Wheeled mechanical energy storage coke slag crushing machine

A mechanical energy storage and coke machine technology, which is applied in the field of machinery and wheeled mechanical energy storage coke machines to achieve a stable and stable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

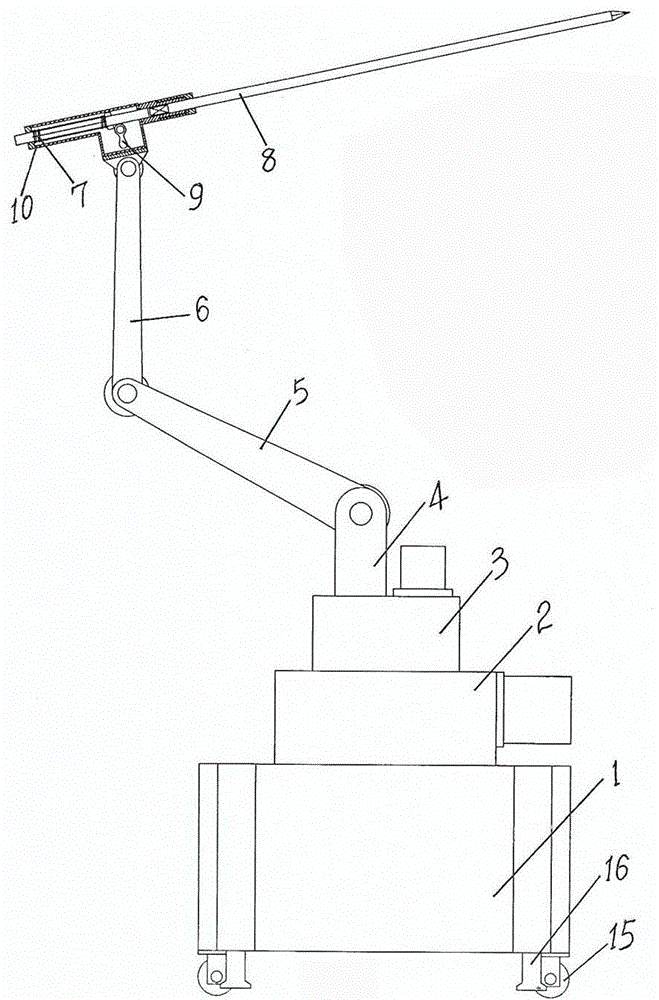

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , as shown in 3:

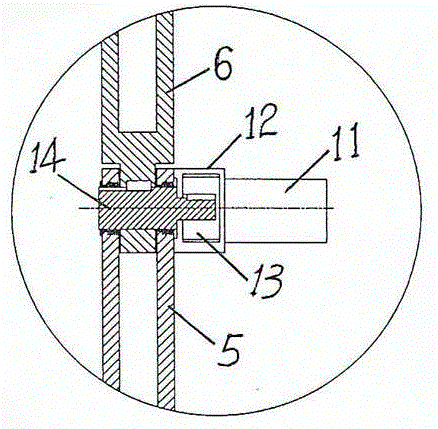

[0038] A wheel-type mechanical energy storage coking machine, which consists of a frame plate 1, a rotating body 2, a frame body 3, a lifting arm 4, a driving arm 5, a linkage arm 6, a sleeve 7, a steel drill 8, an energy storage cam 9, and a spring 10. Consists of a reduction motor 11, a reducer 12, a reduction gear 13, a rotating shaft 14, a drive wheel 15, a support 16, and a crawler belt 17;

[0039]The wheel-type mechanical energy storage coke machine, the bottom end of the frame plate 1 is connected flexibly with the drive wheel 15, the output end of the pneumatic device fixedly connected to the frame plate 1 is fixedly connected to the upper end of the support 16, and the The ring gear is engaged with the ring gear on the output shaft of the gearbox connected to the rotary motor on the rotating body 2,...

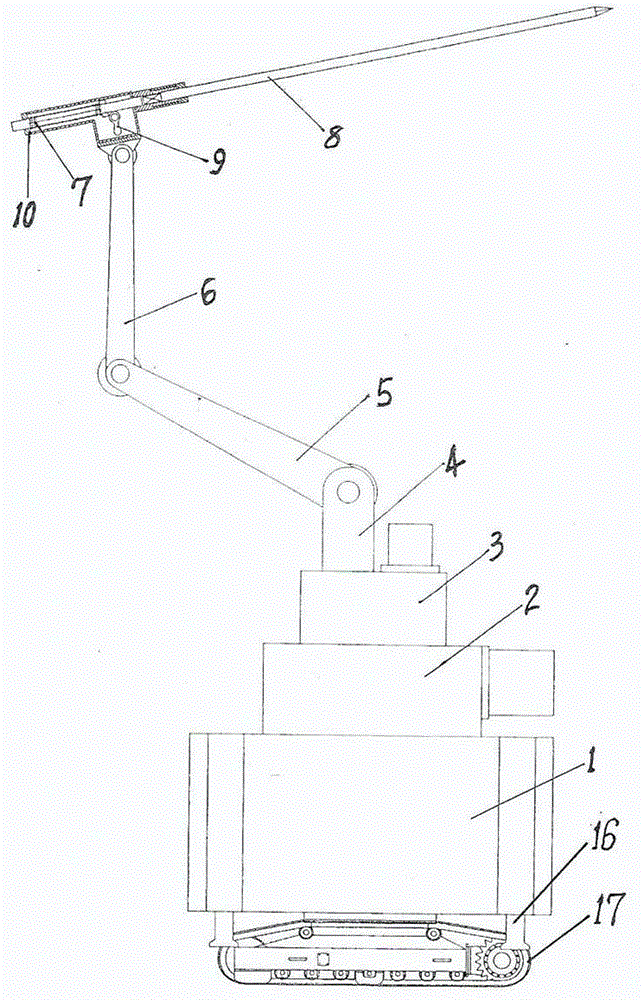

specific Embodiment approach 2

[0049] Carried out on the basis of specific implementation mode 1 implementation, just as the description attached figure 2 , 3 Shown, just: described drive wheel 15 is replaced by crawler belt 17, and the bottom end of frame dish 1 and drive wheel 15 rotation live connection are replaced by the bottom end of frame dish 1 and the supporting crawler belt shaft of crawler belt 17 rotation live connection, In this way, the key technology of "driving wheel walking and spring energy storage" has been transformed into the key technology of "track walking and spring energy storage". Type mechanical energy storage coking machine", thus producing another new product of coking machine.

[0050] The crawler-type mechanical energy storage coking machine of the present invention is equipped with a visual system, electrical control components and a remote remote controller. The operator can observe the real-time status of the working surface through the display on the control cabinet in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com