Automatic anti-slip system for passenger trains and stop retarder quantity calculating method

A technology for railway passenger cars and parking roofs, which is applied to railway car body parts, mandatory railway stoppers, transportation and packaging, etc. The effect of saving labor cost and system safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

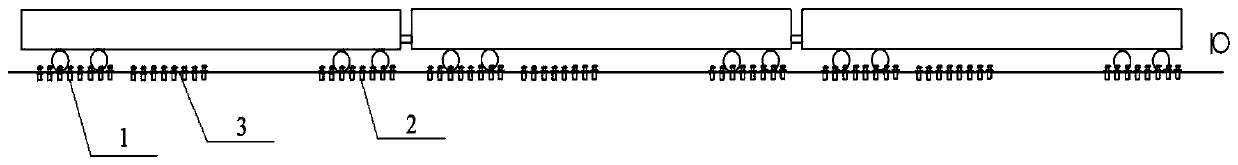

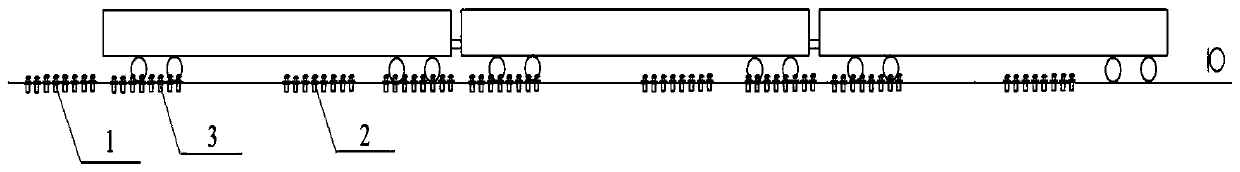

[0053] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment mode, a kind of hybrid parking system of railway marshalling yard described in this embodiment mode, it comprises multiple groups of first parking roof 1, multiple groups of second parking roofs 2 and multiple groups of third parking roofs 3, multiple groups of first parking roofs Parking roofs 1 and multiple groups of second parking roofs 2 are alternately installed on the parking rail tracks, and each group of third parking roofs 3 is arranged between a group of first parking roofs 1 and a group of second parking roofs 2, and each group The third parking roof 3 is installed on the parking rail track near one group of first parking roofs 1 .

specific Embodiment approach 2

[0054] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, a kind of railway marshalling station hybrid parking system described in this embodiment, the number of groups of the first parking roof 1, the number of groups of the second parking roof 2 and the group number of the third parking roof 3 are the same, each group The first parking roof 1, the second parking roof 2 of each group and the third parking roof 3 of each group have the same structure quantity and installation method, and other methods are the same as the specific embodiment one.

[0055] In this embodiment, the first parking roof 1, the second parking roof 2 and the third parking roof 3 are all the same parking roof. The manufacturer is Harbin Railway Deceleration Top Speed Regulation Research Co., Ltd., and the production model is TDJGST202 high-speed locking parking roof .

specific Embodiment approach 3

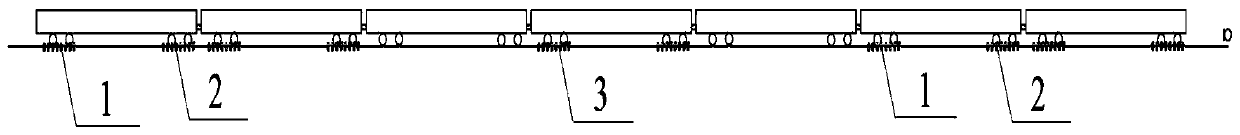

[0056] Specific implementation mode three: combination Figure 5Describe this embodiment, a hybrid parking system of a railway marshalling yard described in this embodiment, each group of first parking roofs 1 includes a first parking roof 1-1, a second parking roof 1-2, a third parking roof 1- 3. The fourth parking roof 1-4, the fifth parking roof 1-5, the sixth parking roof 1-6, the seventh parking roof 1-7, the eighth parking roof 1-8, the ninth parking roof 1-9, Tenth parking roof 1-10, eleventh parking roof 1-11, twelfth parking roof 1-12, thirteenth parking roof 1-13, fourteenth parking roof 1-14, fifteenth parking roof 1 -15 and the sixteenth parking roof 1-16, the first parking roof 1-1, the second parking roof 1-2, the third parking roof 1-3, the fourth parking roof 1-4, the fifth parking roof 1- 5. The sixth parking roof 1-6, the seventh parking roof 1-7 and the eighth parking roof 1-8 are installed on the rails on one side of the railway in sequence, the ninth park...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com