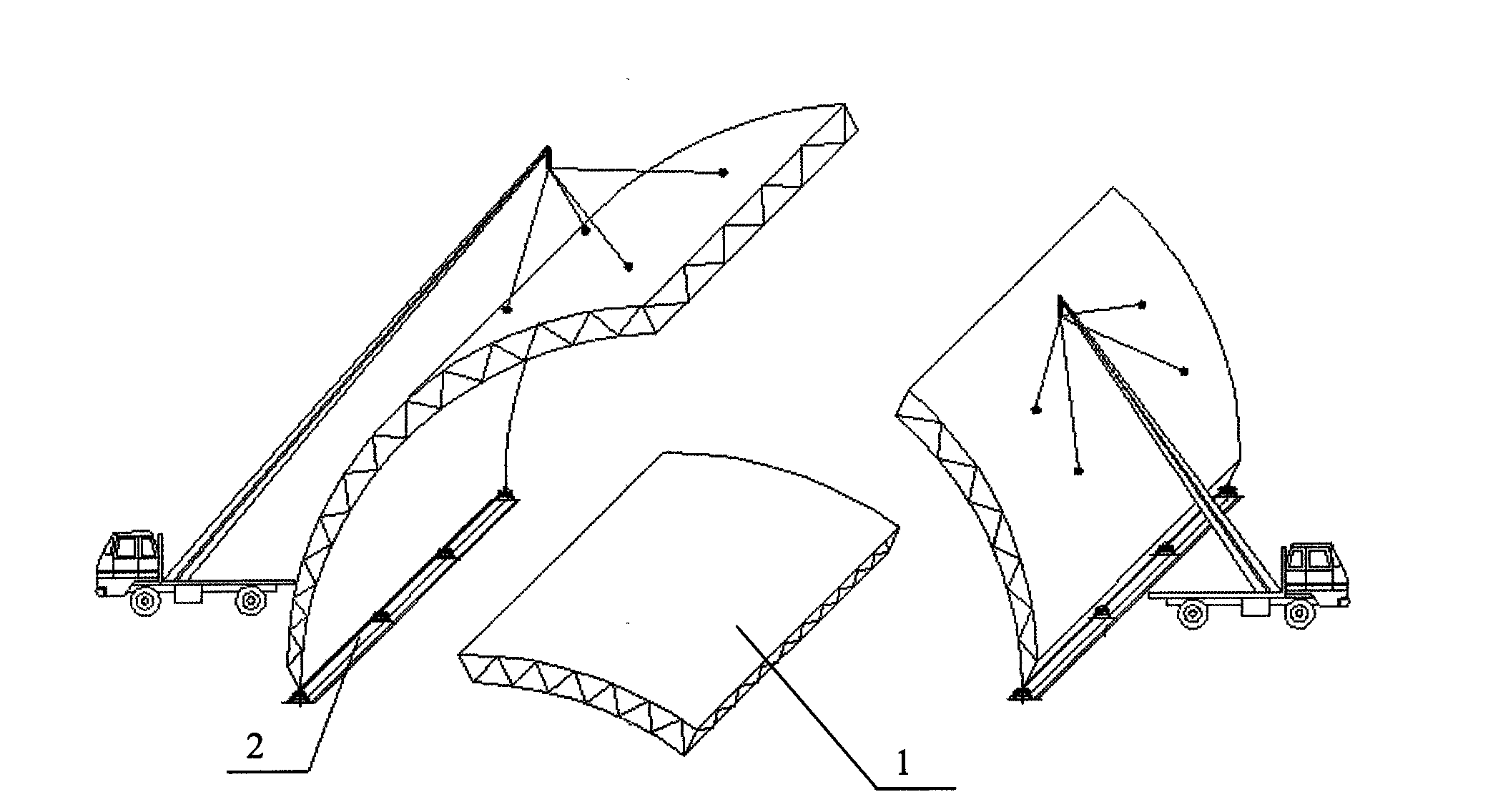

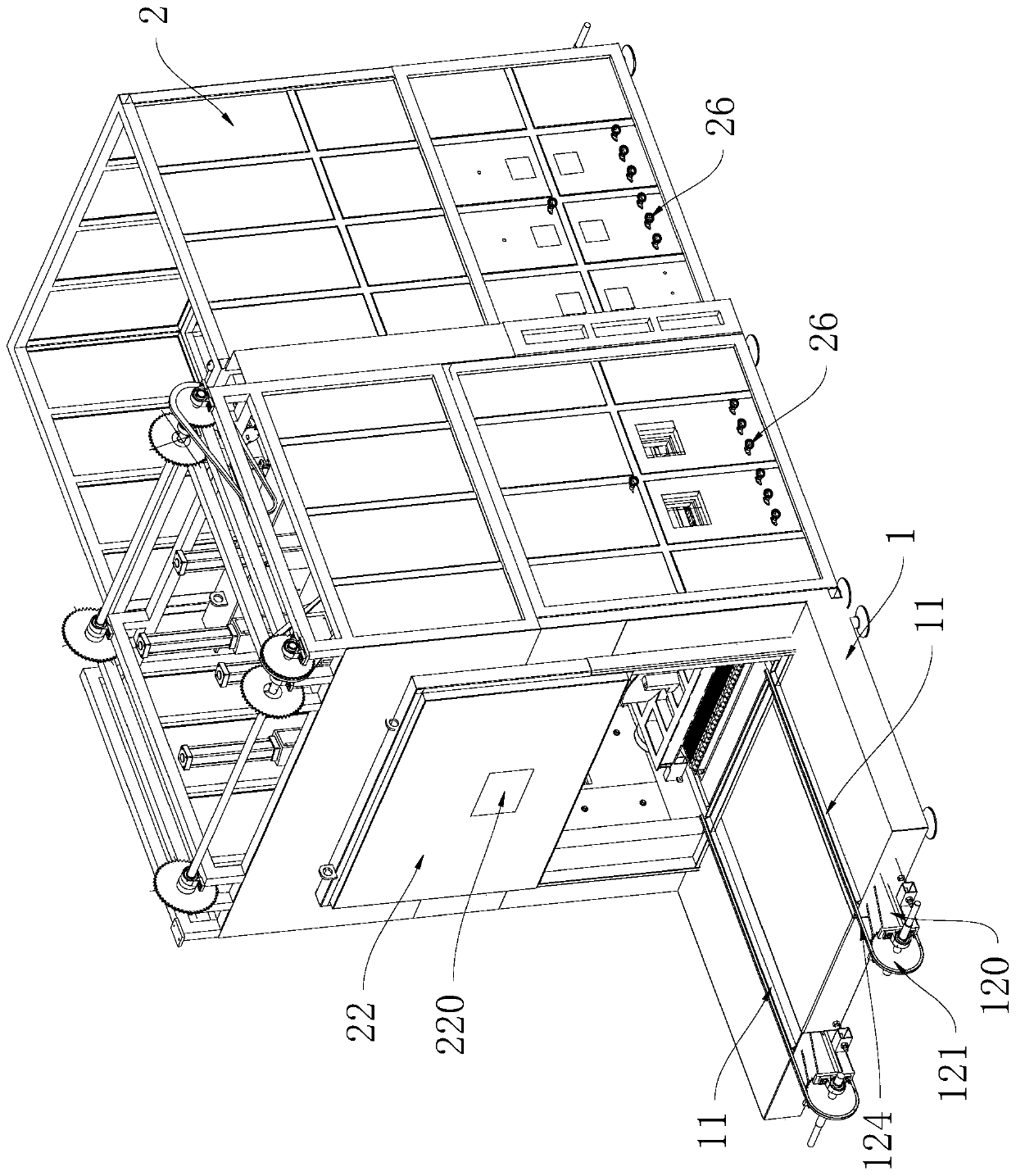

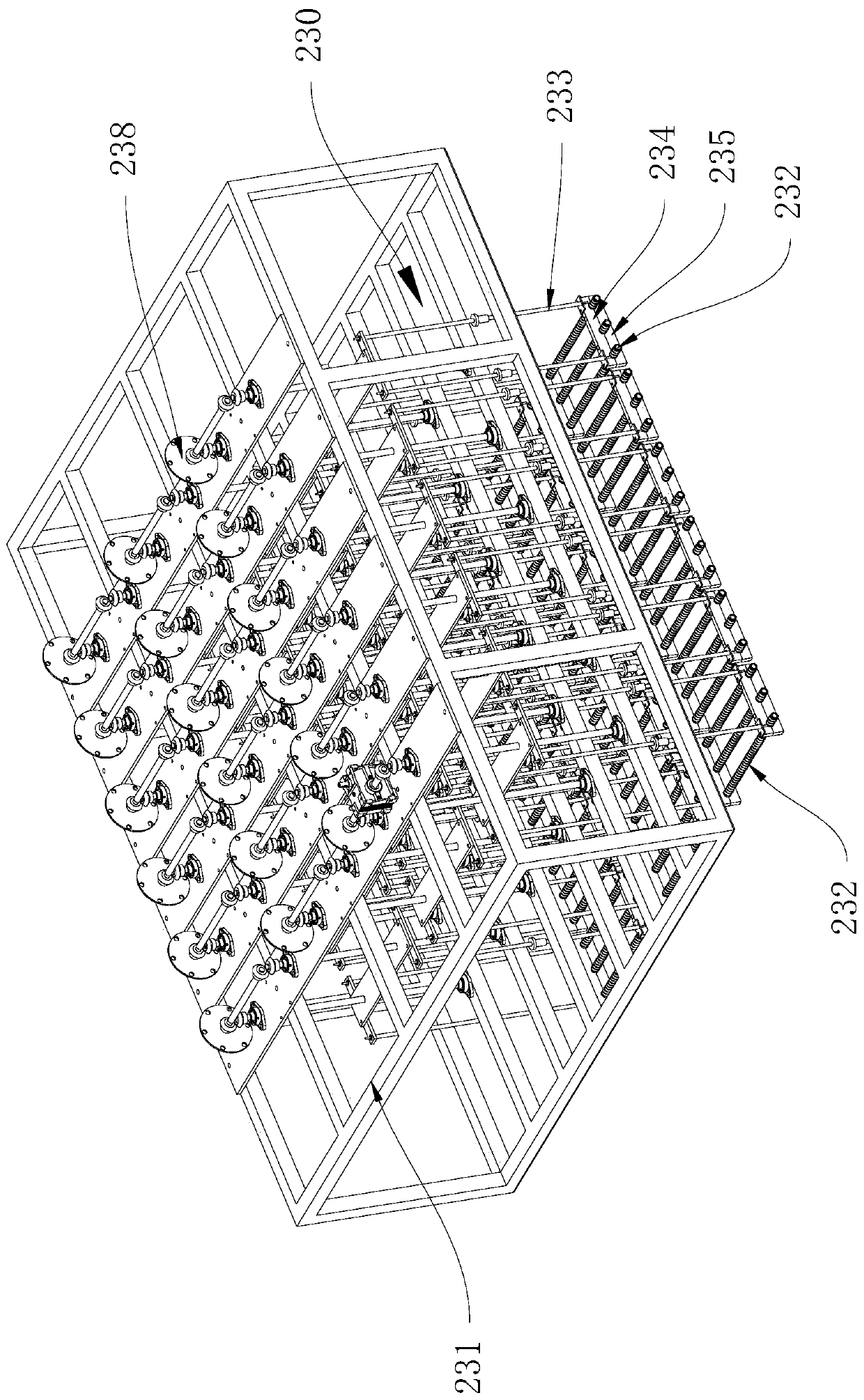

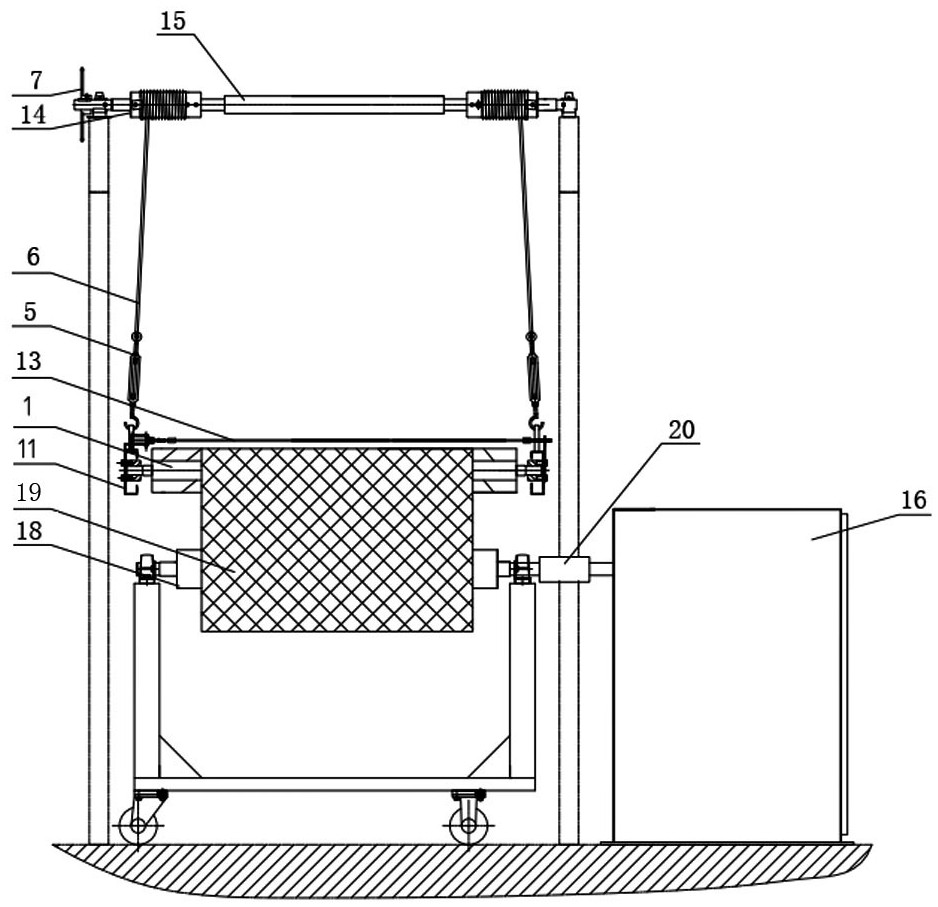

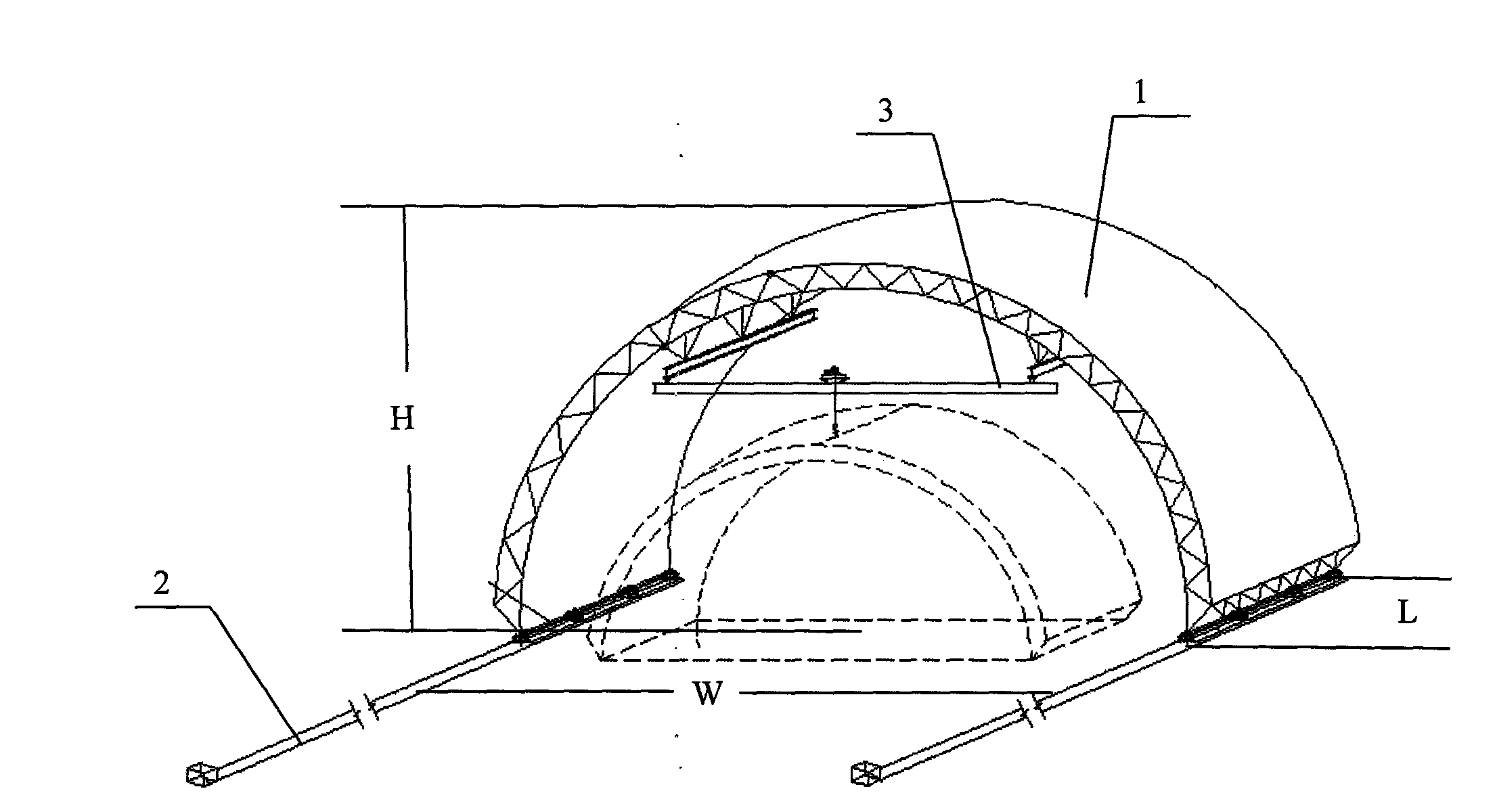

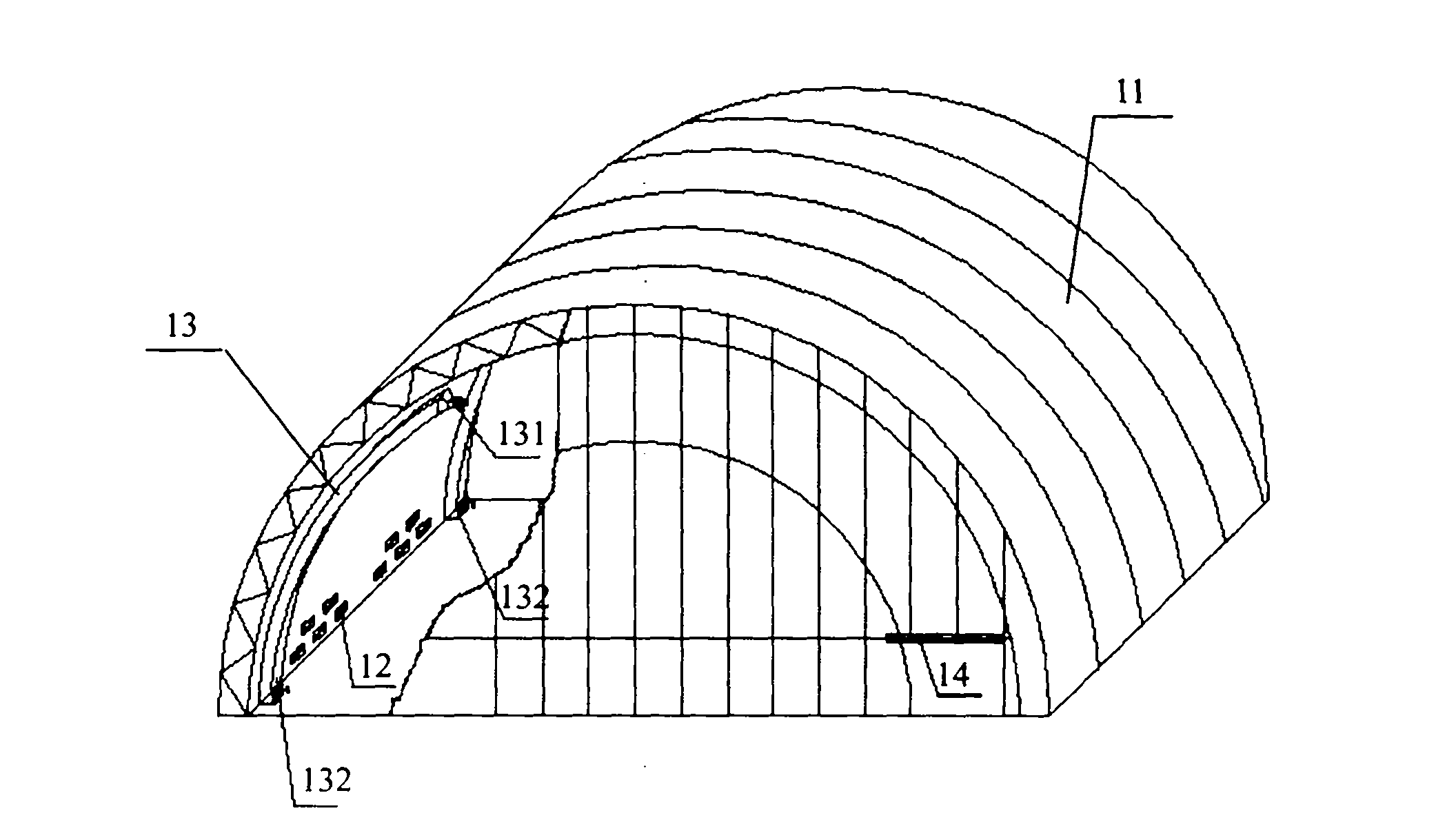

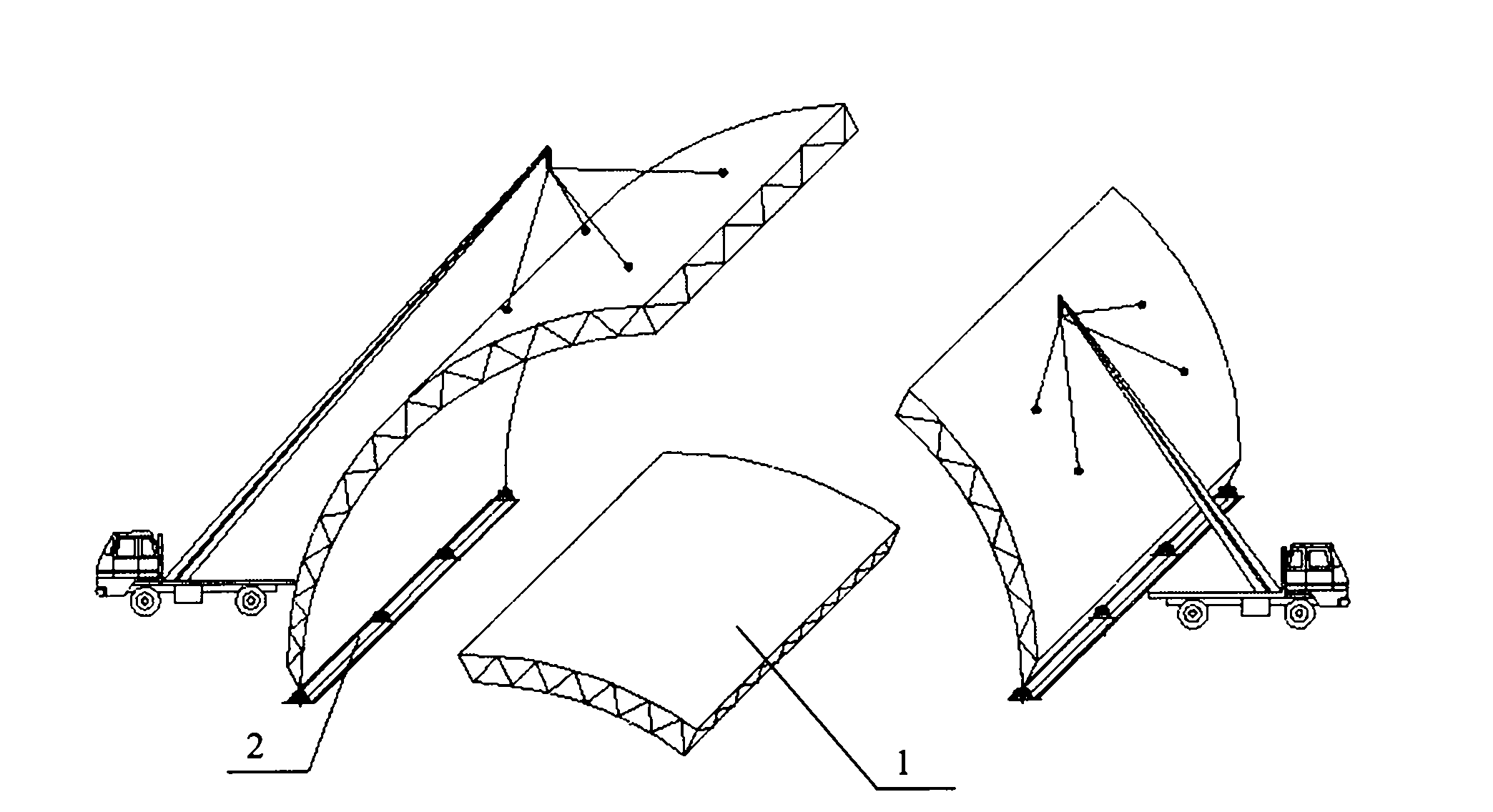

Construction protective cover and its construction method

InactiveCN102277960AHelp project progressHelp construction costsBuilding material handlingTemperature controlArchitectural engineering

The invention relates to building construction equipment, in particular to a construction shield and a construction method. The construction shield comprises a net rack shield body, sliding rails and crown block, wherein the net rack shield body is arched and formed by combining standard bolt sphere anti-vibration net rack components; the sliding rails are arranged on two side edges at the bottomof the net rack shield body respectively; a plurality of roller supports are arranged on the sliding rails; at least one row of detachable joints is arranged along the length direction of the net rack shield body; construction walkways are formed on the two sides of inner ground of the net rack shield body respectively; at least one suspended crown block is arranged at the inner arch of the net rack shield body; a suspension point at which the crown block is suspended on the net rack shield body adopts a pipe joint with a sleeve; temperature control equipment, a power supply and illuminating equipment are arranged in the net rack shield body; a heat-preservation covering layer is arranged outside the net rack shield body; and closing / opening cord fabrics are arranged at worker / crown blockentrances / exits at the two ends of each construction walkway on the heat-preservation covering layer. By the construction shield and the construction method, a construction process can be ensured notto be influenced by weather.

Owner:安徽优技工程科技有限公司

Method for cultivating and acclimating wild indocalamus leaves artificially

InactiveCN102379205ATo promote metabolismImprove germination rateHorticultureMedium densityBamboo shoot

The invention relates to a method for cultivating and acclimating wild indocalamus leaves artificially. The method is characterized by comprising the following steps of: 1) selecting transplanting varieties, namely selecting wild indocalamus seedlings which grow in relatively poor conditions and have vigorous growth vigor and large laminae; 2) transplanting and propagating, namely selecting a transplanting field, making preparation for ploughing and sowing; intertilling, so that the depth of loosening soil is between 25 and 35 centimeters, dividing ridges, and arranging a drainage ditch; lifting seedlings, transplanting, and performing vegetative propagation, namely transplanting from October in the current year to May in the next year; after the seedlings are lifted, pruning the original root whips completely and reserving fibrous roots; planting in a large field in the original natural growth direction of the indocalamus leaves in a medium density mode, wherein the planting depth is between 20 and 30 centimeters; 3) performing fertilizer and water management, namely fertilizing according soil fertility and a soil measuring formula, and preferably applying an organic fertilizer to the roots; and 4) picking and cultivating rationally, namely avoiding picking in the current year, and picking seldom in the second year to achieve an effect of closing in the third year. By the method, the problem of cultivating and acclimating the wild indocalamus leaves artificially is solved, the metabolism of indocalamus and the flourishing of the root whips are promoted, and the germination rate of bamboo sprouts is improved.

Owner:黄山市徽顶箬业有限公司

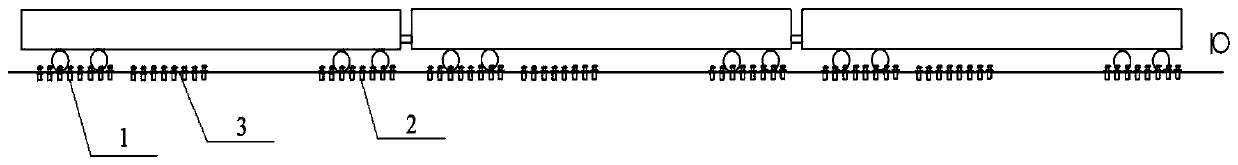

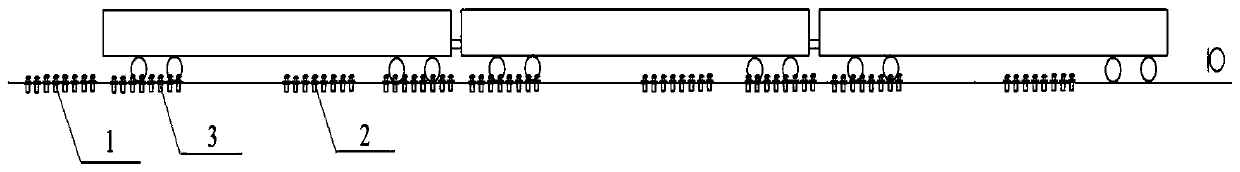

Automated roofing material removal machine and method

ActiveUS7552976B2Ensure labor safetyQuick serviceRoof toolsMetal working apparatusControl powerRemote control

A roofing material removal machine and method for removing roofing materials wherein the machine travels along guide rails mounted on a roof surface and roofing material lifting elements carried by the machine are operated to lift the roofing materials as the machine moves along the guide rails after which the removed materials are conveyed to a collection receptacle. A remote control device may be used to control power to and movement of the machine along the guide rails.

Owner:ARREL TECH

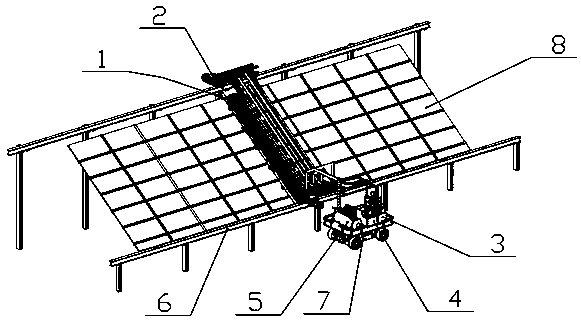

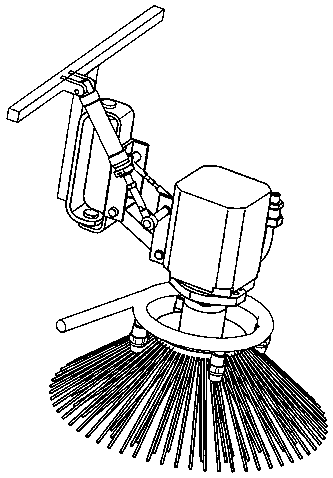

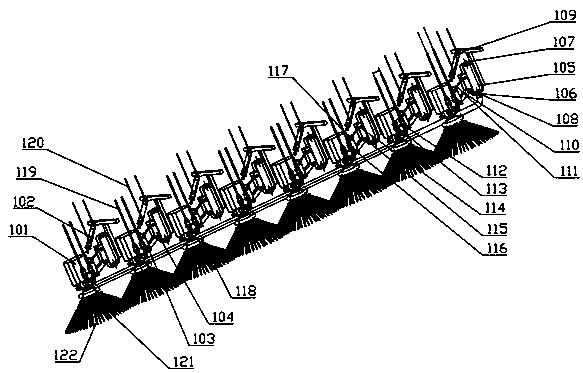

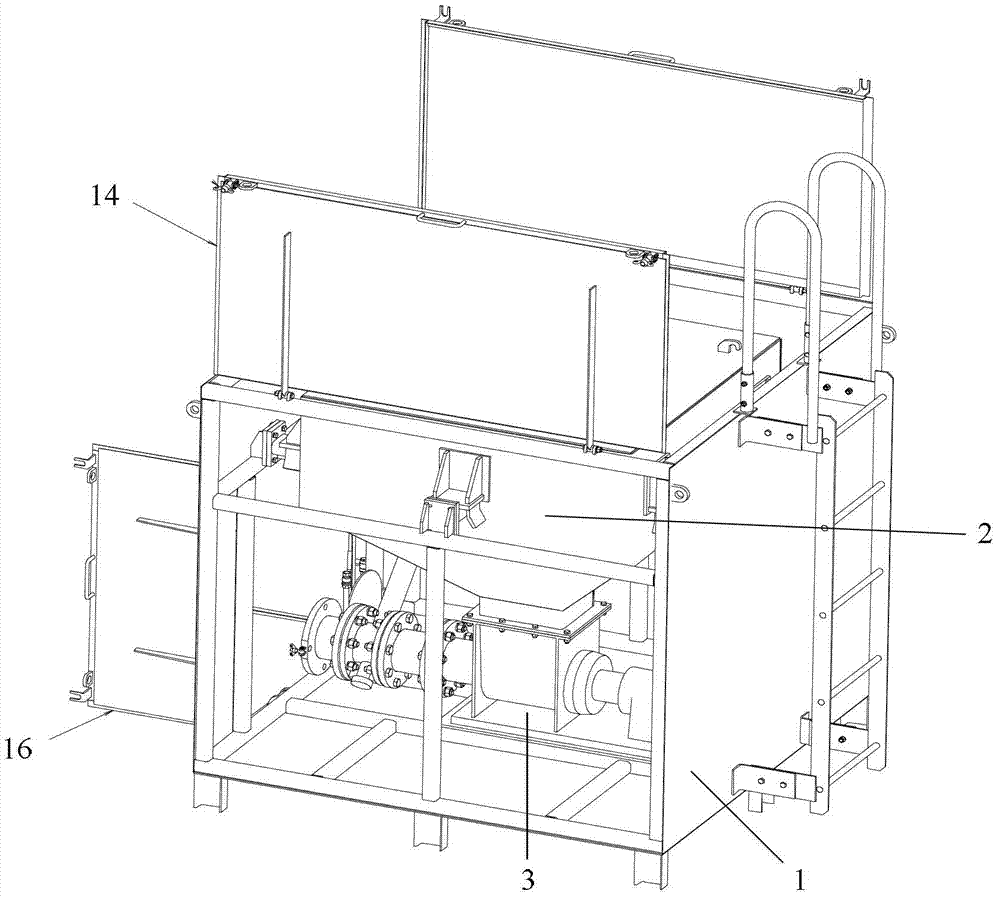

Solar photovoltaic assembly wiping mechanism

InactiveCN111327262AEasy to wipeReduce manual labor intensityPhotovoltaicsPhotovoltaic energy generationHydraulic motorHydraulic pump

The invention provides a solar photovoltaic assembly wiping mechanism. The solar photovoltaic assembly wiping mechanism comprises sweeping disc mechanisms, a transverse moving trolley, a hydraulic system, a water system, a blow-drying system, a guide rail and a battery car, wherein each set of sweeping disc mechanism is provided with an independent lifting oil cylinder used for adjusting and controlling the distance between a rotating brush and a photovoltaic assembly, each set of sweeping disc mechanism is fixedly installed on the transverse moving trolley through bolts, a hydraulic system pipeline, a water system pipeline and a blow-drying system pipeline are fixedly installed on the transverse moving trolley through pipe clamps, and a roller assembly of the transverse moving trolley isinstalled on a low rail and a high rail of the guide rail in a sliding mode. The brush is driven by a hydraulic motor to rotate, and the transverse moving trolley drives the sweeping disc mechanisms to operate along the guide rail to wipe the photovoltaic assembly. The battery car is loaded an air compressor, a hydraulic pump station and a water pump to operate in the same direction along with thetransverse moving trolley. The cleaning process is simple and reliable, the wiping efficiency is high, and the labor intensity of operators is reduced.

Owner:南通大鹏光电有限公司

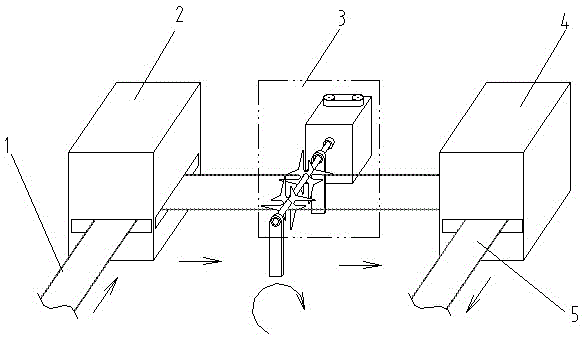

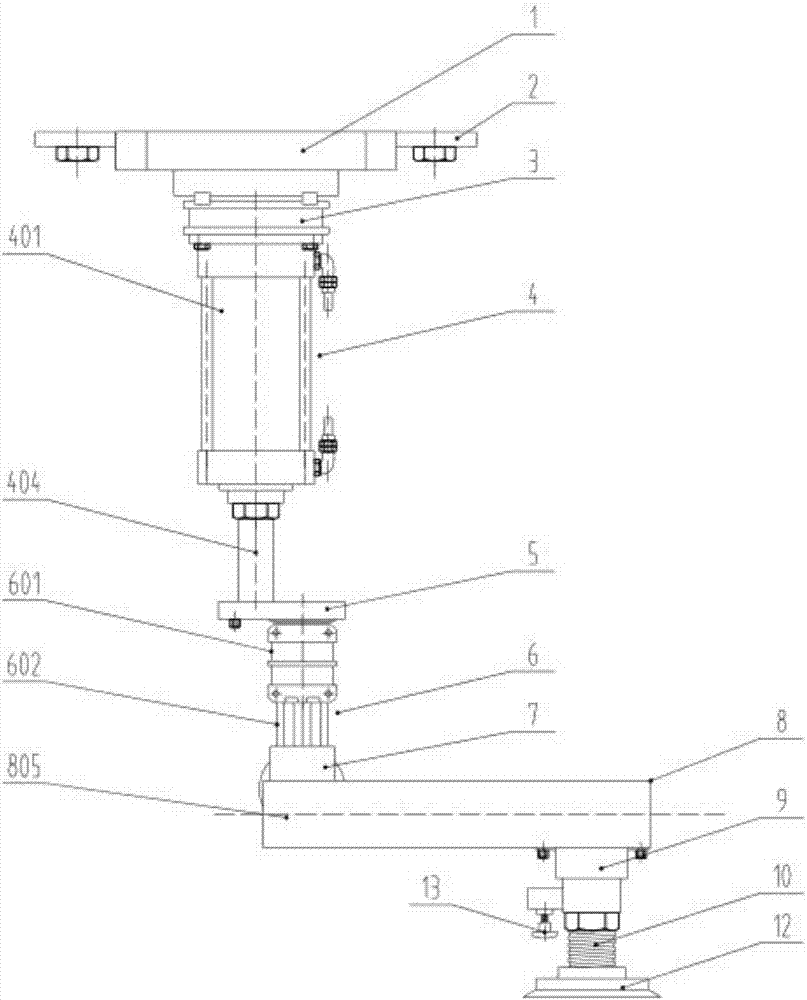

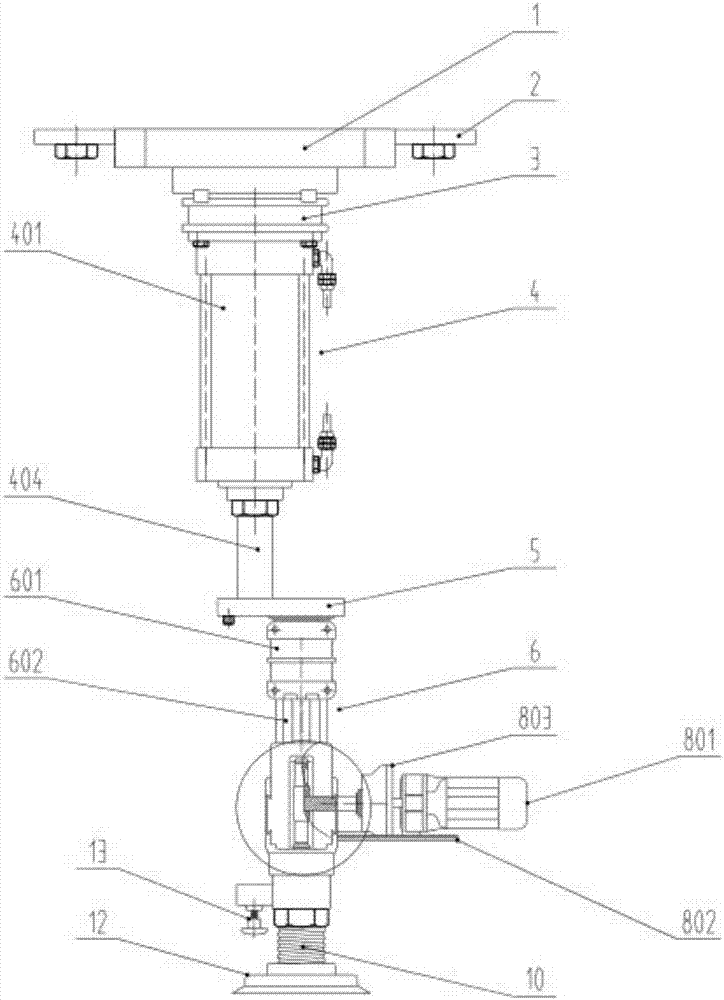

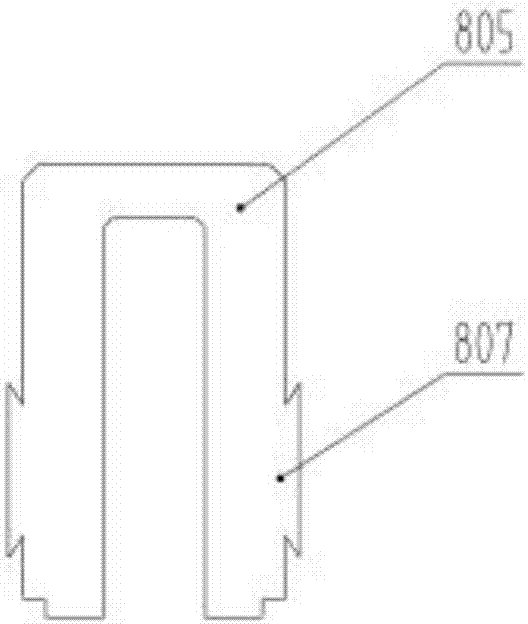

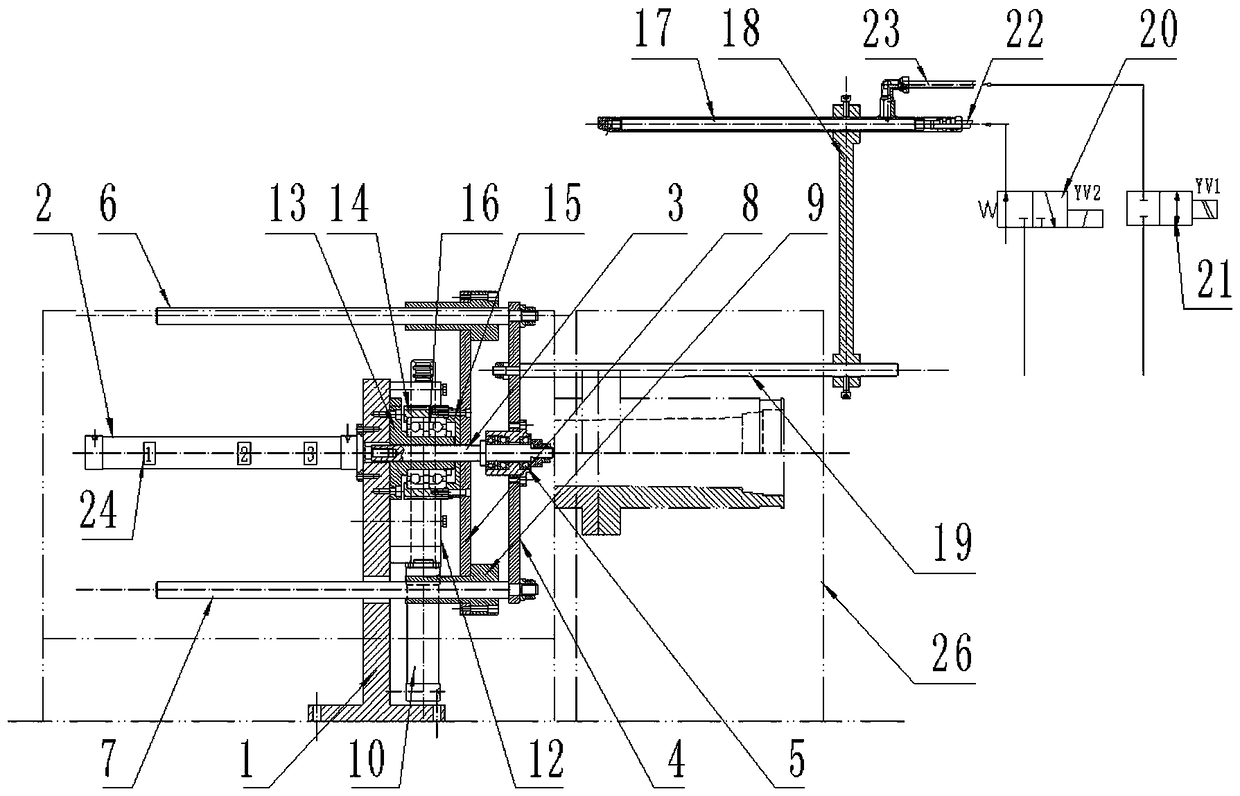

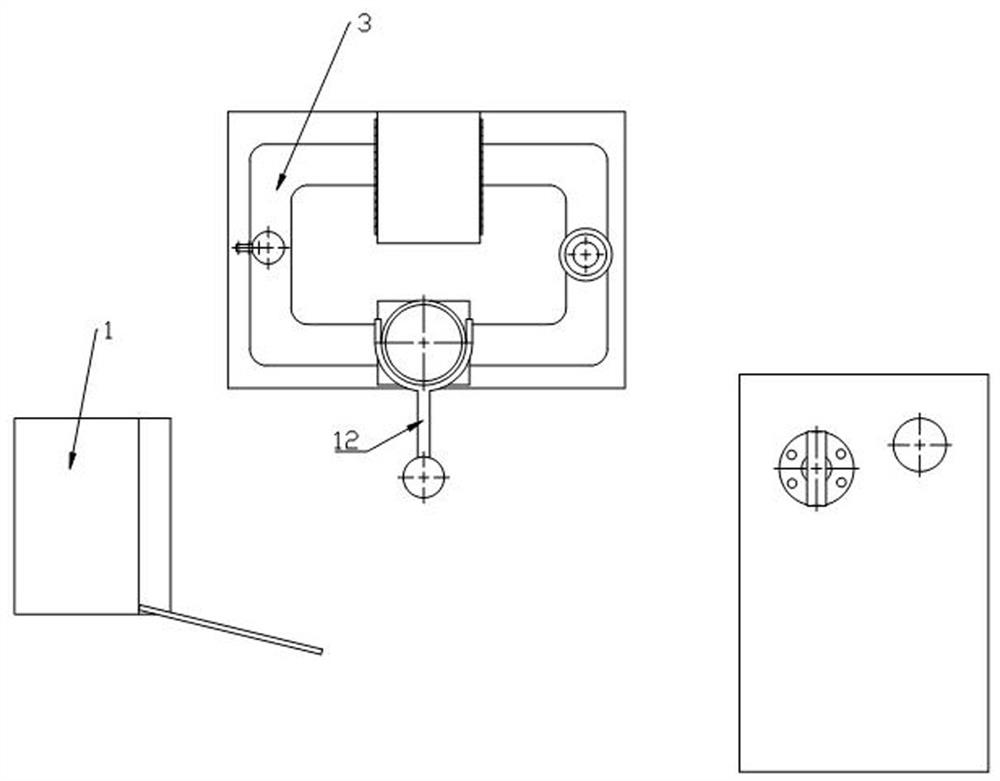

PTC thermistor ceramic aluminum spraying carrier plate turnover device and aluminum spraying equipment

InactiveCN105836435AImprove the quality of sprayed aluminumImprove the working environmentConveyorsControl devices for conveyorsSynchronous motorThermistor

The invention relates to a PTC thermistor ceramic aluminum spraying carrier plate turnover device and aluminum spraying equipment. A mechanical part of the turnover device comprises a synchronous motor, a speed reducer and a cross jaw mechanism; a control system comprises a driver, a sensor and a relay; the synchronous motor is in transmission with the cross jaw mechanism through the speed reducer; the sensor senses the position where an aluminum spraying carrier plate is located, and the driver drives the synchronous motor to run under the coordinated control of the sensor and the relay so as to control running of the cross jaw mechanism; the aluminum spraying equipment comprises an input conveying belt, a first aluminum spraying chamber, a middle conveying belt, a second aluminum spraying chamber, an output conveying belt and the aluminum spraying carrier plate turnover device arranged on the middle conveying belt; and continuous and automatic running of aluminum spraying to the two faces of PTC thermistor ceramic can be achieved, the aluminum spraying quality is improved, labor environment is improved, labor intensity is reduced, and labor safety and sanitation of production workers are ensured.

Owner:HAINING YONGLI ELECTRONICS CERAMICS

Automatic grabbing device for injection-molded blades

InactiveCN106865214ARealize automatic pickingReduce labor intensityConveyor partsEngineeringUltimate tensile strength

Owner:苏州晟炅精密电子有限公司

Rodenticide bait casting machine

PendingCN107372454AReduce labor intensityAvoid poisoningPoisonAgainst vector-borne diseasesAnimal scienceVenomous snake

The invention discloses a rodenticide bait casting machine. The rodenticide bait casting machine can effectively lower labor intensity of personnel, have higher safety, and achieve precise quantitative bait casting. The machine comprises a rodenticide storage box, a back belt is arranged on the rodenticide storage box, and the machine further comprises a rodenticide guiding tube; a bait guiding tube is arranged on the side wall, close to the lower end, of the rodenticide guiding tube, a bait blocking plate is arranged in the rodenticide guiding tube, and a quantitative bait casting device is arranged in an inner cavity in the upper portion of the rodenticide guiding tube. In the process of bait casting by using the rodenticide bait casting machine, operating personnel do not need to bend down and only stand so that the operation can be completed, through the design of the cane type, the labor intensity of the operating personnel is greatly reduced, the operating personnel are not in contact with the bait in the process of bait casting, and the situation is also avoided that the operation personnel are poisoned; meanwhile, the situation is also avoided that the bait casting personnel are in contact with poisonous snakes on the grassland, so that the safety is greatly improved, the amount of bait casting every time is fixed, and precise quantitative bait casting can be achieved. The rodenticide bait casting machine is suitable for application and popularization in the field of grassland treatment.

Owner:SICHUAN ACAD OF GRASSLAND SCI

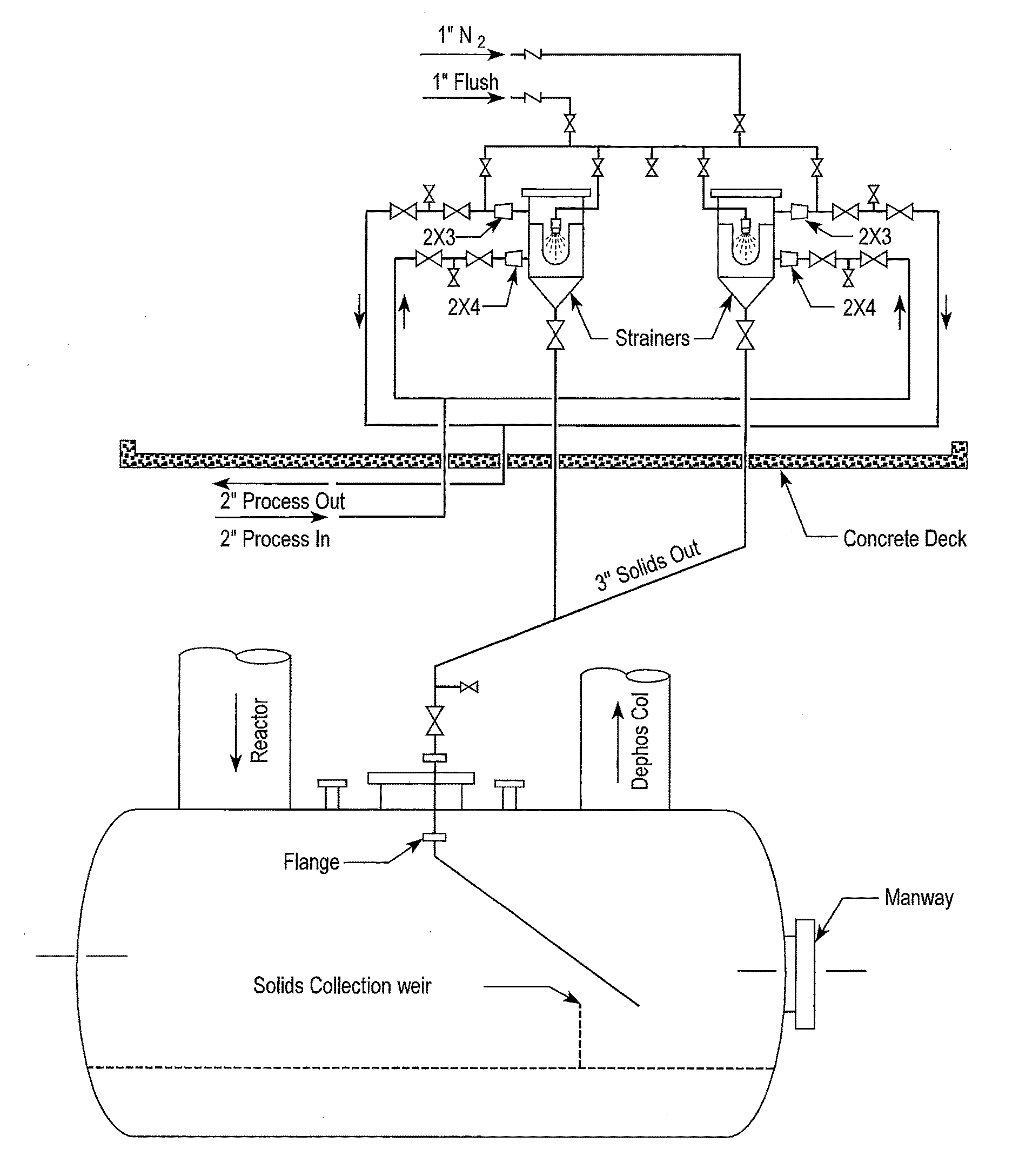

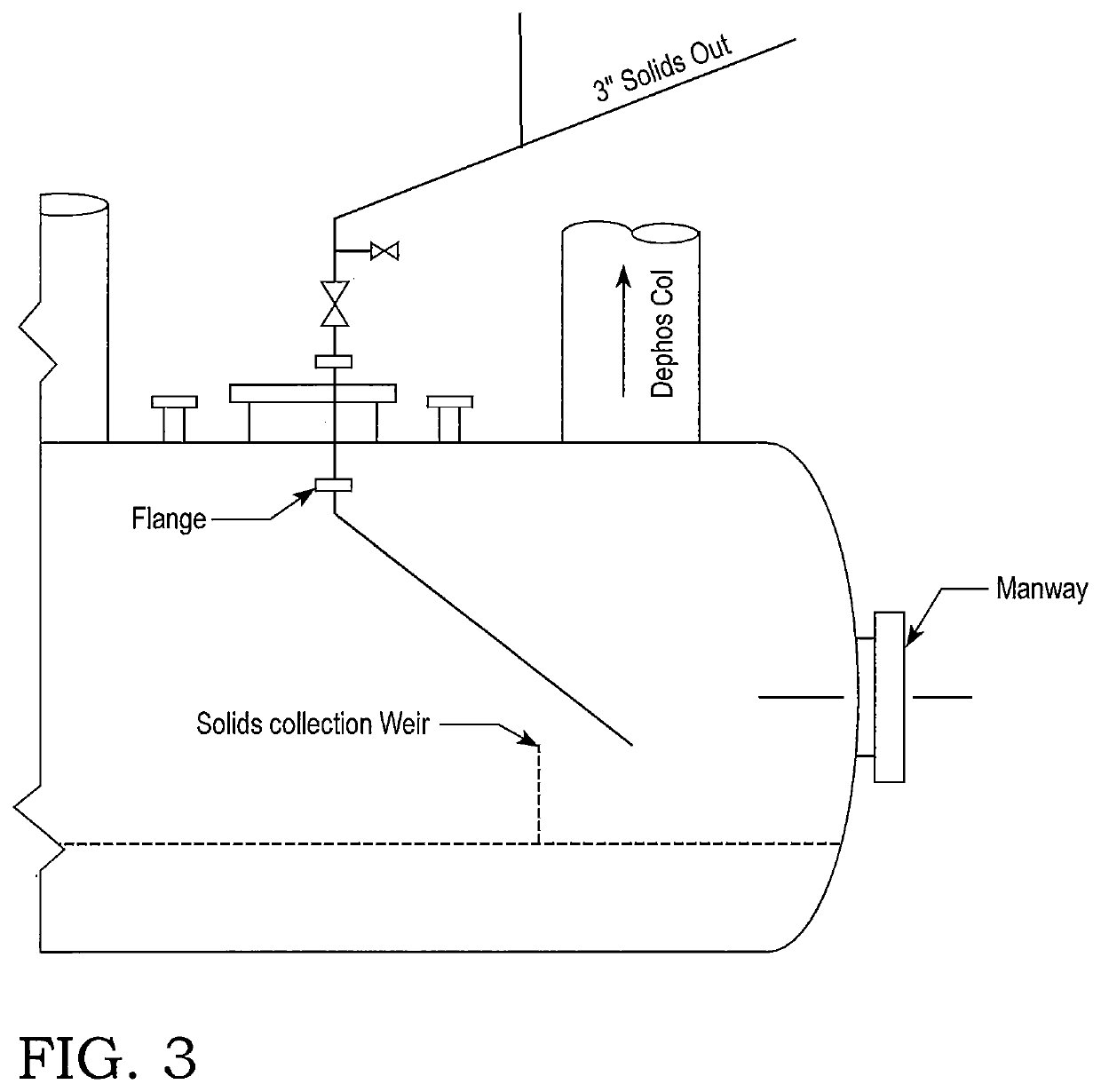

Process for the continual inline filtration of a process stream

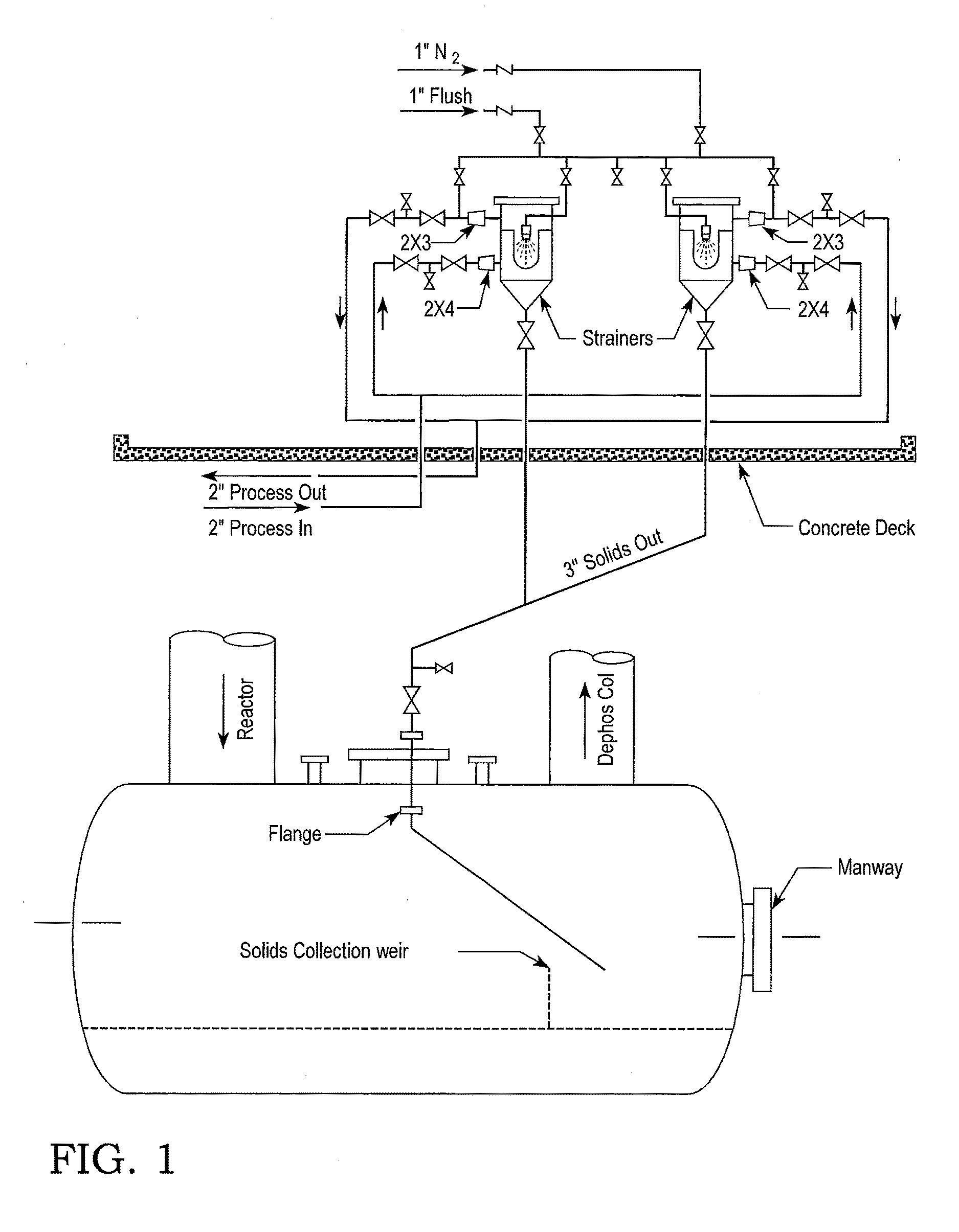

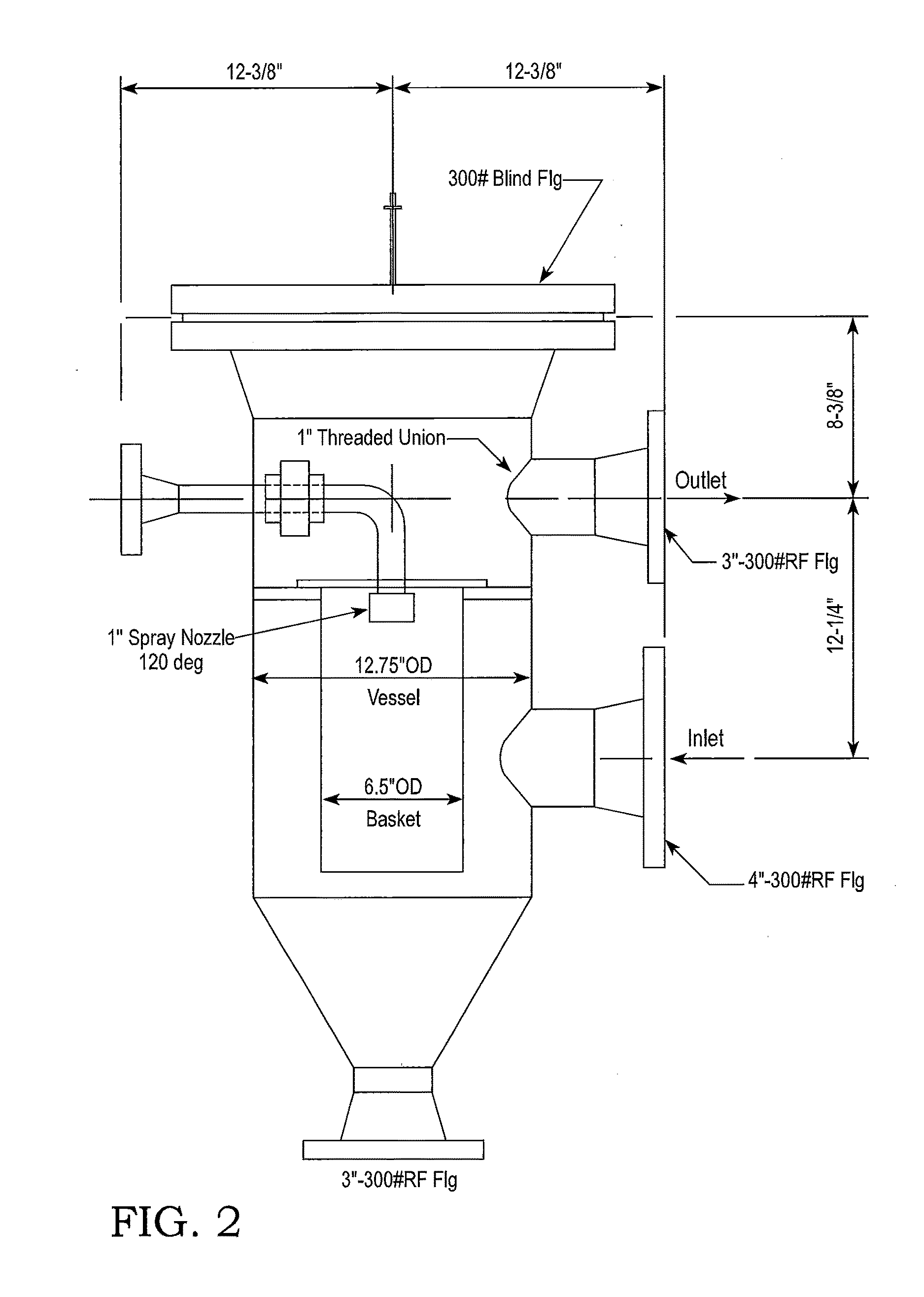

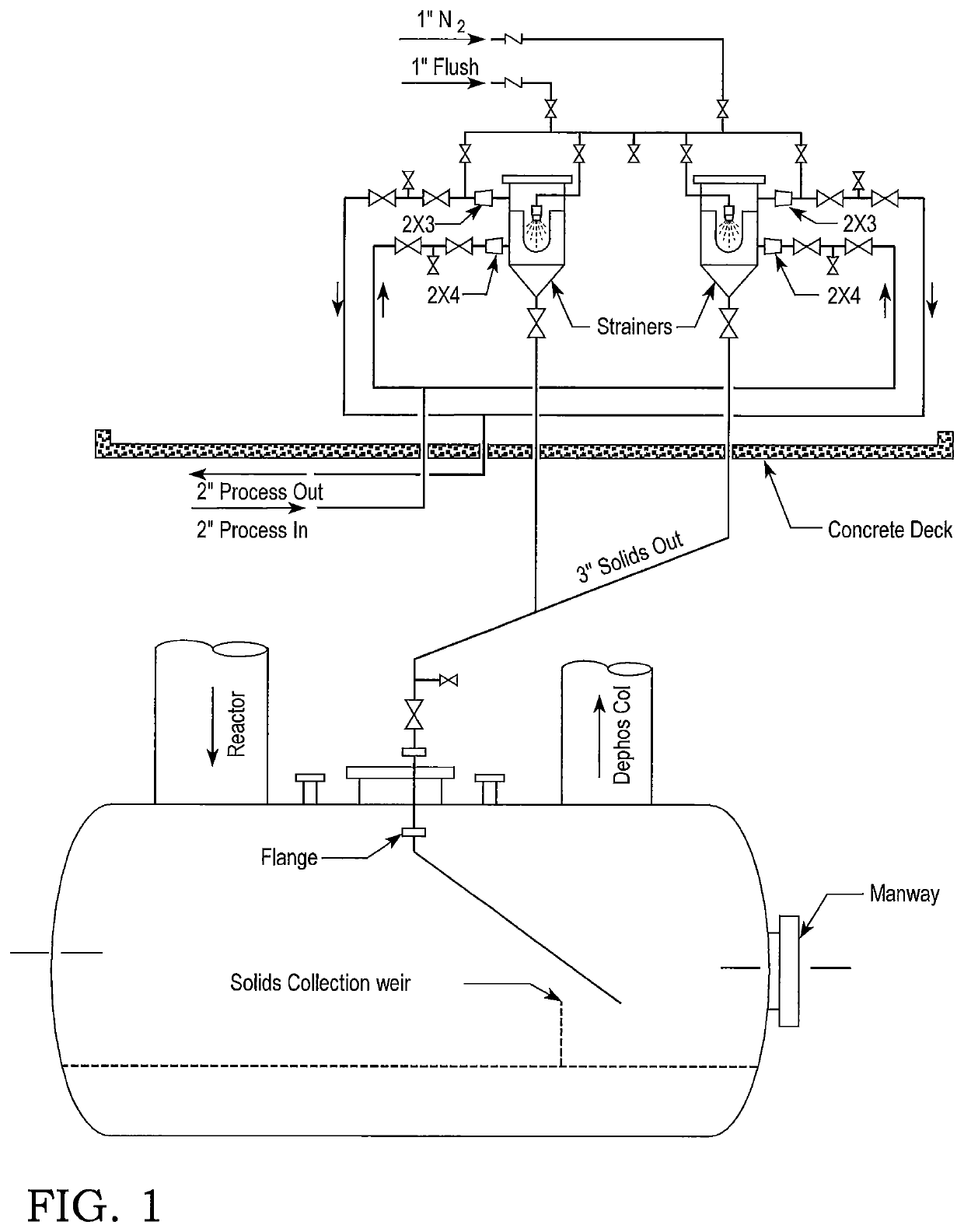

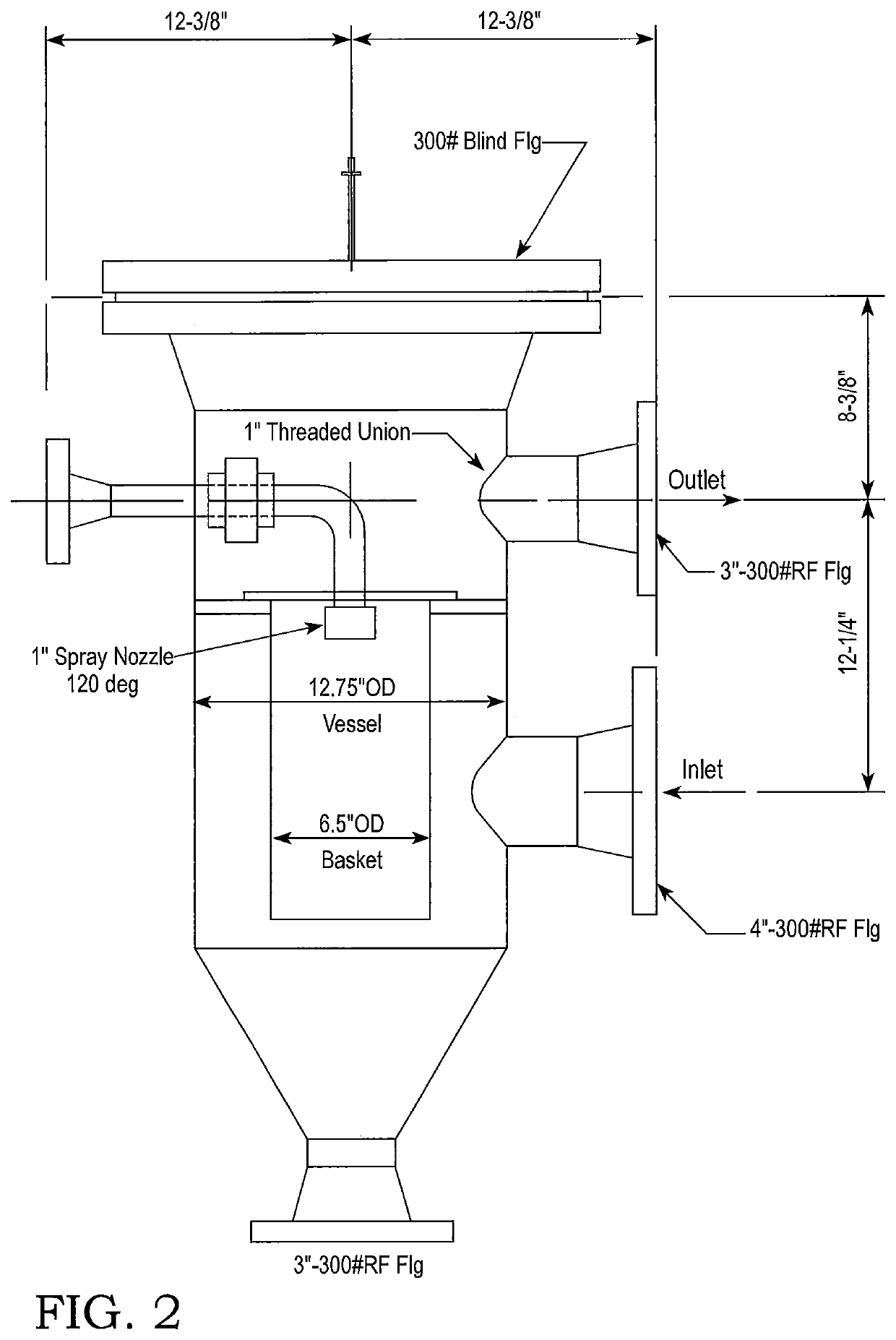

ActiveUS20170021289A1Eliminating labor requirementAvoid safety hazardsStationary filtering element filtersProcess systemsFiltration

The present invention provides a new type of filtration system. Traditional designs required that personnel open the system to clean / change strainers while a process was in operation. This invention provides a straining system that allows process stream to be filtered in a manner completely internal to the process. The system includes dual strainers with a nitrogen purging system and solvent flush system. A creatively designed “catch” area is installed internal to the process to collect all solids that are flushed from the strainer system. The system remains completely closed for the duration of each production campaign, thus eliminating the safety hazard and labor requirement associated with opening a process system.

Owner:COVESTRO LLC +1

Process for the continual inline filtration of a process stream

ActiveUS10751649B2Ensure labor safetyStationary filtering element filtersProcess systemsFilter system

The present invention provides a new type of filtration system. Traditional designs required that personnel open the system to clean / change strainers while a process was in operation. This invention provides a straining system that allows process stream to be filtered in a manner completely internal to the process. The system includes dual strainers with a nitrogen purging system and solvent flush system. A creatively designed “catch” area is installed internal to the process to collect all solids that are flushed from the strainer system. The system remains completely closed for the duration of each production campaign, thus eliminating the safety hazard and labor requirement associated with opening a process system.

Owner:COVESTRO LLC +1

Automatic cylinder sleeve casting coating spraying device

InactiveCN108097908AEnsure process stabilityReduce labor intensityMoulding toolsSingle stationAutomation

The invention discloses an automatic cylinder sleeve casting coating spraying device which comprises a base, a spray gun support reciprocator, a spray gun support swing mechanism and a coating spraying mechanism. The spray gun support reciprocator comprises a reciprocating cylinder, a cylinder connecting push rod, a guide rod connecting plate, a thrust swing connecting seat, an upper guide rod, alower guide rod, a guide plate and a guide sleeve, the spray gun support swing mechanism comprises a swing push cylinder, a swing push rack, a rack seat, a bearing block, a turning gear and a turninggear end cover, and the coating spraying mechanism comprises a spray gun, a spray gun support, a supporting rod, an electromagnetic gas valve and an electromagnetic coating valve. Based on an existingtraditional single-station centrifugal casting machine, automation and program control of the coating spraying process are realized, the device can be independently operated and can also be subjectedto on-line operation with the casting machine with an automatic casting function, the device is stable in structure, safe and reliable, process stability of the casting quality of a cylinder sleeve is ensured, the labor intensity of workers is greatly reduced, and labor safety of the workers is guaranteed.

Owner:ANHUI WHITE RABBIT POWER

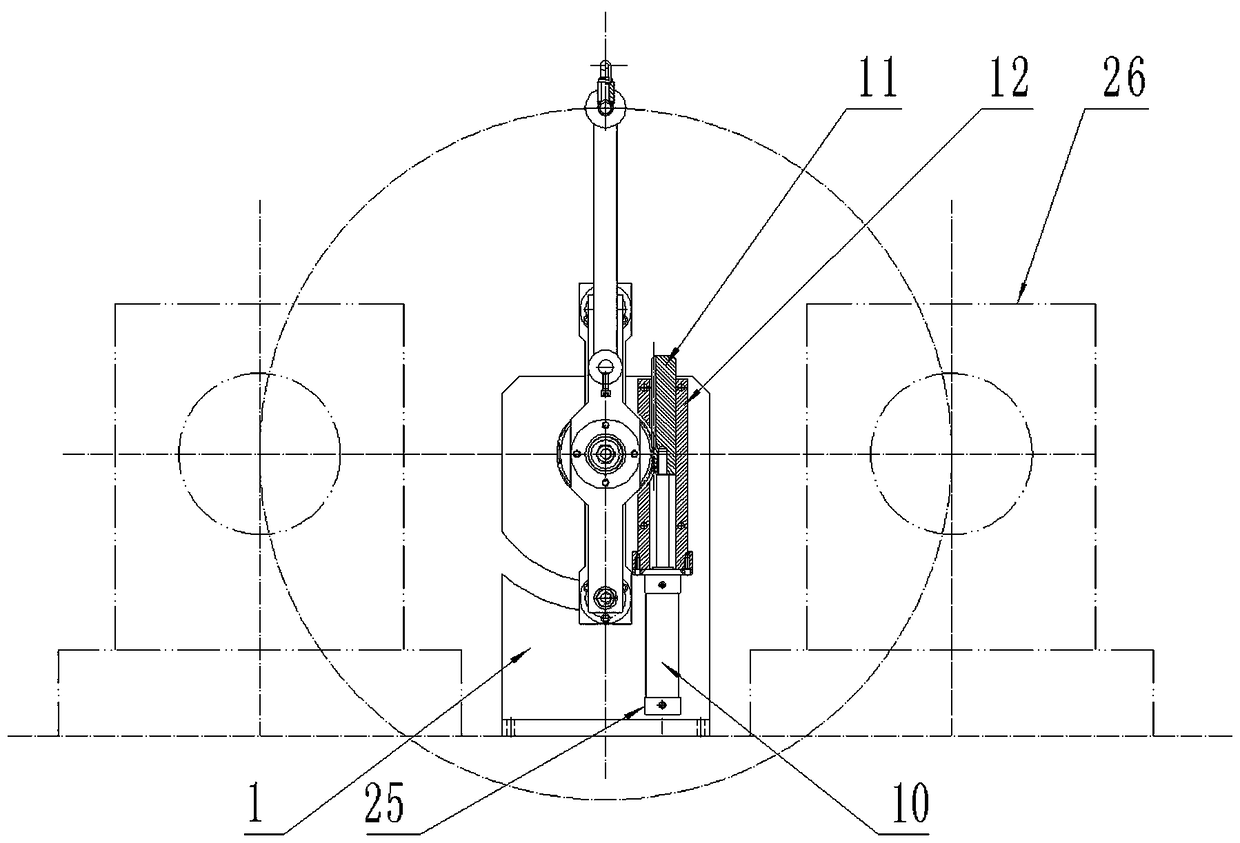

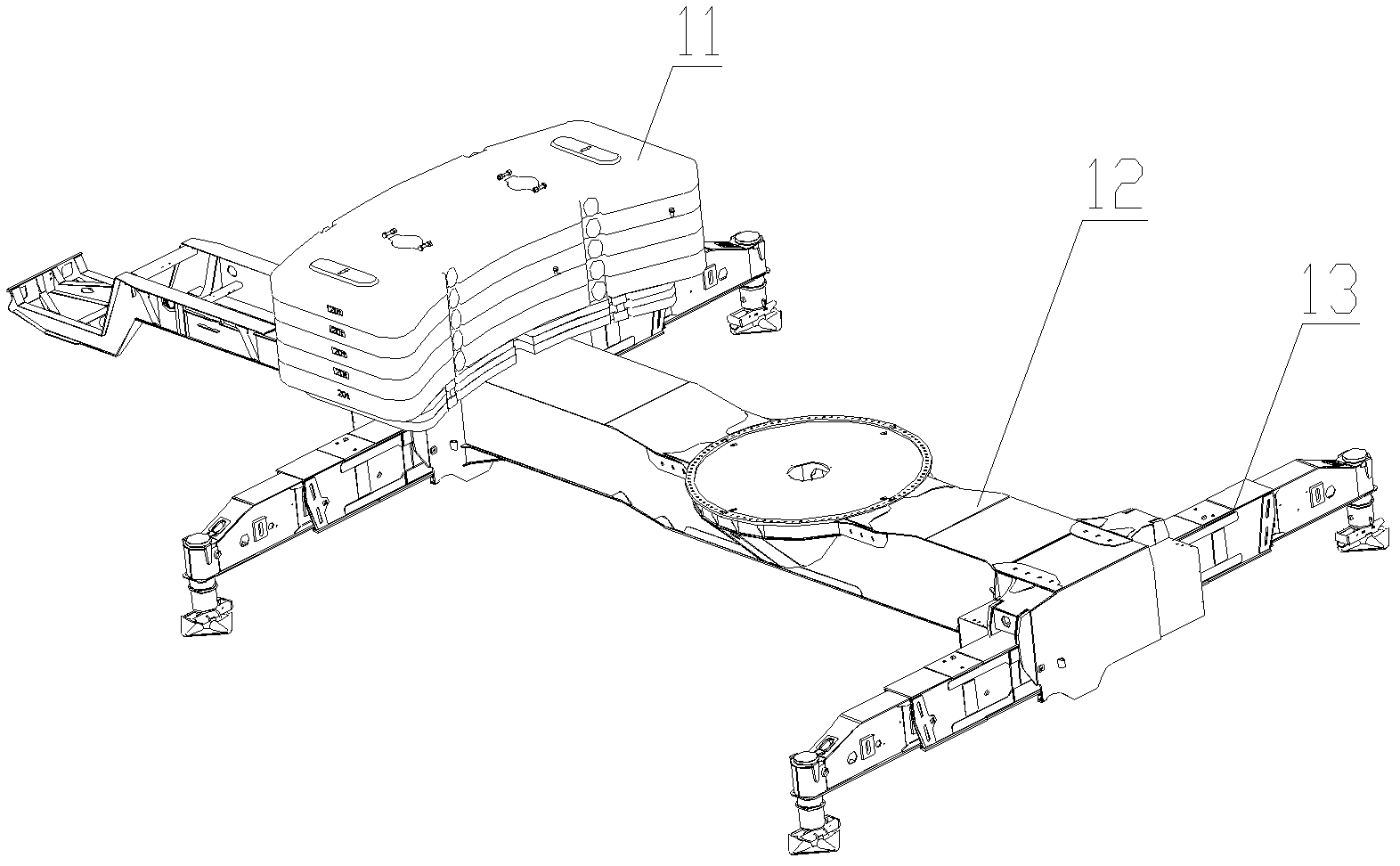

Wheeled crane and moveable counterweight component thereof

InactiveCN102556862AEliminate manual collaborationAvoid potential dangerCranesVehicle frameEngineering

The invention discloses a moveable counterweight component of a wheeled crane. The moveable counterweight component of the wheeled crane comprises a counterweight body (26) and a positioning mechanism, wherein the counterweight body (26) is arranged on a vehicle frame (21) of the wheeled crane through the positioning mechanism. The moveable counterweight component of the wheeled crane also comprises a guide mechanism, wherein the guide mechanism (22) further comprises a first guide part and a second guide part; the second guide part is connected with the first guide part in a sliding and detachable manner; the first guide part is arranged on the vehicle frame (21) and extends outwards relative to the vehicle frame (21); the second guide part is arranged on the outer surface of the counterweight body (26); and the sliding direction of the two guide parts is as same as the assembling direction of the counterweight body (26). The moveable counterweight component has short operating time during assembling, effectively avoids potential hazards to workers when the counterweight is arranged and guarantees labor safety. The invention also discloses the wheeled crane comprising the moveable counterweight component.

Owner:XUZHOU HEAVY MASCH CO LTD

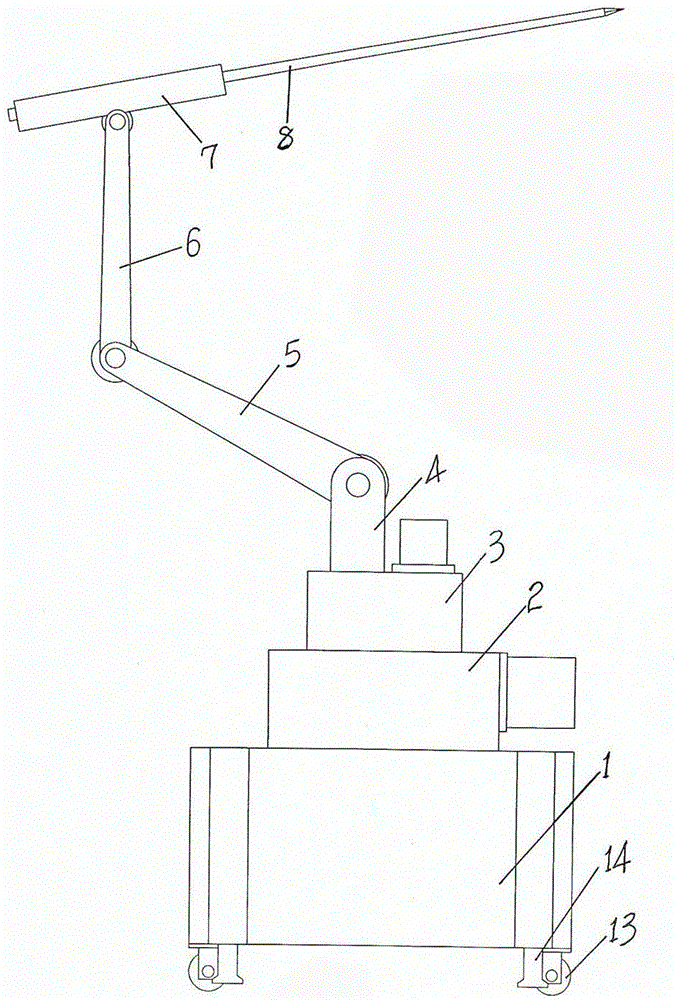

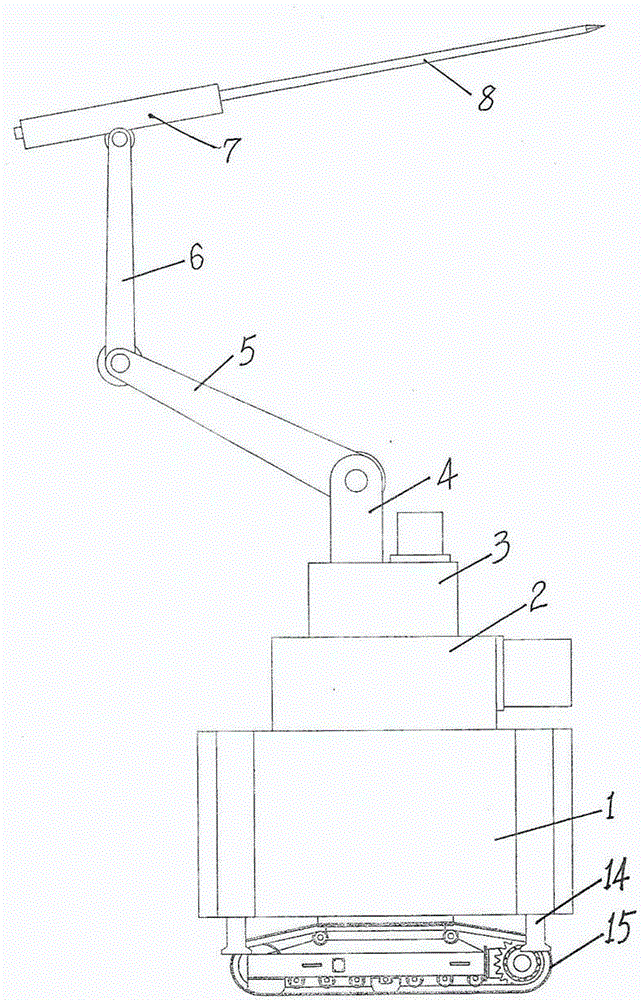

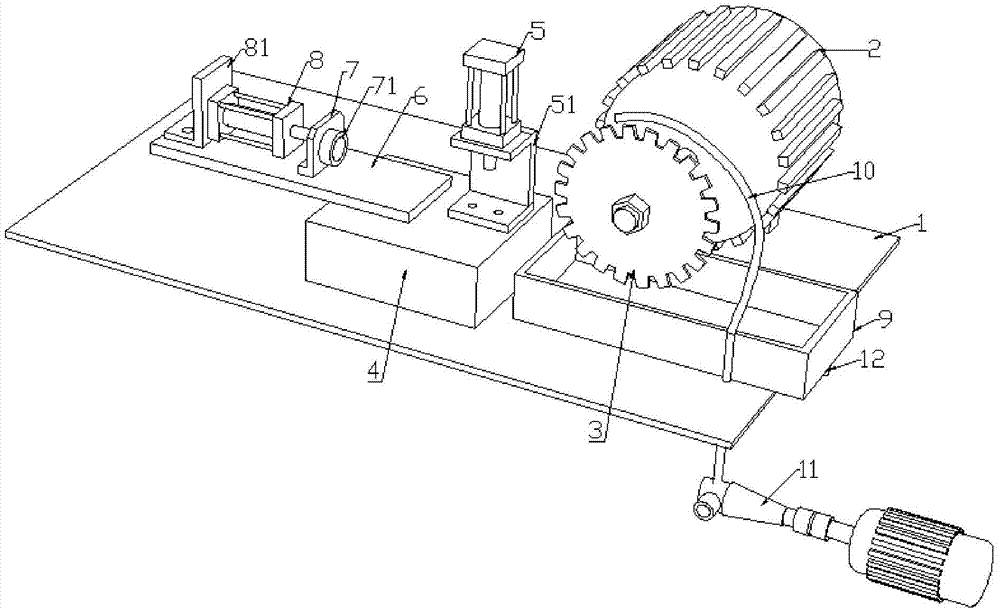

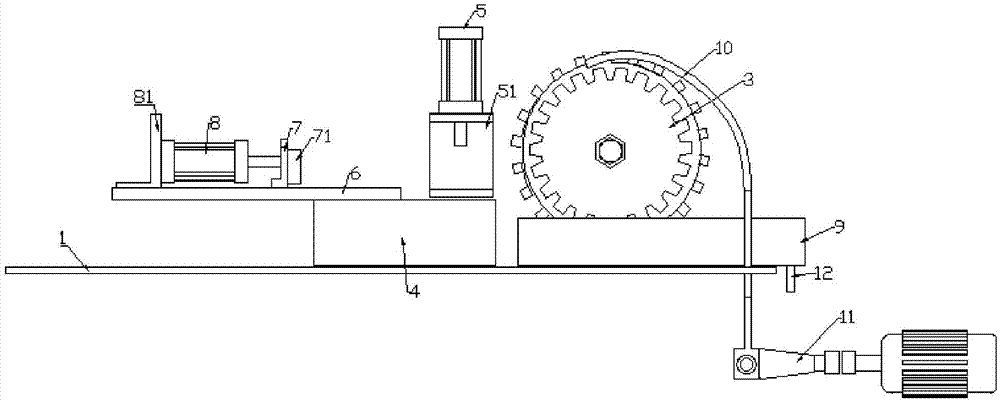

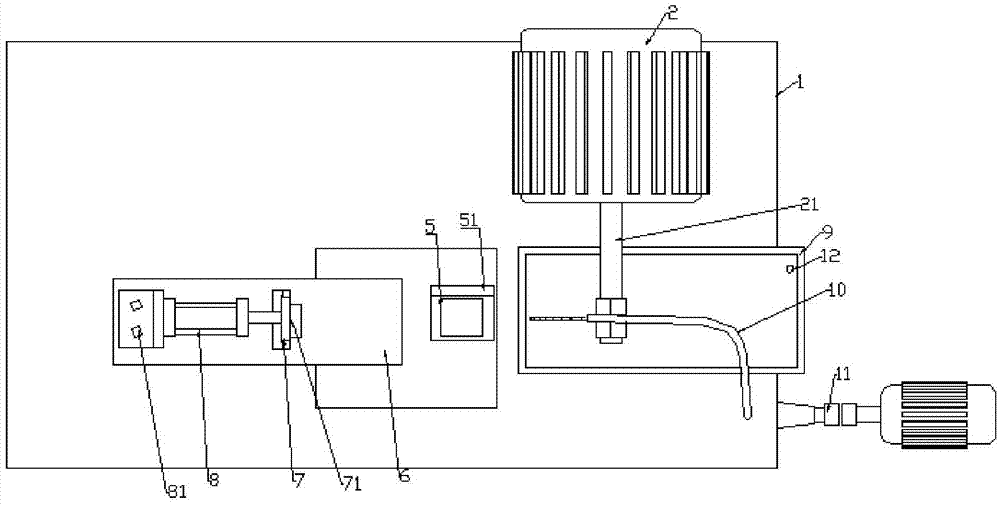

Wheel type pneumatic energy storage coke removing machine

InactiveCN105823068AEasy to fixChange the original manual labor state of heavy laborLighting and heating apparatusDrive wheelChisel

The invention discloses a wheel type pneumatic energy storage coke removing machine, and relates to the technical field of machinery. The key technology of driving wheel walking pneumatic or hydraulic energy storage or caterpillar band walking pneumatic or hydraulic energy storage is adopted. The wheel type pneumatic energy storage coke removing machine is characterized in that the bottom end of a frame plate is rotatably and movably connected with driving wheels; the frame plate is fixed to a pneumatic device; an output end of the pneumatic device is fixed to the upper ends of supports; an annular gear on the frame plate is in occlusion with a circular gear on an output shaft of a gearbox connected with a rotating motor on a rotating body; an annular rail on the frame plate is movably connected with a rail wheel of the lower end of the rotating body in a rolling manner; the upper end of the rotating body is fixed to the lower end of a frame body; the frame body is fixed to the pneumatic device; the output end of the pneumatic device is fixed to a lifting arm; the upper end of the lifting arm and the lower end of a master arm, the upper end of the master arm and the lower end of a linkage arm, and the upper end of the linkage arm and a pneumatic part are rotatably and movably connected through deceleration motors; and an output end of the pneumatic part is fixed to the back end of a steel chisel. The wheel type pneumatic energy storage coke removing machine is used for removing cokes of a utility boiler, and is a new product which is simple and ingenious in structure, stable in effect, easy to manufacture, and low in cost.

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

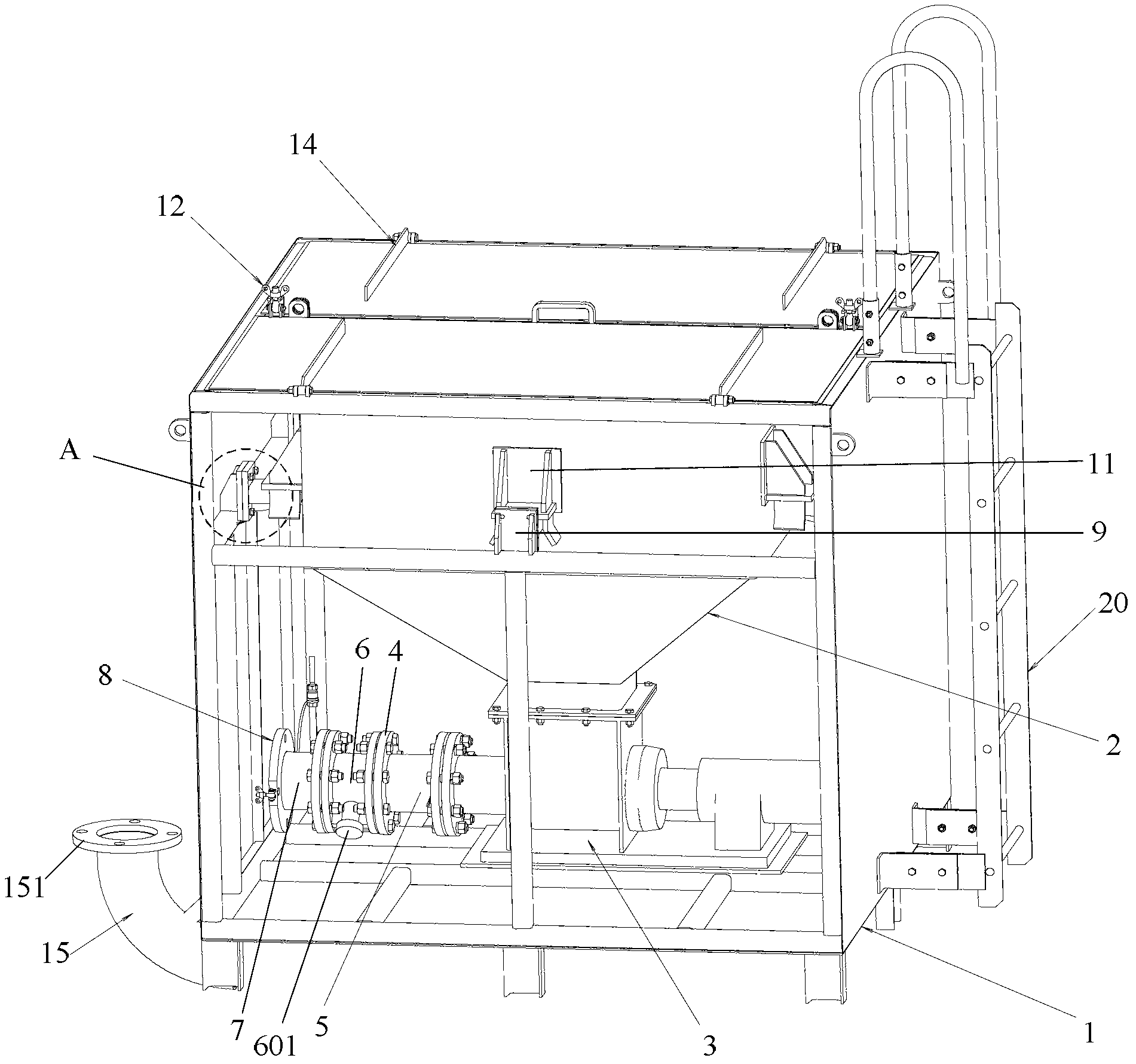

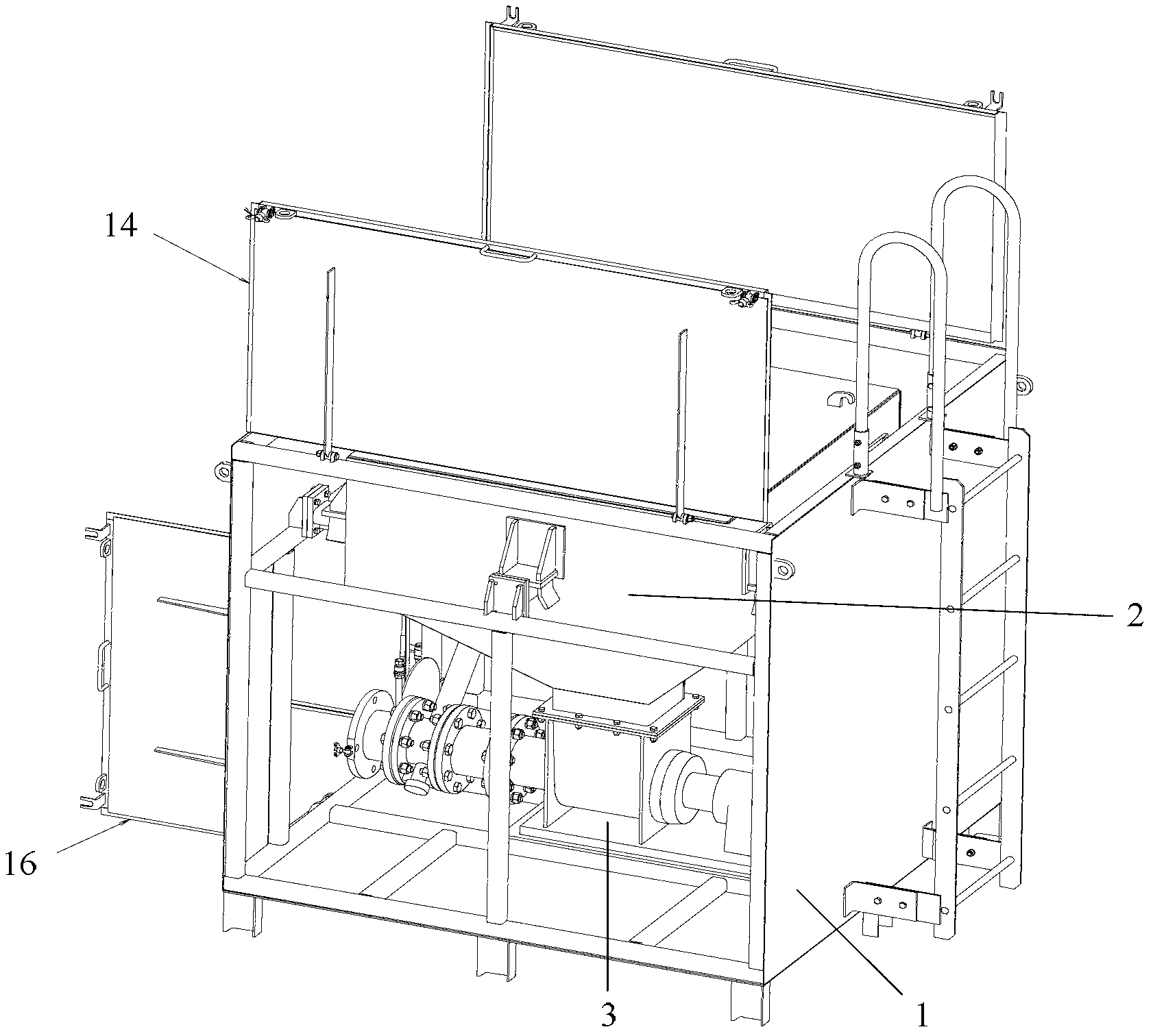

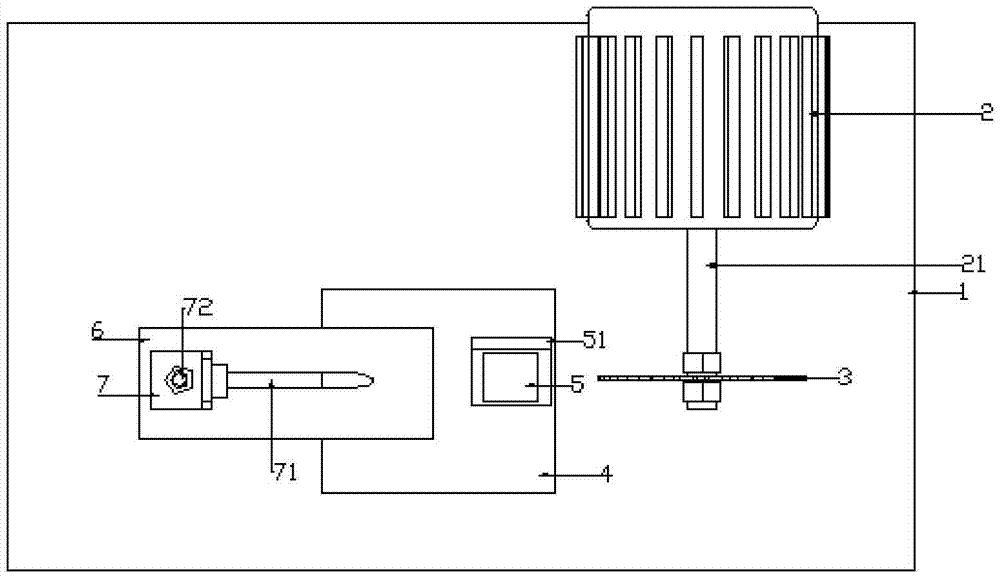

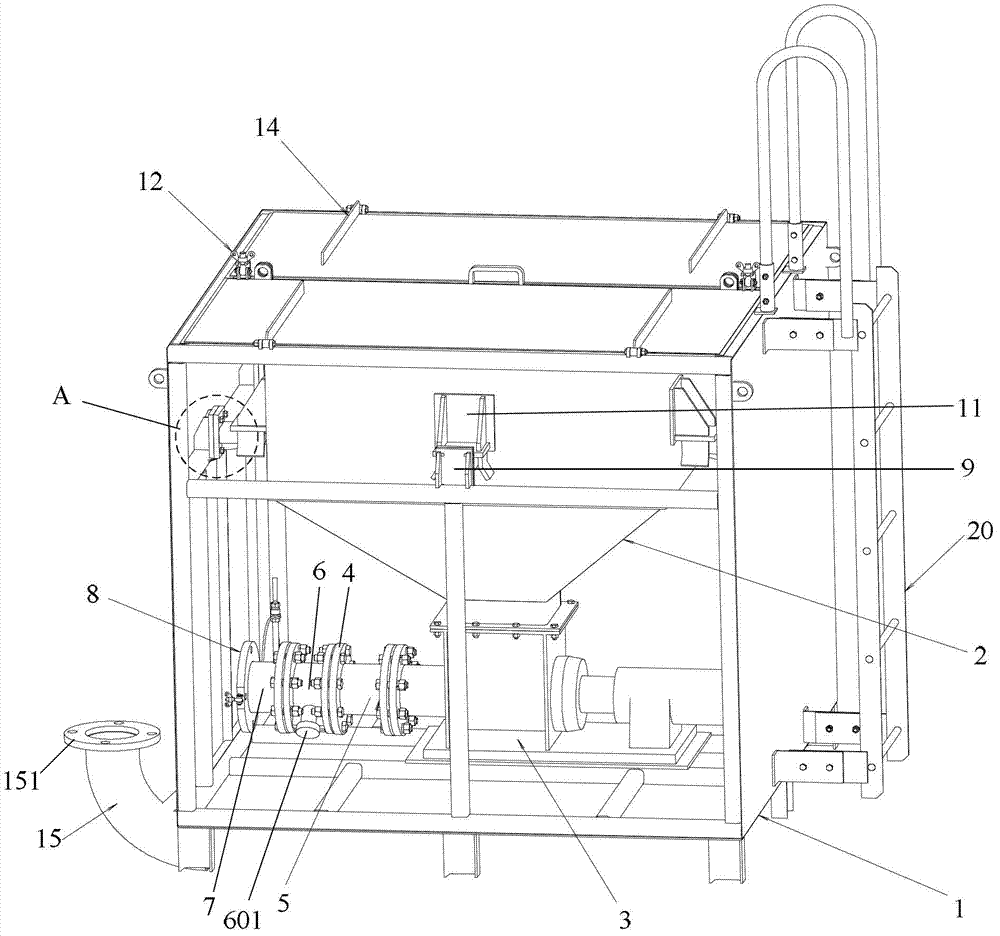

Device and method for transporting and feeding toxic powder

ActiveCN103264905AEnsure labor safetyMeet transportation needsLarge containersLoading/unloadingCombined useEngineering

The invention provides a device and method for transporting and feeding toxic powder. The device is used for feeding toxic the toxic powder to a solution tank. The device comprises an inner stock bin, a screw feeder and a transporting box body, the inner stock bin and the screw feeder are located in the transporting box body, the inner stock bin is connected with the screw feeder, and an output end of the screw feeder is connected with a delivering pipeline, wherein the delivering pipeline is used for being connected with the solution tank. The combined using of the designed inner stock bin and the screw feeder is adopted, the danger that an operator operates through a hopper is avoided, operating safety of the operator is guaranteed, meanwhile, the inner stock bin and the screw feeder are arranged in the transporting box body, the need for transporting the toxic powder is met, in addition, the inner stock bin is connected with the screw feeder, the inner stock bin and the screw feeder can be integrally placed in and taken out of the box body, and a feeding system can be examined, repaired and maintained conveniently. The device and method for transporting and feeding the toxic powder has the advantages that the toxic powder is easy to feed and transport, and the device and method for transporting and feeding the toxic powder is safe relatively.

Owner:BAOSTEEL ENG & TECH GRP

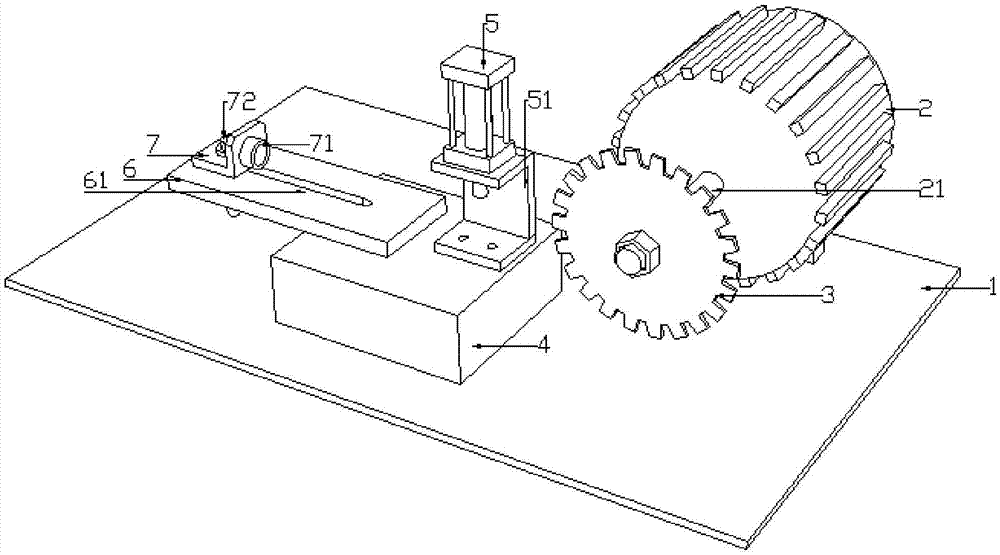

Full-automatic pipe fitting mouth milling machine

PendingCN106926035AEnsure labor safetyImprove labor efficiencyWork clamping meansMilling equipment detailsVertical planePipe fitting

The invention provides a full-automatic pipe fitting mouth milling machine which comprises a platform; a rotating motor is arranged on the platform, and is connected with a milling cutter which is a saw blade middling cutter through a motor connecting shaft; a workbench is also arranged on the platform; a rail plate is fixed to the workbench; a rail groove is formed in the rail plate; a fixed air cylinder is also arranged on the workbench, and is fixed to the platform through an air cylinder fixing seat; the center of the rail groove, a center point of a piston of the fixed air cylinder, and a center point of the milling cutter are in the same vertical plane; a sliding block is arranged on the rail plate; a limiting bar inserted into the rail groove is arranged at the lower part of the sliding block; and a pipe groove is formed in the side surface of the sliding block. Automatic cutting can be realized, the efficiency is high, and the safety of workers can be guaranteed.

Owner:天津市深呼吸自行车业有限公司

Device and process for hot-working forming of aviation transparent material

PendingCN110845125AReduce lossReasonable structure layoutGlass reforming apparatusGlass productionSprocketHot working

The invention discloses a device for hot-working forming of an aviation transparent material. The device comprises a base, wherein a furnace body is fixedly arranged on the base; the furnace body comprises a heating chamber and a forming chamber which are in communication; a feeding and discharging platform is arranged at one end of the base; an electric heating mechanism is arranged in the heating chamber; a profiling mechanism is arranged in the forming chamber; two parallel guide rails are arranged on the base; a translation vehicle is arranged on the base, front chain wheel frames are arranged on the front end surface of the base; a front chain wheel is arranged on each front chain wheel frame; rear chain wheel frames are arranged on the rear end surface of the base; a rear chain wheelis arranged on each rear chain wheel frame; front chain wheels and rear chain wheel are sleeved by chains; a conveying driving mechanism used for driving the rear chain wheels to operate is arrangedat the rear end of the base; chains are close to the top part of the base; the front and rear ends of the translation vehicle are respectively provided with a traction block; traction blocks are closeto the top part of the base; and two ends of the chains are correspondingly connected with two traction blocks. The device provided by the invention can reduce a scald accident rate and potential safety hazards, and can improve production efficiency.

Owner:SHENZHEN SANXIN JMT GLASS

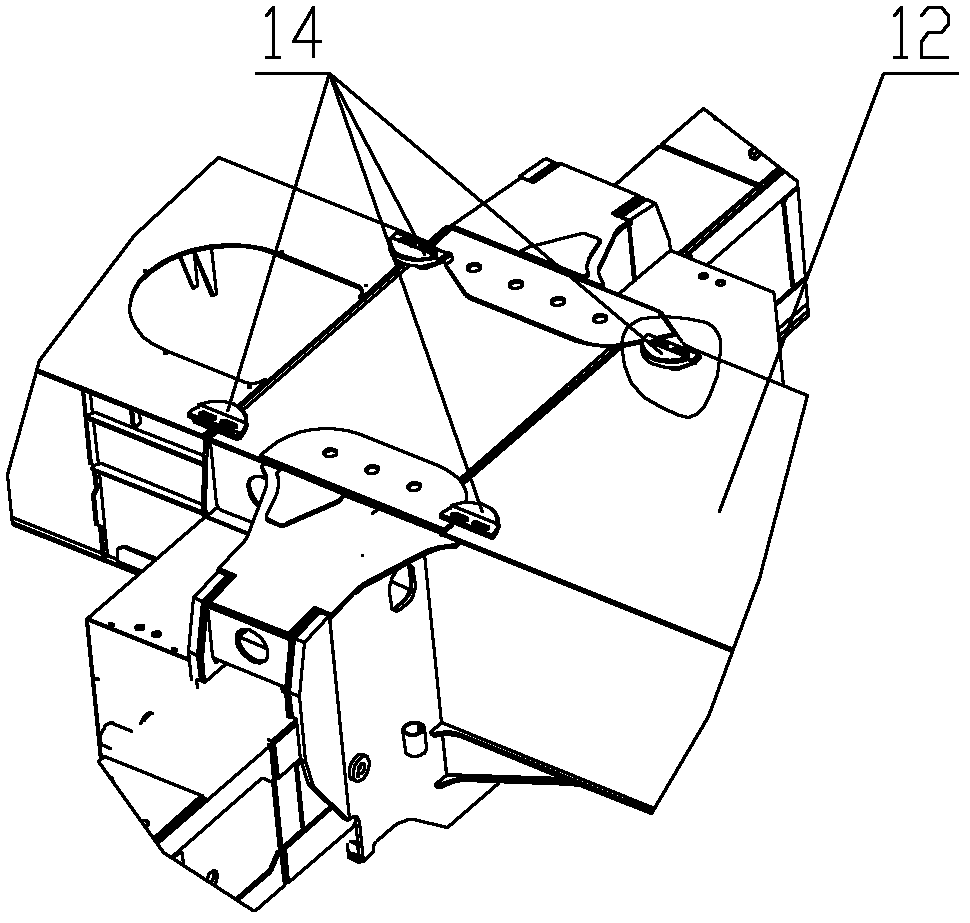

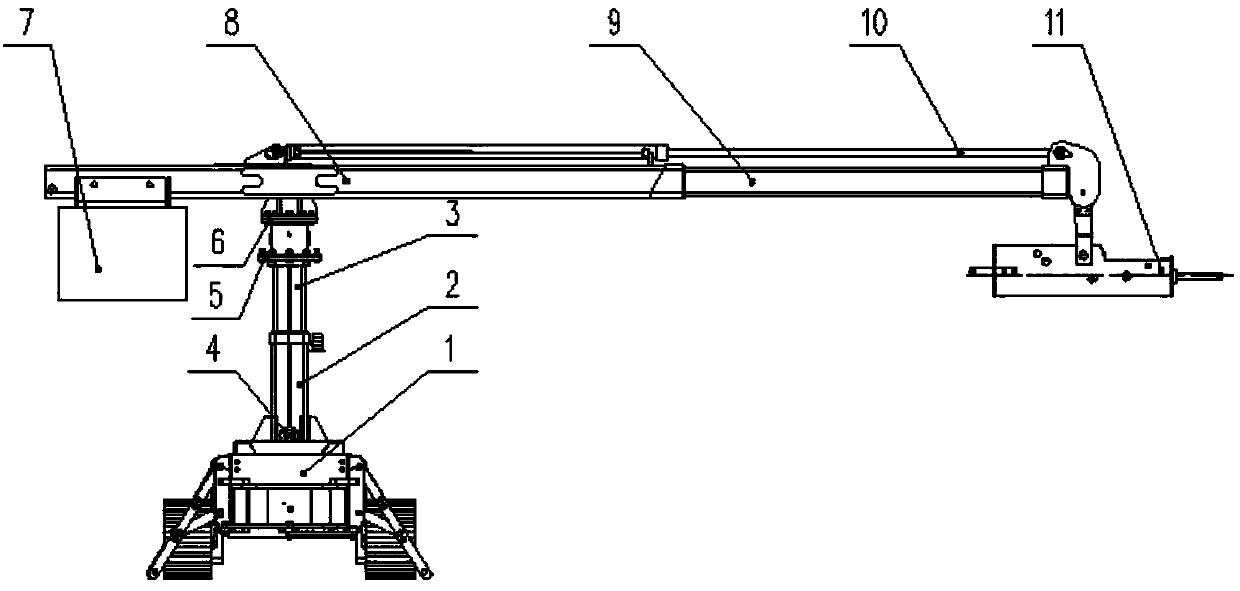

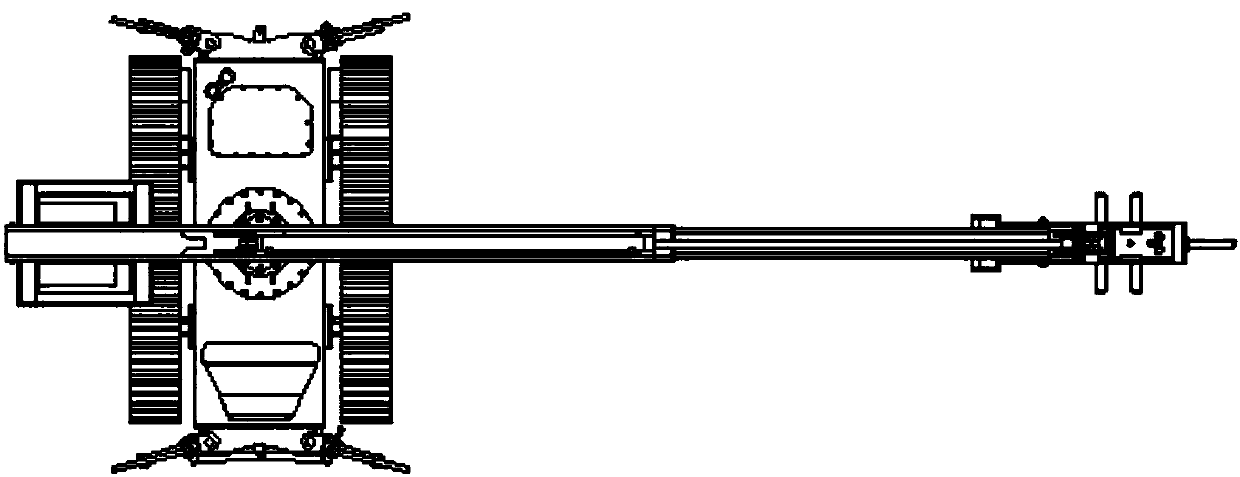

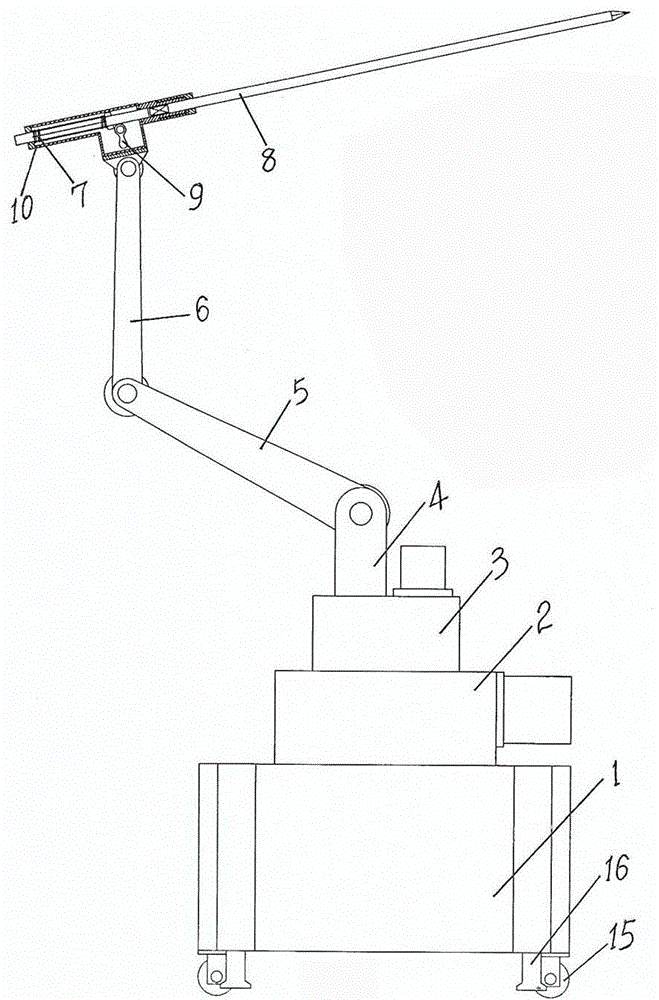

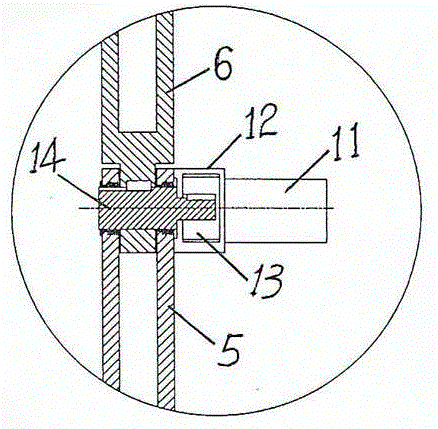

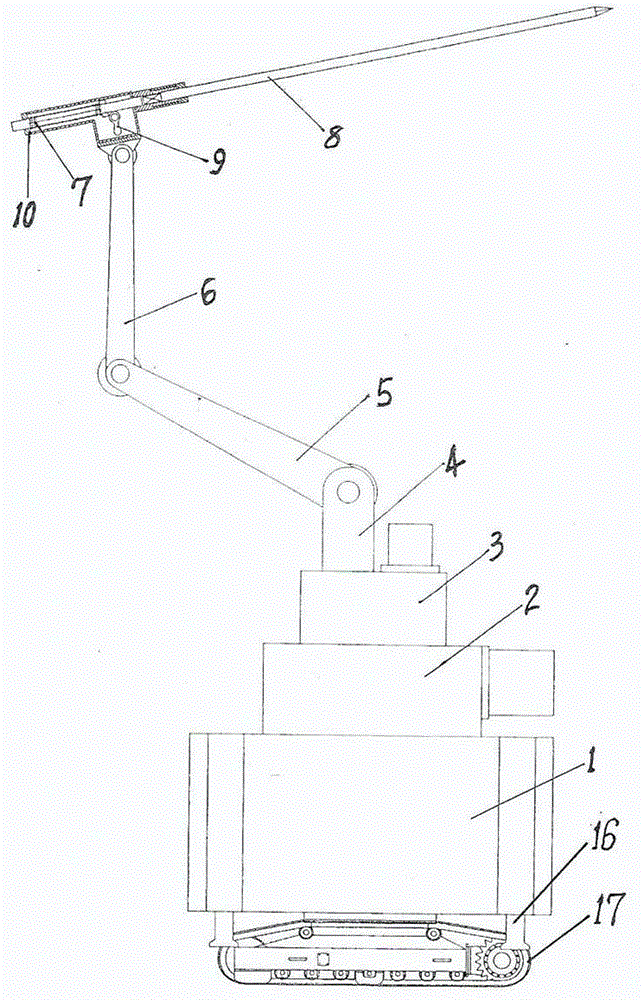

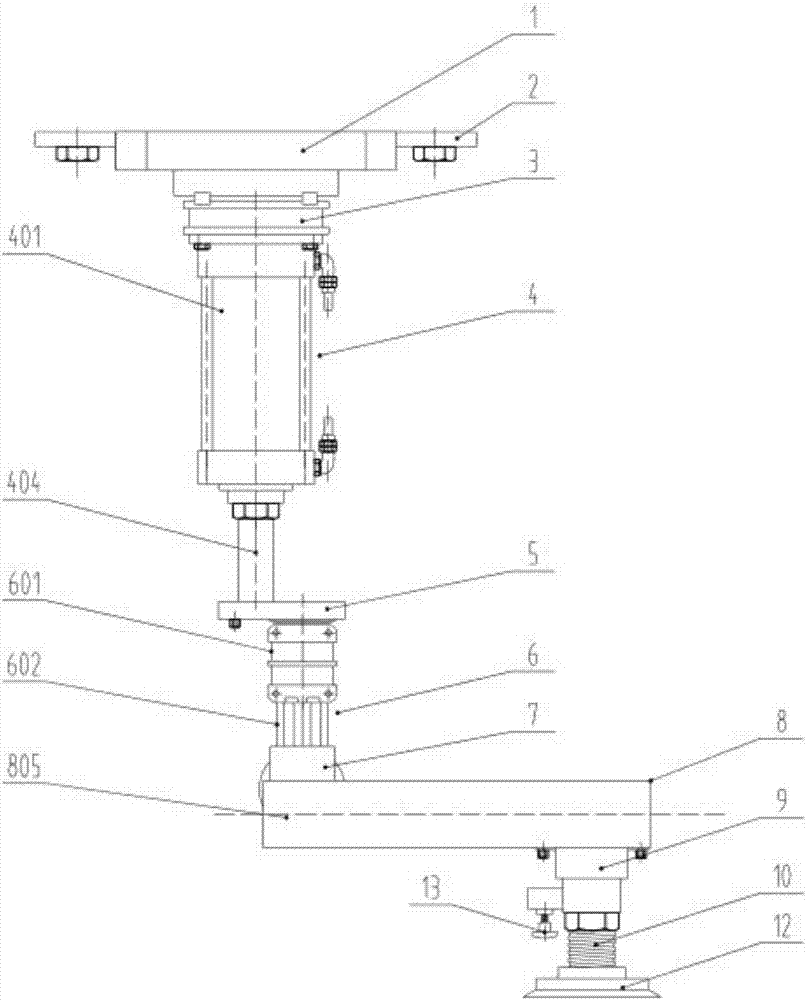

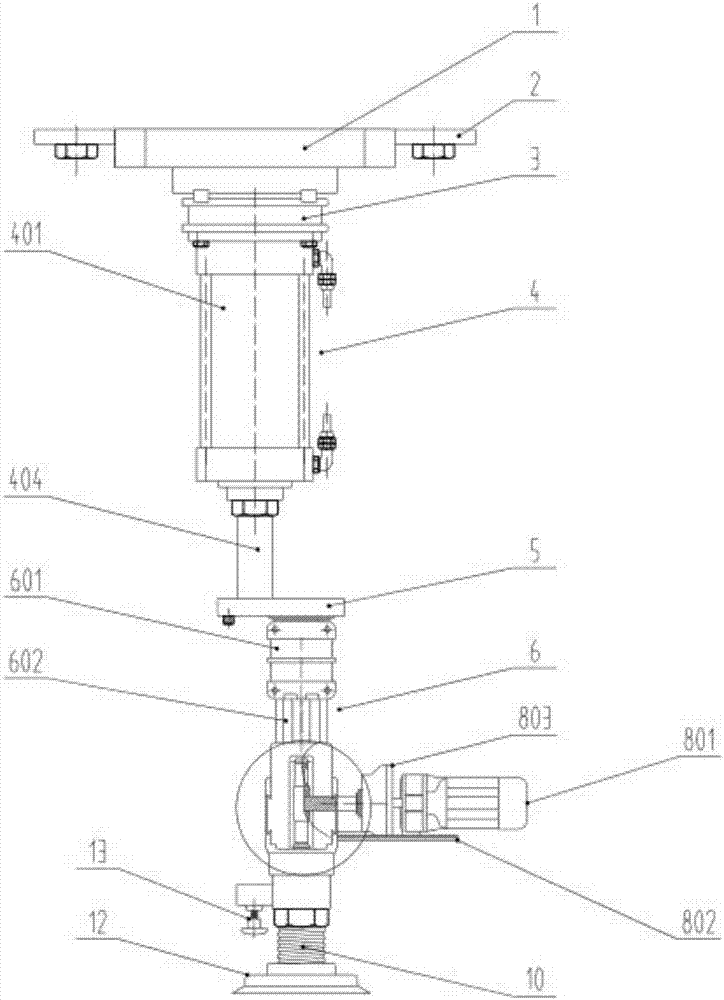

Connection dismantling robot

ActiveCN104985421BReduce labor intensityEnsure labor safetyLifting devicesMetal working apparatusControl engineeringLeg mechanism

The invention discloses a robot for dismantling connecting pieces. The robot comprises a travelling chassis, an elevating mechanism, a telescoping arm mechanism, and a punching body, the upper side and the lower side of the elevating mechanism are respectively connected with the telescoping arm mechanism and the travelling chassis, the punching body is arranged on the telescoping arm mechanism, four supporting leg mechanisms in bilateral symmetry are fixedly arranged on the travelling chassis, the elevating mechanism comprises a big arm outer arm, a big arm inner arm, and a big arm oil cylinder, the telescoping arm mechanism comprises a telescoping arm outer arm, a telescoping arm inner arm, and a telescoping arm oil cylinder, the telescoping arm outer arm is connected with the big arm inner arm, the telescoping arm inner arm is arranged in the telescoping arm outer arm and can move left and right, a cylinder end of the telescoping arm oil cylinder is hinged to the telescoping arm outer arm, a rod end of the telescoping arm oil cylinder is hinged to the telescoping arm inner arm, and the punching body is connected to the outer end of the telescoping arm inner arm. According to the robot for dismantling the connecting pieces, the relative position of the connecting piece and an execution mechanism of the robot can be flexibly adjusted via the elevating mechanism, a rotation mechanism, and the telescoping arm mechanism, the connecting pieces can be dismantled, and the work efficiency is improved.

Owner:惊天智能装备股份有限公司

Full-automatic bicycle pipe fitting opening milling equipment

InactiveCN106925821AEnsure labor safetyImprove labor efficiencyMilling equipment detailsPositioning apparatusPistonEngineering

The invention provides a full-automatic bicycle pipe fitting milling device, which includes a platform, on which a rotating motor is arranged, and the rotating motor is connected to a milling cutter through a motor connecting shaft, and the milling cutter is a saw blade milling cutter , the platform is also provided with a workbench, the workbench is fixed with a track plate, the workbench is provided with a fixed cylinder, the fixed cylinder is fixed on the platform through the cylinder fixing seat, and the fixed cylinder The center line of the piston and the center point of the milling cutter are in the same vertical plane, the track plate is provided with a slide block, the side of the slide block is provided with a pipe groove, and the slide block rests on the track plate, A moving cylinder is fixed on the side of the slider, and a cooling pipe is also provided on the platform. The outlet end of the cooling pipe is located above the milling cutter, and a liquid tank is provided below the milling cutter. The liquid tank A liquid outlet pipe is arranged below, and the cooling pipe communicates with the liquid delivery pump. The invention overcomes the disadvantages of the prior art, uses the action of the cylinder to move the bicycle pipe, has high safety and is easy to operate.

Owner:天津市深呼吸自行车业有限公司

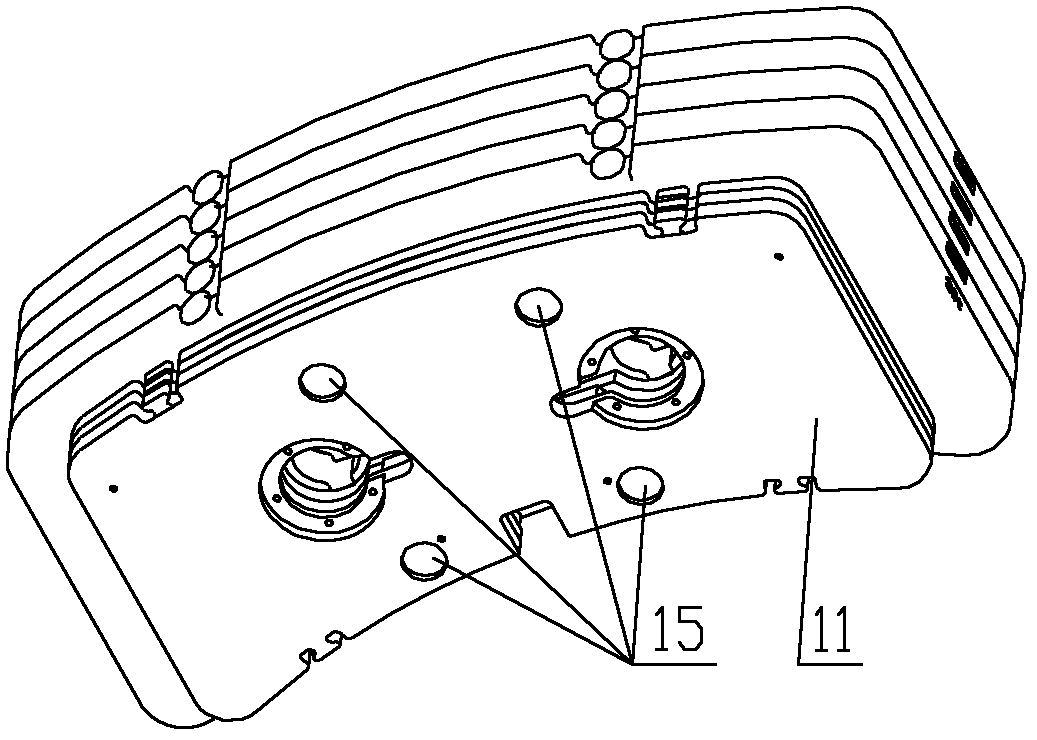

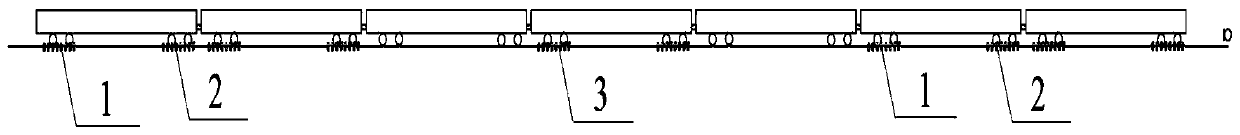

Automatic anti-slip system for passenger trains and stop retarder quantity calculating method

InactiveCN110293992ASimple structureImprove performancePositive railway stopsPassenger trainElectrical and Electronics engineering

The invention discloses an automatic anti-slip system for passenger trains and a stop retarder quantity calculating method and relates to a railway stopping system. In order to solve the problems thatswitch split or off-line leads to a huge loss as metal shoes are often not removed because the metal shoes are needed for preventing slip in a passenger train technical service workshop of China, andaccidents occur easily as slip prevention of a bottom line of the stored passenger train is greatly affected by human factors in staff participation because the metal shoes are unstable and easy to loosen or fall from a rail surface, the invention provides the automatic anti-slip system which comprises a plurality of first stop retarders, a plurality of second stop retarders and a plurality of third stop retarders, wherein the first stop retarders and the second stop retarders are alternately mounted on a stop steel rail successively, each third stop retarder is arranged between the first andsecond stop retarders, and each third stop retarder close to the first stop retarder is mounted on the stop steel rail. The automatic anti-slip system disclosed by the invention is used in the passenger train technical service workshop in stopping the passenger trains.

Owner:哈尔滨铁路减速顶调速研究有限公司

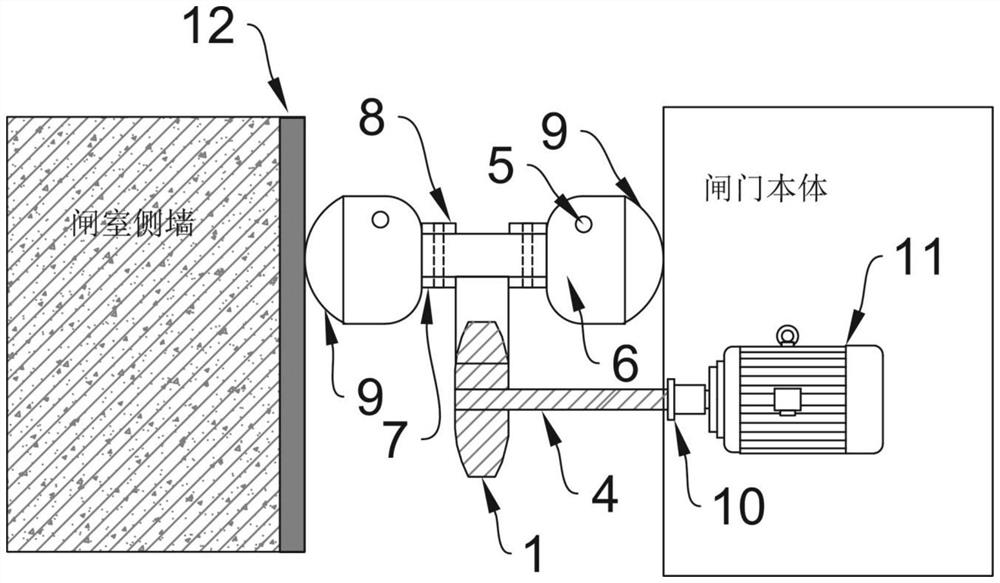

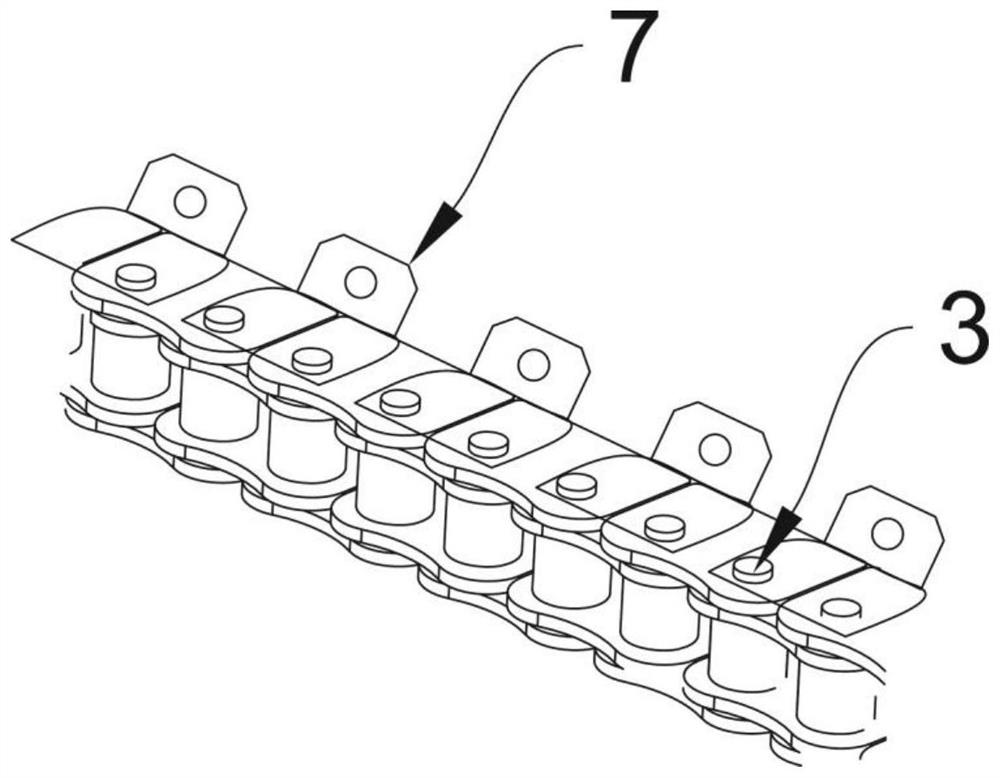

Bottom pivot flap gate side water stop device and structure convenient to overhaul

ActiveCN112854150AReduce manufacturing costSimple and safe operationBarrages/weirsWater stopGear wheel

The invention relates to a bottom pivot flap gate side water stop device and structure convenient to overhaul. The bottom pivot flap gate side water stop device convenient to overhaul comprises a chain with a bracket, a plurality of gears connected to and used for driving the chain, an inflatable water stop part fixed to the bracket of the chain, a transmission shaft connected with the gears, and a gear motor connected with the transmission shaft; the gear motor is arranged in a gate body; and one side face of the inflatable water stop part abuts against a gate side rail, and the other side face of the inflatable water stop part abuts against the side face of the gate body. According to the bottom pivot flap gate side water stop device and structure convenient to overhaul, the plane positions of the water stop part and the gears can be adjusted through the telescopic transmission shaft, deviation generated in the gate construction and installation period can be overcome, and water stopping can be better achieved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

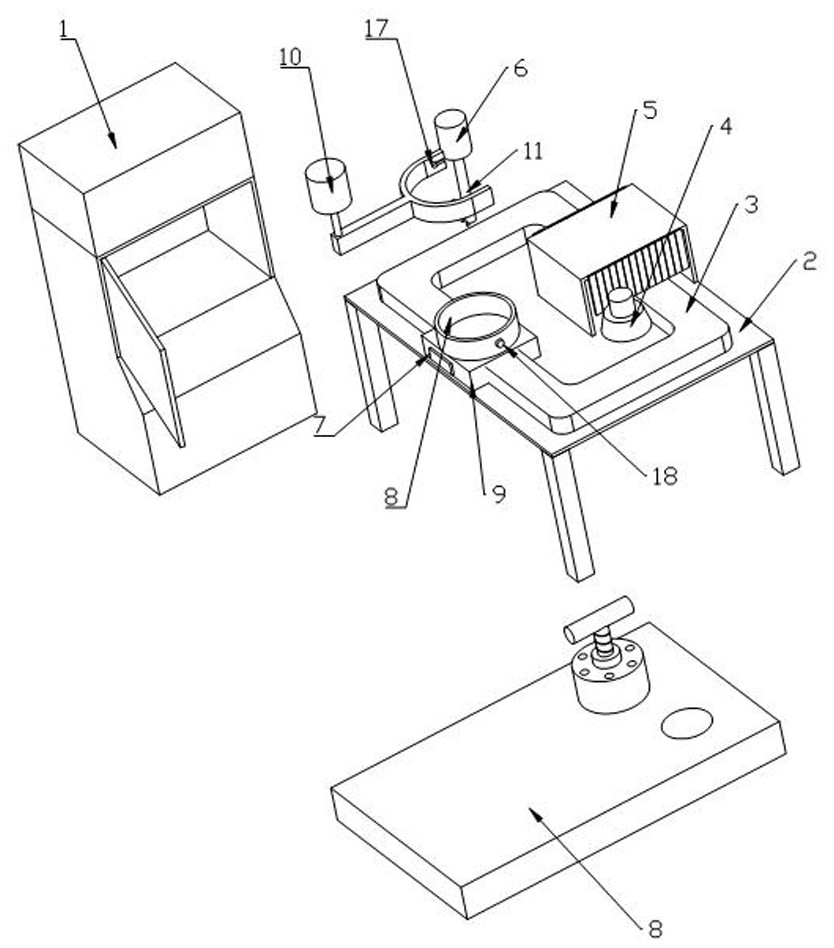

Heating sorting equipment used in process of detecting asphalt content by combustion method

PendingCN114216810ASmall footprintEasy to processWeighing by removing componentChemical analysis using combustionProcess engineeringAssembly line

The invention relates to the field of asphalt detection equipment, in particular to heating and sorting equipment used in the process of detecting the asphalt content through a combustion method. The invention aims to improve the asphalt content detection efficiency and the precision of the detection result at the present stage. The device comprises an asphalt detection furnace, a discharge port of a hoisting mechanism is located at an inlet of the asphalt detection furnace, the inlet is located at an outlet of a pilot detection device, the pilot detection device comprises a feeding platform, and the feeding platform is provided with a square assembly line and a power element for driving the assembly line to operate. A drying mechanism, a heating mechanism, a uniform smearing mechanism and an observation mechanism through which a test block table can pass are sequentially arranged along the direction of the assembly line, and the test block table comprises a square platform and a cylindrical test block basket mounted on the square platform. The method has the advantages that the pilot step is preset in front of the detection furnace, so that a more accurate detection result and higher detection efficiency are provided.

Owner:李靖

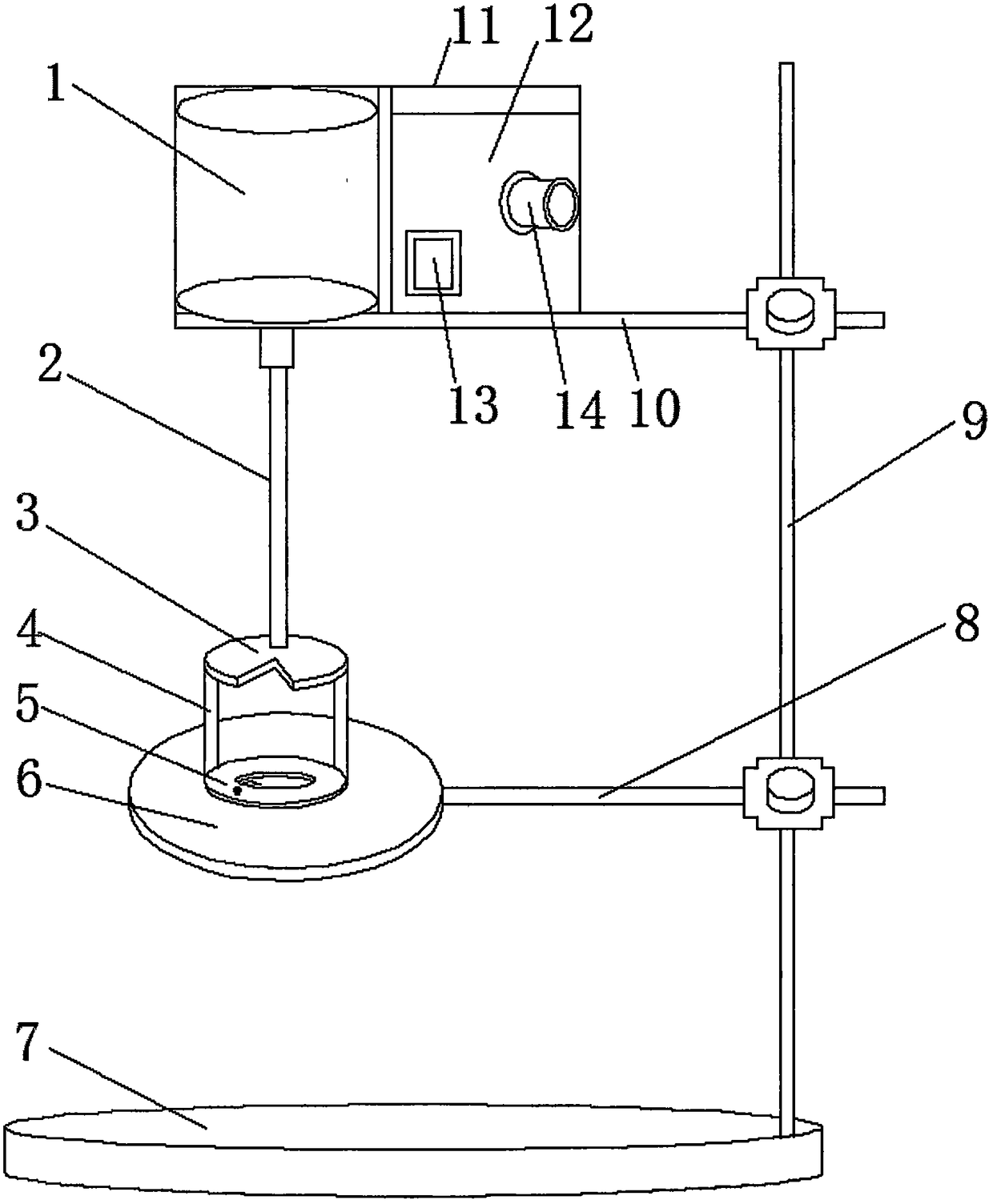

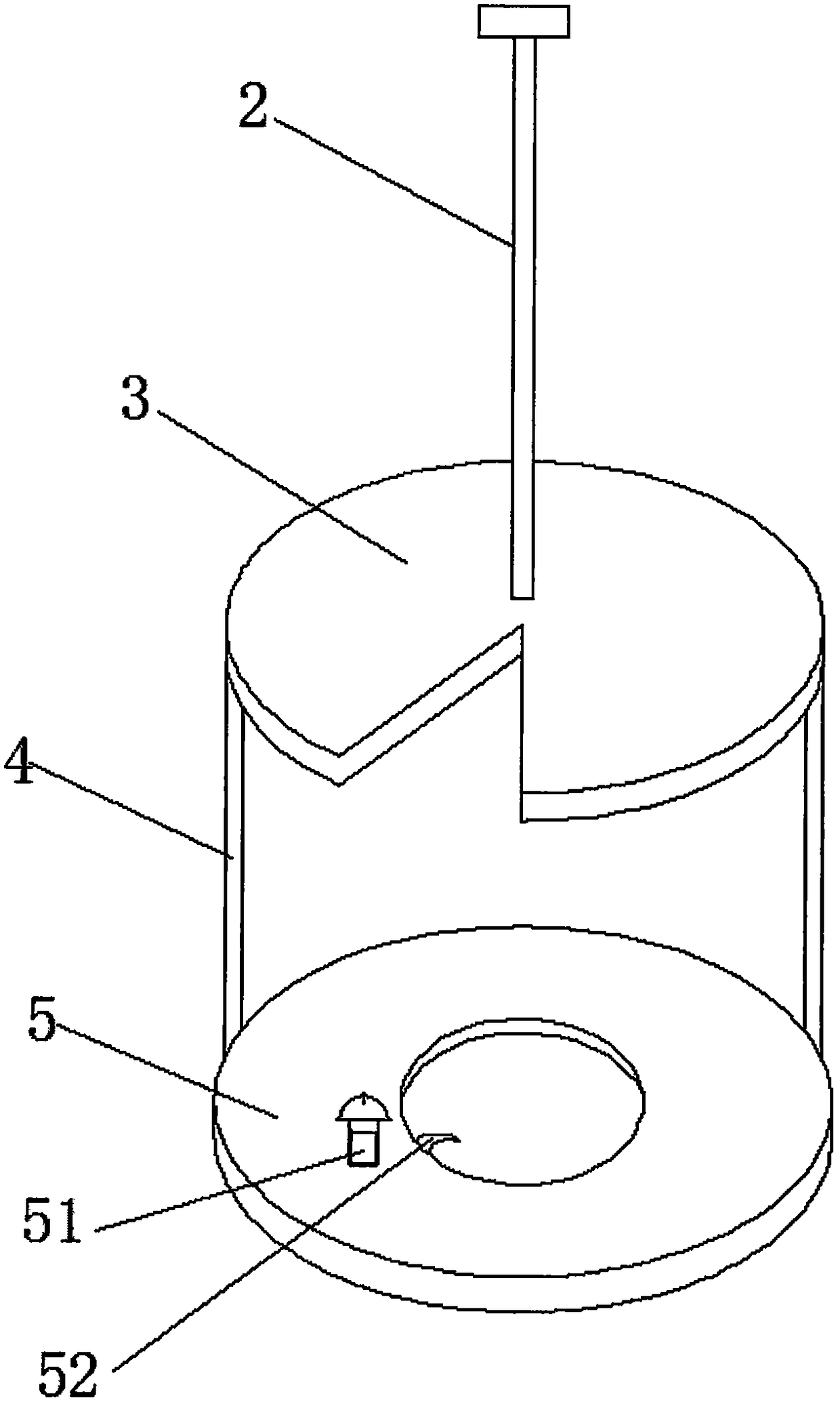

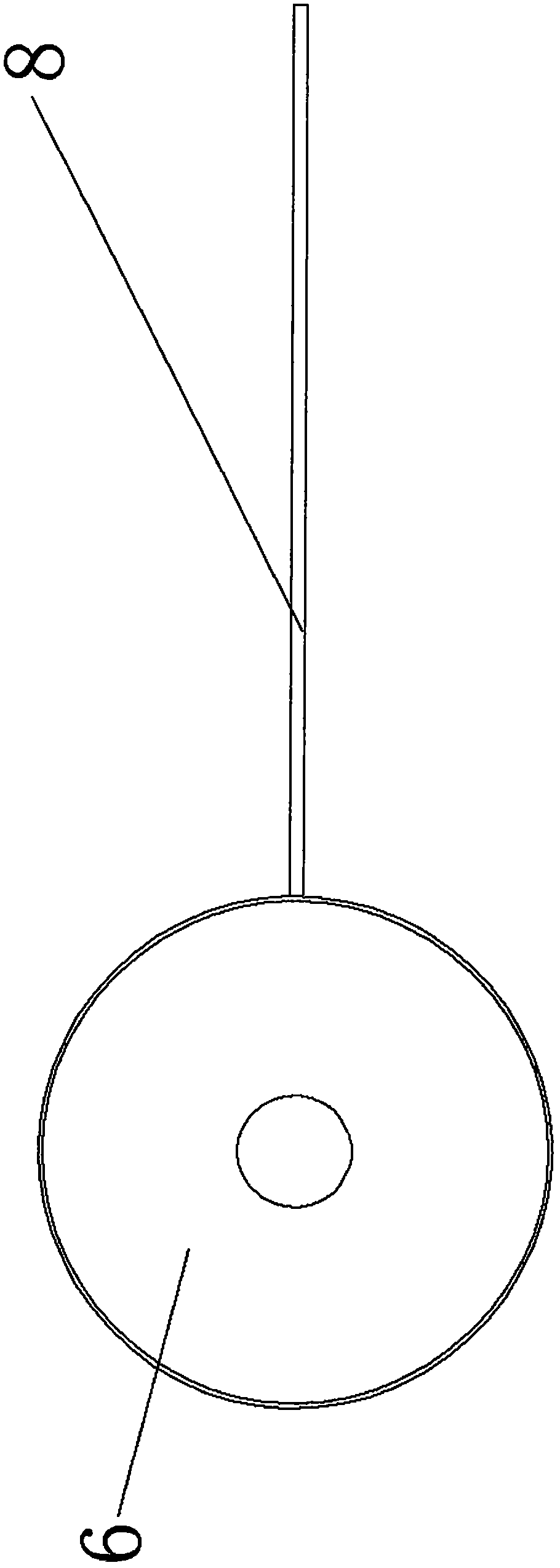

A top-mounted tussah cocoon peeling machine

InactiveCN105794734BAdjustable speedHeight adjustableAnimal husbandryElectricityAgricultural engineering

The invention discloses an overhead type tussah cocoon cutting machine and relates to the technical field of cocoon processing. The overhead type tussah cocoon cutting machine is used for solving the problems that in the prior art, the cocoon cutting labor load is large, cocoon cutting efficiency is low, and the pupa damage rate is high. The overhead type tussah cocoon cutting machine comprises a cocoon cutting device, a hand protection device, a fixing frame, a base, a first adjusting transverse rod and a supporting rod, the base is fixedly connected with the supporting rod perpendicular to the base, one end of the first adjusting transverse rod is movably connected with the supporting rod, the other end of the first adjusting transverse rod is fixedly connected with the fixing frame, a motor and a rotating speed adjuster are fixed into the fixing frame, and an output shaft of the motor is connected with a vertical rod of the cocoon cutting device; the hand protection device is arranged below the cocoon cutting device, and the motor, the rotating speed adjuster and a power source are electrically connected in sequence. By means of the overhead type tussah cocoon cutting machine, it is guaranteed that hands are not hurt in the cocoon cutting process, the pupa damage rate and the labor load are lowered, and cocoon cutting efficiency is greatly improved.

Owner:SHENYANG AGRI UNIV

Non-indentation variable-tension rolling mechanism

The invention discloses a non-indentation variable-tension rolling mechanism which comprises a spreading roller, a lifting device, a photoelectric distance measuring device, a rolling vehicle, a variable-tension power transmission box and a PLC. The lifting device comprises lifting steel wires on the two sides, steel wire length adjusting bolts, a large winding chain wheel, a small winding chain wheel, a winding motor, a lifting arm supporting pipe, lifting arms on the two sides, a hinge iron support, a winding sleeve and a lifting winding shaft. The photoelectric distance measuring device comprises a photoelectric distance measuring sensor, and the photoelectric distance measuring sensor is installed on the lifting arm supporting pipe through an adjusting plate and a support. The rolling vehicle comprises a vehicle frame and a rolling roller, and fabric is wound on the rolling roller. The lifting winding shaft is driven by the winding chain wheels to rotate, the steel wires are pulled, the lifting arm is pulled upwards by a certain distance, automatic rolling of the press-roller-free fabric is achieved, it is guaranteed that the fabric is smooth, and free of wrinkles and indentations after being processed and stored; and meanwhile, the labor intensity of workers is relieved, and the labor safety is guaranteed.

Owner:HAINING TEXTILE MACHINERY FACTORY

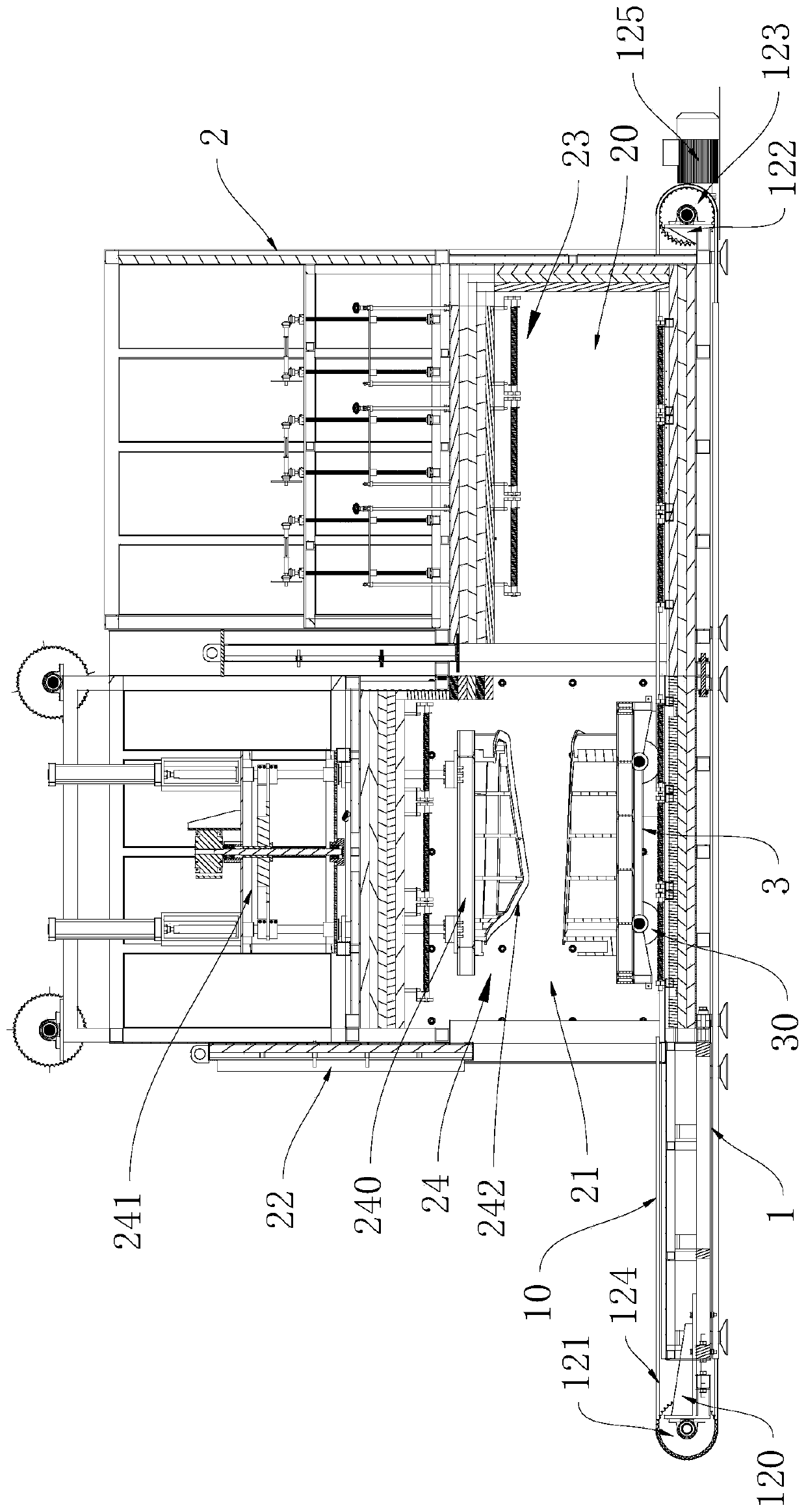

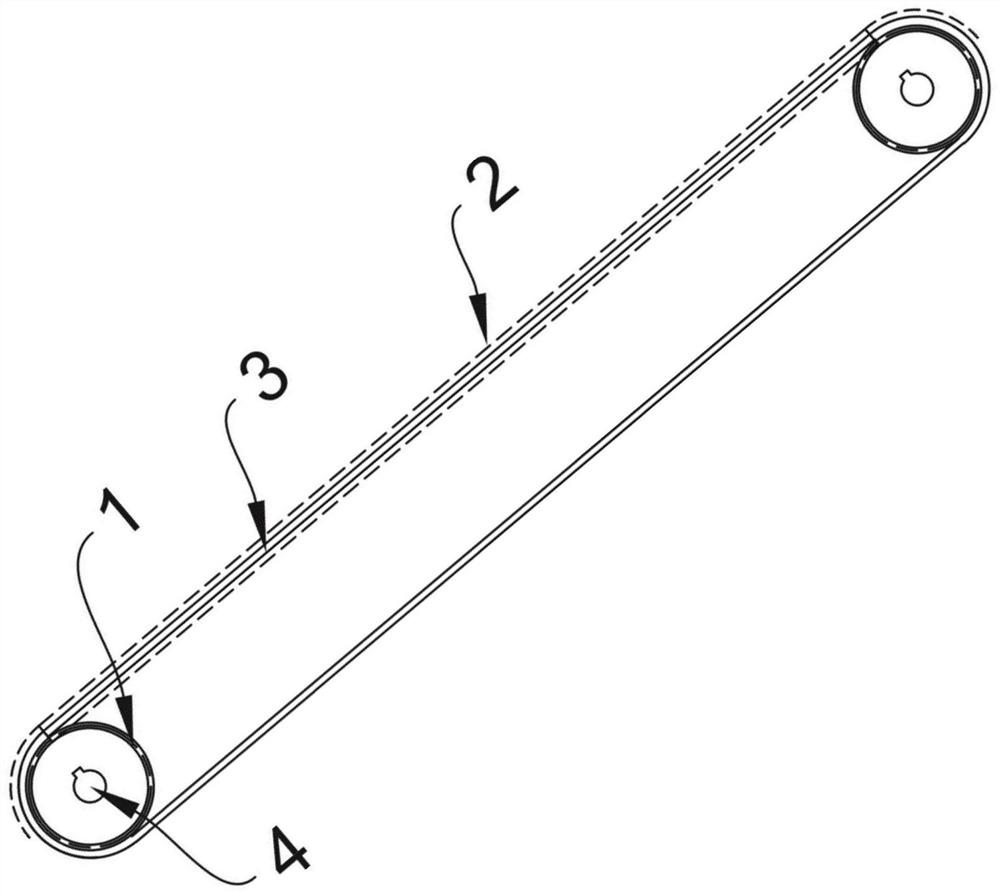

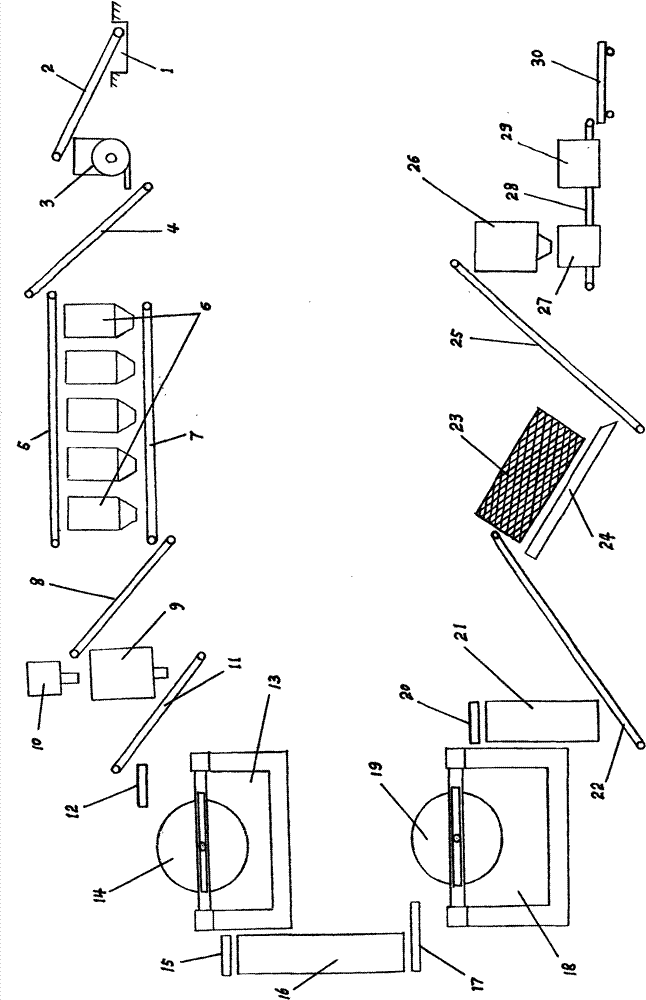

Automatic production line device of biological organic fertilizer

InactiveCN101575228BGuaranteed benefitsAvoid turning jobsBio-organic fraction processingOrganic fertiliser preparationProduction lineEngineering

The invention discloses an automatic production line device of a biological organic fertilizer, which is complete equipment of the automatic production line of the biological organic fertilizer. The invention solves the technical problem of the complete equipment of integrated and automatic production in scale production. The technical proposal is as follows: the automatic production line device comprises a crusher 3, all conveying belts, all motors, a primary fermentor 13, a secondary 18, crushing-turning feeding machines 14 and 19, a rolling and vibrating sieve 23, a packing machine 27, a mass detector 29 and the like. The automatic production line device can be used for producing and manufacturing the biological organic fertilizer automatically in a production line mode.

Owner:云南华卿亿安生物工程有限公司

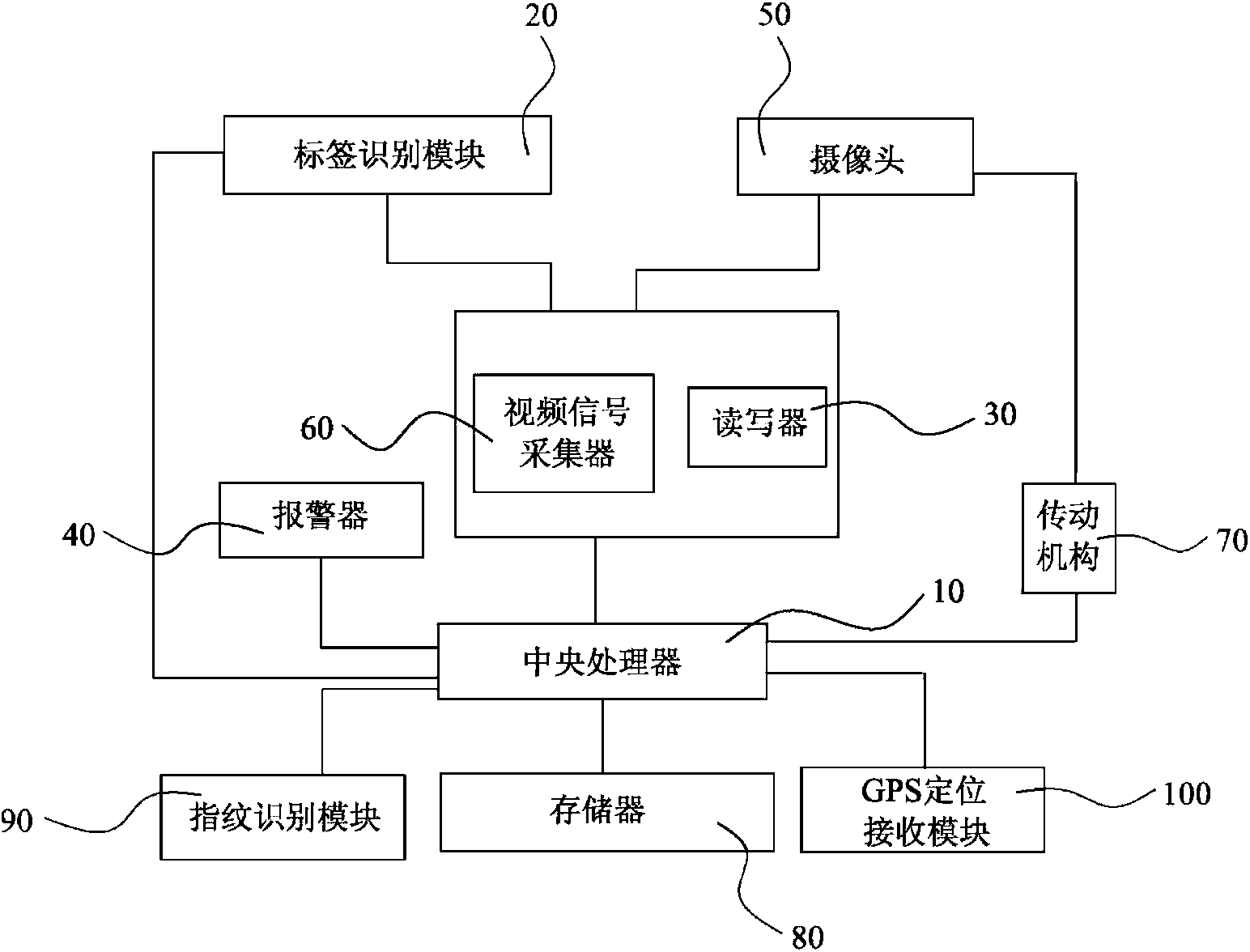

Device conducting intelligent recognition and management on operation and working safety

InactiveCN103324968ARealize managementImprove efficiencyRegistering/indicating time of eventsCo-operative working arrangementsPattern recognitionRadio frequency signal

The invention discloses a device conducting intelligent recognition and management on operation and working safety. The device comprises a central processing unit, a label recognition module used for recognizing labels on objects, a reader-writer used for reading and writing radio-frequency signals of positions of the objects, and an alarm apparatus used for giving out warning signals. The alarm apparatus, the reader-writer and the label recognition module are all connected with the central processing unit, and the label recognition module is connected with the reader-writer. The labels on the objects can be recognized through matched utilization of the central processing unit, the label recognition module and the reader-writer, the warning signals are given out at the right moment through the alarm apparatus, intelligent recognition and management are conducted on the operation and the working safety, traditional artificial recognition and management are replaced, the efficiency is greatly improved, manpower is saved, no missing detection will occur, and guarantees are provided for safety production.

Owner:ZHONGSHAN TOPWARE ELECTRONICS TECH

Wheeled mechanical energy storage coke slag crushing machine

The invention belongs to the technical field of machines, and provides a wheeled mechanical energy storage coke slag crushing machine. A frame disk of the machine is rotatably and movably connected with a driving wheel. The output end of a pneumatic device fixed to the frame disk is fixed to supports. A circular gear of the frame disk is engaged with a circular gear on an output shaft of a gearbox connected with a rotating motor on a rotary body. A circular track of the frame disk is movably connected with a track wheel of the rotary body in a rolling mode. The rotary body and a frame body are fixed. A threaded rod fixed to the output shaft of the gearbox connected with a lifting motor on the frame body is in threaded connection with a threaded barrel fixed to a lifting arm. The upper end of the lifting arm is rotatably and movably connected with the lower end of a driving arm through a speed reduction motor. The upper end of the driving arm is rotatably and movably connected with the lower end of a linkage arm through a speed reduction motor. The upper end of the linkage arm is rotatably and movably connected with a protruding part of a sleeve through a speed reduction motor. An energy storage motor is fixed into a protruding cavity of the sleeve. An energy storage cam on an output shaft of the energy storage motor is movably connected with a protruding stopper on a steel chisel in a sliding mode. The steel chisel is sleeved with the sleeve and is movably connected with the sleeve in a sliding mode. The rear end section of the steel chisel is inserted into a spring. The rear end of the spring abuts against a clamping neck of the sleeve, and the front end of the spring abuts against a spring stopper on the steel chisel. The wheeled mechanical energy storage coke slag crushing machine is used for crushing coke slag in power station boilers and is simple and ingenious in structure, stable in effect, easy to manufacture and low in cost.

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

Highly toxic powder transportation and feeding equipment and method

ActiveCN103264905BEnsure labor safetyMeet transportation needsLarge containersLoading/unloadingCombined useEngineering

Owner:BAOSTEEL ENG & TECH GRP

An automatic grabbing device for injection molded blades

InactiveCN106865214BRealize automatic pickingReduce labor intensityConveyor partsEngineeringUltimate tensile strength

Owner:苏州晟炅精密电子有限公司

Construction shield and construction method

InactiveCN102277960BImprove securityImprove health securityBuilding material handlingTemperature controlLight equipment

The invention relates to building construction equipment, in particular to a construction shield and a construction method. The construction shield comprises a net rack shield body, sliding rails and crown block, wherein the net rack shield body is arched and formed by combining standard bolt sphere anti-vibration net rack components; the sliding rails are arranged on two side edges at the bottomof the net rack shield body respectively; a plurality of roller supports are arranged on the sliding rails; at least one row of detachable joints is arranged along the length direction of the net rack shield body; construction walkways are formed on the two sides of inner ground of the net rack shield body respectively; at least one suspended crown block is arranged at the inner arch of the net rack shield body; a suspension point at which the crown block is suspended on the net rack shield body adopts a pipe joint with a sleeve; temperature control equipment, a power supply and illuminating equipment are arranged in the net rack shield body; a heat-preservation covering layer is arranged outside the net rack shield body; and closing / opening cord fabrics are arranged at worker / crown blockentrances / exits at the two ends of each construction walkway on the heat-preservation covering layer. By the construction shield and the construction method, a construction process can be ensured notto be influenced by weather.

Owner:安徽优技工程科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com