Patents

Literature

39results about How to "Evenly focused" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

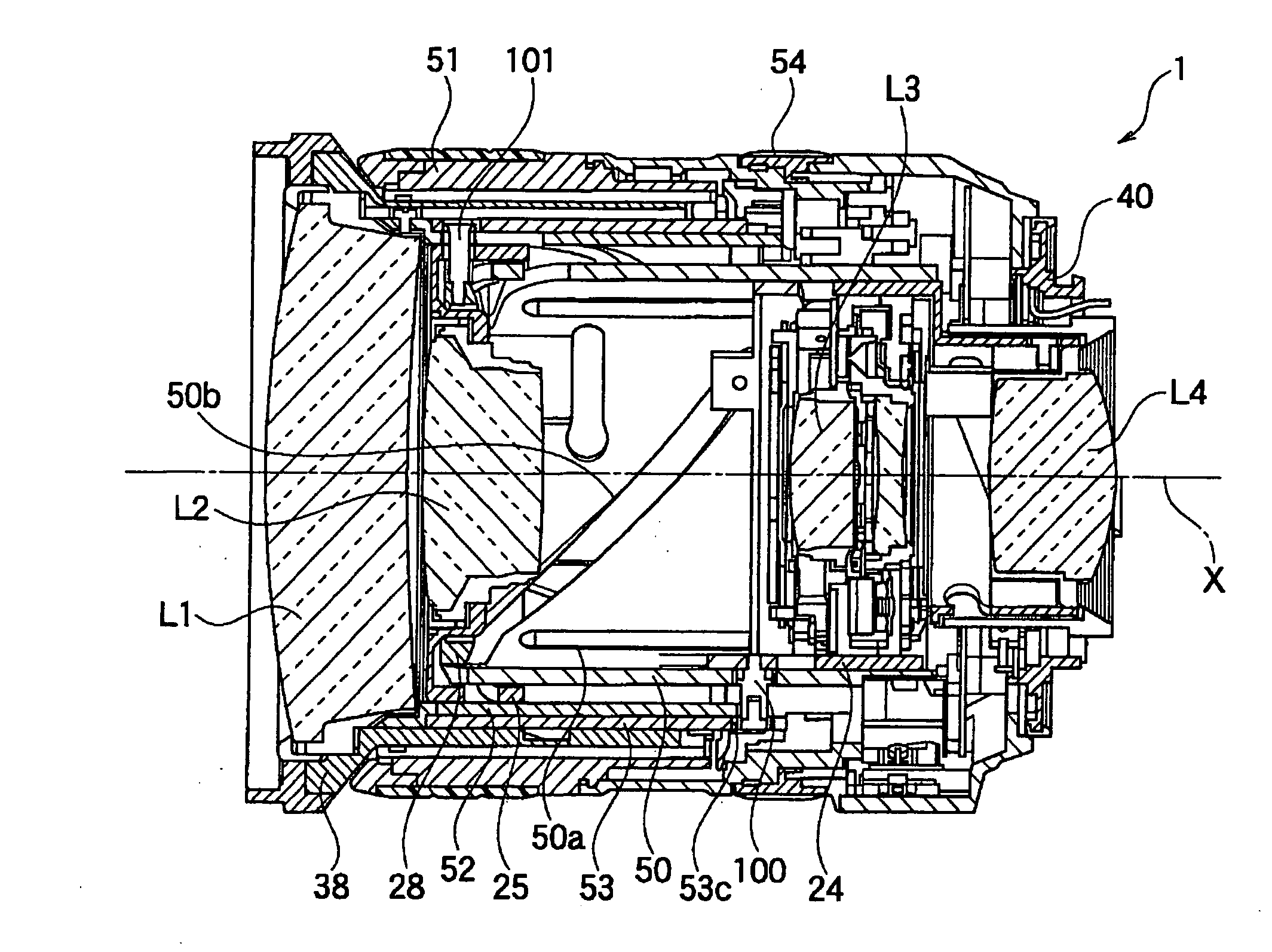

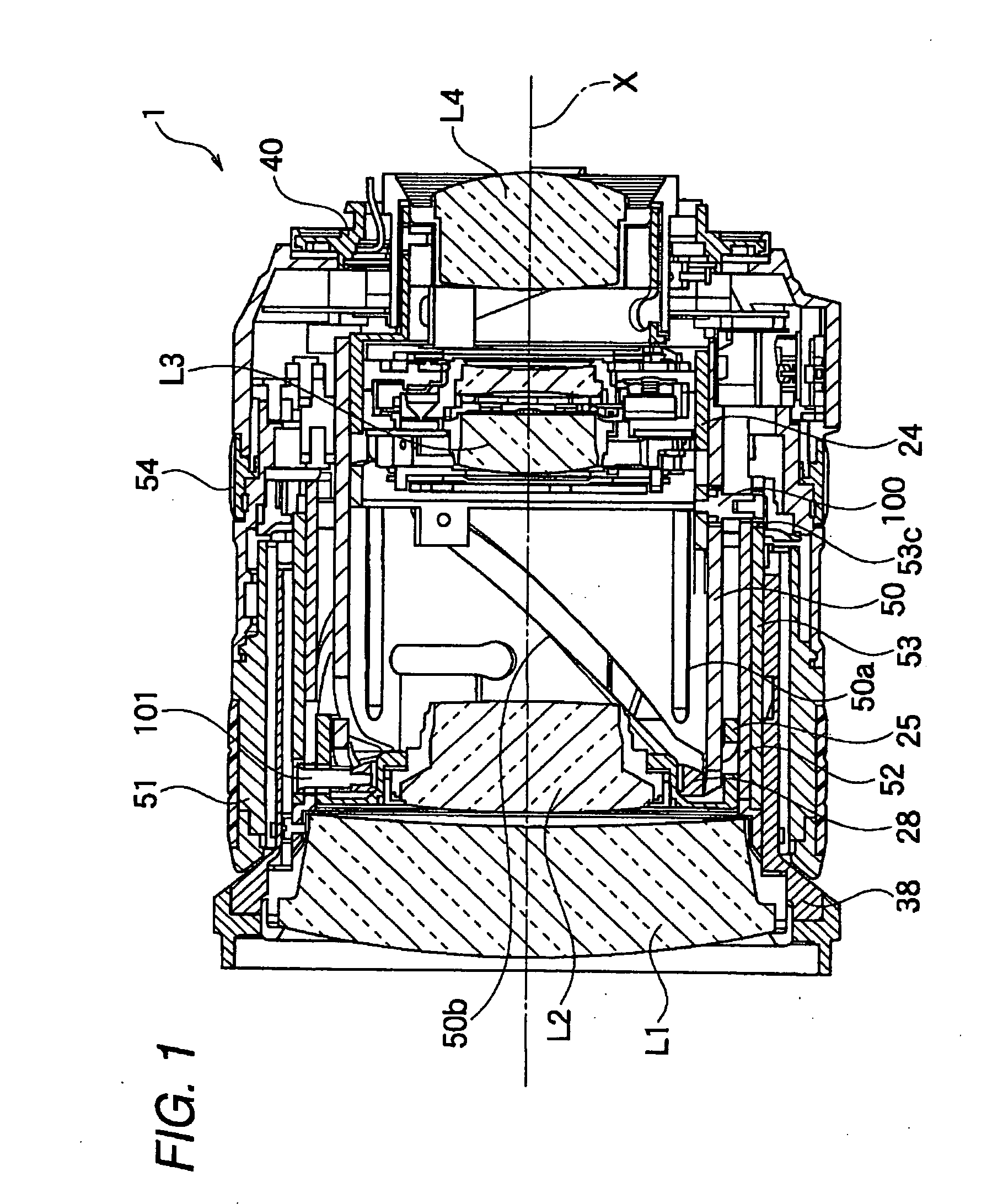

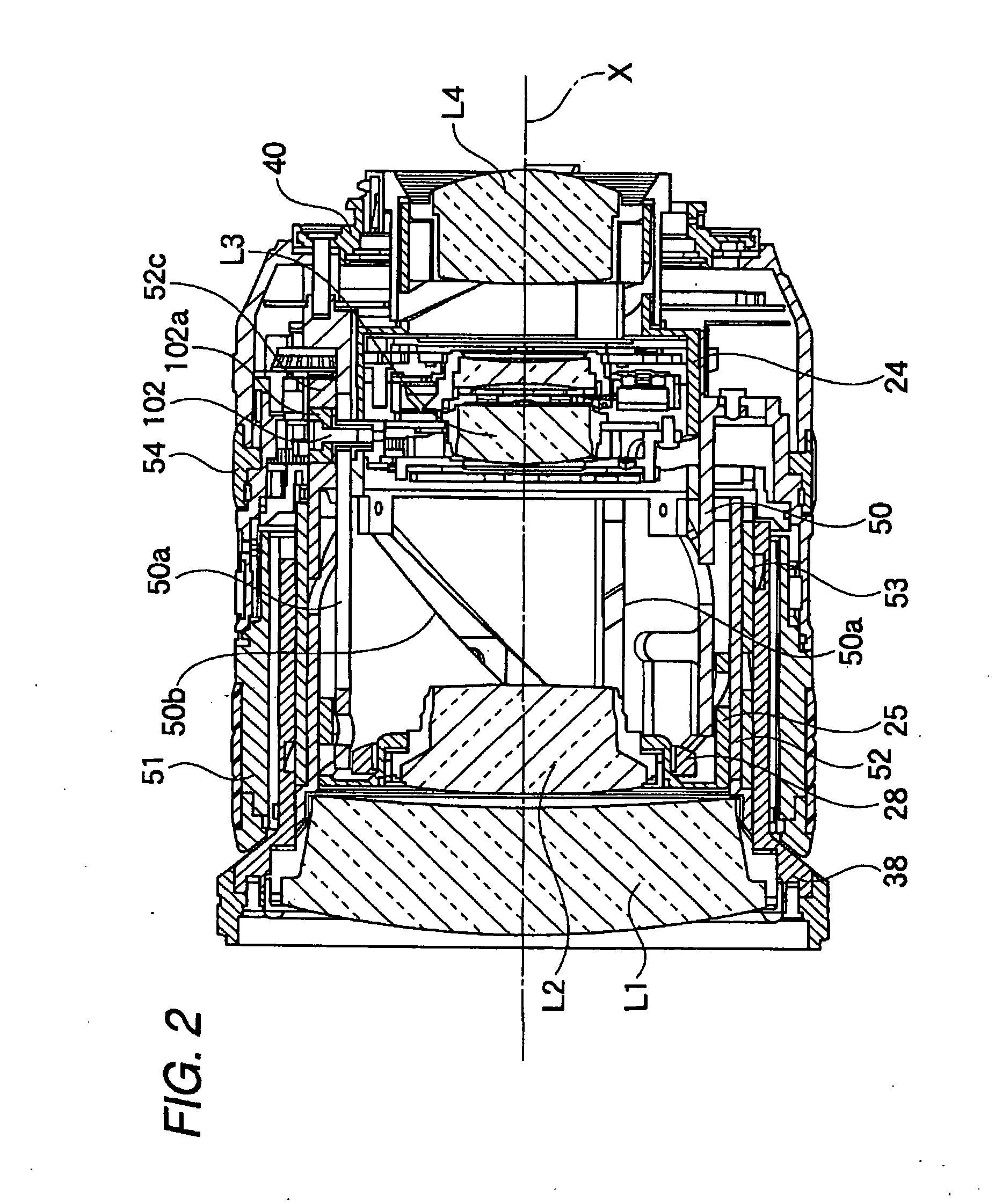

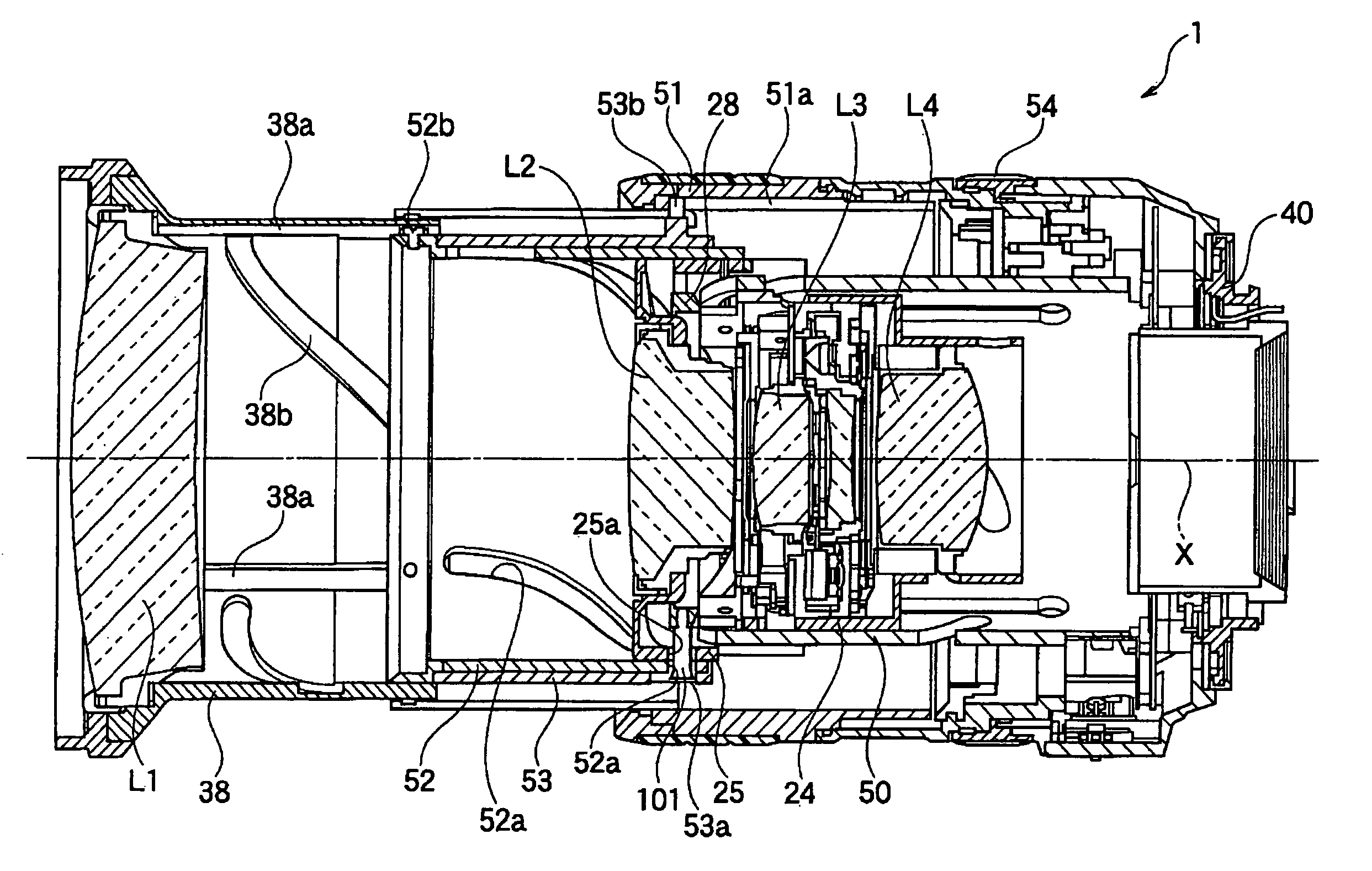

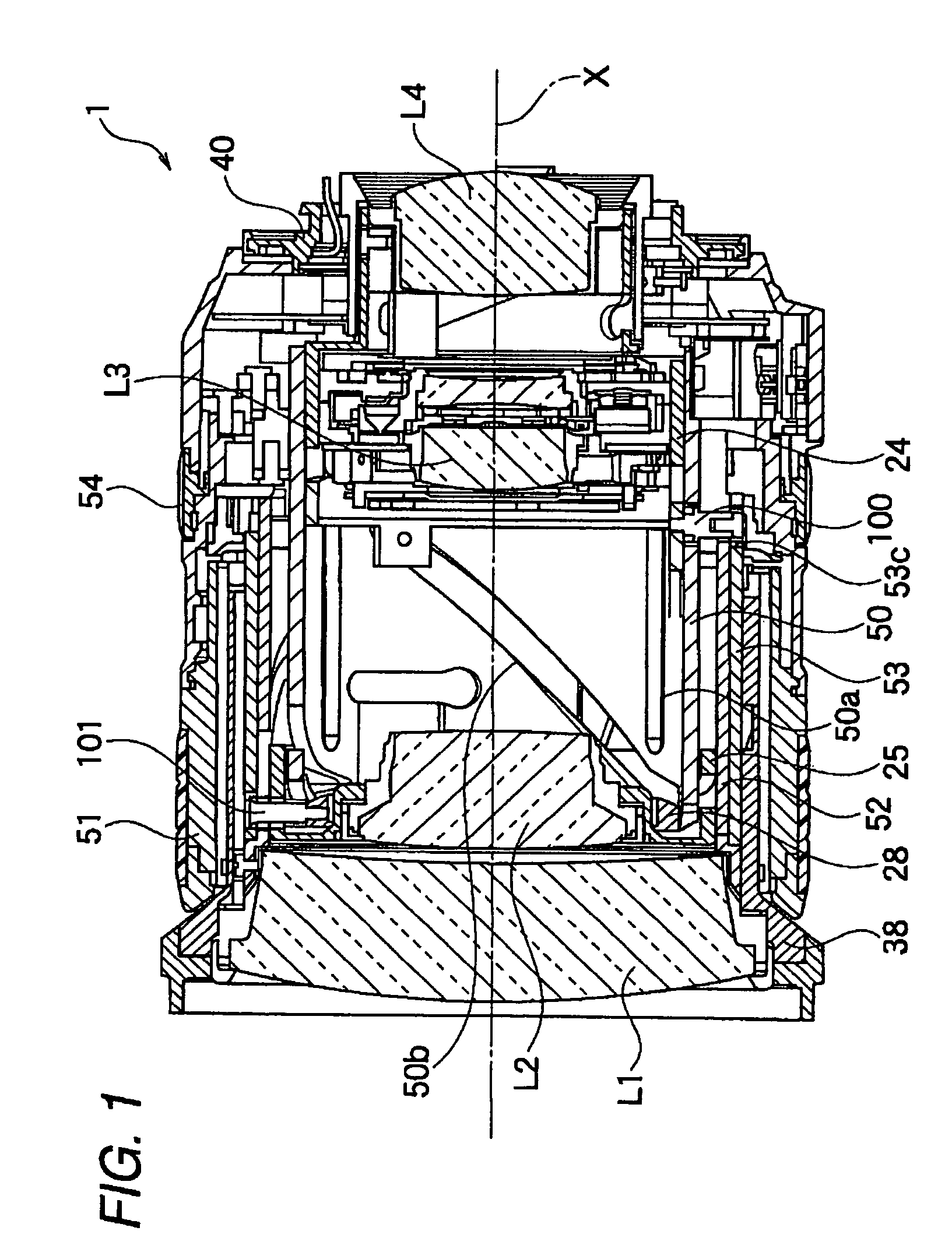

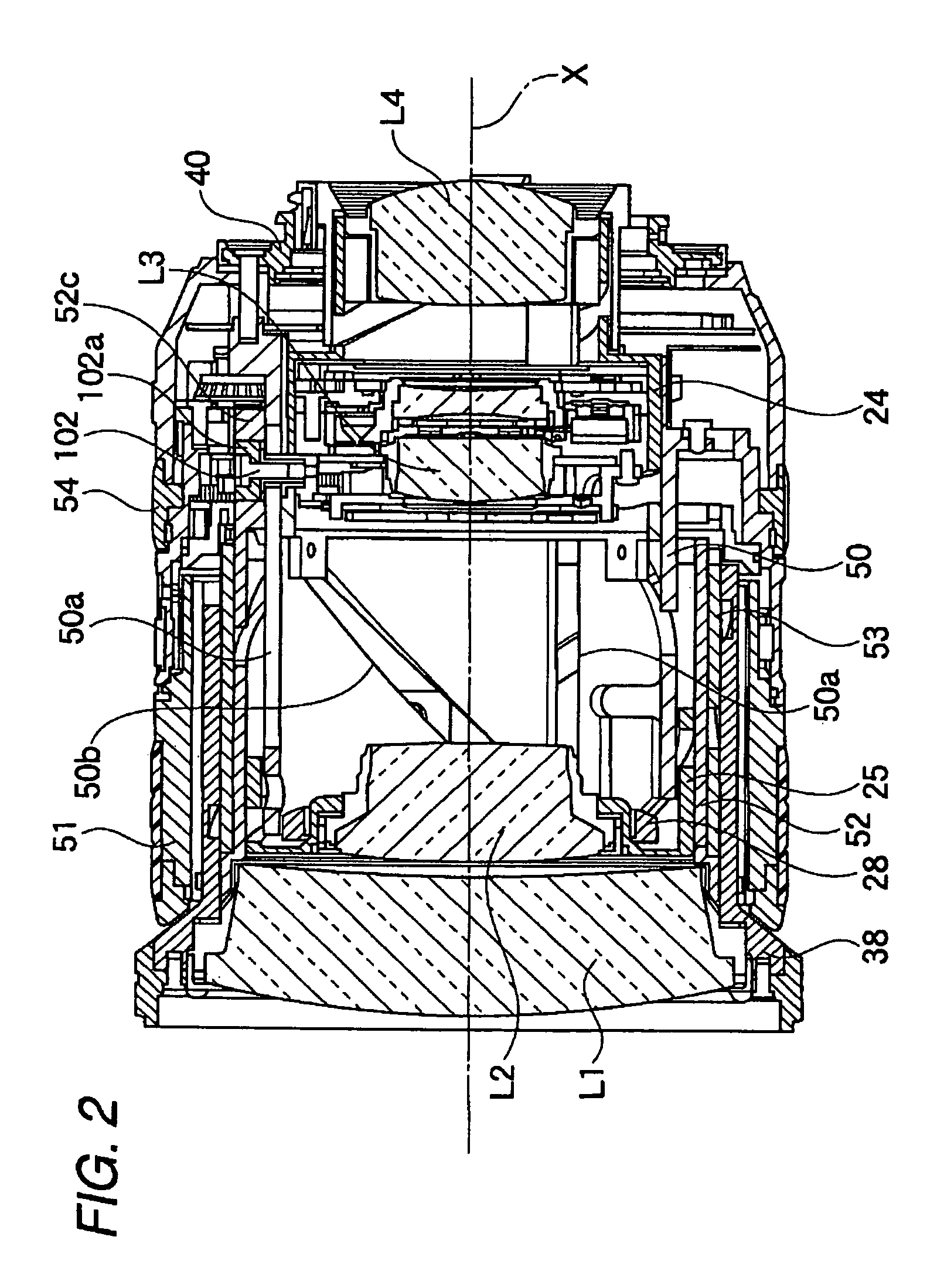

Lens barrel and method of operation of lens barrel

A lens barrel having a first moving barrel, second moving barrel, and a third moving barrel. The first moving barrel has first cam grooves configured corresponding to a focusing operation and holds an optical system used in a focusing operation. The second moving barrel has second cam grooves and is provided in relation to the first moving barrel. The third moving barrel has third cam grooves configured corresponding to a zoom operation and can move relative to a fixed barrel. The second cam grooves correct a position of said optical system corresponding to a drive operation of the third cam grooves.

Owner:NIKON CORP

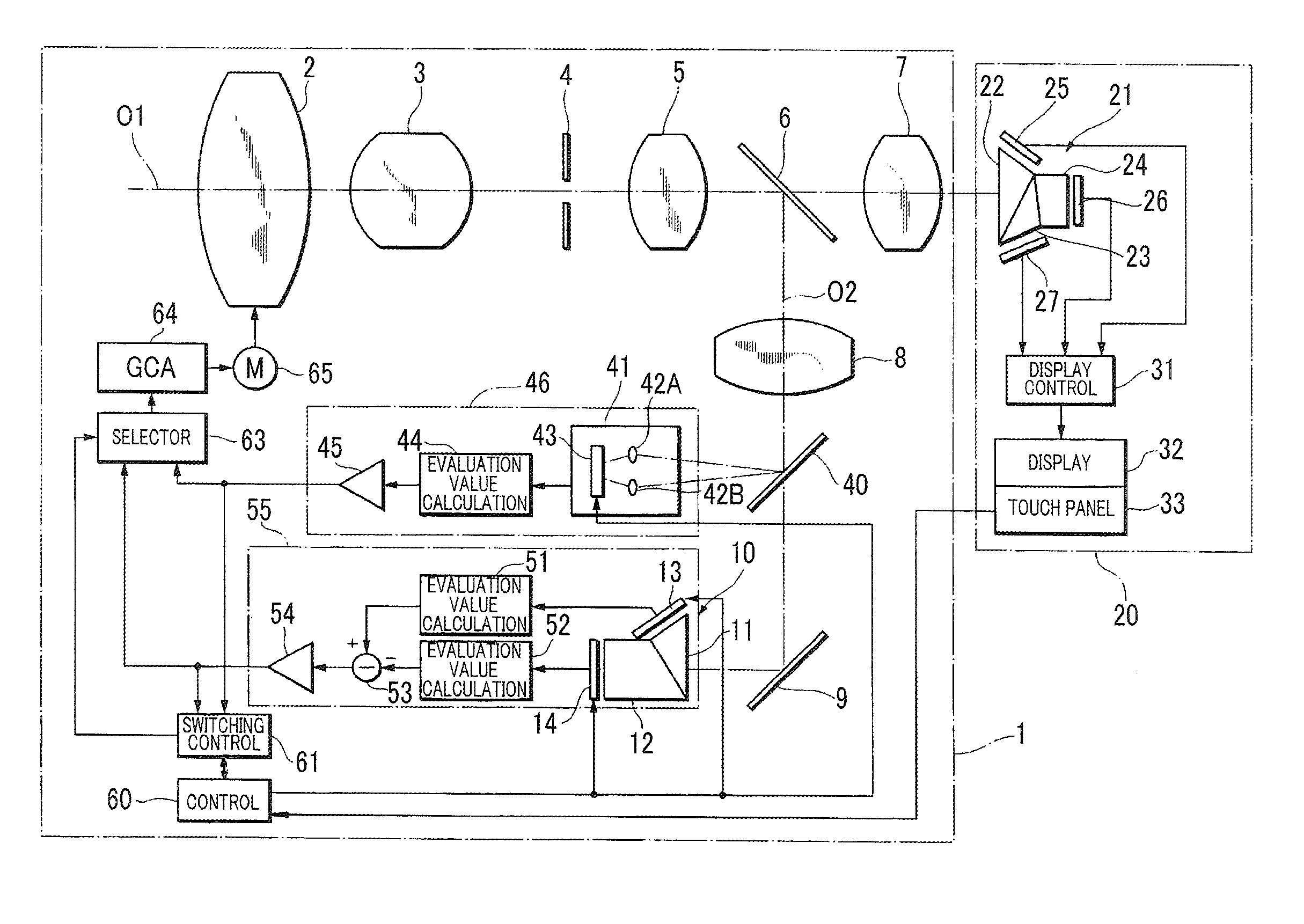

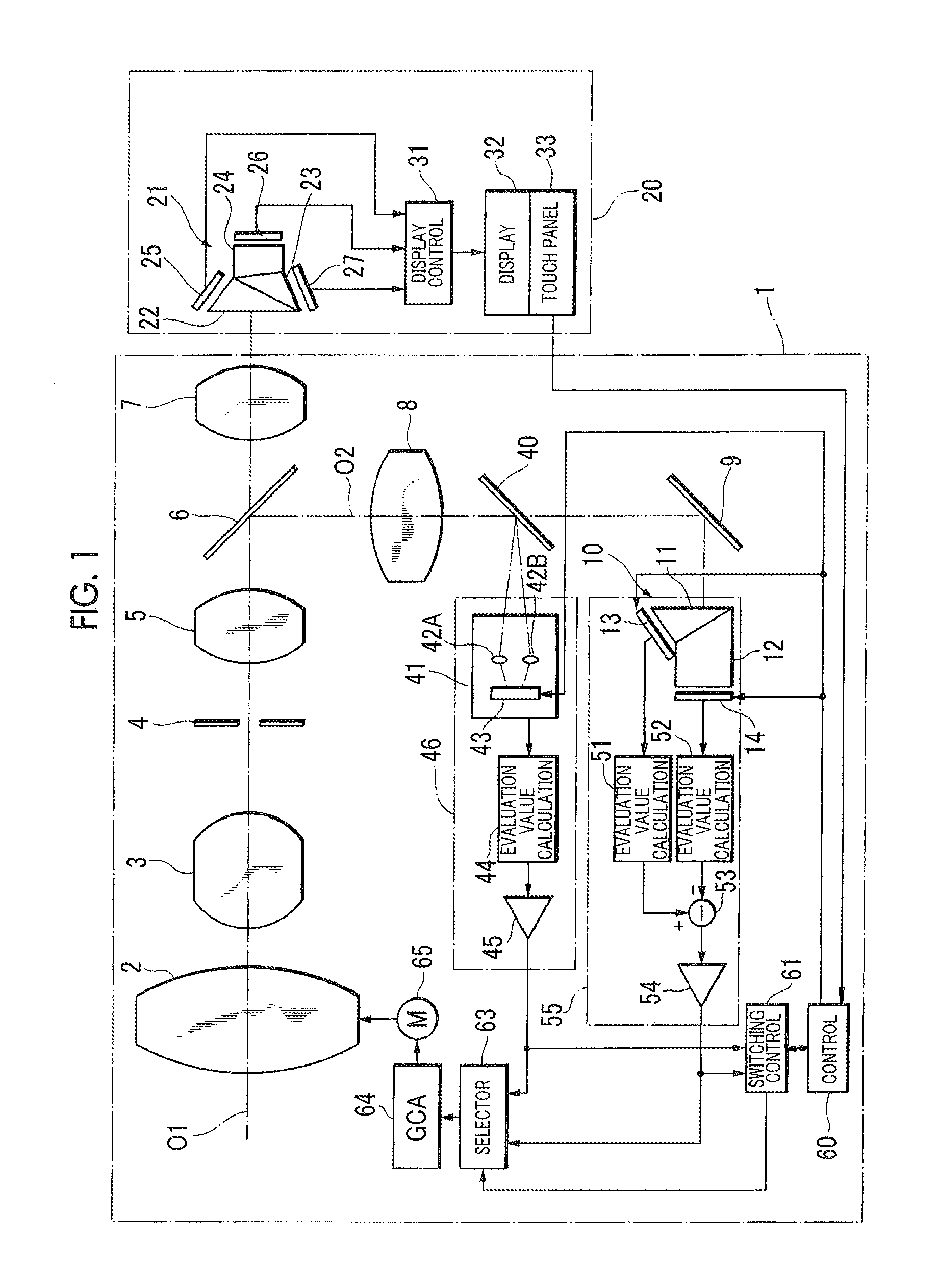

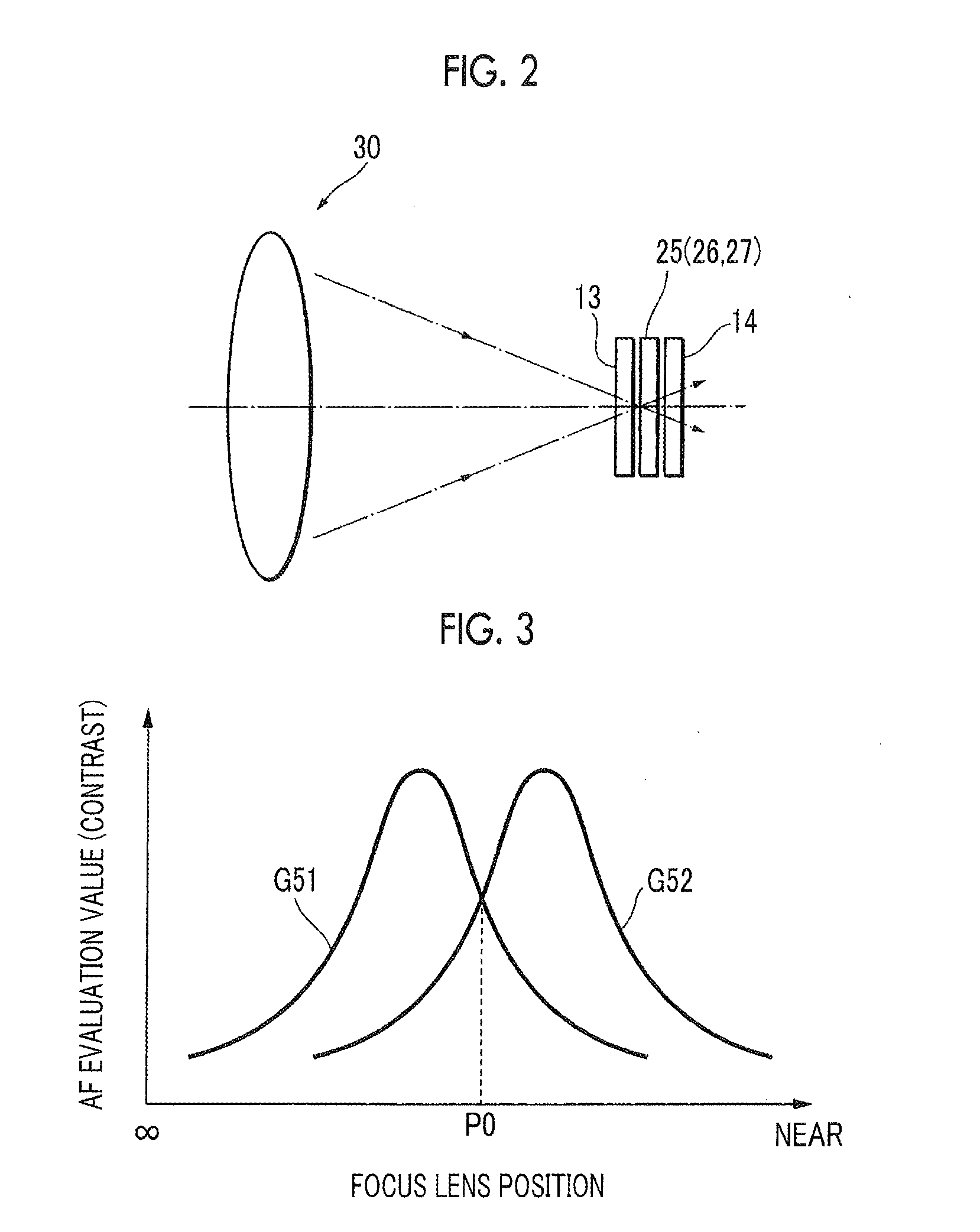

Auto-focus device and method for controlling operation of same

ActiveUS20160094781A1Eliminate uncomfortable feelingSmoothly brought into focusTelevision system detailsColor television detailsComputational physicsAutofocus

This invention provides an auto-focus device, which is for eliminating an uncomfortable feeling when phase difference AF is switched to optical path length difference AF when an arbitrary area is set as a focusing target area, and a method for controlling operation of the same. A cameraman sets a desired area as the focusing target area. Until a focus lens reaches a first threshold value position, the focus lens is moved on the basis of a phase difference AF evaluation value obtained from a phase difference AF sensor so as to bring the center portion of the imaging area into focus. Until the focus lens reaches a second threshold value position, the focus lens is moved on the basis of a phase difference AF evaluation value which is output from a phase difference imaging element and is obtained from a signal of an area corresponding to the set focusing target area. When the focus lens reaches the second threshold value position, the focus lens is positioned at the focusing position using the differential AF evaluation value, which is obtained on the basis of the set focusing target area, among the differential AF evaluation values obtained from an optical path length difference AF sensor.

Owner:FUJIFILM CORP

Lens barrel and method of operation of lens barrel

A lens barrel having a first moving barrel, second moving barrel, and a third moving barrel. The first moving barrel has first cam grooves configured corresponding to a focusing operation and holds an optical system used in a focusing operation. The second moving barrel has second cam grooves and is provided in relation to the first moving barrel. The third moving barrel has third cam grooves configured corresponding to a zoom operation and can move relative to a fixed barrel. The second cam grooves correct a position of said optical system corresponding to a drive operation of the third cam grooves.

Owner:NIKON CORP

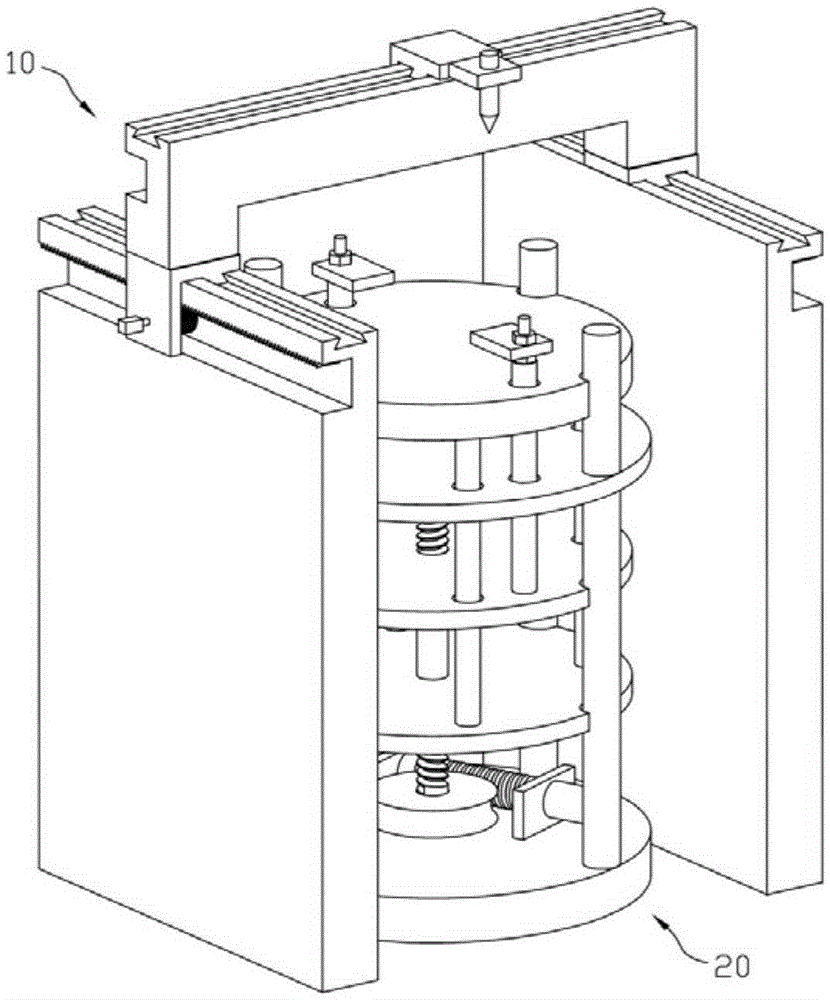

Laser template cutting machine

InactiveCN105397309AShort operating timeSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser beams

The invention discloses a laser template cutting machine which comprises a cutting mechanism and a template fixture, wherein the cutting mechanism comprises a laser head; the laser head performs two-dimensional motion through an X-direction slide and Y-direction slides; and the template fixture is positioned between a pair of rack plates of the cutting mechanism and is positioned below the laser head. According to the laser template cutting machine, workpieces to be cut are located through the template fixture, and templates are cut through laser beams, so that the speed is high, the efficiency is high, and the cutting is smooth, fluent and neat.

Owner:苏州市众鑫激光科技有限公司

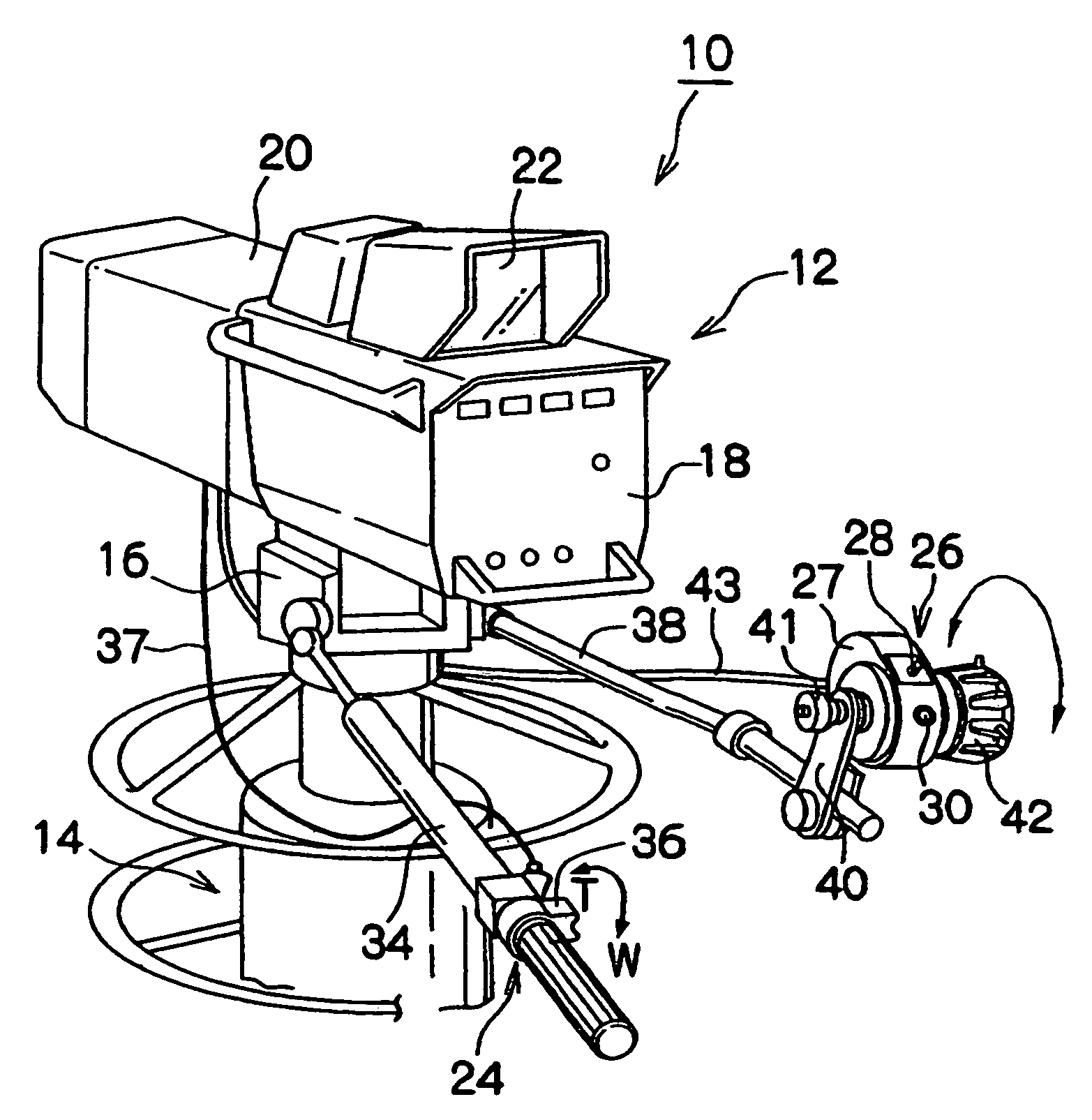

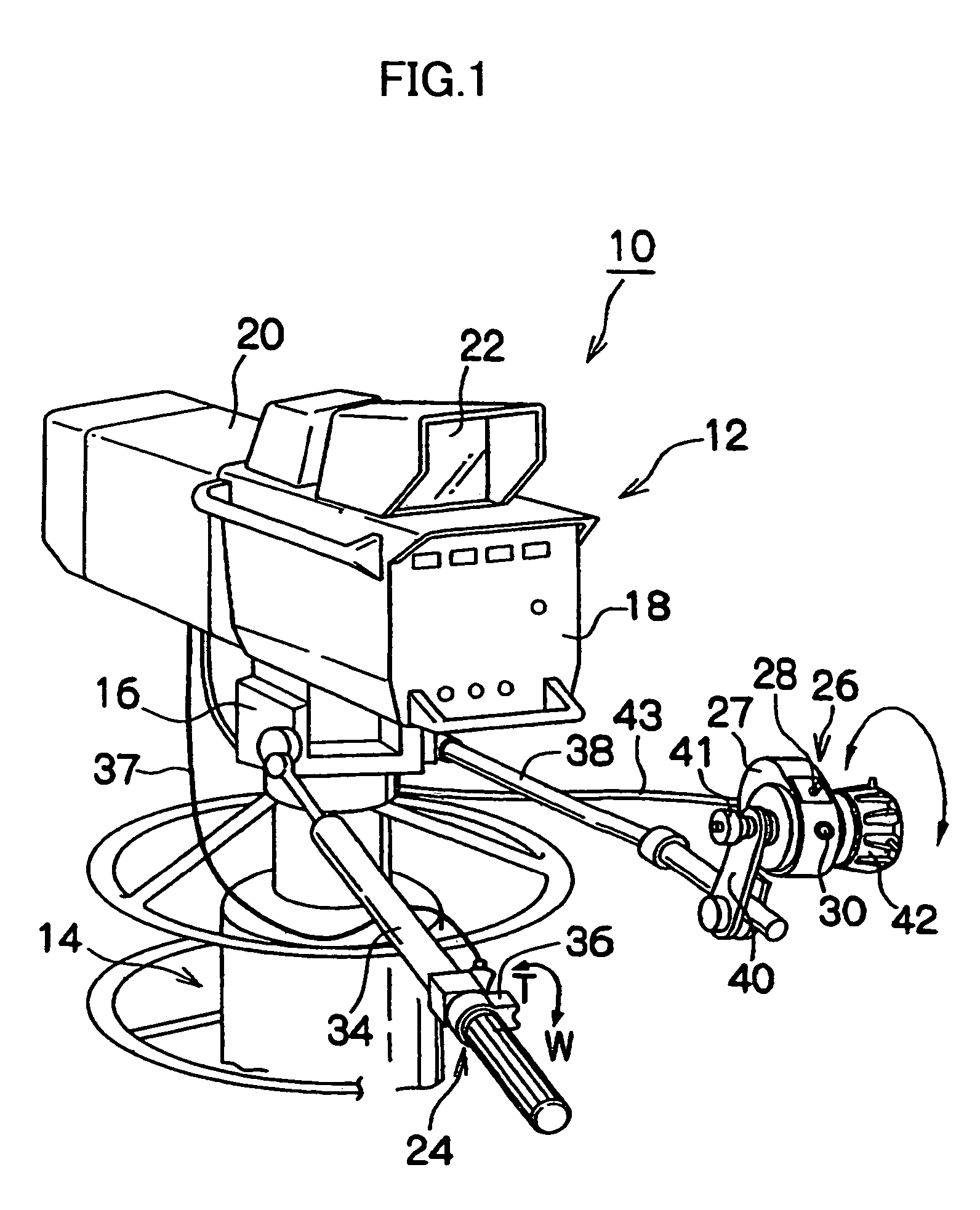

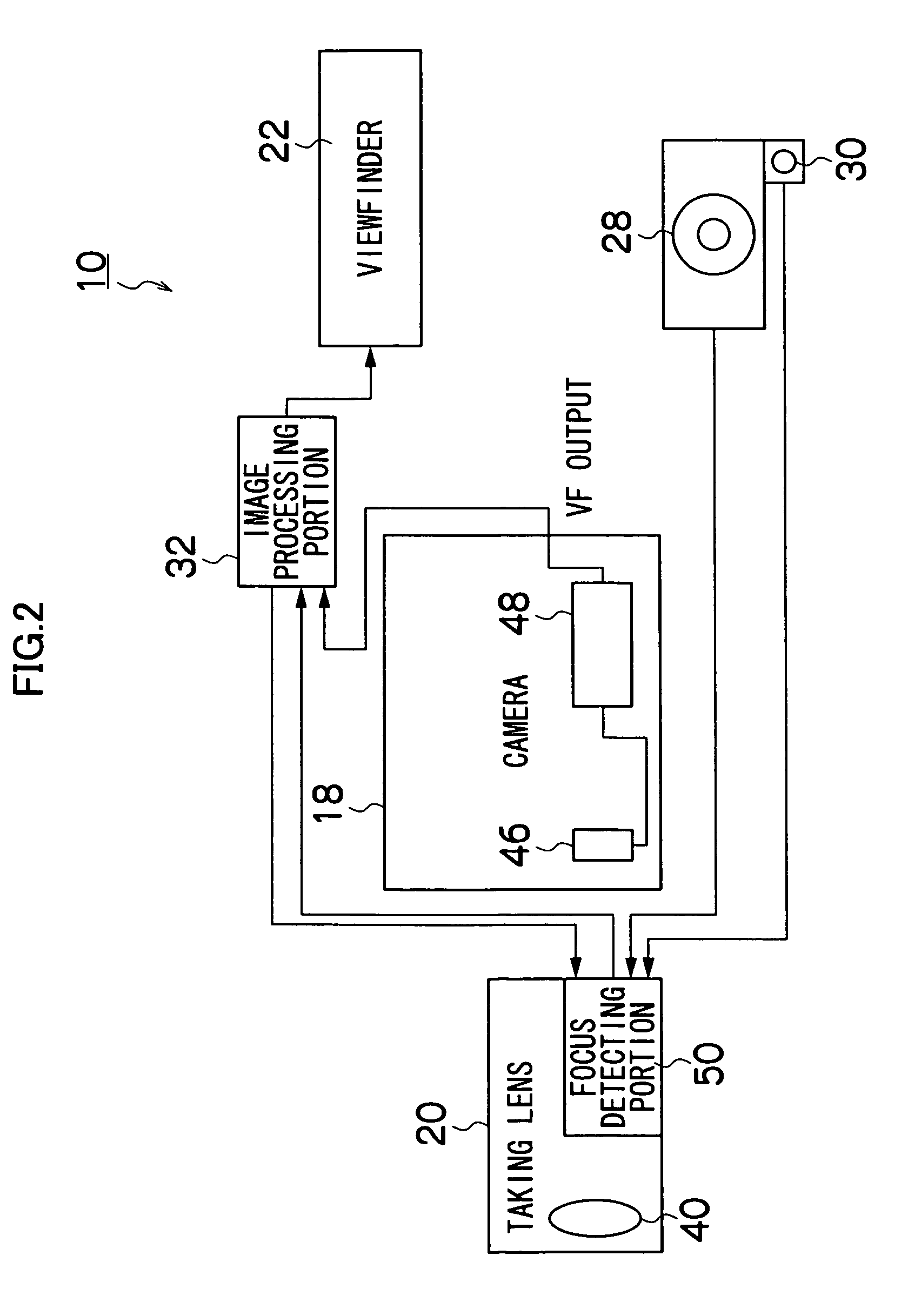

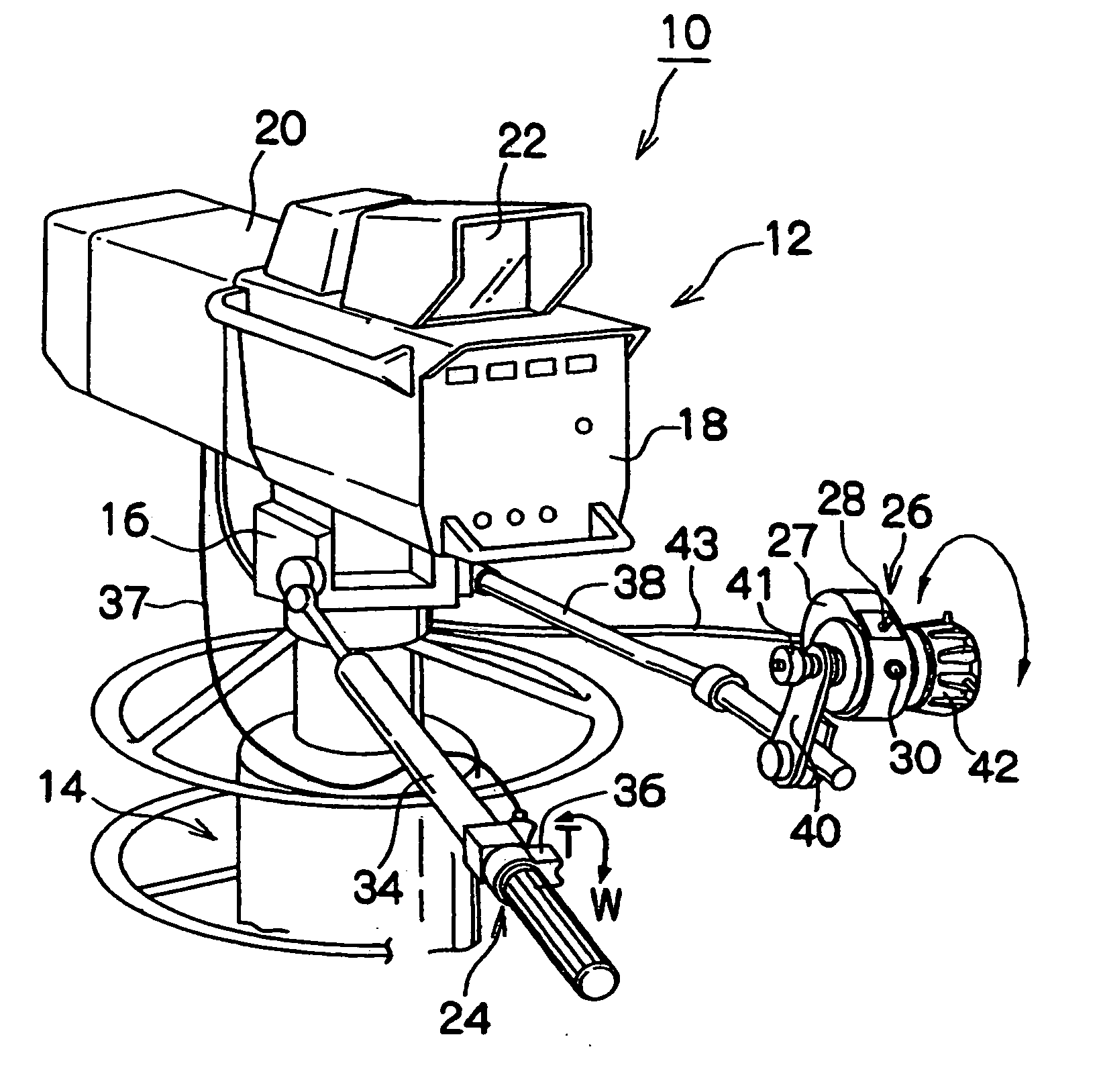

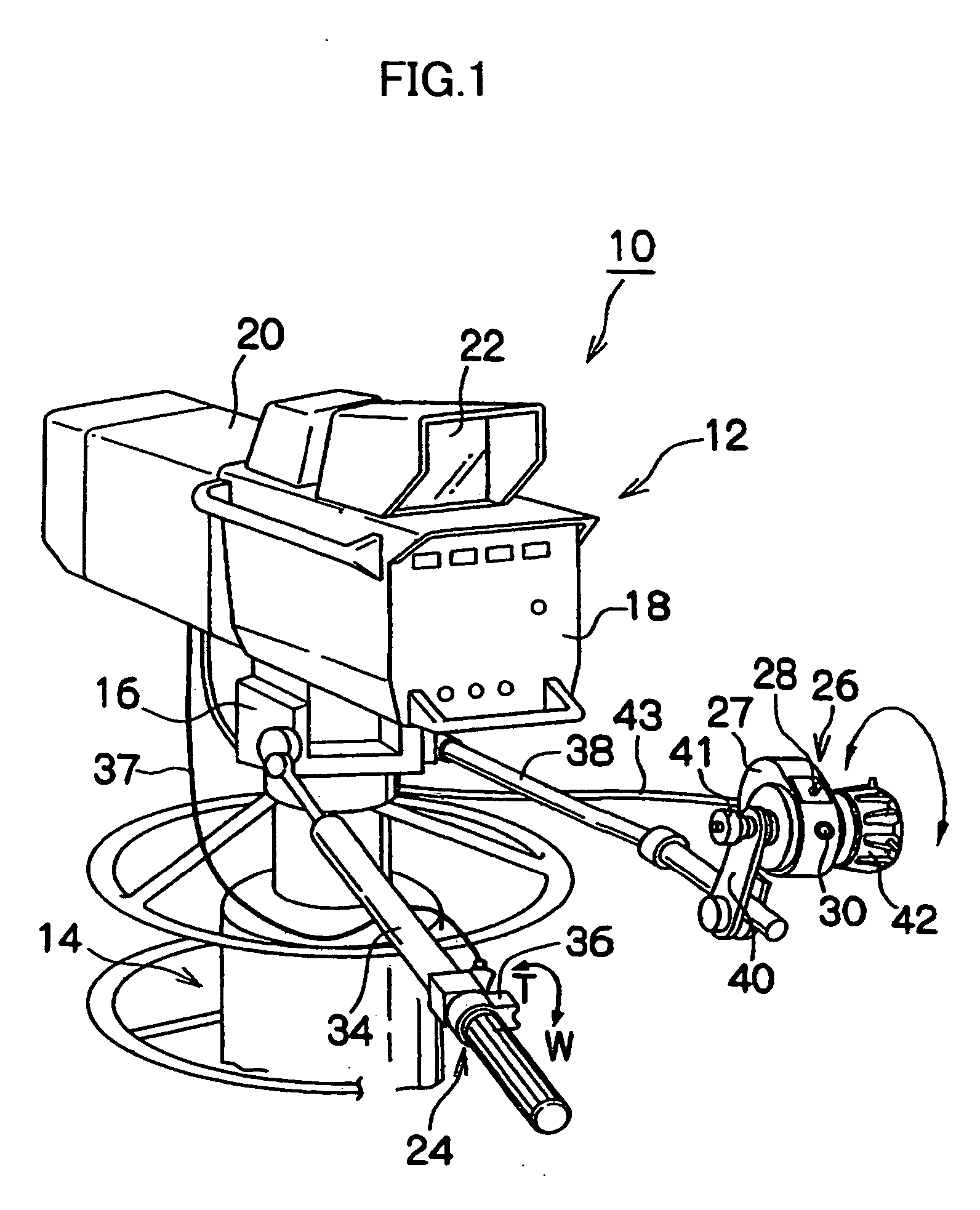

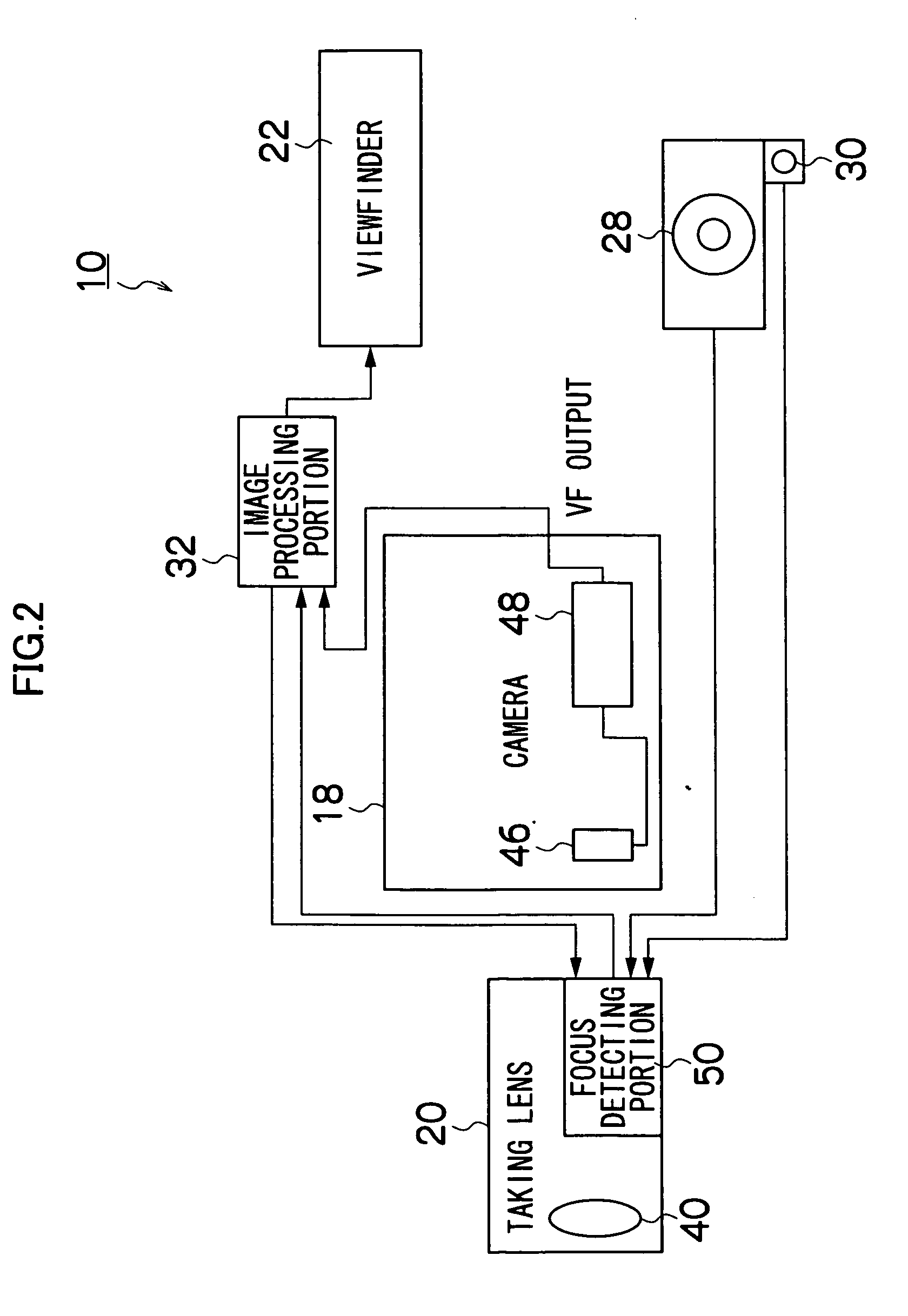

Focus control apparatus for auto-focusing on a subject in an area specified within a range of a camera image picked up by a television camera

InactiveUS7636122B2Evenly focusedRegulation stabilityTelevision system detailsProjector focusing arrangementCamera imageComputer science

The present inention proides a focus control apparatus for a television camera comprising a focus adjusting portion for manual focus adjustment of the television camera, an indicating member for use to specify an area desired to be brought into focus within a range of a camera image being picked up by the television camera, an area display deice which displays position of the area specified with the indicating member, on a camera screen and a switch which outputs a command signal to auto-focus on a subject in the area specified with the indicating member, wherein the indicating member and the switch are positioned such that the indicating member and the switch can be operated simultaneously with the focus adjusting portion by the same hand.

Owner:FUJI PHOTO OPTICAL CO LTD

Focus control apparatus

InactiveUS20060033834A1Adjust focus smoothlyManual operationTelevision system detailsProjector focusing arrangementCamera imageDisplay device

The present invention provides a focus control apparatus for a television camera comprising a focus adjusting portion for manual focus adjustment of the television camera, an indicating member for use to specify an area desired to be brought into focus within a range of a camera image being picked up by the television camera, an area display device which displays position of the area specified with the indicating member, on a camera screen and a switch which outputs a command signal to auto-focus on a subject in the area specified with the indicating member, wherein the indicating member and the switch are positioned such that the indicating member and the switch can be operated simultaneously with the focus adjusting portion by the same hand.

Owner:FUJI PHOTO OPTICAL CO LTD

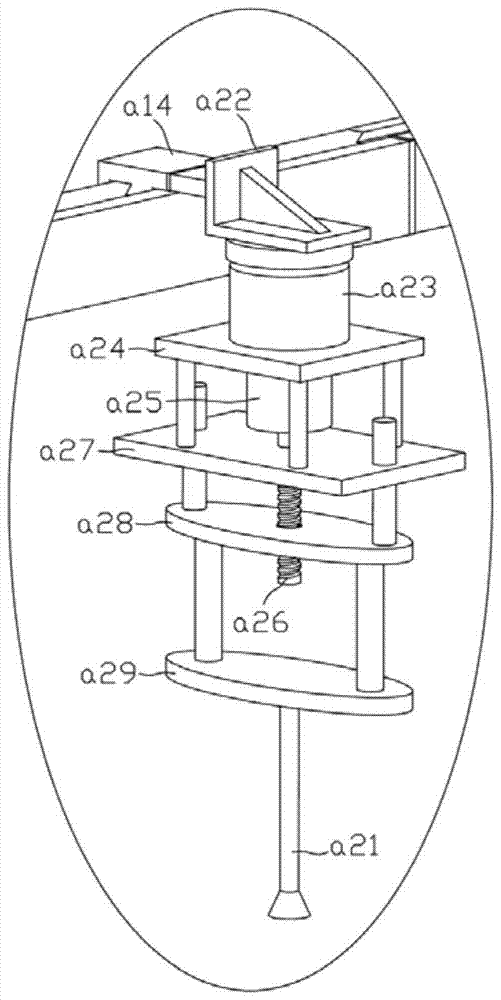

Laser template polishing clamp

ActiveCN105463563AShort operating timeSimple and fast operationElectrolysis componentsGear driveEngineering

The invention discloses a laser template polishing clamp. The laser template polishing clamp comprises a support body, a locking body and a fixed seat. The support body comprises a base, supporting plates and supporting columns. The locking body comprises first base plates and lock blocks, wherein the first base plates and the lock blocks are connected through first guiding columns, and the first guiding columns penetrate the supporting plates. The fixed seat comprises second base plates and fixing discs, the second base plates and the fixing discs are connected through second guiding columns, the second guiding columns upward penetrate the first base plates and the supporting plates, and the lock blocks are located above the fixing discs. The support body comprises threaded rods different in vertical screwing direction. The upper sections and the lower sections of the threaded rods are in screw joint with the first base plates and the second base plates respectively. Worms and gears are arranged at the bottoms of the threaded rods. The worms and gears drive the first base plates to drive the lock blocks to descend through driving of the threaded rods, meanwhile, the second base plates are driven to drive the fixing discs to ascend, accordingly, workpieces on the fixing discs are vertically clamped through the fixing discs and the lock blocks, operation is easy and convenient, and production efficiency is high.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

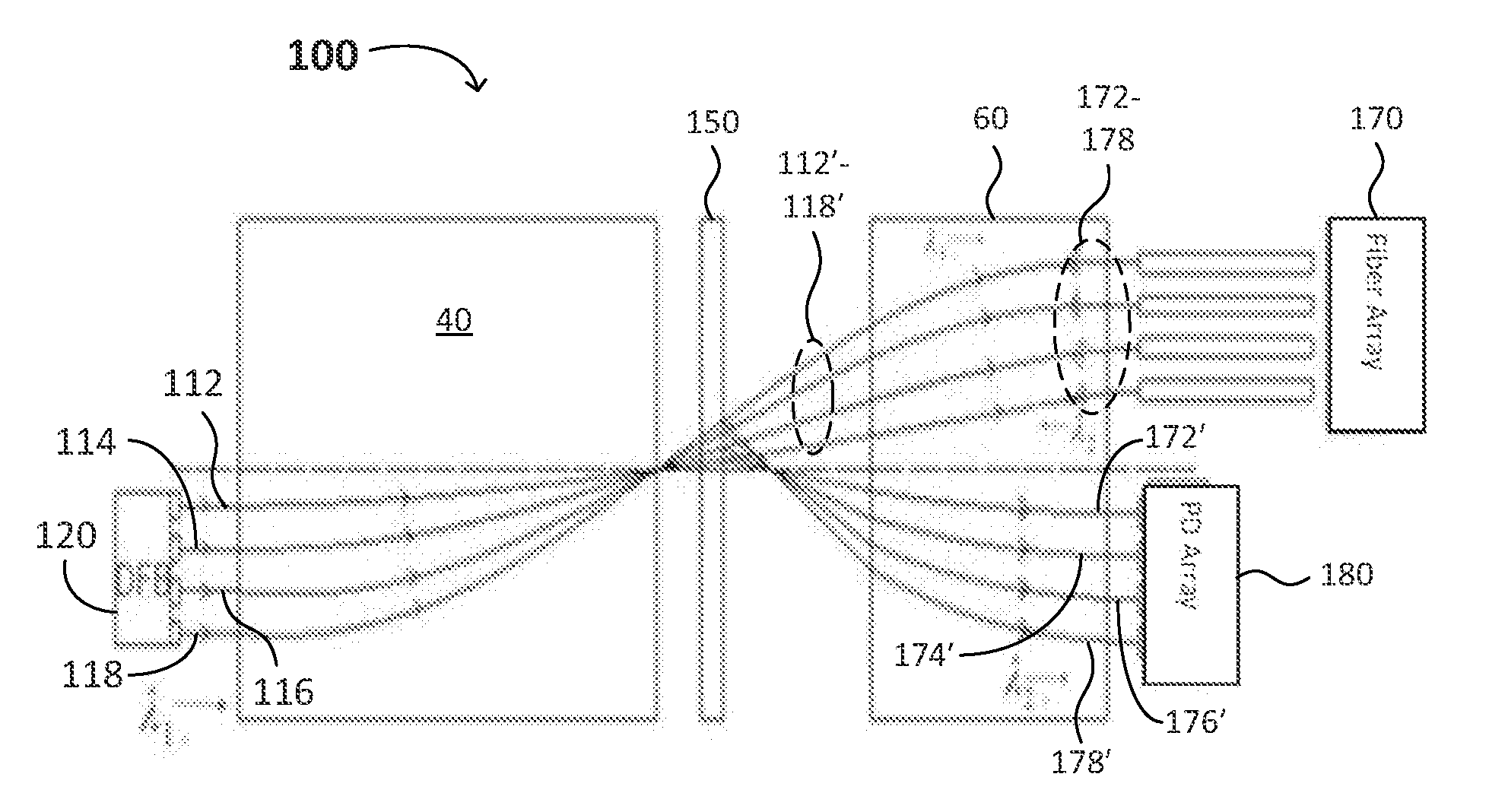

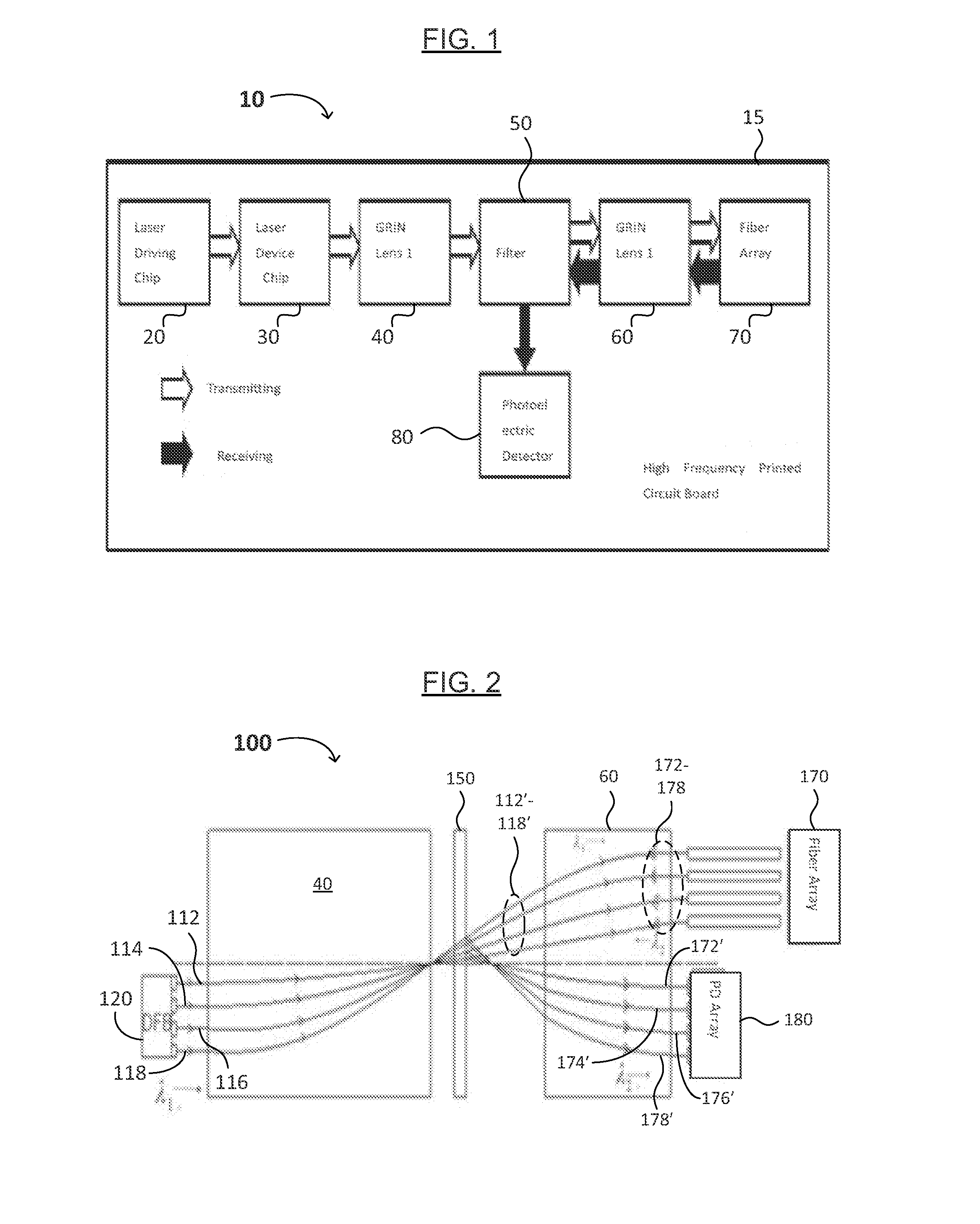

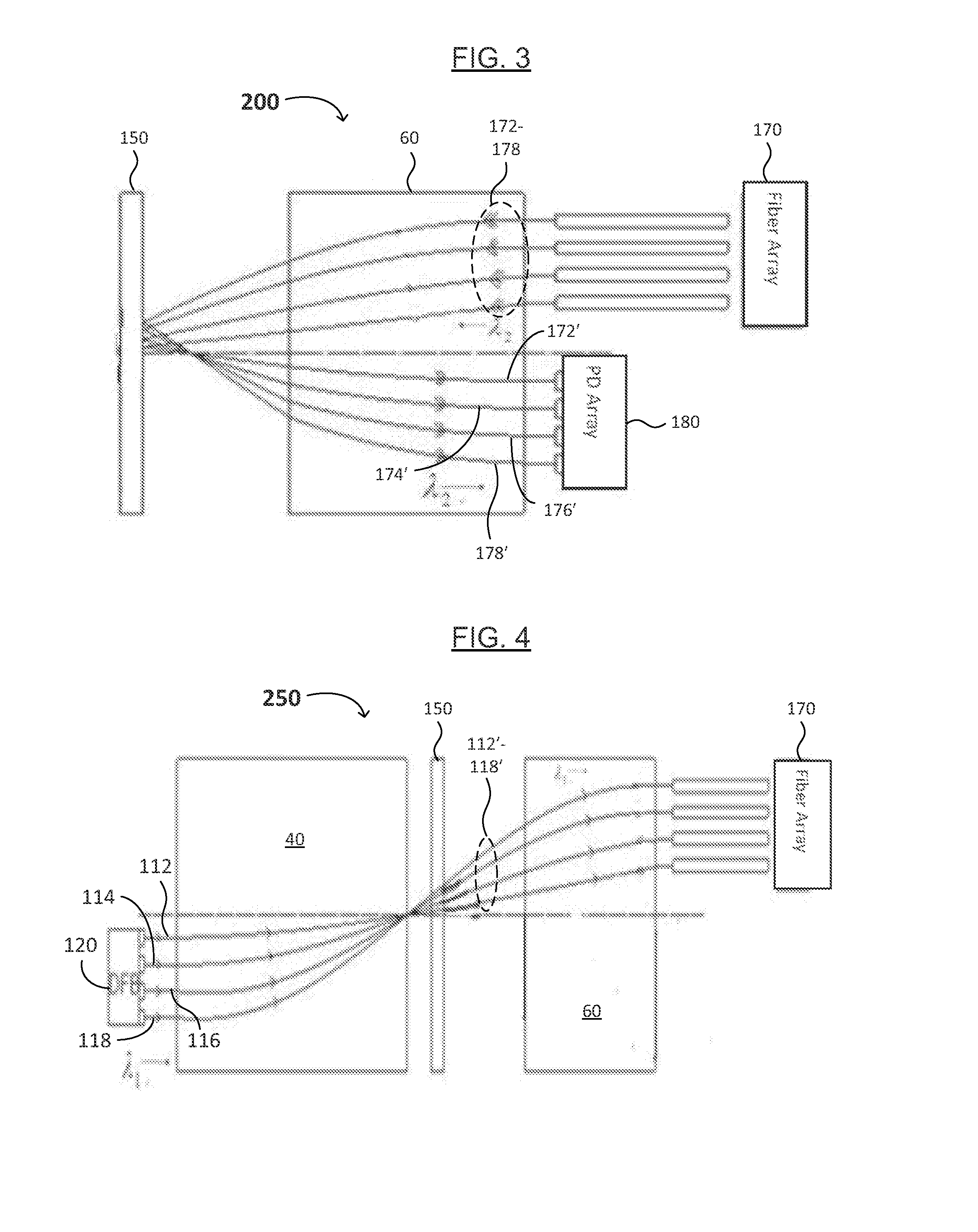

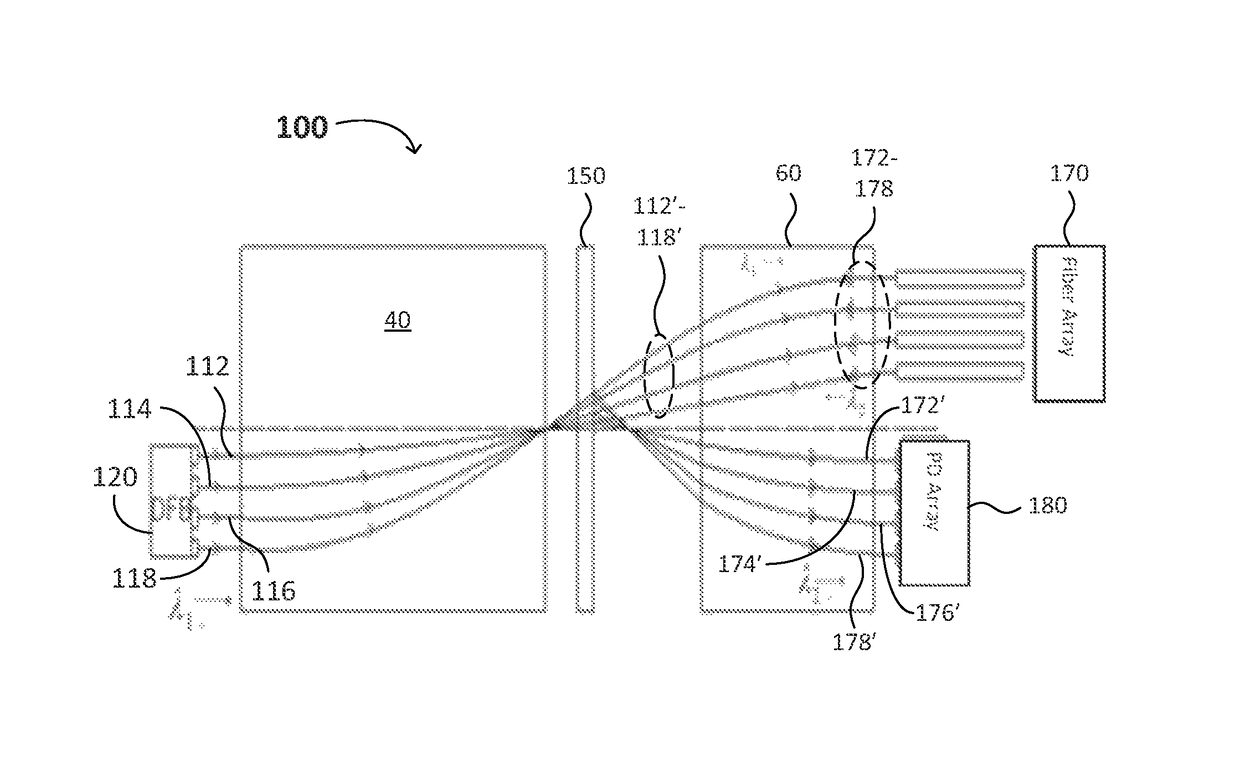

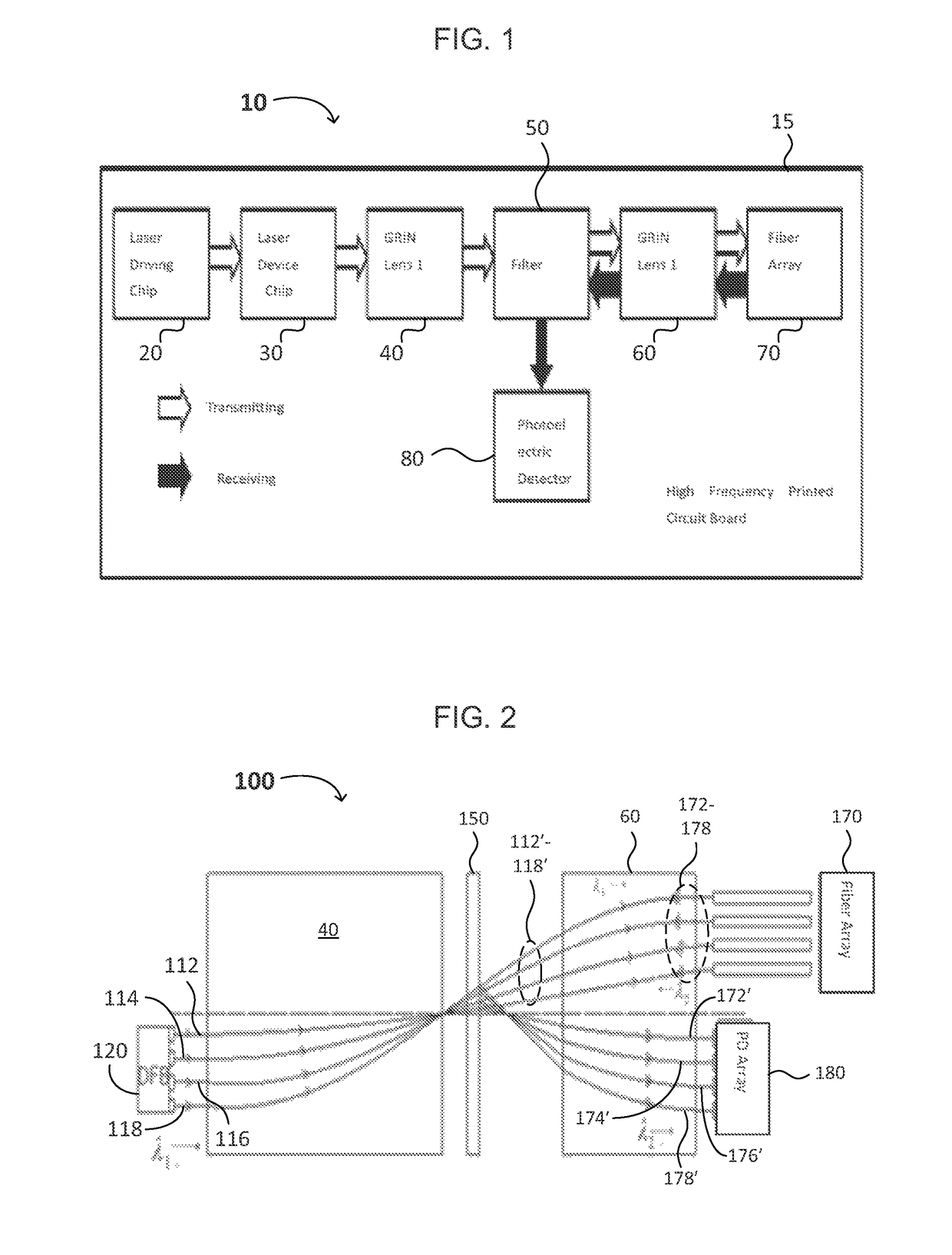

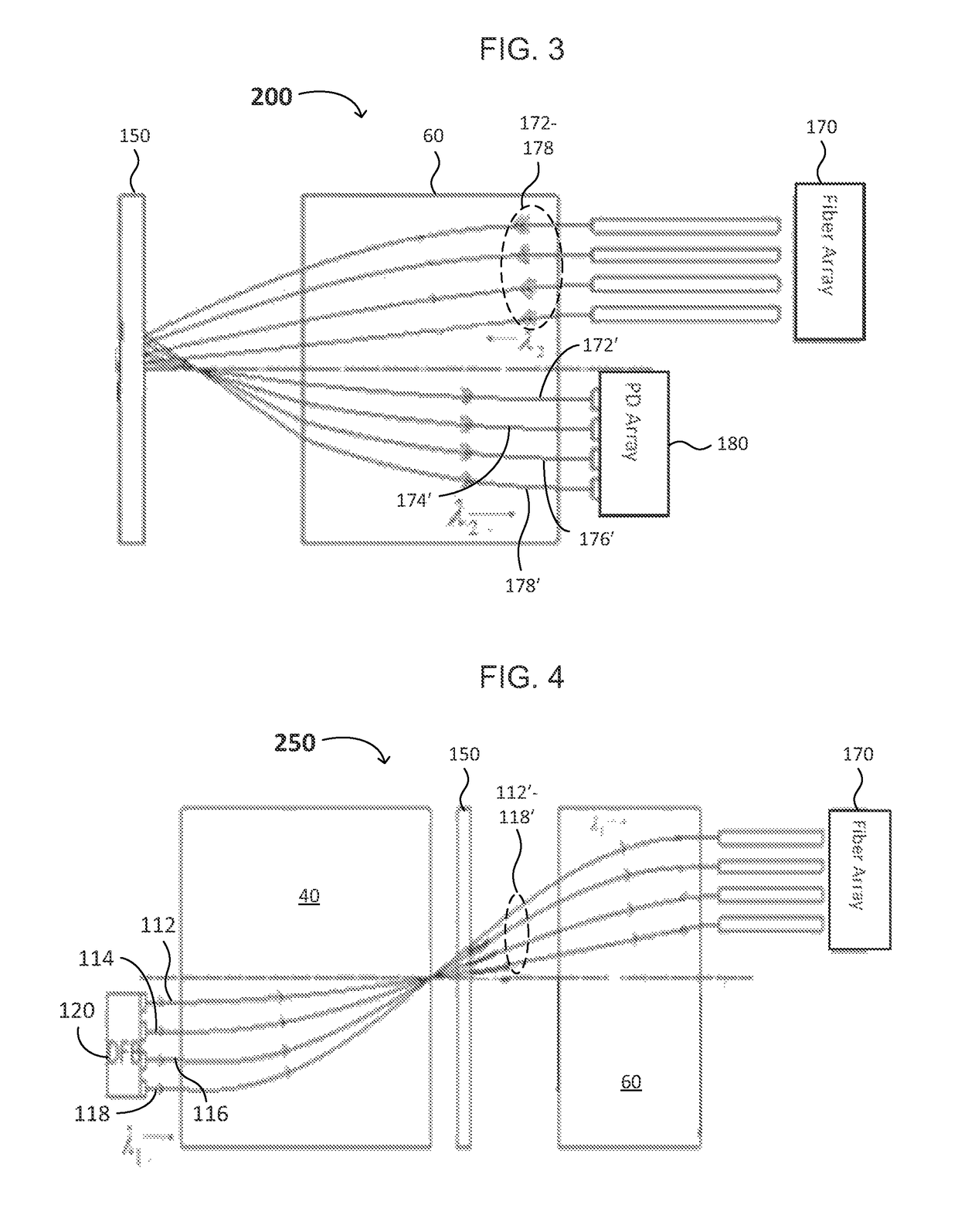

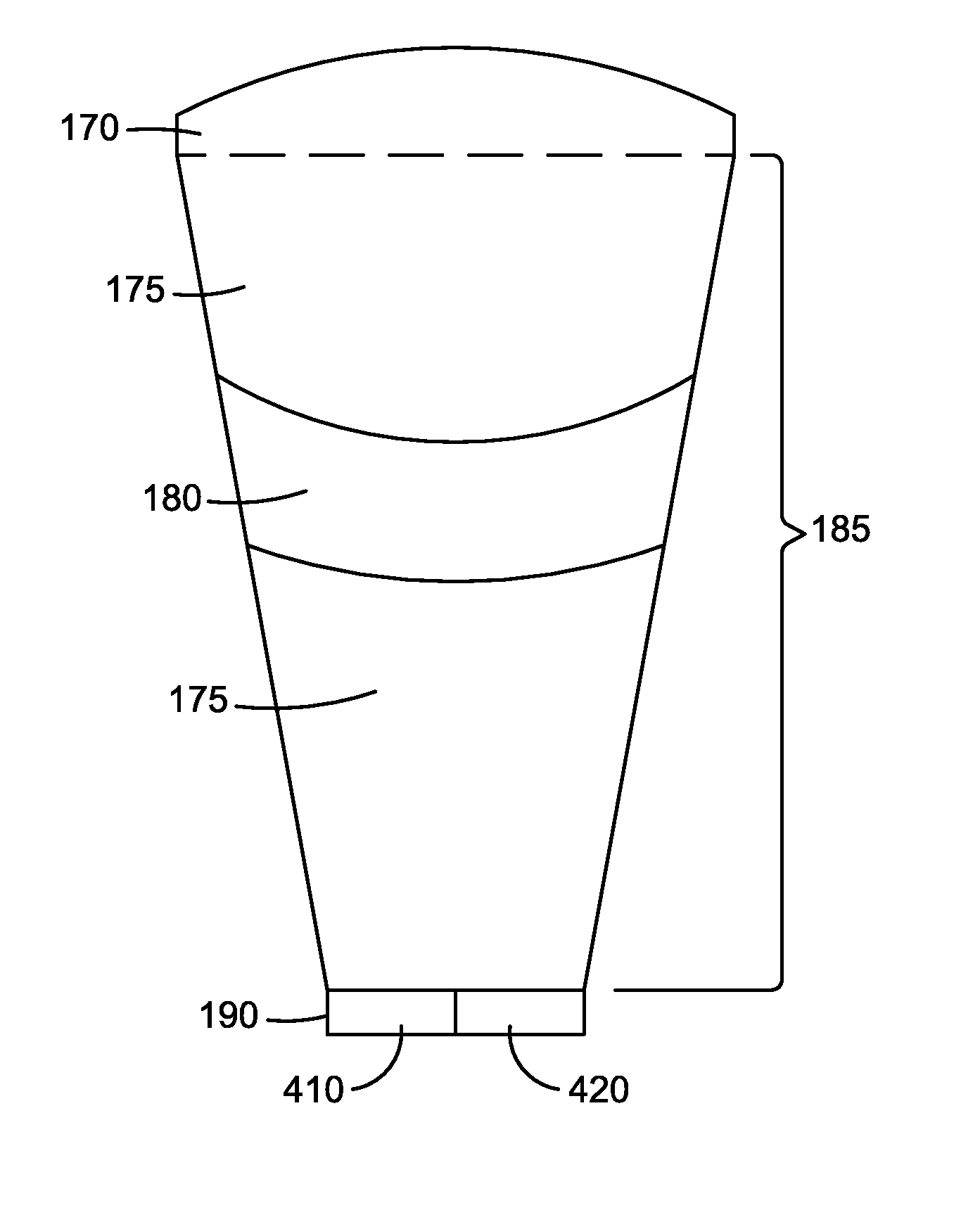

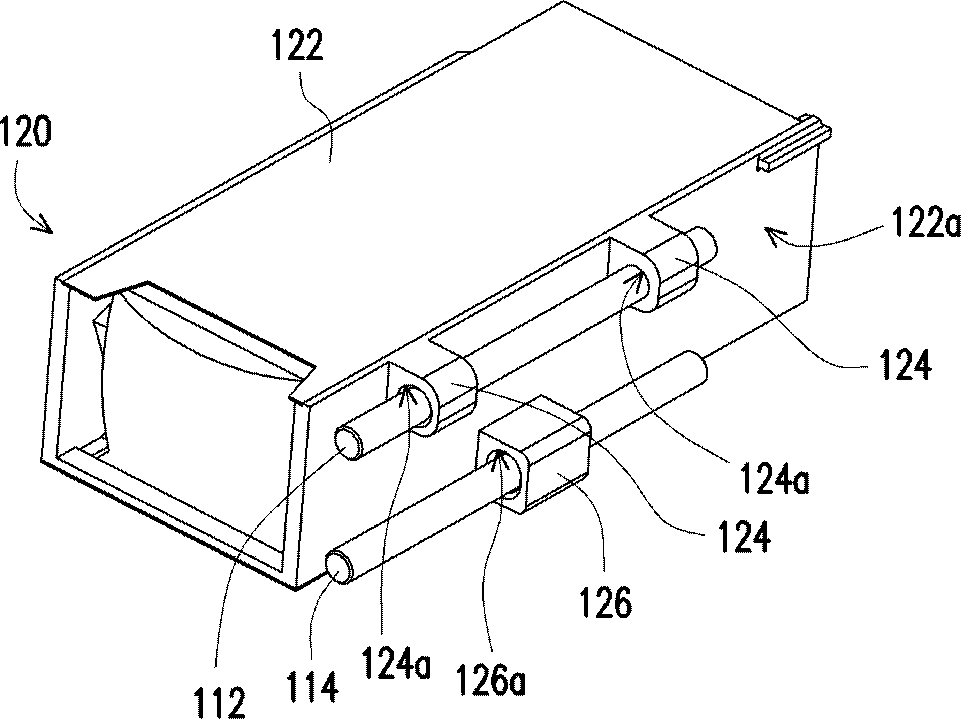

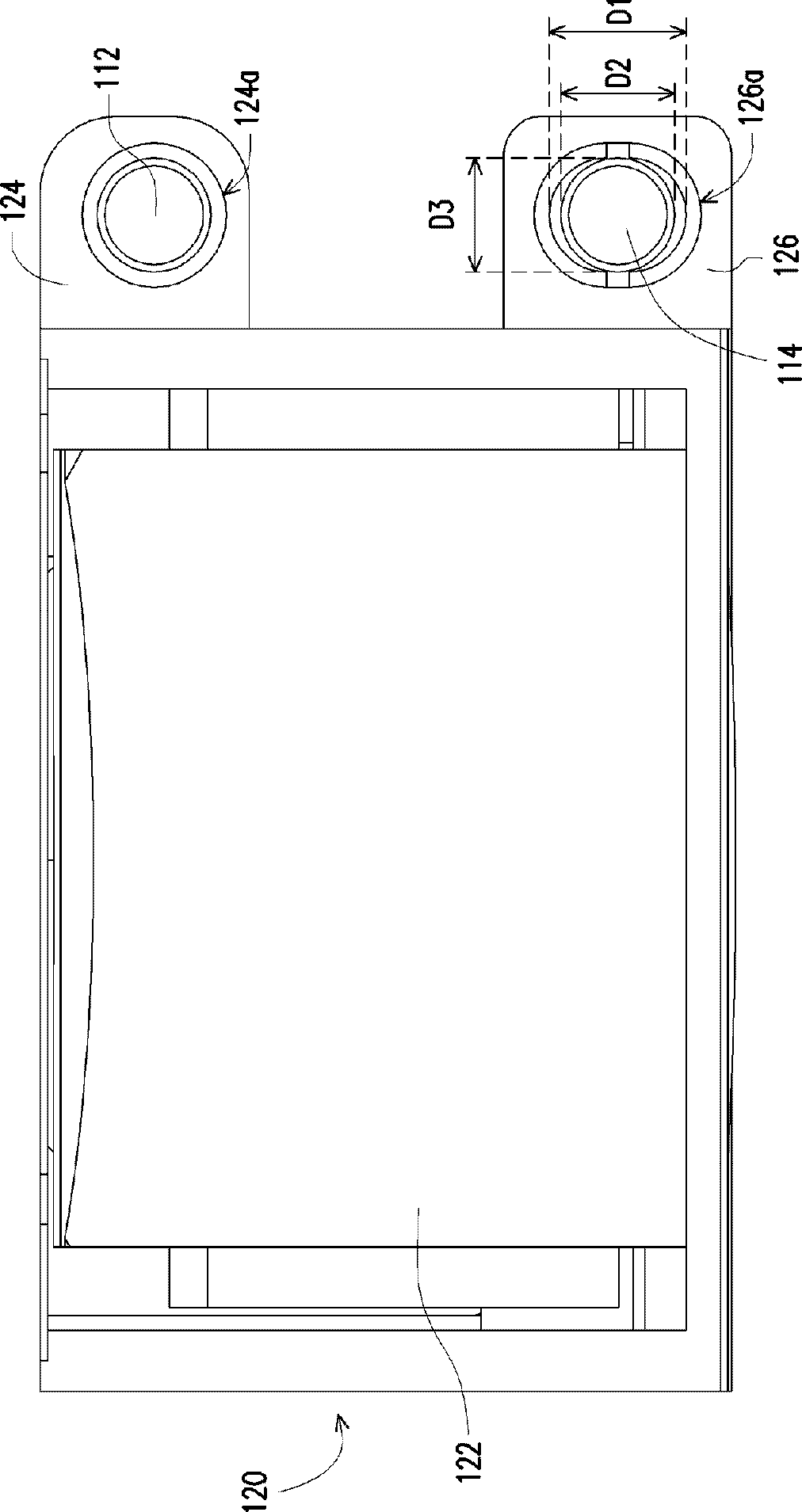

NxN PARALLEL OPTICAL TRANSCEIVER

ActiveUS20170023750A1Evenly focusedCoupling light guidesOptical waveguide light guideTransceiverLow-pass filter

An N×N parallel optical transceiver includes a printed circuit board, a laser driving control chip, one or more lasers, two GRIN lenses, an optical band-pass filter, a multimode fiber array and a photodiode array. In the transmitter, laser beams of the same wavelength simultaneously output from the laser chip are first focused by the first GRIN lens, then the beams pass through a wavelength band-pass filter and are refocused by the second GRIN lens, and enter the channels in the multimode fiber array. In the receiver, laser beams of a different wavelength from the multimode fiber array are focused by the second GRIN lens, then reflected by the band-pass filter, refocused by the second GRIN lens, and received by the photodiode array. The multi-channel parallel transceiver has a small form, and can integrate a DFB or FP laser chip and GRIN lenses.

Owner:SOURCE PHOTONICS CHENGDU

NxN parallel optical transceiver

ActiveUS9709759B2Evenly focusedCoupling light guidesOptical waveguide light guideTransceiverLow-pass filter

An N×N parallel optical transceiver includes a printed circuit board, a laser driving control chip, one or more lasers, two GRIN lenses, an optical band-pass filter, a multimode fiber array and a photodiode array. In the transmitter, laser beams of the same wavelength simultaneously output from the laser chip are first focused by the first GRIN lens, then the beams pass through a wavelength band-pass filter and are refocused by the second GRIN lens, and enter the channels in the multimode fiber array. In the receiver, laser beams of a different wavelength from the multimode fiber array are focused by the second GRIN lens, then reflected by the band-pass filter, refocused by the second GRIN lens, and received by the photodiode array. The multi-channel parallel transceiver has a small form, and can integrate a DFB or FP laser chip and GRIN lenses.

Owner:SOURCE PHOTONICS CHENGDU

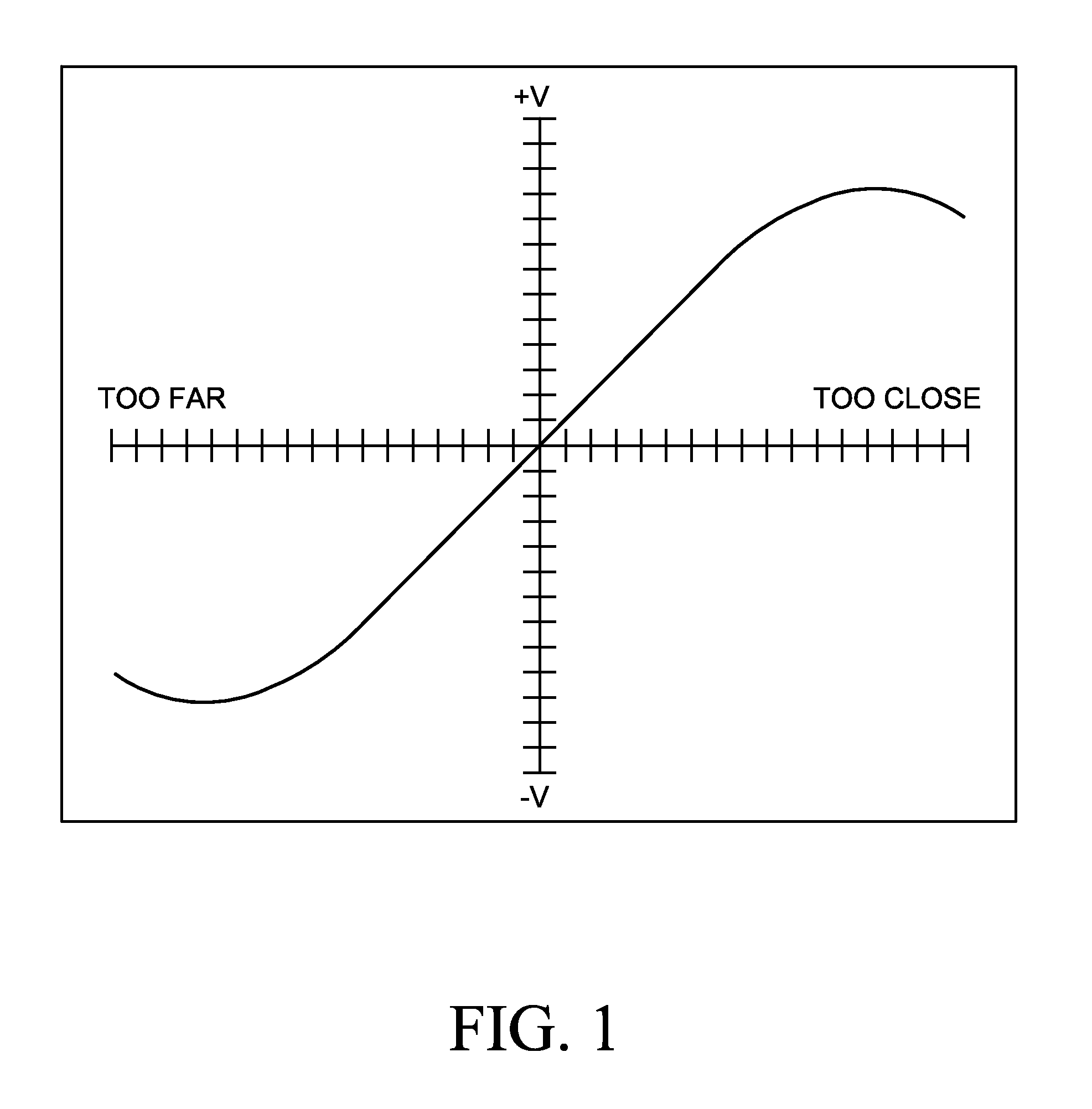

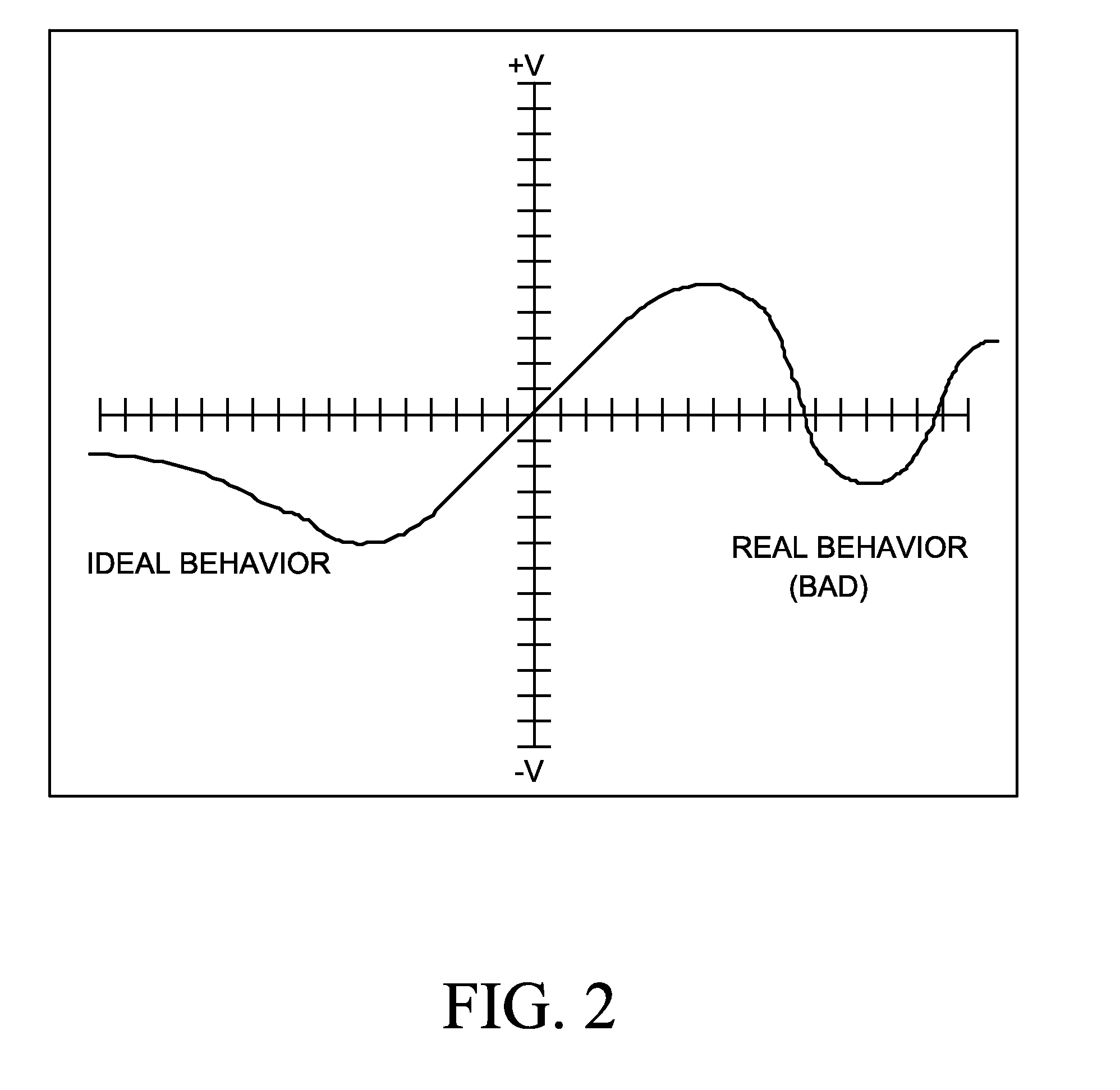

Three-dimensional filter enables adaptive focus sensing

InactiveUS8785835B1Quality improvementSmoothing focus curveRadiation pyrometryBeam/ray focussing/reflecting arrangementsPhysicsWavefront

This focus sensor is readily usable in a system using pupil obscuration to measure the state of focus of a light beam. A scattering volumetric filter modifies a three-dimensional wavefront so that focus can be detected by a two-dimensional detector for conversion to a one-dimensional signal having values of plus, zero and minus. This diffusing filter comprises sub wavelength particles having a high index of refraction suspended in an adhesive to produce a solid diffuser. This focus sensor enables a well-behaved focus curve having a constant slope near best focus, while maintaining a slope that is either constant or monotonic at a minimal rate over an extended distance to support a long capture-range over which a focus-controlling servo-mechanism can acquire and maintain focus in the presence of corrupting target surface topography or optical defects.

Owner:MARSHALL DANIEL R

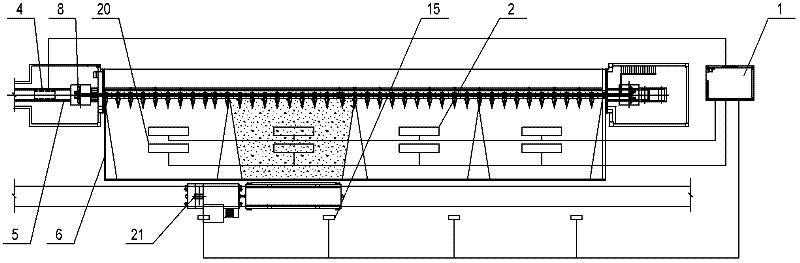

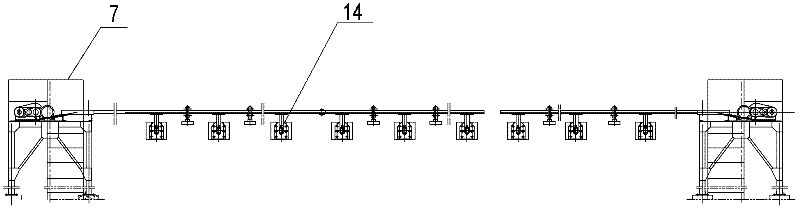

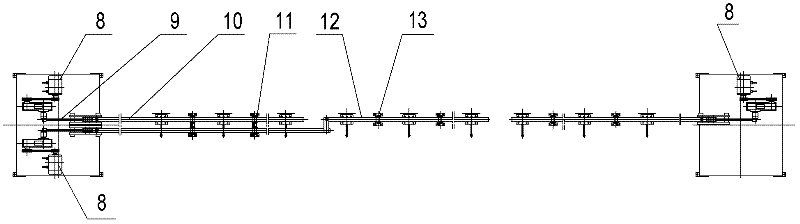

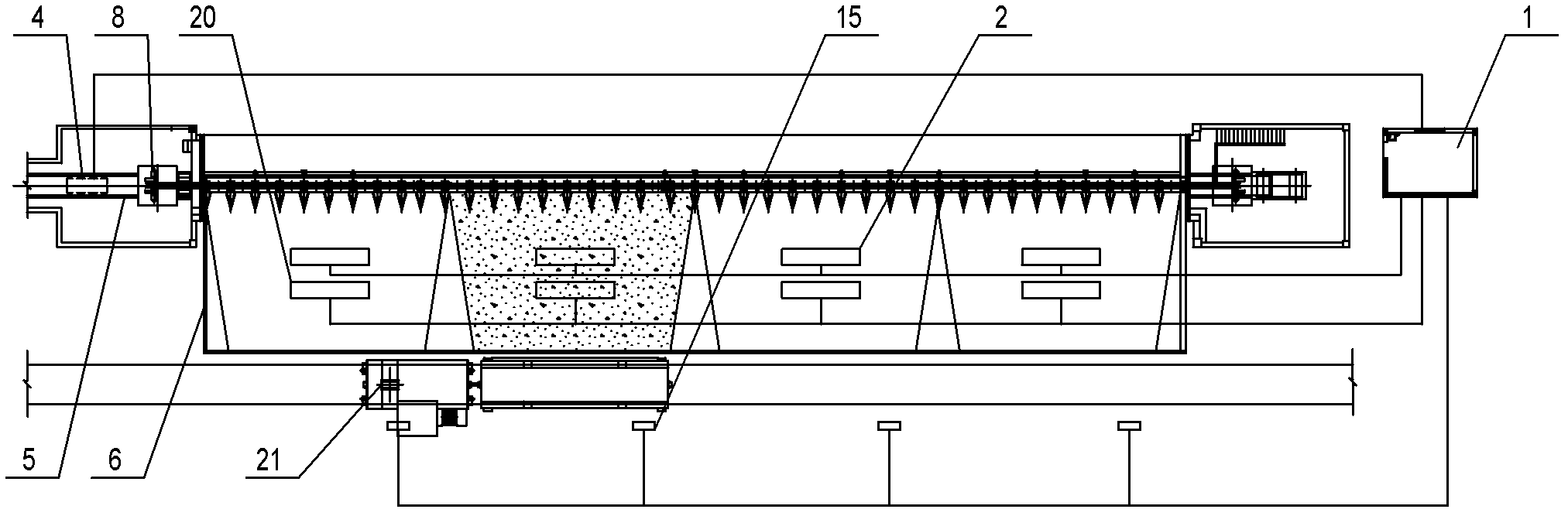

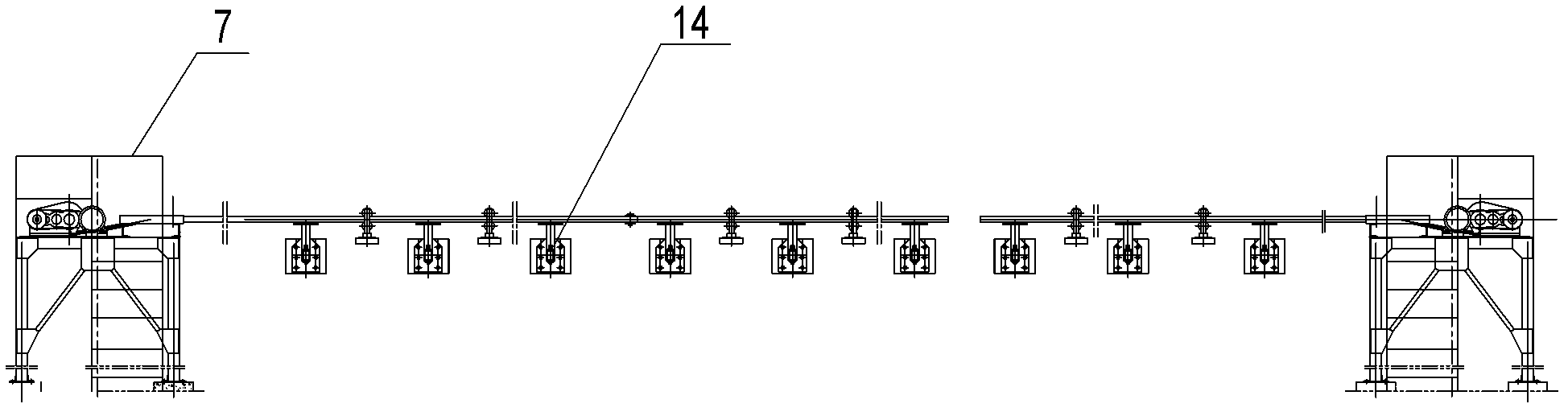

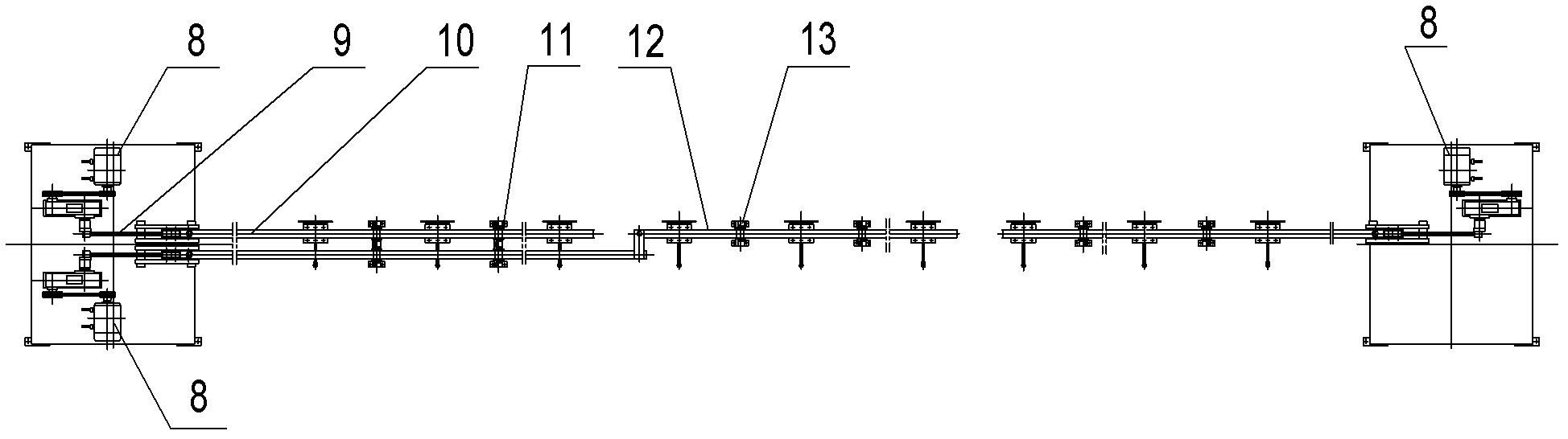

Intelligent gate-type coke feeder and control method

ActiveCN102517045ARealize remote monitoringHigh degree of automationProgramme control in sequence/logic controllersDischarging devicesMotor driveAutomatic control

The invention relates to a coke feeder for a coke bench used for wet quenching in a coking plant and a control method for the coke feeder, in particular to an intelligent gate-type coke feeder. The intelligent gate-type coke feeder comprises a variable frequency motor, eccentric cranks, a brace, a plurality of reciprocating open doors with flexible guide rolls, wherein the brace adopts a structure with independent segments; the reciprocating open doors are arranged on the brace at intervals; each segment of the brace is connected with the variable frequency motor through an eccentric crank matched with the segment of the brace; the variable frequency motor drives the segment of the brace to move; a material detection device is arranged in a unit area of the coke bench; a plurality of cokeplacing positioning devices are arranged near a rail of a coke quenching vehicle; an electronic scale is arranged on the belt conveyor; and the material detection device, the coke placing positioningdevices, the electronic scale and the variable frequency motor are communicated with the PLC (Programmable Logic Controller) control system respectively. The method has the advantages that the degreeof automation is high; the automatic positioning of the coke quenching vehicle on the coke bench, the automatic control of delay coke feeding and the coke feeding quantity as well as unmanned operation can be realized; and the coke feeding quantity can be controlled effectively, so as to ensure uniform, safe and reliable coke feeding of a system.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

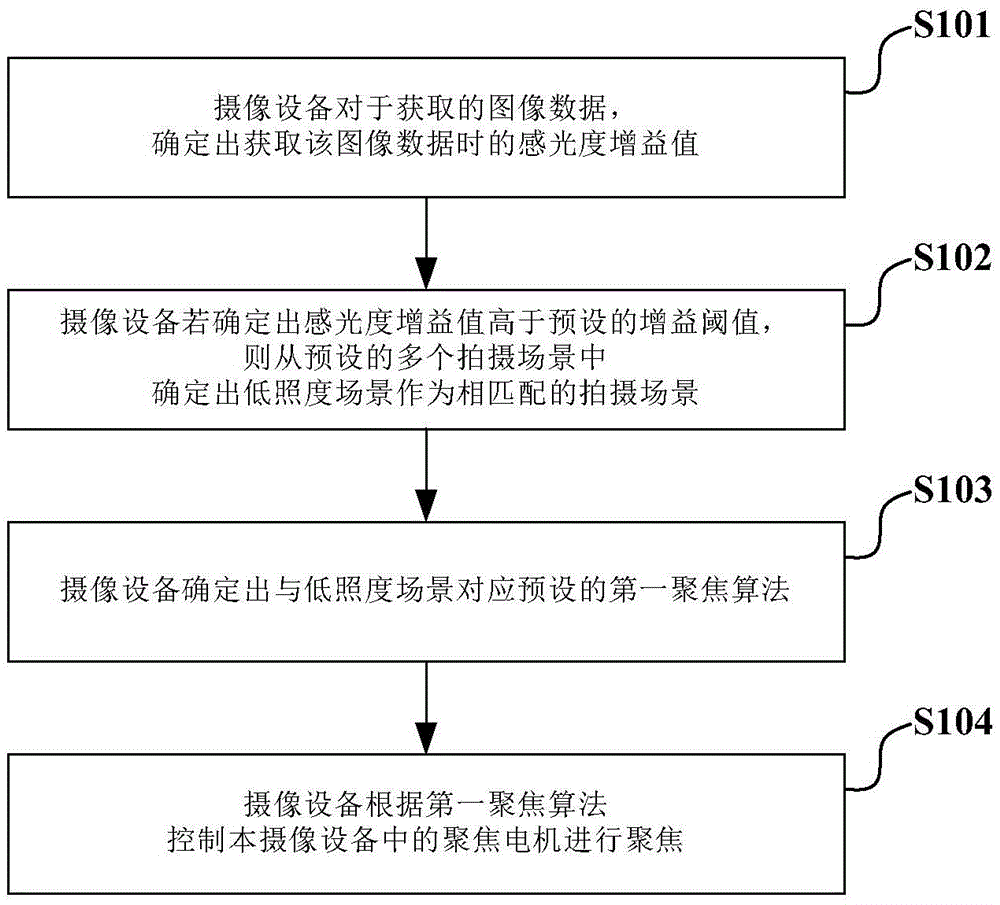

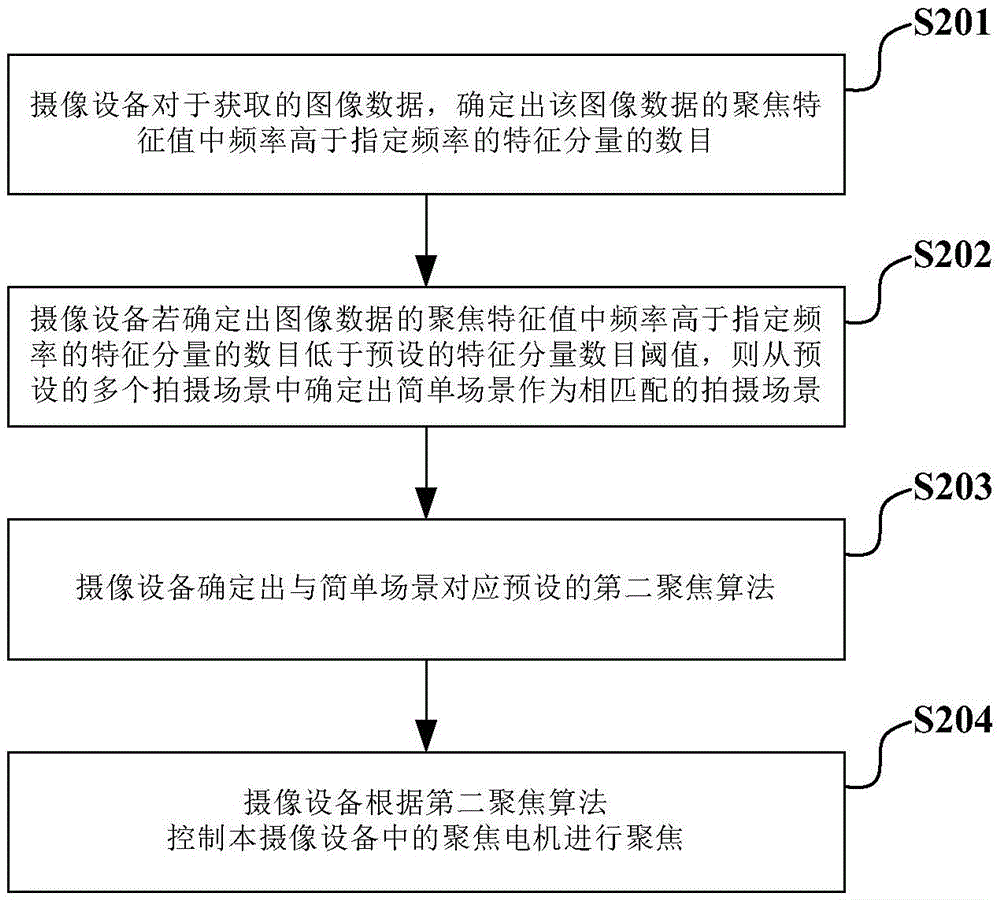

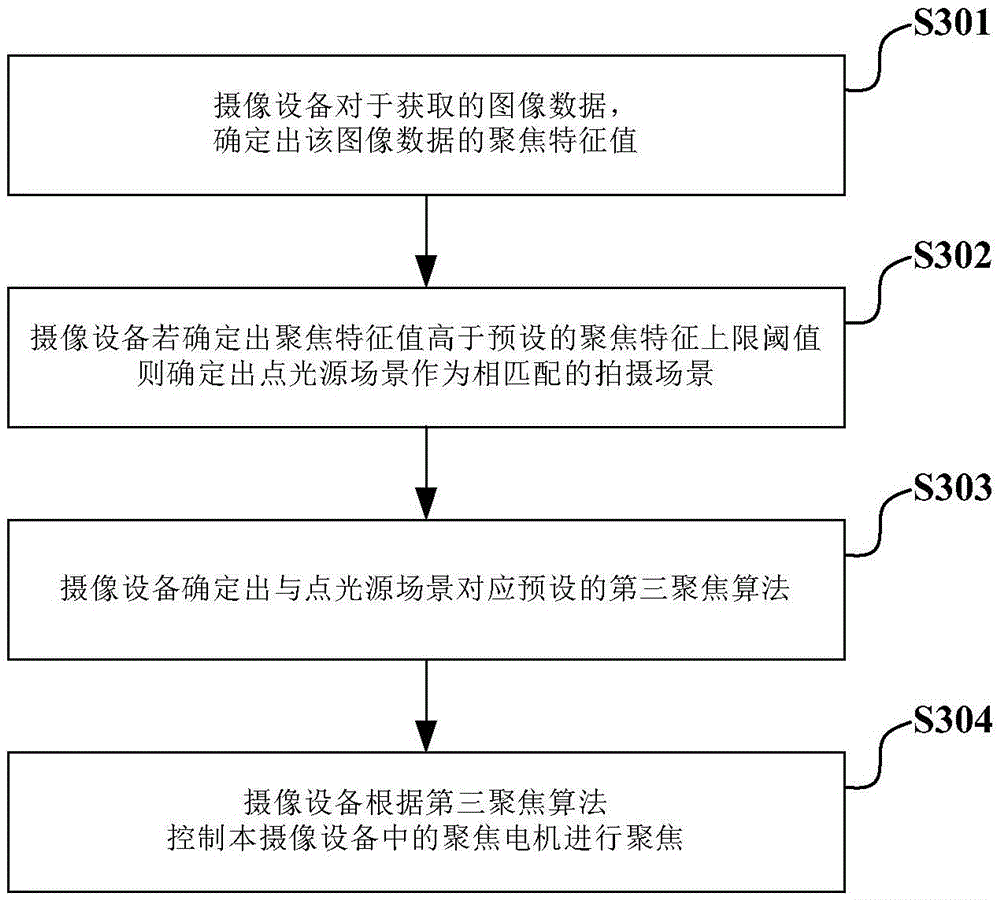

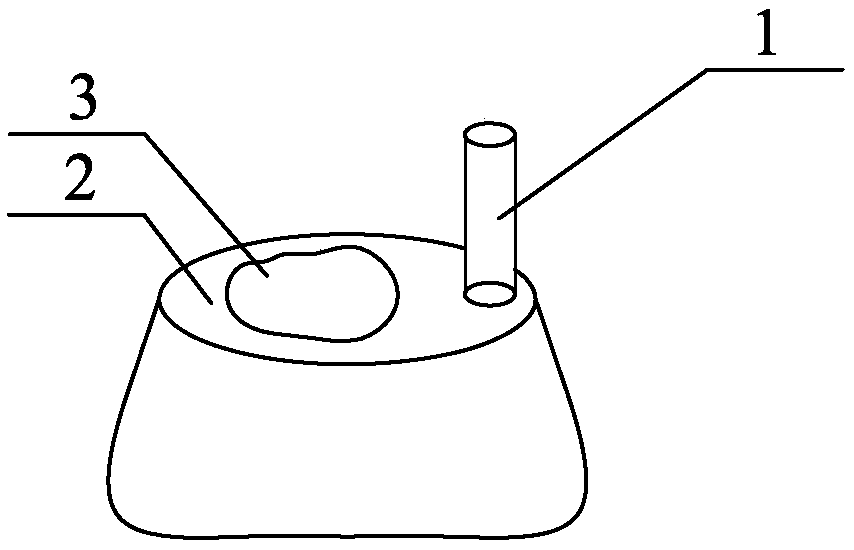

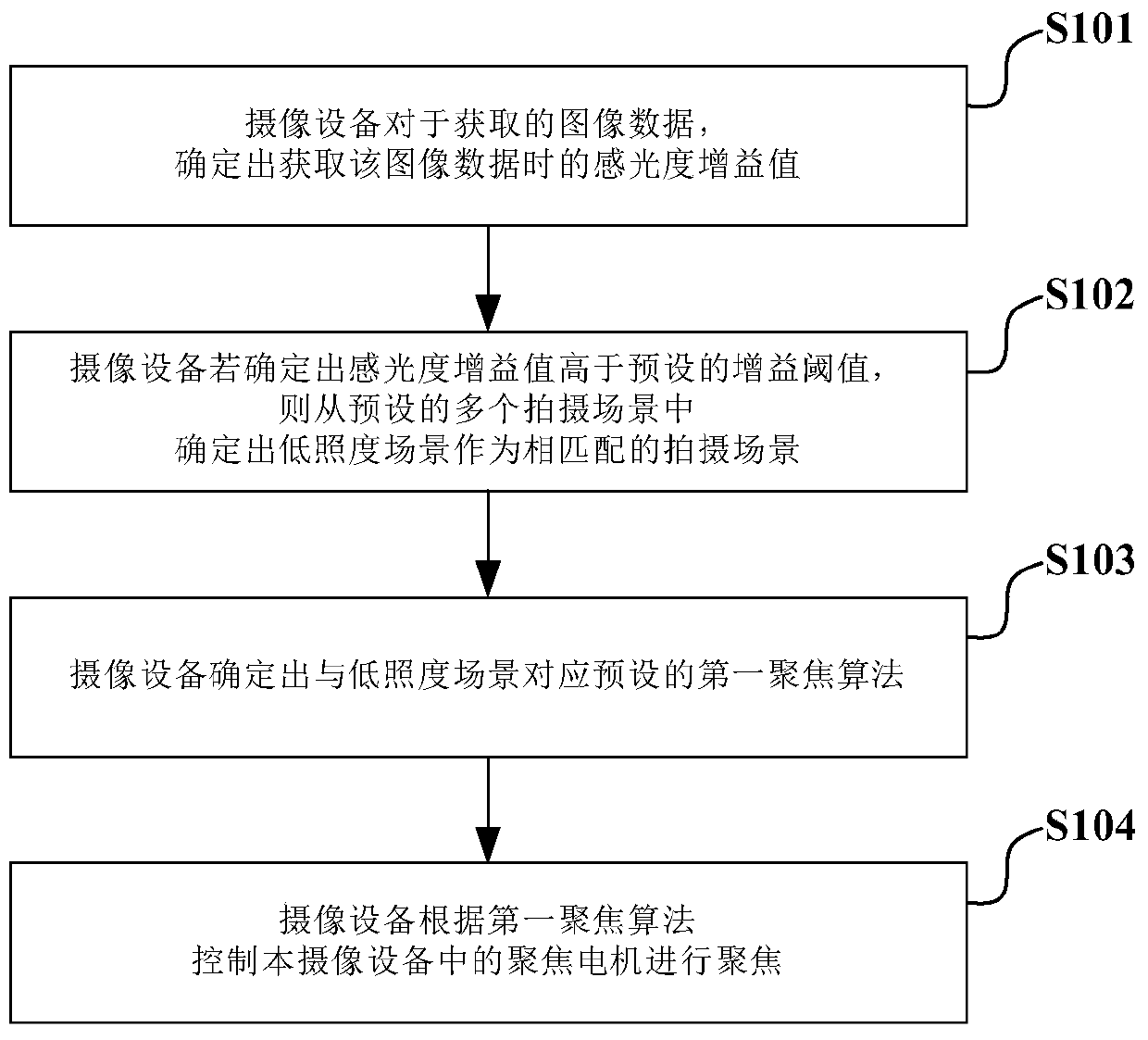

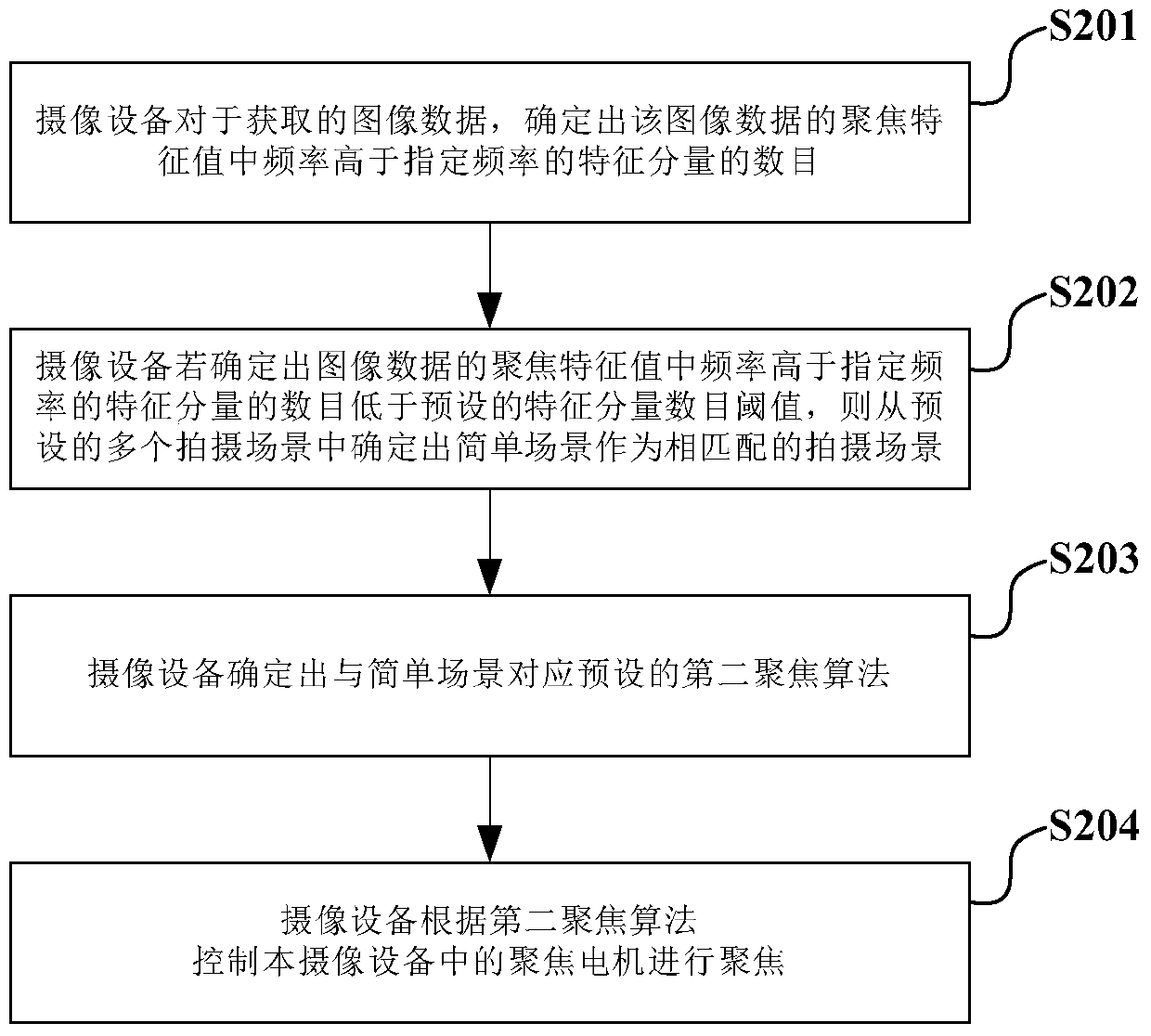

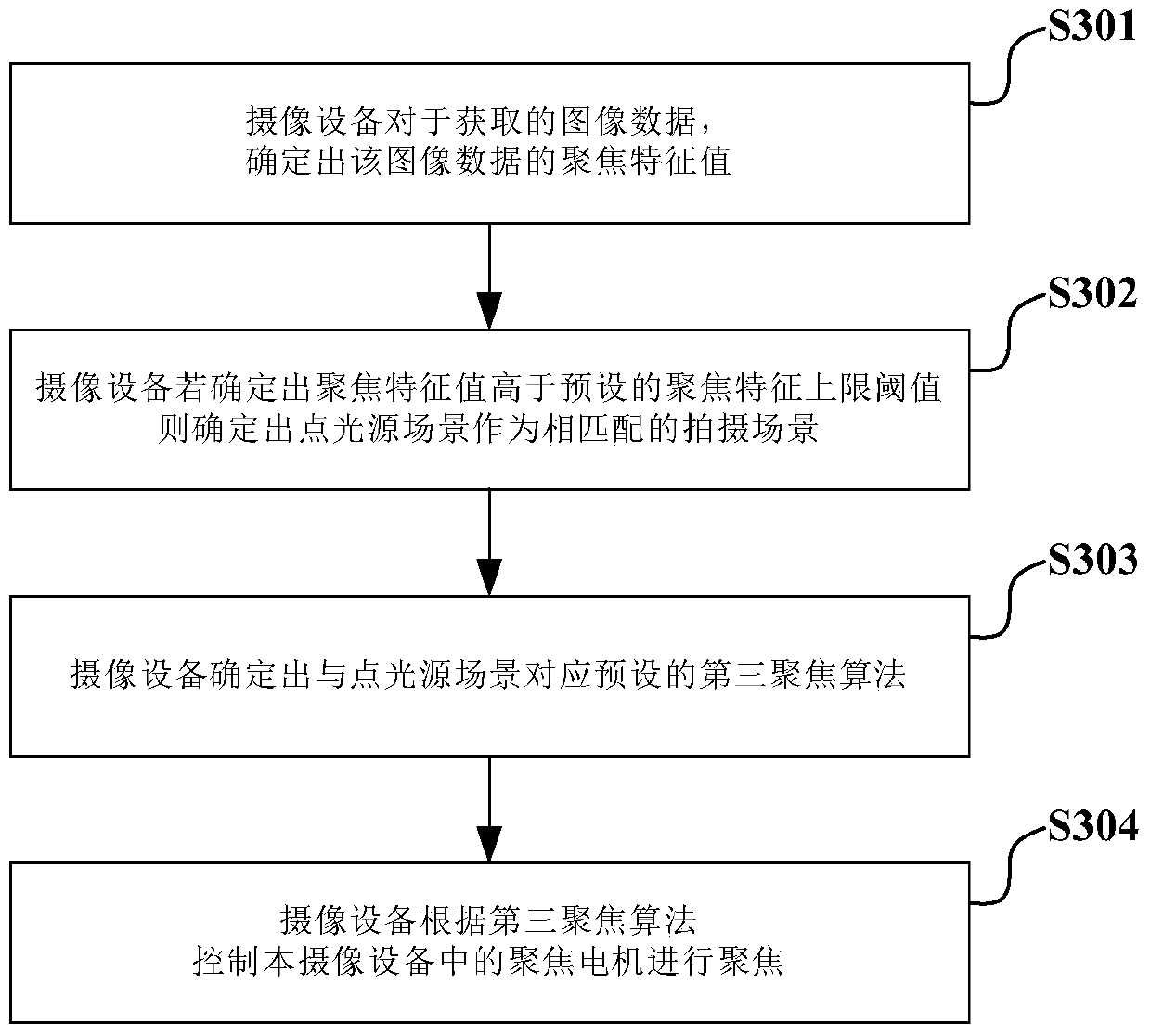

Focusing method based on shooting scene and image pickup equipment

ActiveCN105472248AImprove experienceEfficient focusTelevision system detailsColor television detailsComputer visionImaging data

The embodiment of the invention provides a focusing method based on a shooting scene and image pickup equipment. The method comprises the following steps: determining a feature value of acquired image data and / or a shooting parameter during acquisition of the image data; determining a shooting scene matched with the feature value of the image data and / or the shooting parameter from a plurality of preset shooting scenes; determining a preset focusing mode corresponding to the matched shooting scene; and performing focusing according to the determined focusing mode for shooting. In the embodiment of the invention, focusing in the preset focusing mode corresponding to the shooting scene is more suitable for the shooting scene than focusing in one focusing mode. Through adoption of the focusing method, focusing becomes more efficient and smooth; the phenomenon of virtual focus or dead focus can be avoided; the imaging definition is increased; and the user experience can be improved.

Owner:成都全景智能科技有限公司

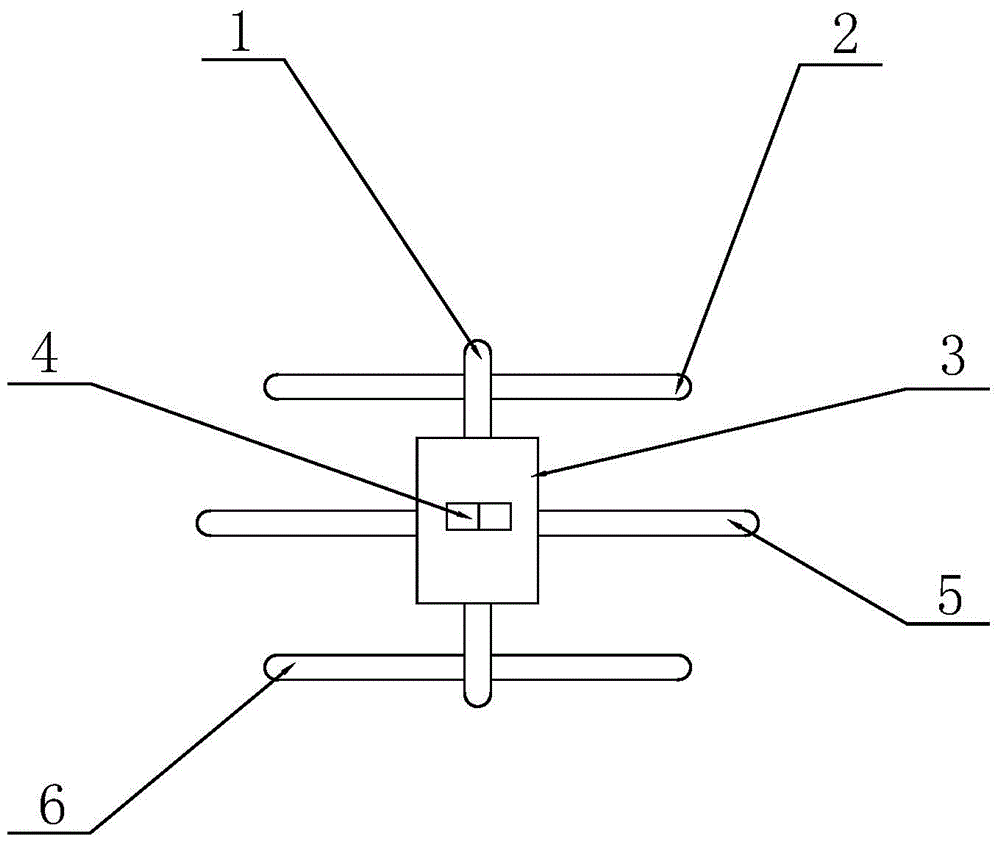

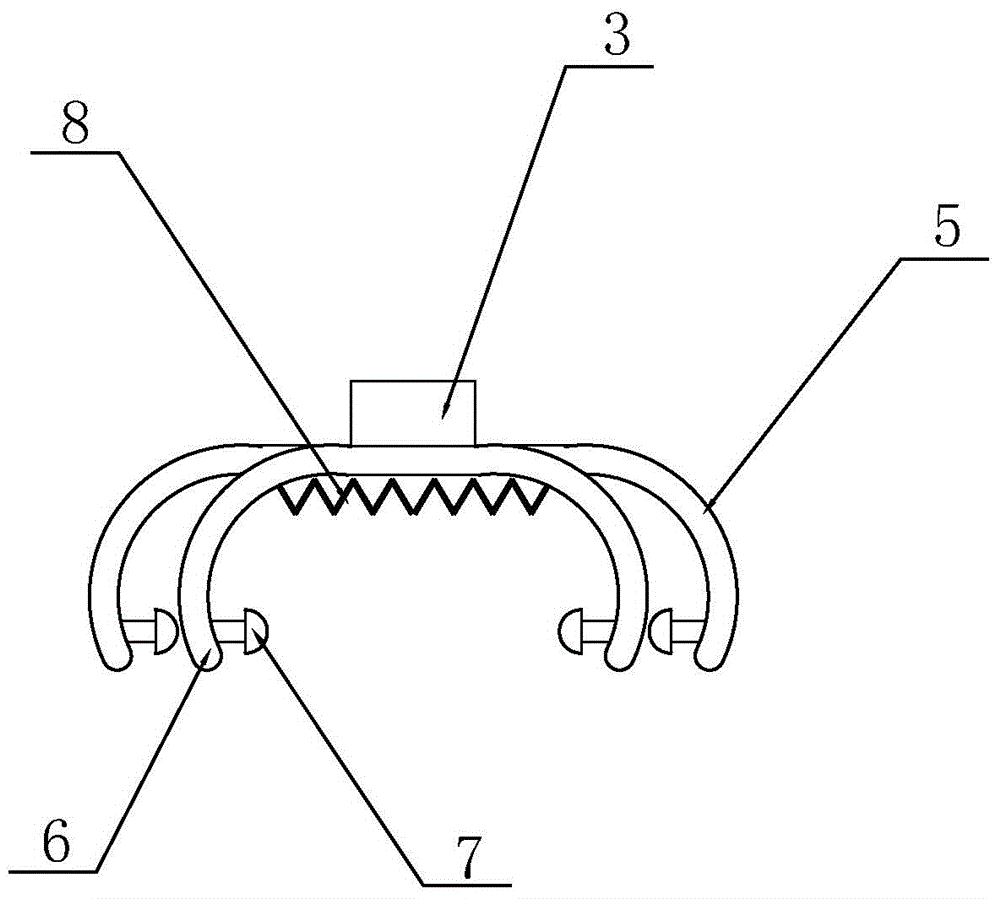

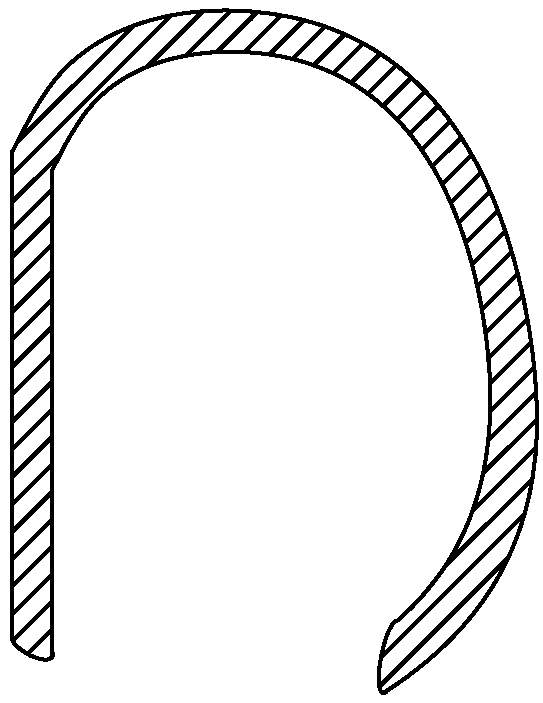

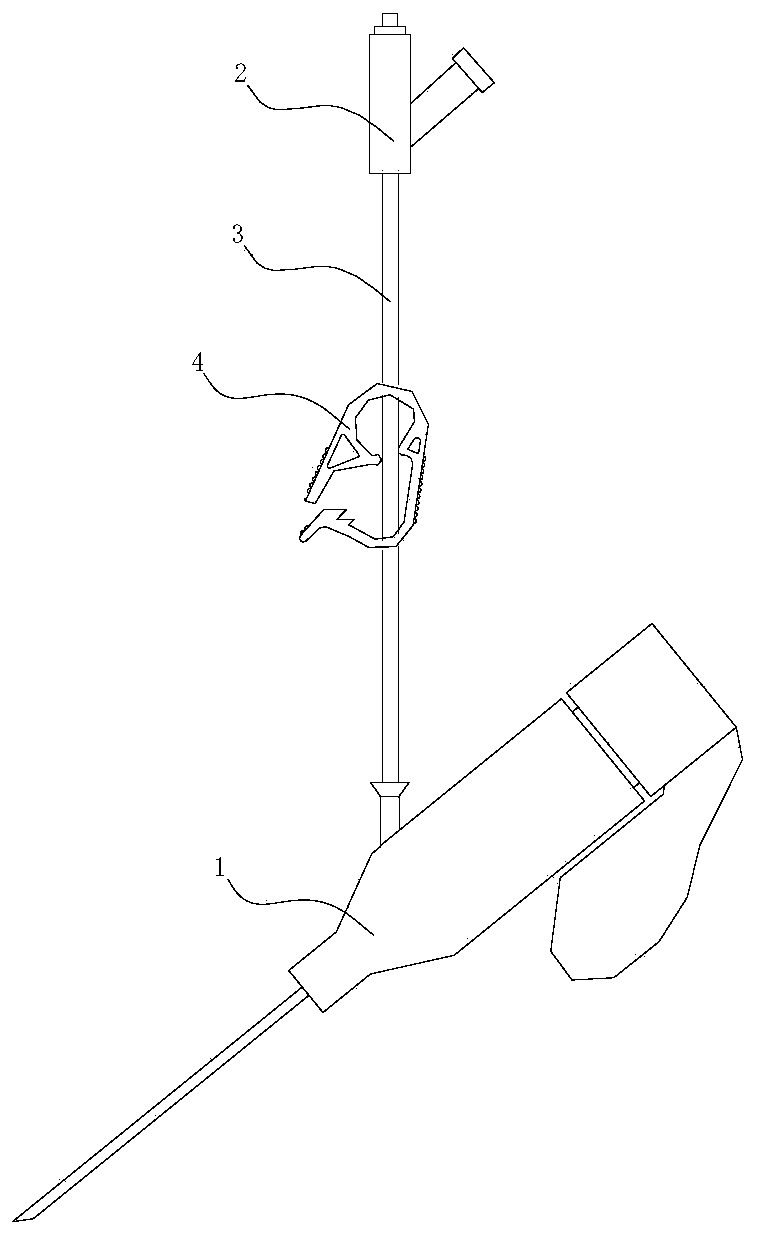

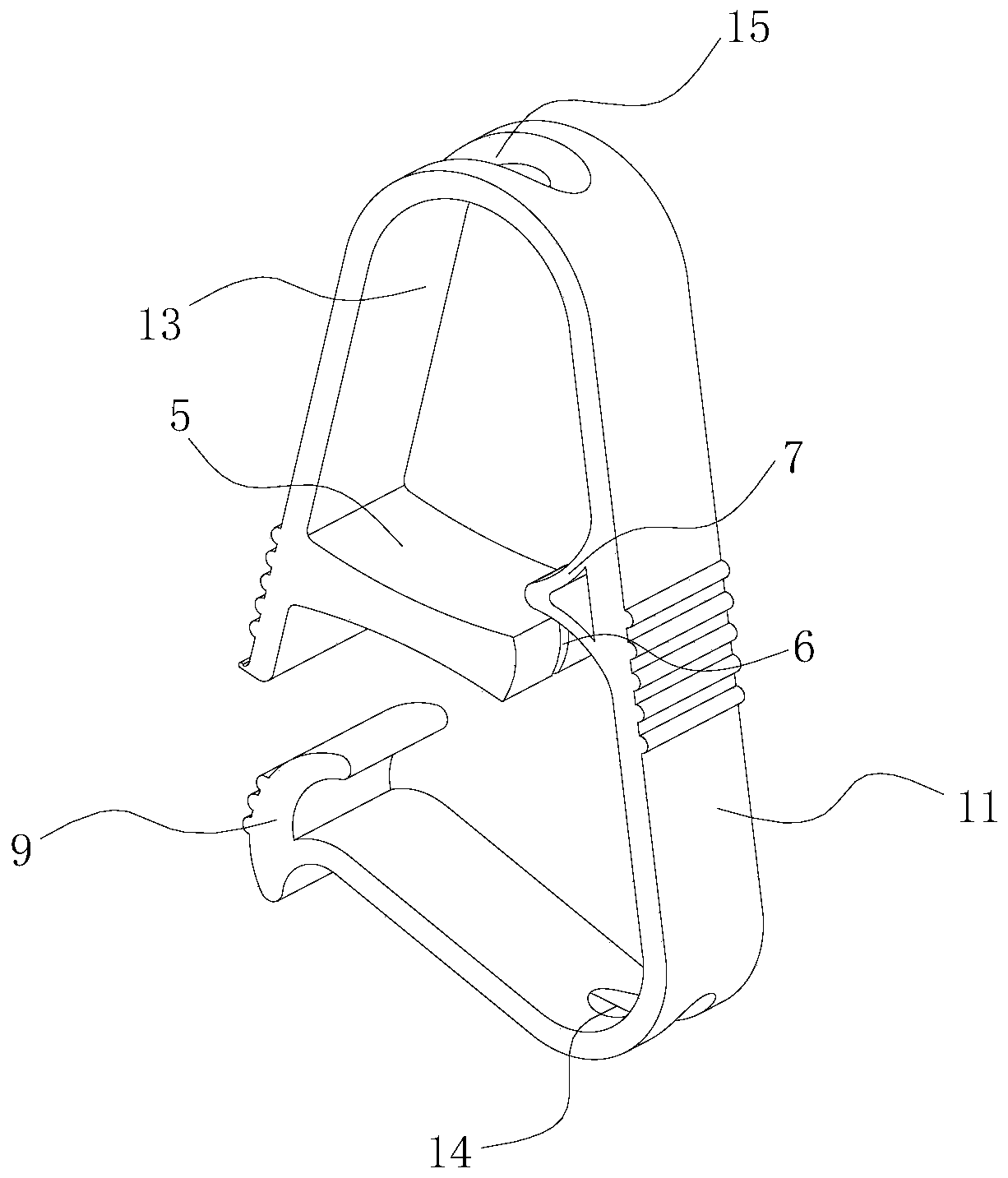

Head massaging device for patients with neurasthenia

InactiveCN105769544ASolve the problem of easy to cause toxic side effectsReduce labor intensityDevices for pressing relfex pointsVibration massagePhysical medicine and rehabilitationPhysical therapy device

The invention relates to a physical therapy device, in particular to a head massaging device for patients with neurasthenia. The head massaging device comprises a longitudinal beam (1), a front claw (2), a control box (3), a switch (4), a middle claw (5), a rear claw (6), massaging pillars (7) and springs (8); the head massaging device is characterized in that the front claw (2) is arranged at one end of the longitudinal beam (1), the rear claw (6) is arranged at the other end of the longitudinal beam (1) and the middle claw (5) is arranged in the middle of the longitudinal beam (1); the control box (3) is arranged in the longitudinal beam (1); a vibrating motor is arranged in the control box (3); the springs (8) are arranged in the front claw (2), the rear claw (6) and the middle claw (5); and the massaging pillars (7) are arranged at the tail ends of the front claw (2), the rear claw (6) and the middle claw (5). The physical therapy device disclosed by the invention is simple in structure, convenient to use and convenient to operate; the efficiency of manual massaging is improved; and the physical therapy device is practical and reliable.

Owner:杨淑珍

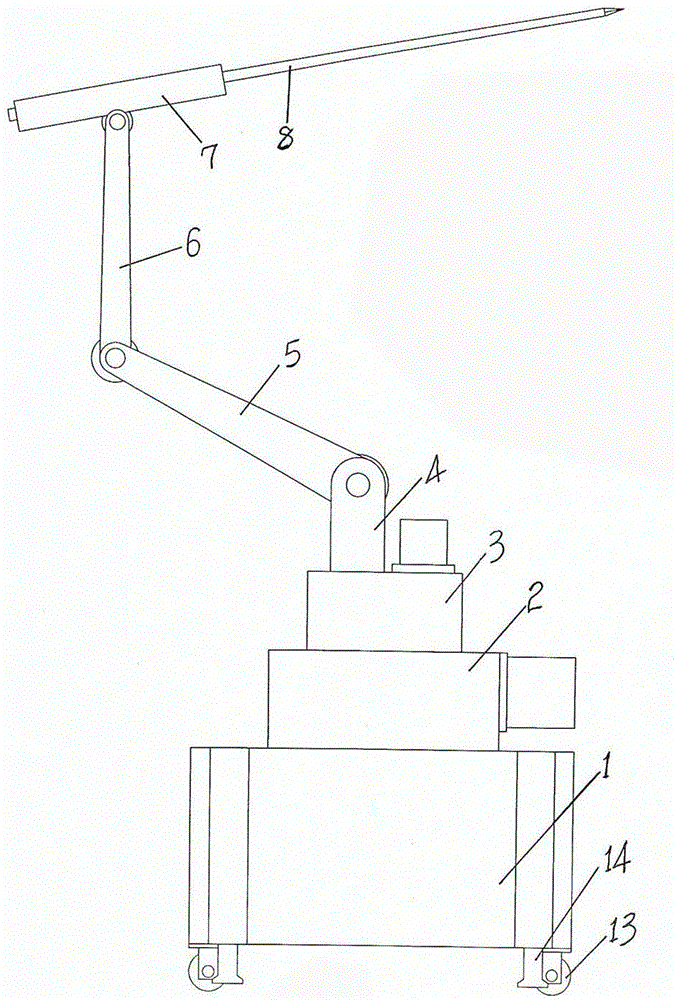

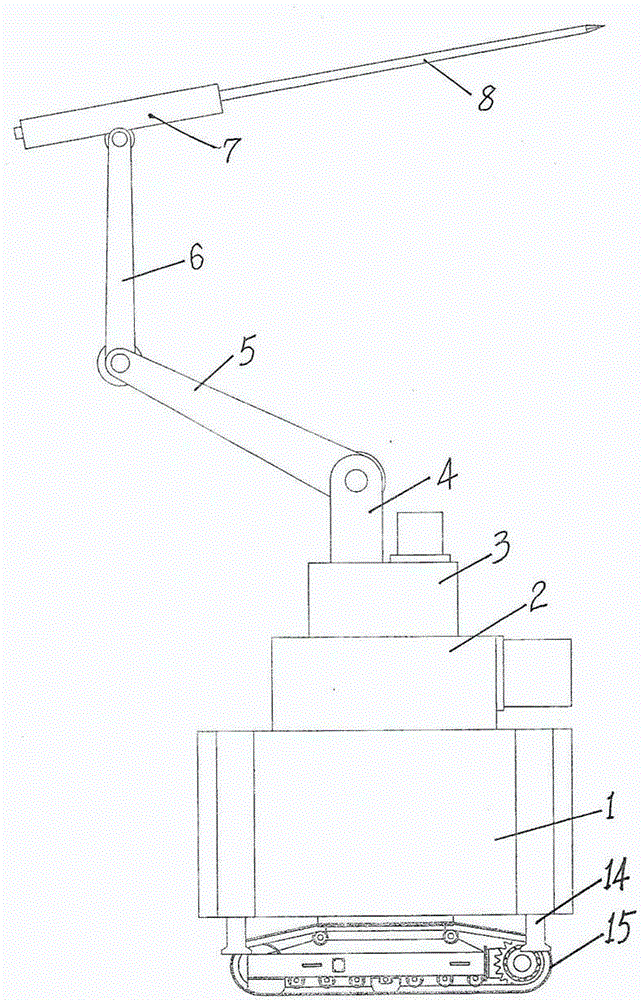

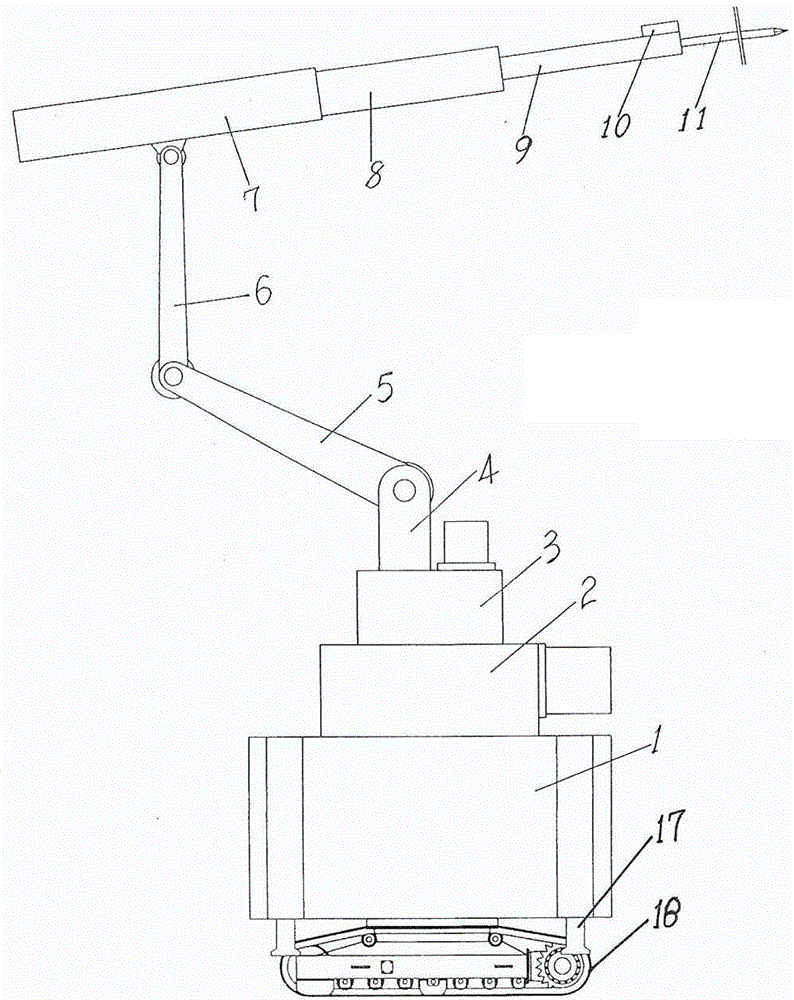

Wheel type pneumatic energy storage coke removing machine

InactiveCN105823068AEasy to fixChange the original manual labor state of heavy laborLighting and heating apparatusDrive wheelChisel

The invention discloses a wheel type pneumatic energy storage coke removing machine, and relates to the technical field of machinery. The key technology of driving wheel walking pneumatic or hydraulic energy storage or caterpillar band walking pneumatic or hydraulic energy storage is adopted. The wheel type pneumatic energy storage coke removing machine is characterized in that the bottom end of a frame plate is rotatably and movably connected with driving wheels; the frame plate is fixed to a pneumatic device; an output end of the pneumatic device is fixed to the upper ends of supports; an annular gear on the frame plate is in occlusion with a circular gear on an output shaft of a gearbox connected with a rotating motor on a rotating body; an annular rail on the frame plate is movably connected with a rail wheel of the lower end of the rotating body in a rolling manner; the upper end of the rotating body is fixed to the lower end of a frame body; the frame body is fixed to the pneumatic device; the output end of the pneumatic device is fixed to a lifting arm; the upper end of the lifting arm and the lower end of a master arm, the upper end of the master arm and the lower end of a linkage arm, and the upper end of the linkage arm and a pneumatic part are rotatably and movably connected through deceleration motors; and an output end of the pneumatic part is fixed to the back end of a steel chisel. The wheel type pneumatic energy storage coke removing machine is used for removing cokes of a utility boiler, and is a new product which is simple and ingenious in structure, stable in effect, easy to manufacture, and low in cost.

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

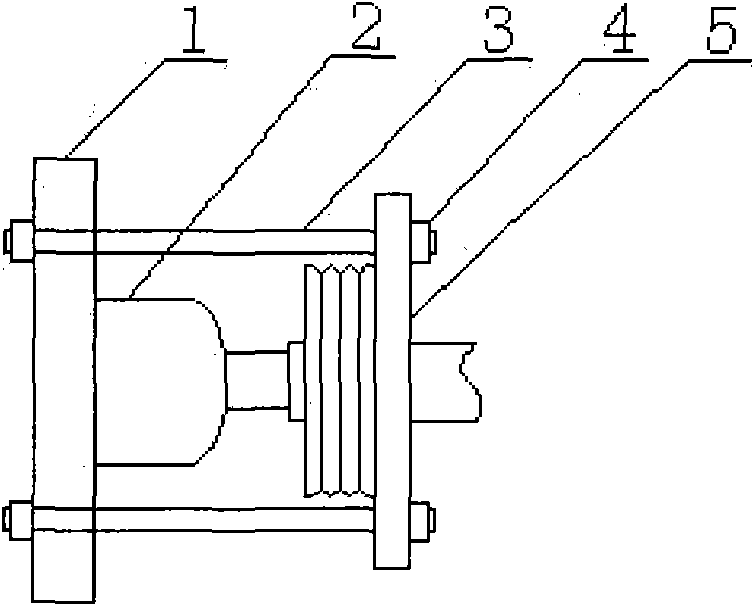

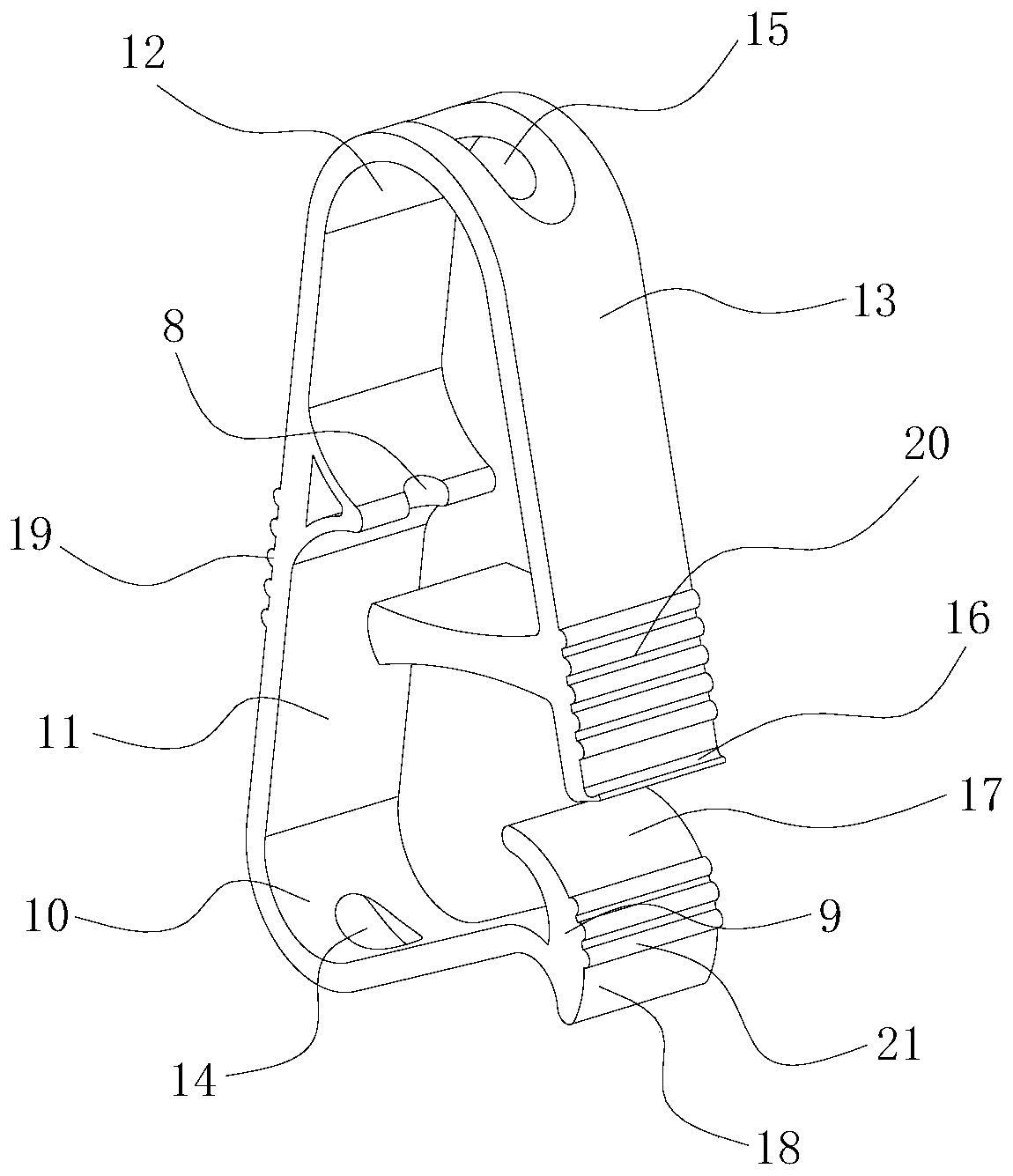

Stable hydraulic wheel puller

The invention relates to the field of a belt pulley pulling device, in particular to a stable hydraulic wheel puller. The stable hydraulic wheel puller comprises a base, a jack, a screw, a nut and a wheel pulling plate. The jack is connected with the base integrally, the wheel pulling plate is connected with the base through the screw, and the wheel pulling plate adopts a lock ring structure. The wheel pulling plate is formed by combining two locking pieces. Each locking piece is provided with a pin shaft and a shaft sleeve. Two crewed holes are formed in both ends of each pin shaft respectively. The wheel puller is arranged on the back of the belt pulley in a sleeving manner, so that the stress area of the belt pulley is enhanced; and the origin of force is uniform, and the belt pulley does not fall off and is not damaged, so that the work efficiency is greatly improved.

Owner:常州市诚万建设工程有限公司

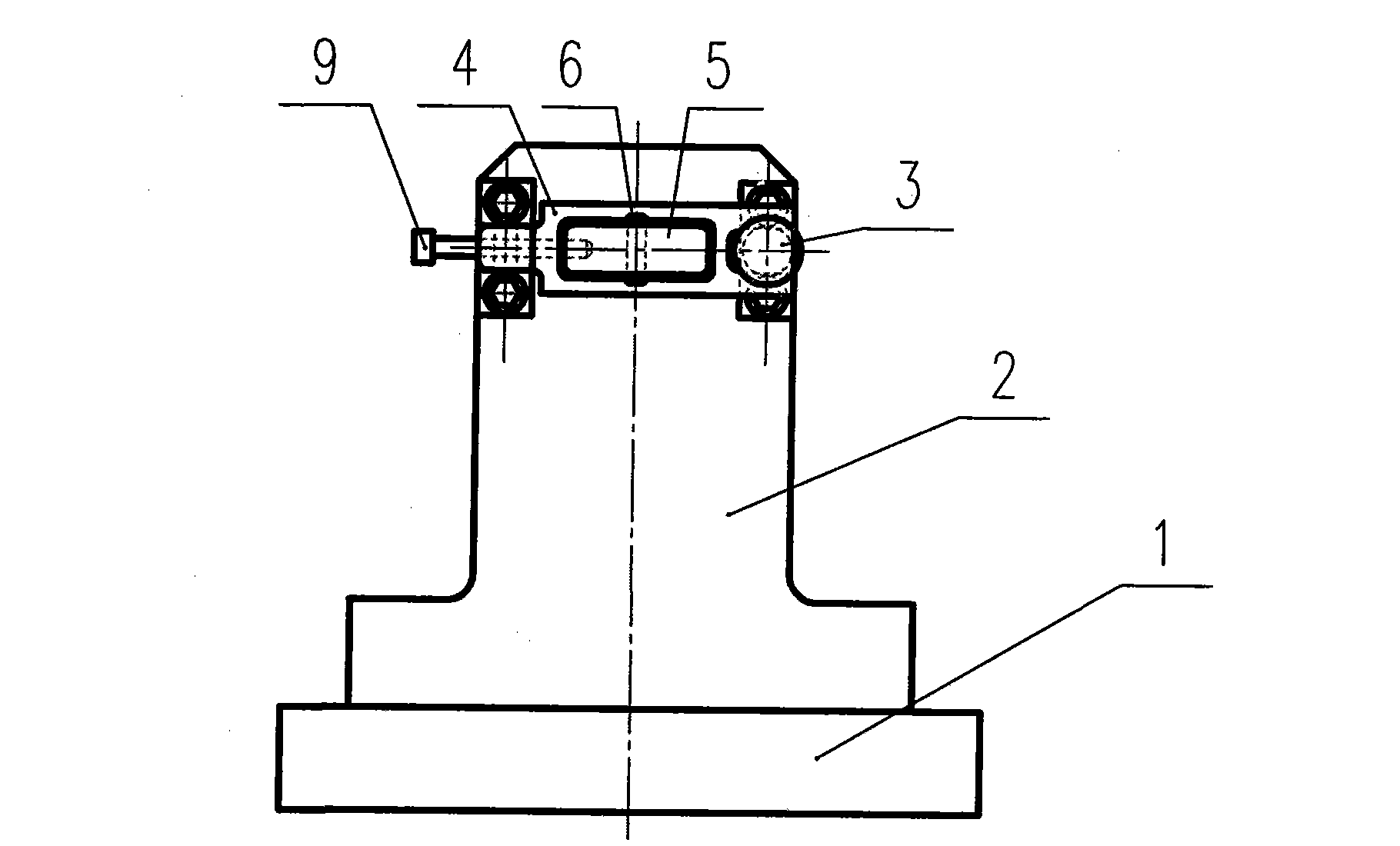

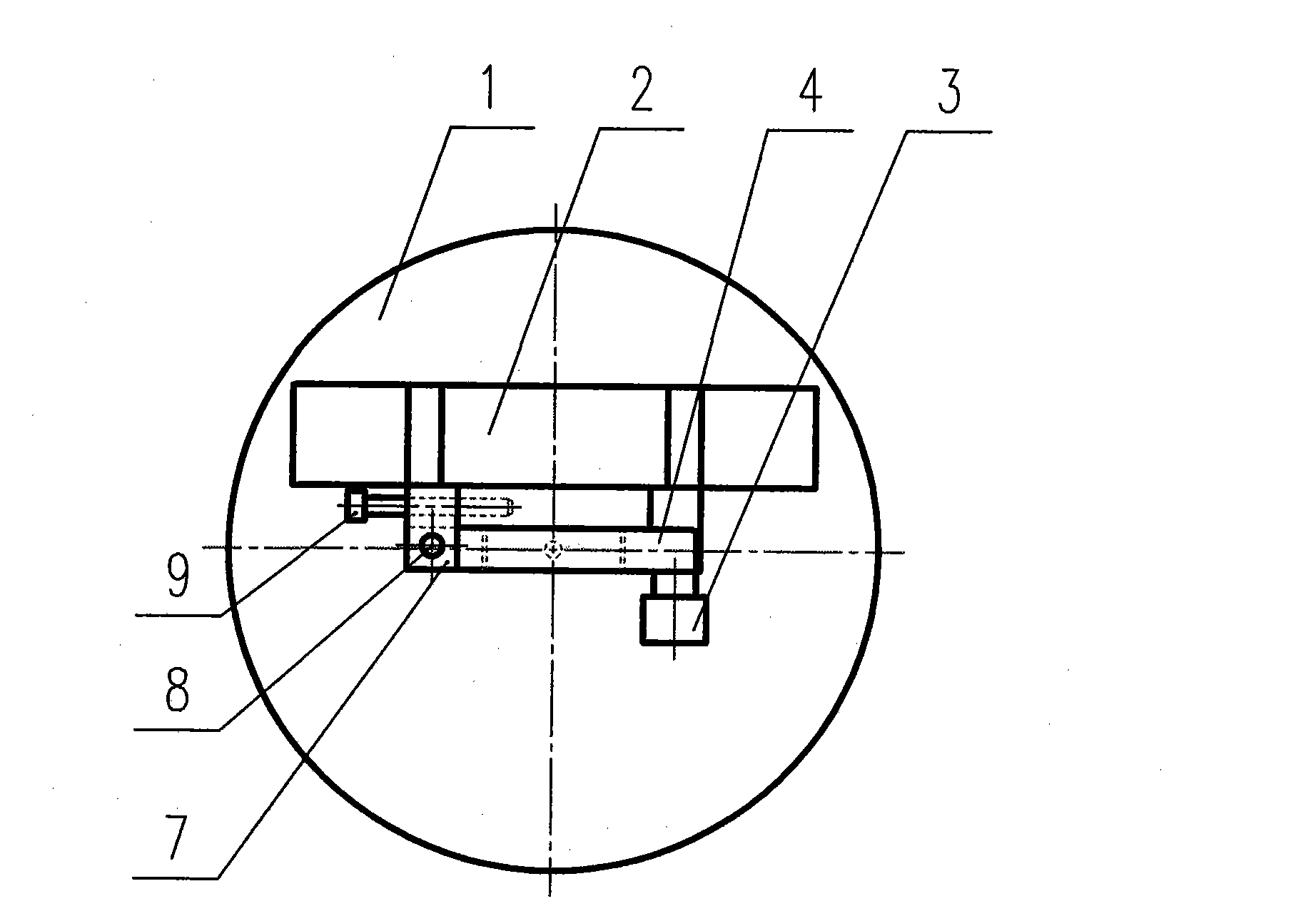

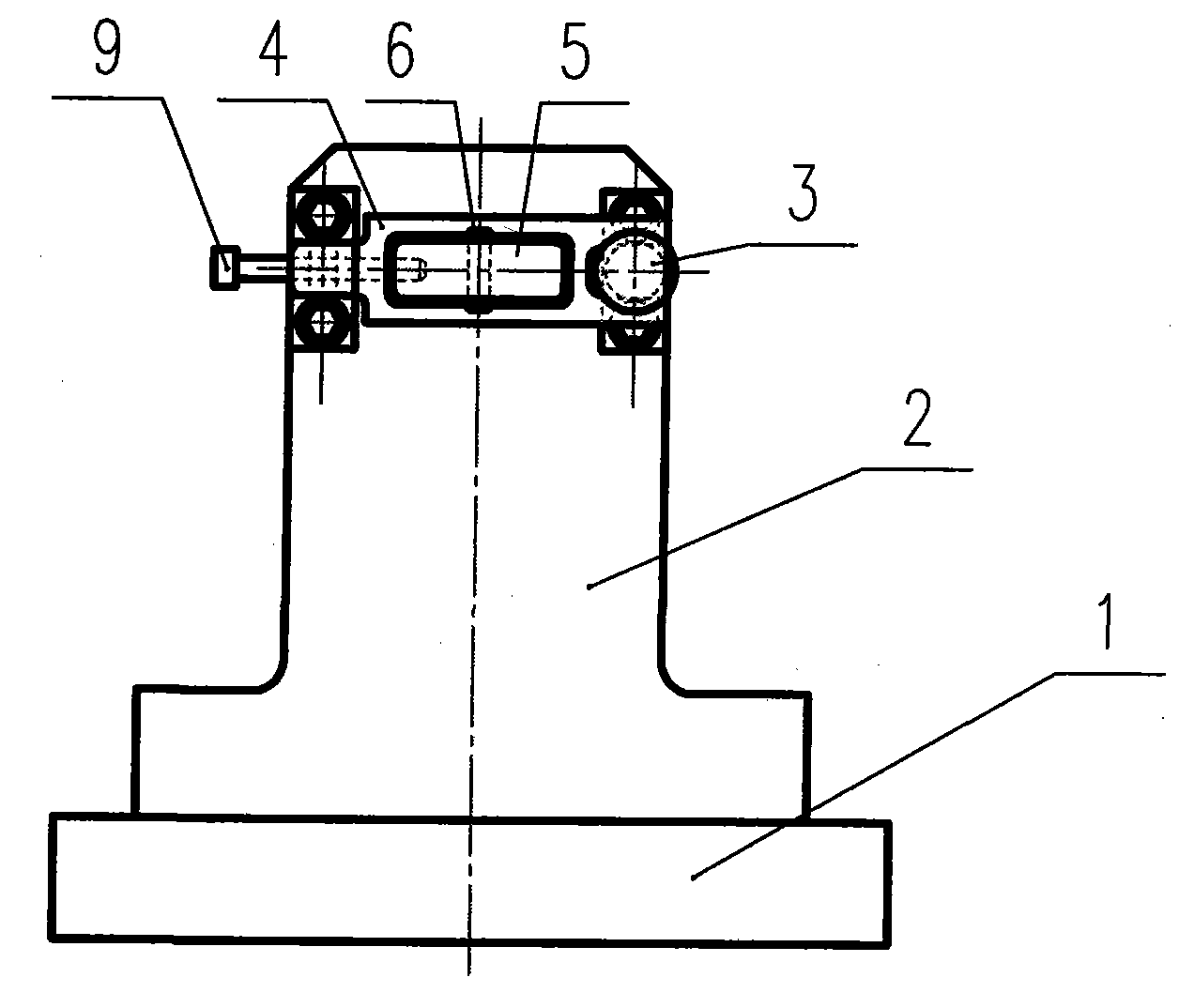

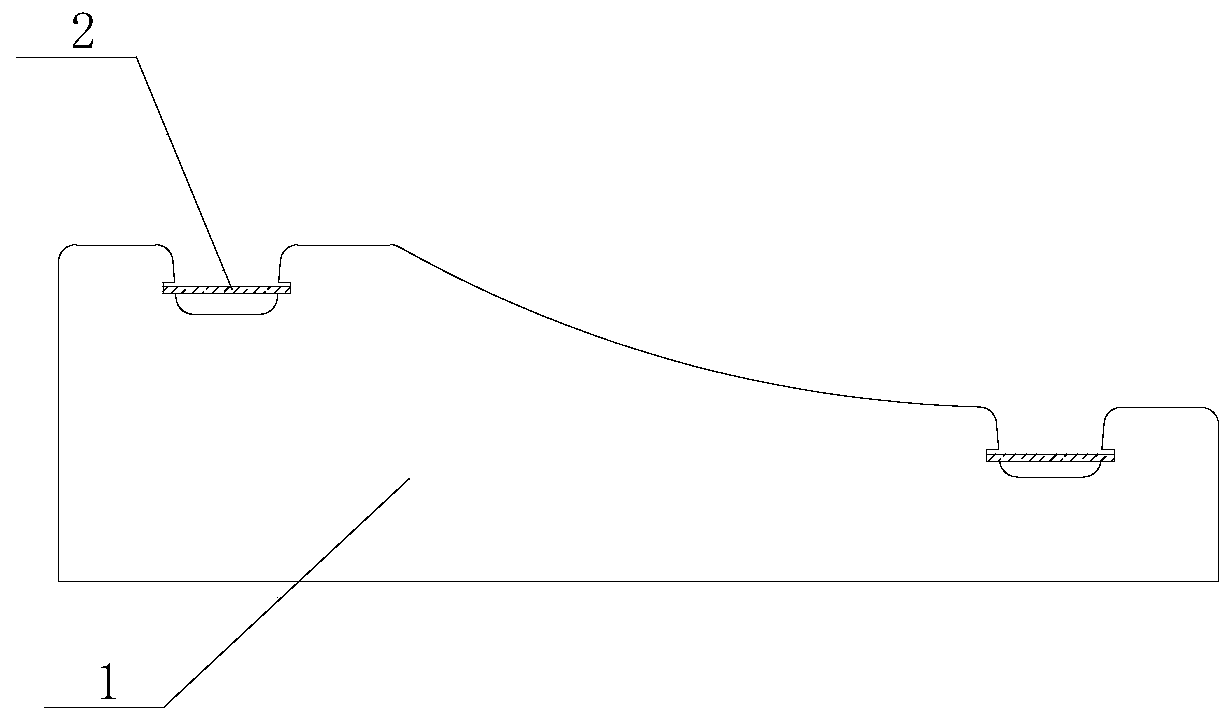

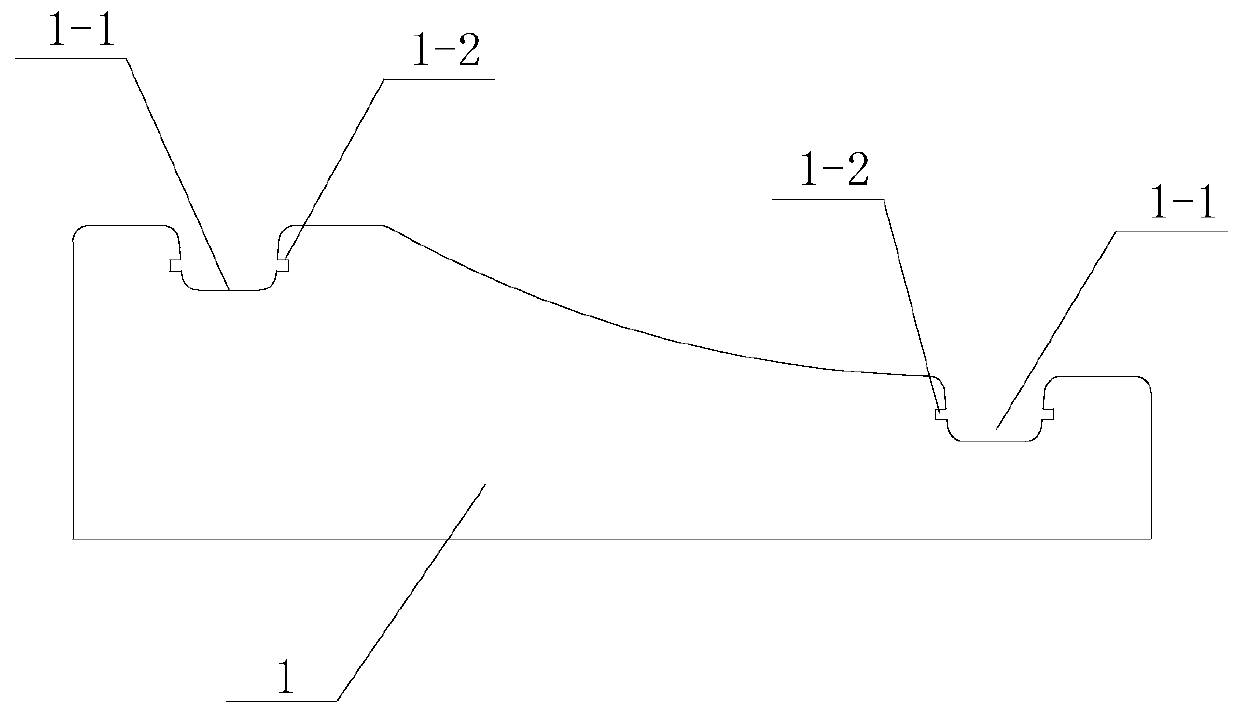

High-precision positioning fixture

InactiveCN102107401AGuaranteed accuracyGuaranteed stabilityWork holdersMechanical engineeringEngineering

Owner:TIANJIN JINLAI PRECISION MACHINERY

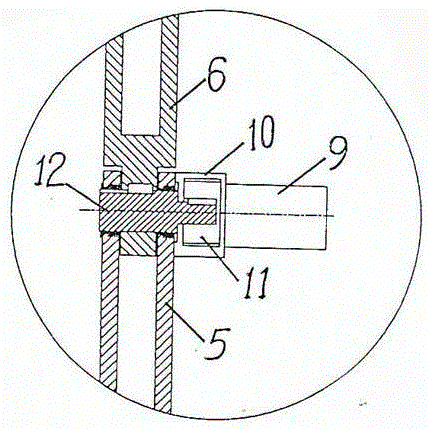

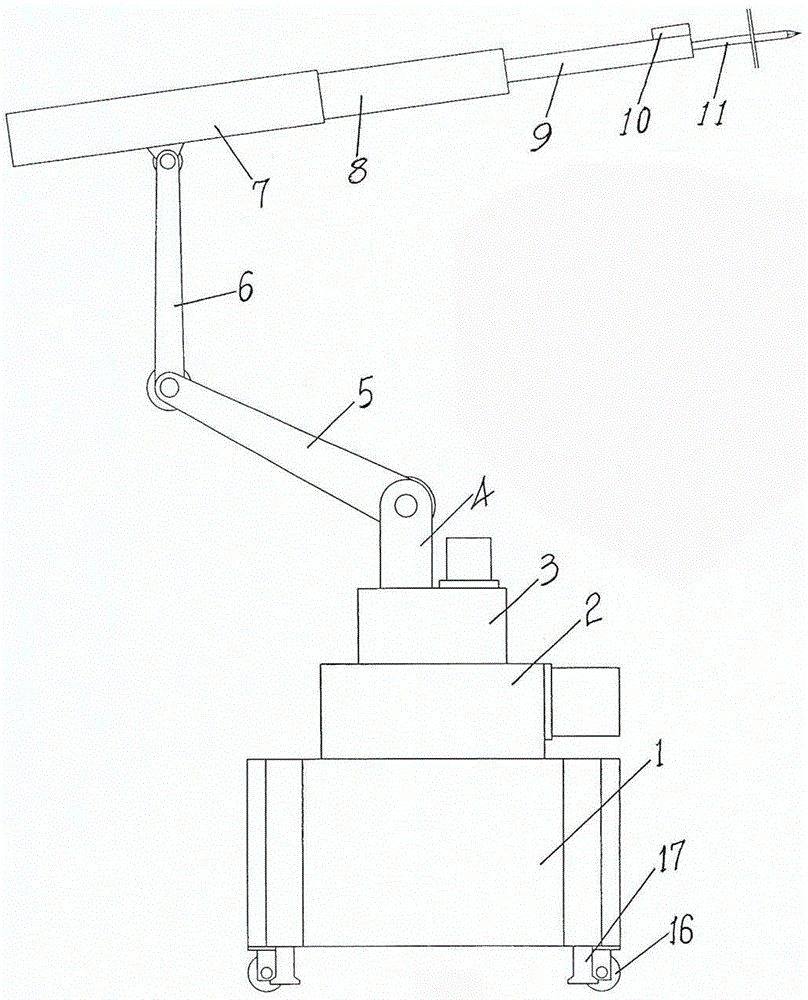

Wheel type air pick energy storage coke removing machine

InactiveCN105823067AEasy to fixFocusing is accurateLighting and heating apparatusTelescopic cylinderEngineering

The invention discloses a wheel type air pick energy storage coke removing machine, and relates to the technical field of machinery. The wheel type air pick energy storage coke removing machine is characterized in that the bottom end of a frame plate and wheels are rotatably connected; the frame plate is fixed to a pneumatic device; an output end of the pneumatic device is fixed to the upper ends of supports; an annular gear on the frame plate is in occlusion with a circular gear on an output shaft of a gearbox connected with a rotating motor on a rotating body; an annular rail on the frame plate is movably connected with a rail wheel of the lower end of the rotating body in a rolling manner; the upper end of the rotating body is fixed to the lower end of a frame body; the frame body is fixed to the pneumatic device; the output end of the pneumatic device is fixed to a lifting arm; the upper end of the lifting arm and the lower end of a master arm, the upper end of the master arm and the lower end of a linkage arm, and the upper end of the linkage arm and a sleeve are rotatably and movably connected through servo motors; the back end inside the sleeve is fixed to the pneumatic device; the output end of the pneumatic device is fixed to the back end of a telescopic cylinder; the front end of the telescopic cylinder is fixed to the back end of an air pick; the upper surface of the front end of the air pick is fixed to a camera; the front end of the air pick is fixed to the back end of a steel chisel; and the sleeve and the telescopic cylinder are in plug-in mounting and the front part of the sleeve and the back part of the telescopic cylinder are movably connected in a sliding manner. The wheel type air pick energy storage coke removing machine is used for removing cokes of a utility boiler, and is simple and ingenious in structure, stable in effect, easy to manufacture, and low in cost.

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

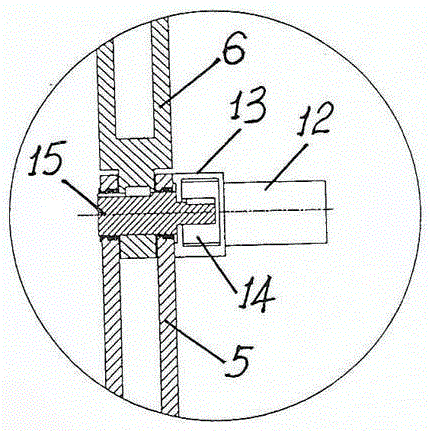

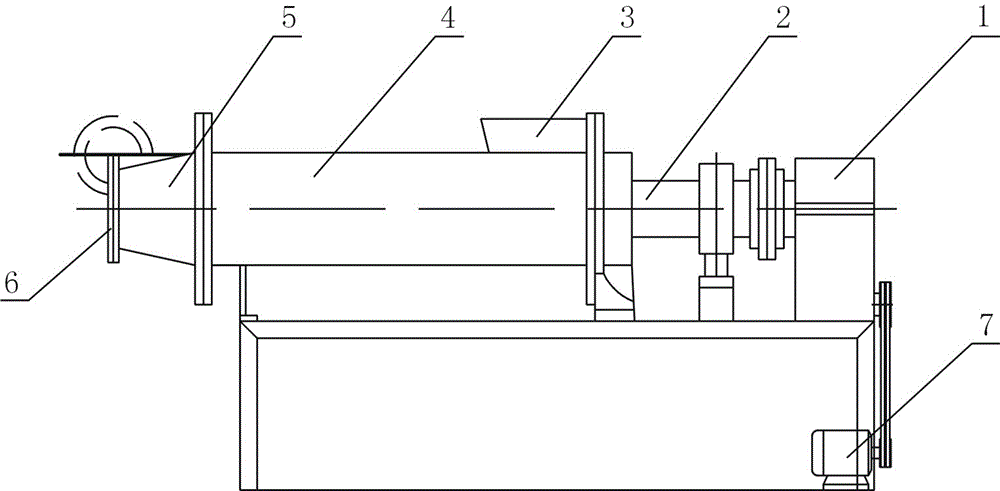

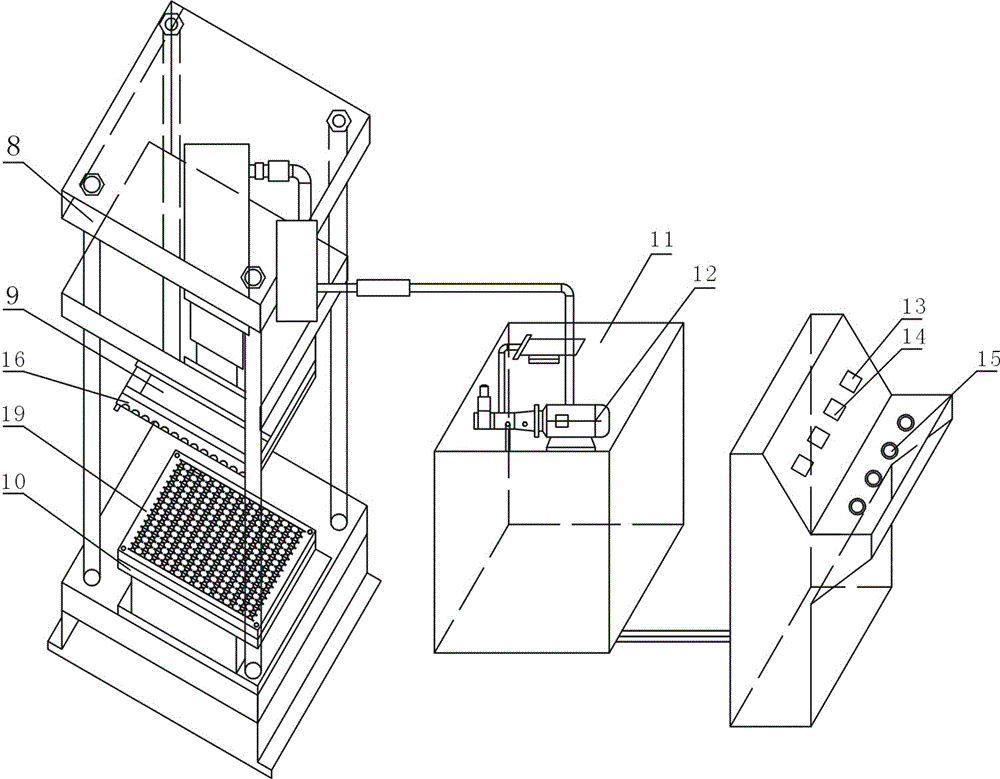

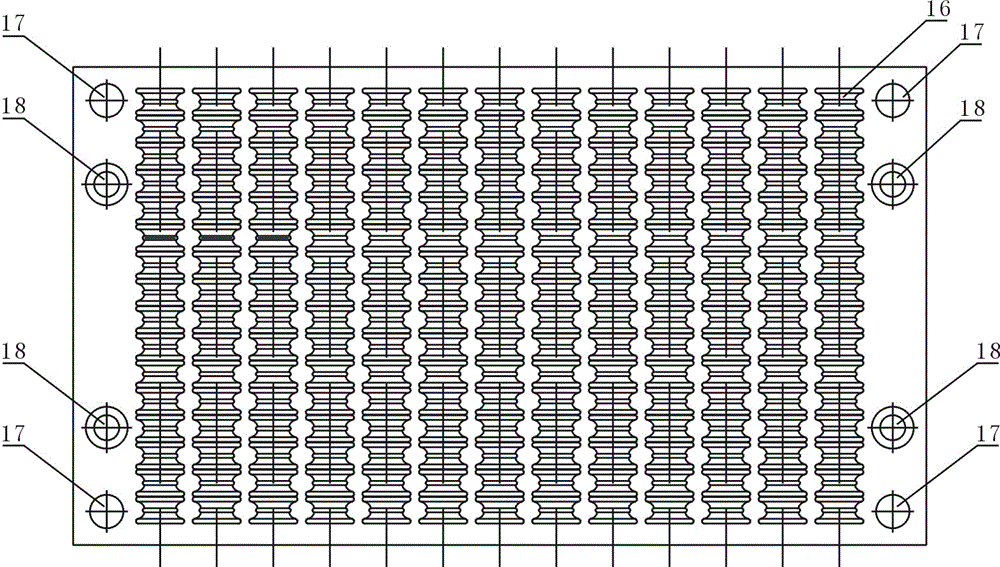

Static pressure molding process device for porcelain packing

InactiveCN105459249AUniform and stable pressureRun fastMouldsAuxillary shaping apparatusWhole bodyControl switch

A static pressure molding process device for porcelain packing is integrally formed by a hydraulic machine 8, an upper cylinder piston column 9, a lower end base 10, an oil supply system 11 of the hydraulic machine, a speed-adjustable motor 12 of the hydraulic machine, computer programming control switches 13 of the hydraulic machine, pressure adjustment switches 14 of the hydraulic machine, power switches 15 of the hydraulic machine, upper concave molding steel dies 16, guide die column holes 17, bolt holes 18, lower convex molding steel dies 19 and clay discharge holes 20; the static pressure molding process device is characterized in that the upper concave molding steel dies 16 are installed on the upper cylinder piston column 9 of the hydraulic machine 8 and are fixed to the upper-end work face of the upper cylinder piston column 9 of the hydraulic machine 8 through bolts and the bolt holes 18, the lower convex molding steel dies 19 are fixed to a work table board of the lower end base 10 of the hydraulic machine 8 through bolts and the bolt holes 18, and the speed-adjustable motor 12 of the hydraulic machine and the computer programming control switches 13 of the hydraulic machine are connected through power lines for forming a whole body after all the components are fastened; the static pressure molding process device has the advantages that the product accuracy is high, the sizes are uniform, the geometrical shapes are normalized, the acting points are balanced, stress on products is uniform, the service life is long, the abrasion is small, the efficiency is high and the operation and maintenance are easy.

Owner:段放云

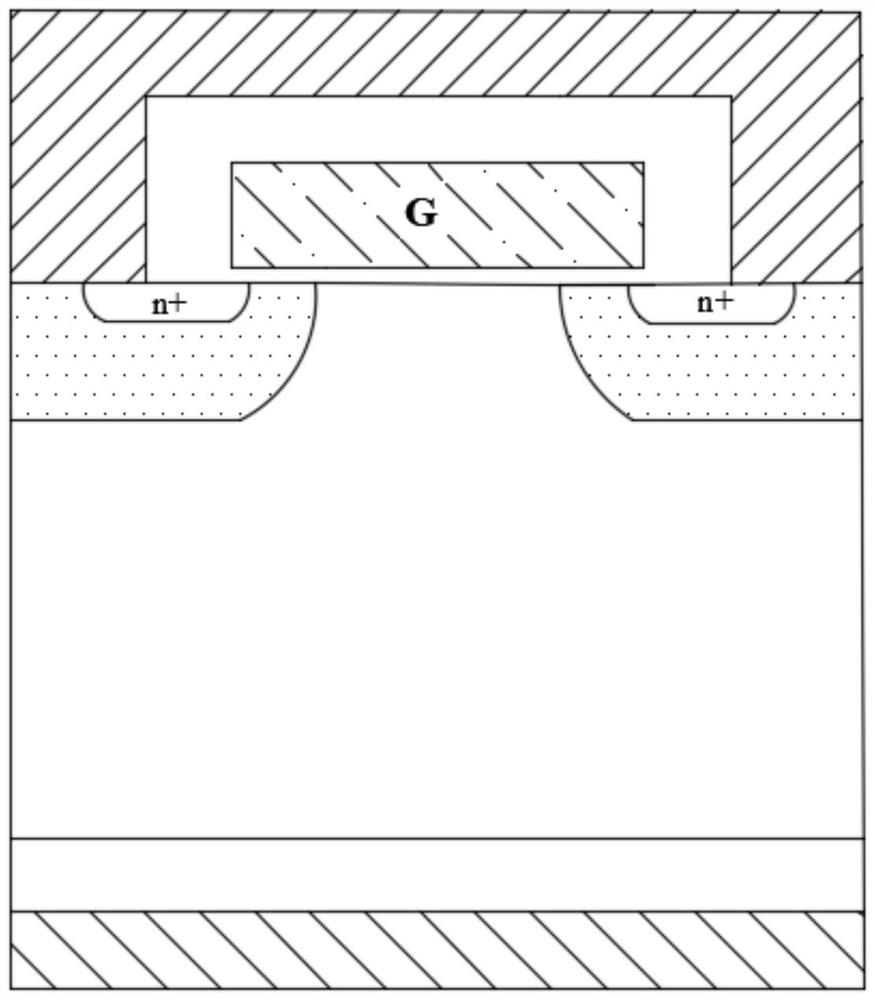

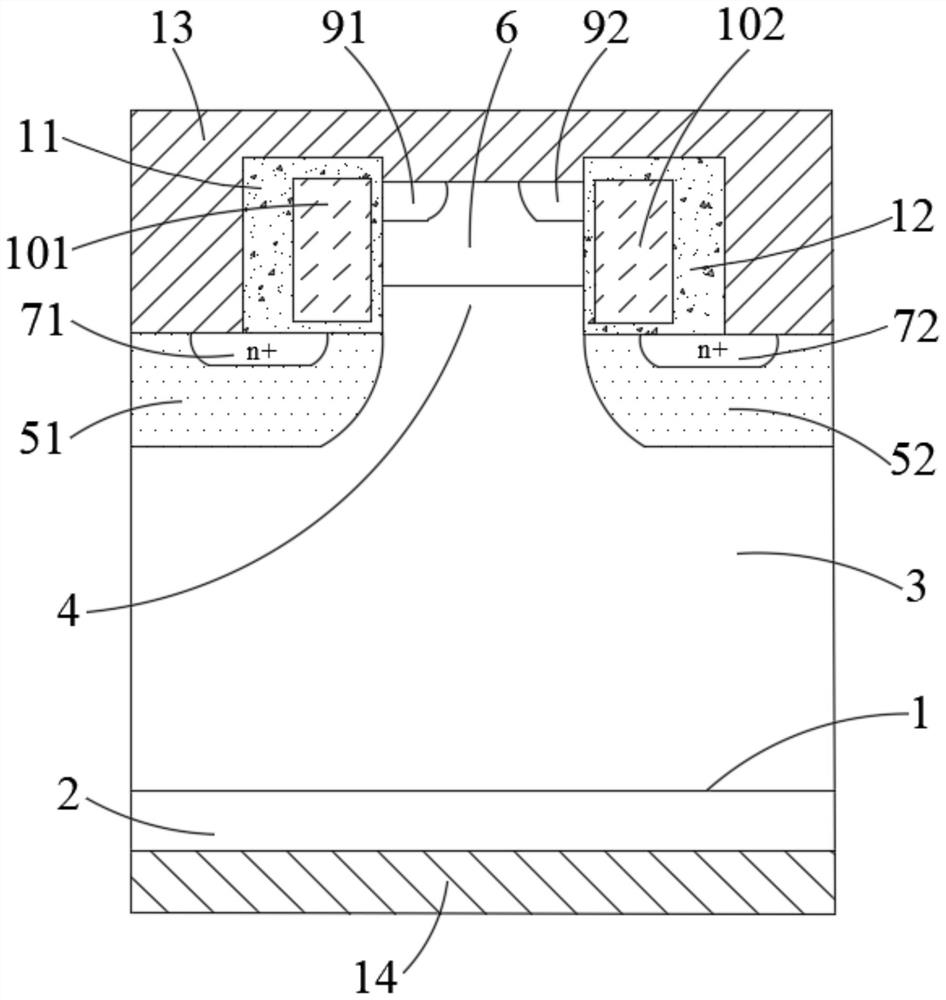

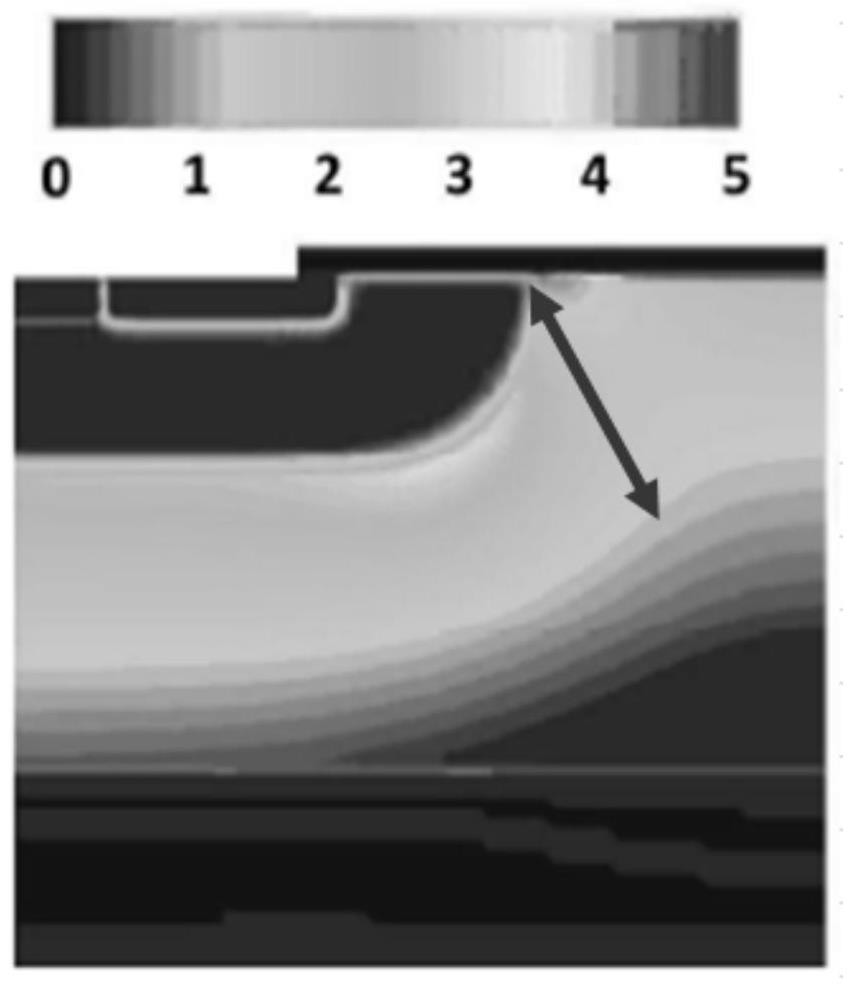

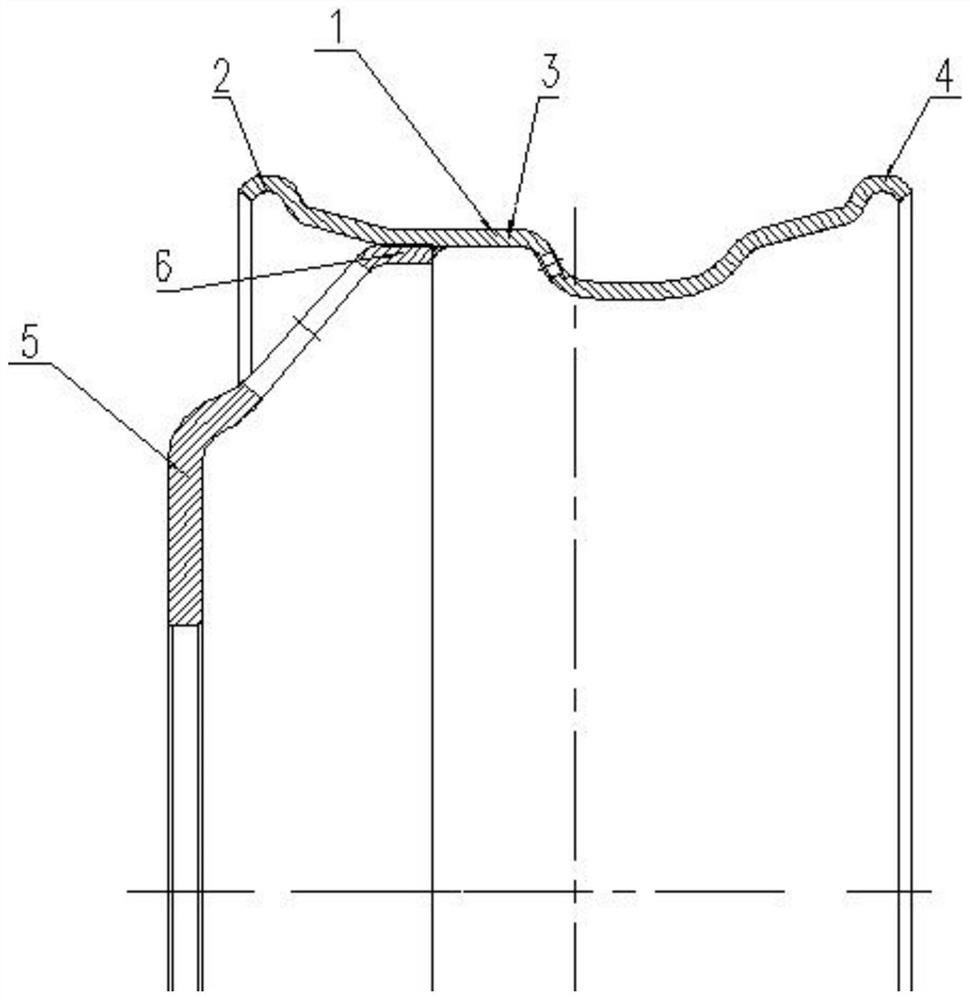

Double-channel MOSFET semiconductor device

The invention discloses a double-channel type MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) semiconductor device, which comprises a heavily doped N-type drain electrode layer positioned at the lower part of a silicon wafer and an N-type doped epitaxial layer positioned at the middle upper part of the silicon wafer, a left gate region and a right gate region which are respectively positioned at two sides of a convex part, the left gate region is located above the P-type left base region between the heavily doped N-type left source region and the central region, the right gate region is located above the P-type right base region between the heavily doped N-type right source region and the central region, and the right side and the lower part of the left gate region are electrically isolated from the P-type upper base region and the P-type left base region through a first insulating layer; and the left side and the lower part of the right gate region are electrically isolated from the P-type upper base region and the P-type right base region through a second insulating layer. According to the invention, the density of a current channel is effectively increased in a unit area, so that the on resistance of the device is effectively reduced, and the device also has a better voltage withstanding characteristic.

Owner:SUZHOU SILIKRON SEMICON CO LTD

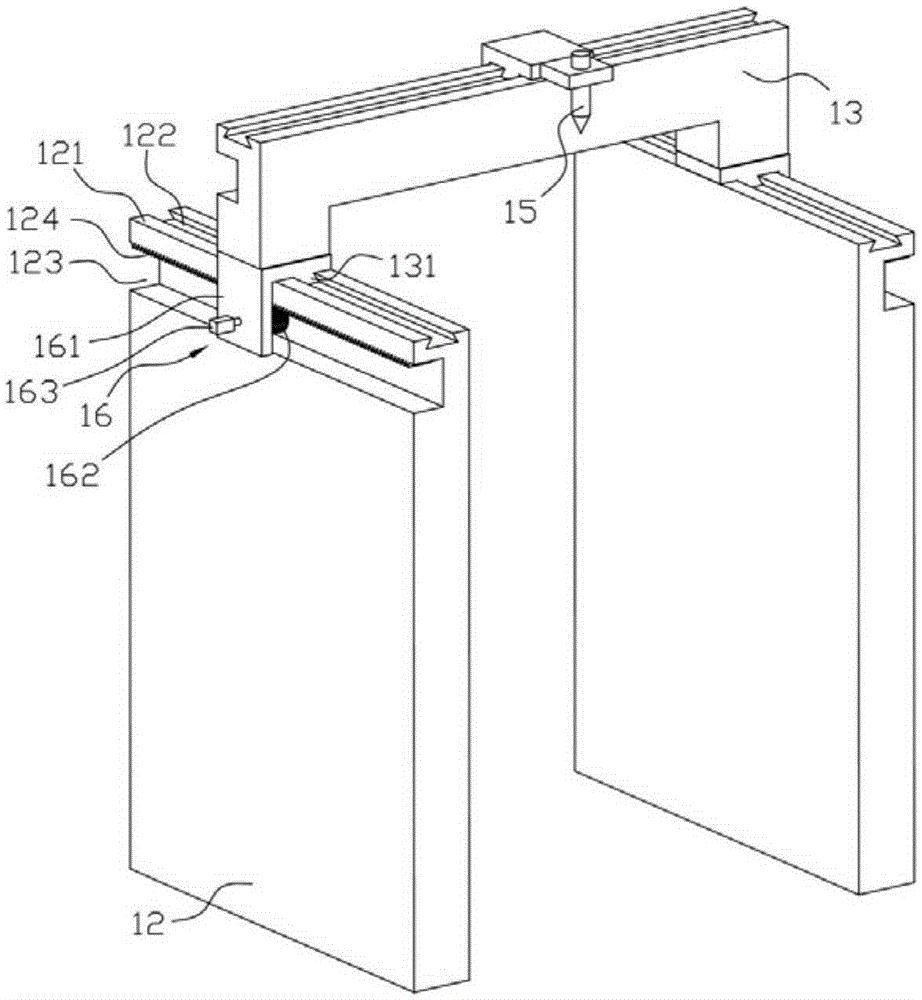

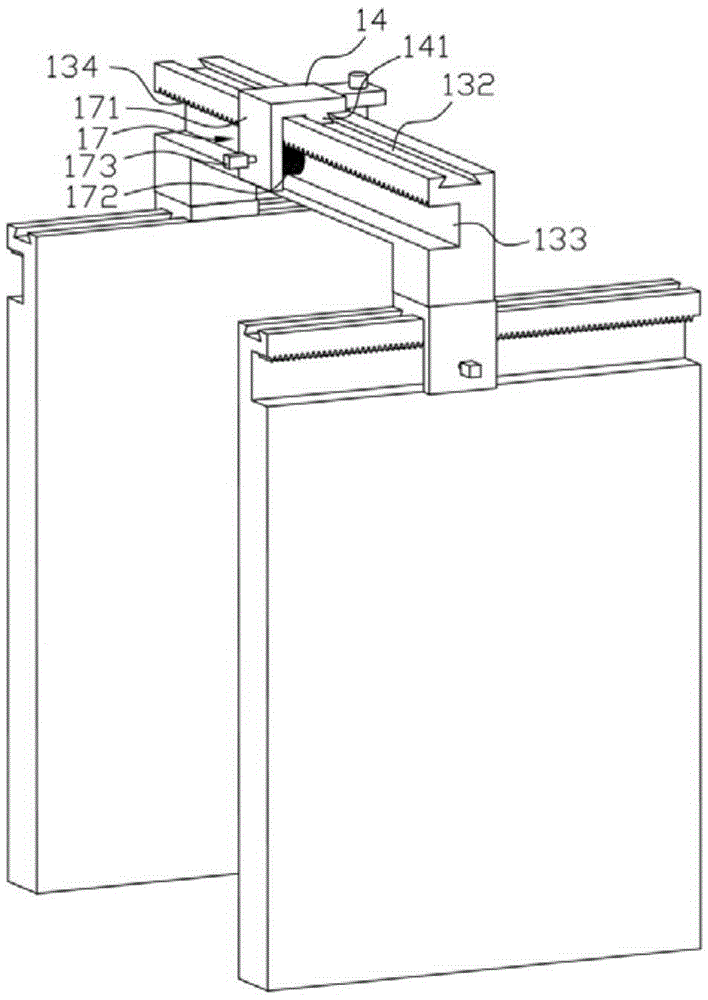

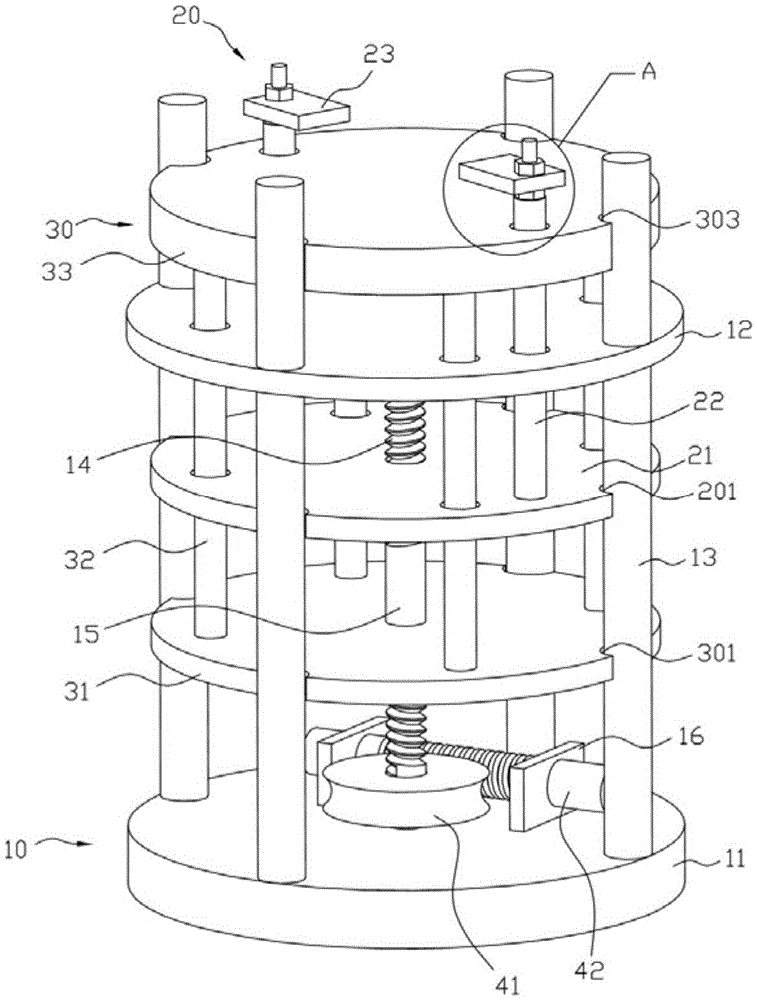

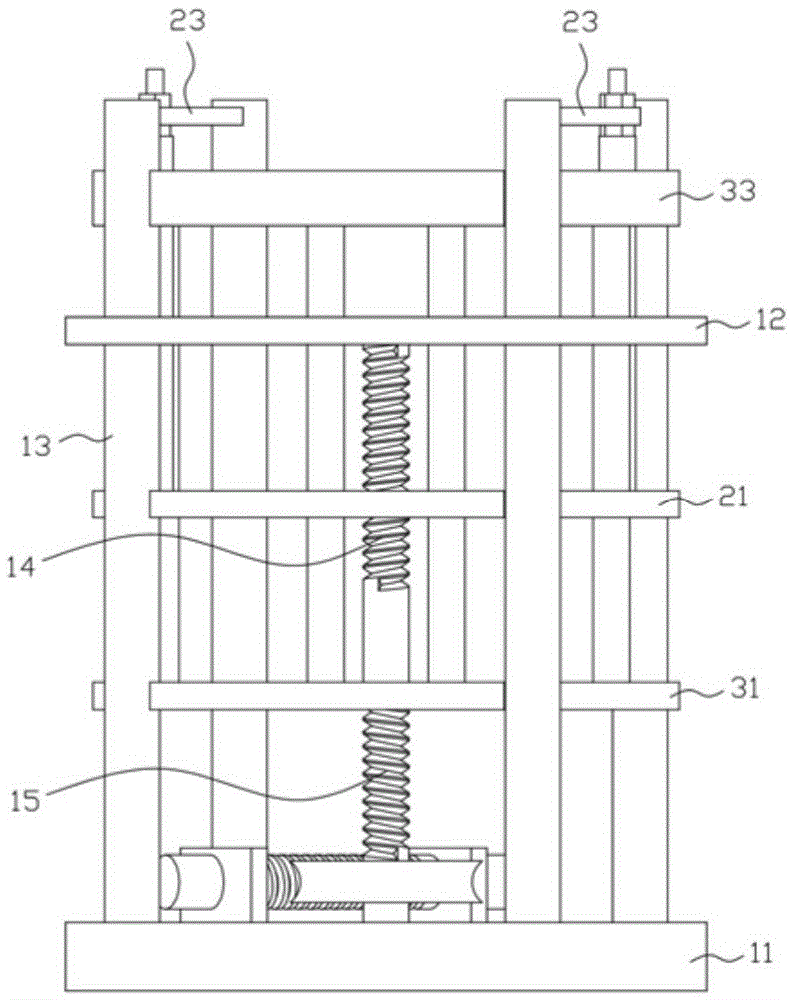

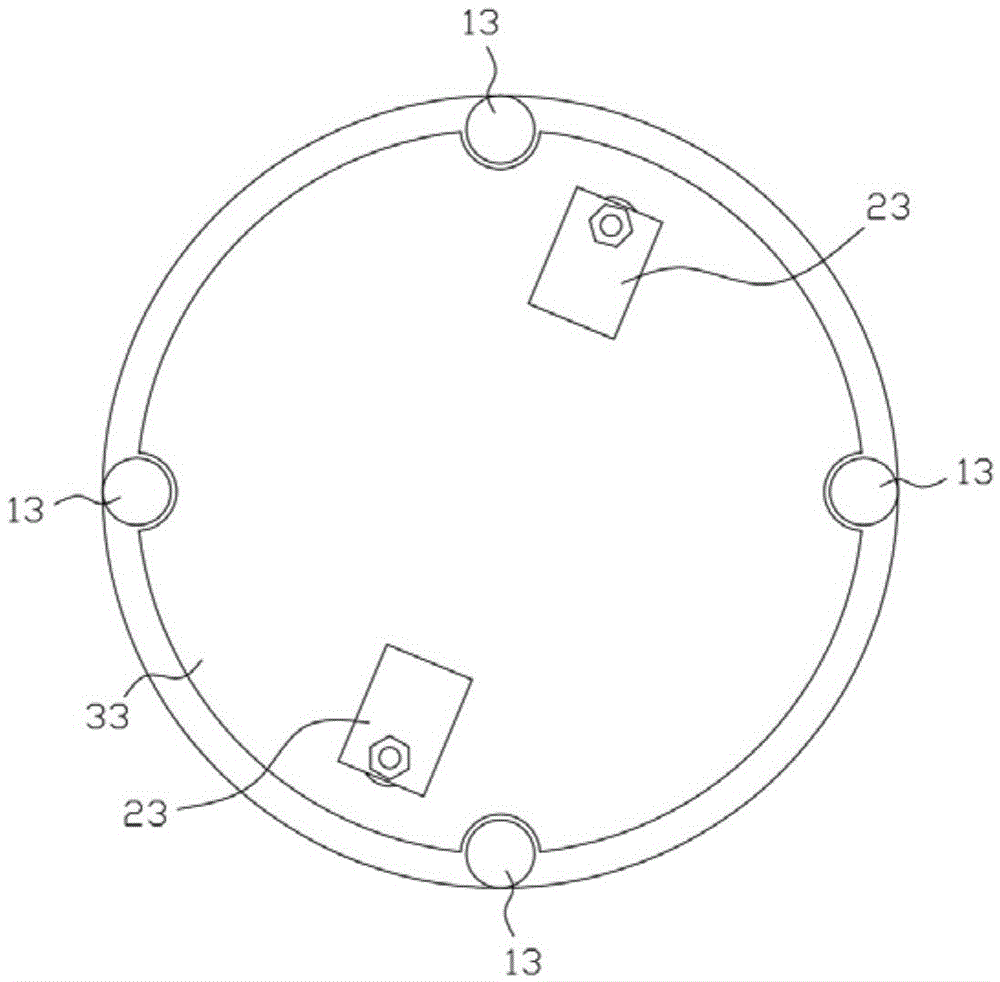

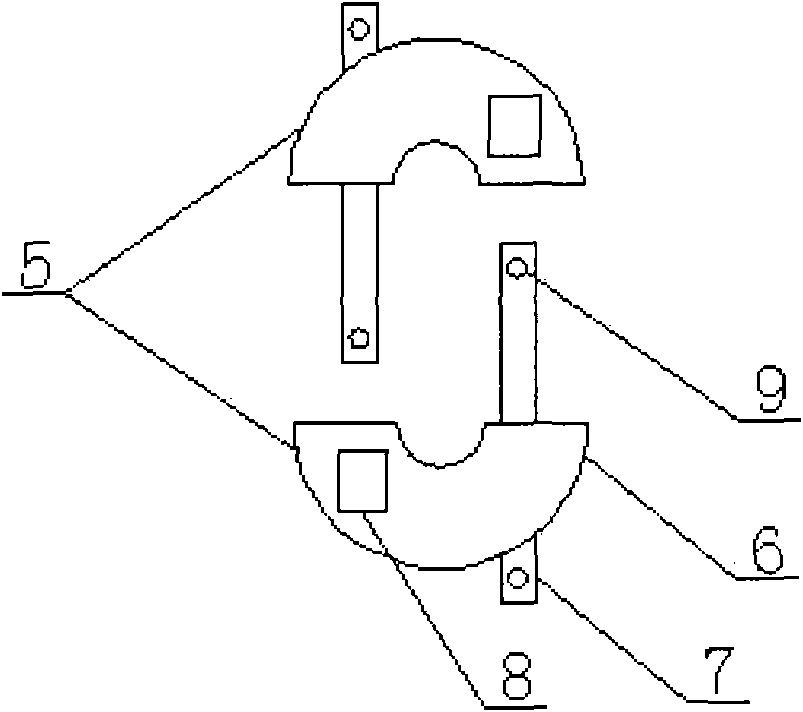

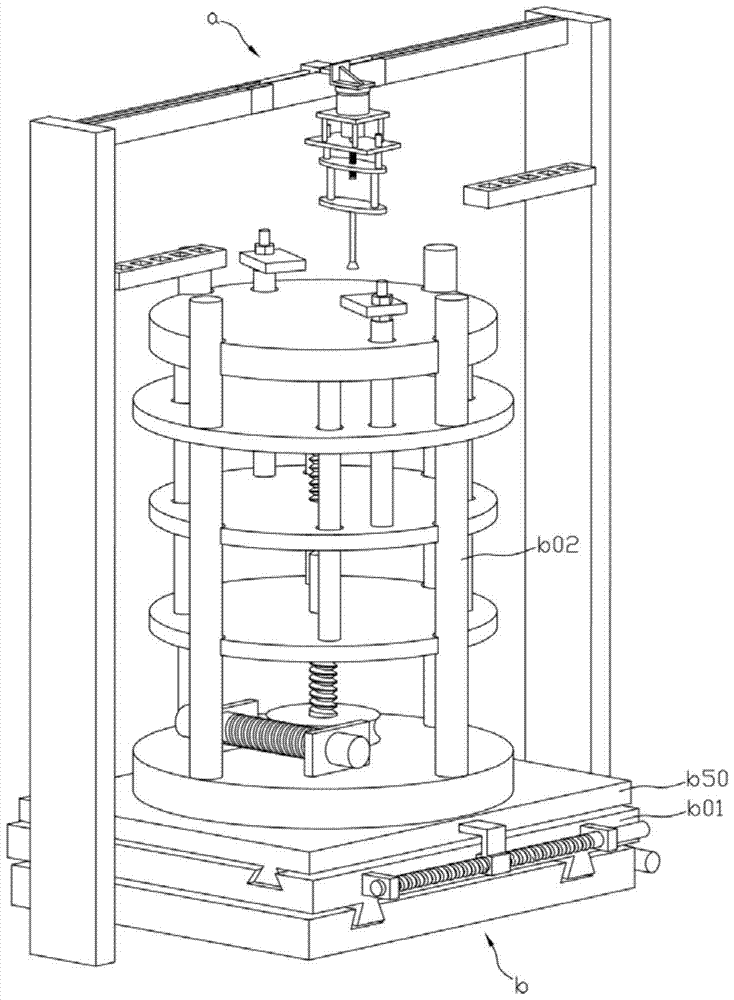

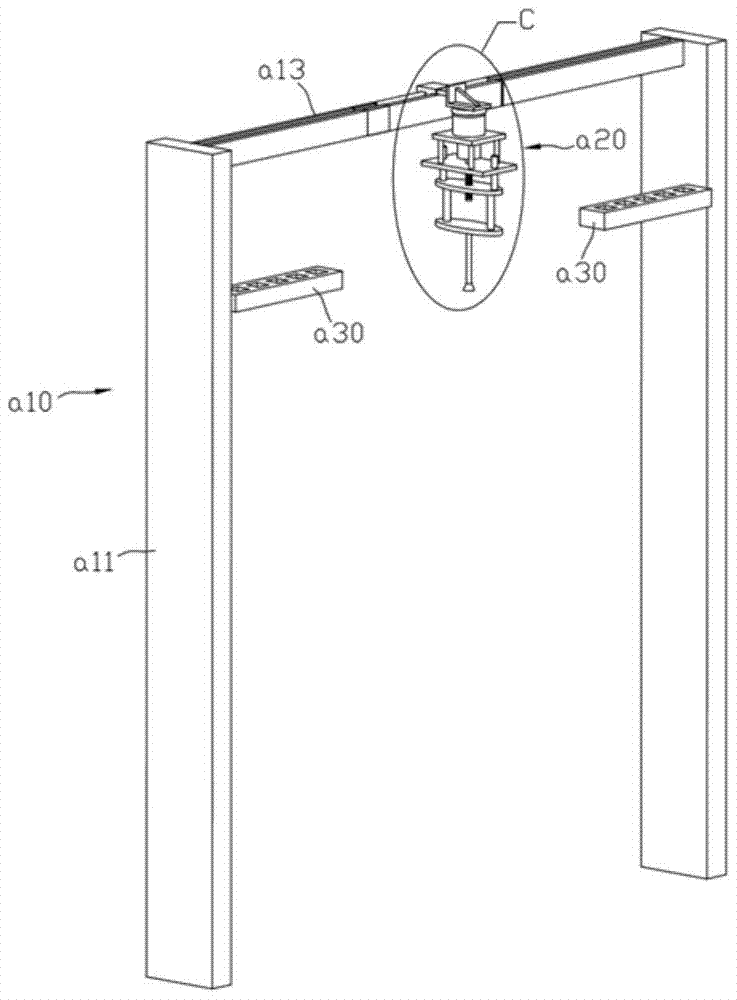

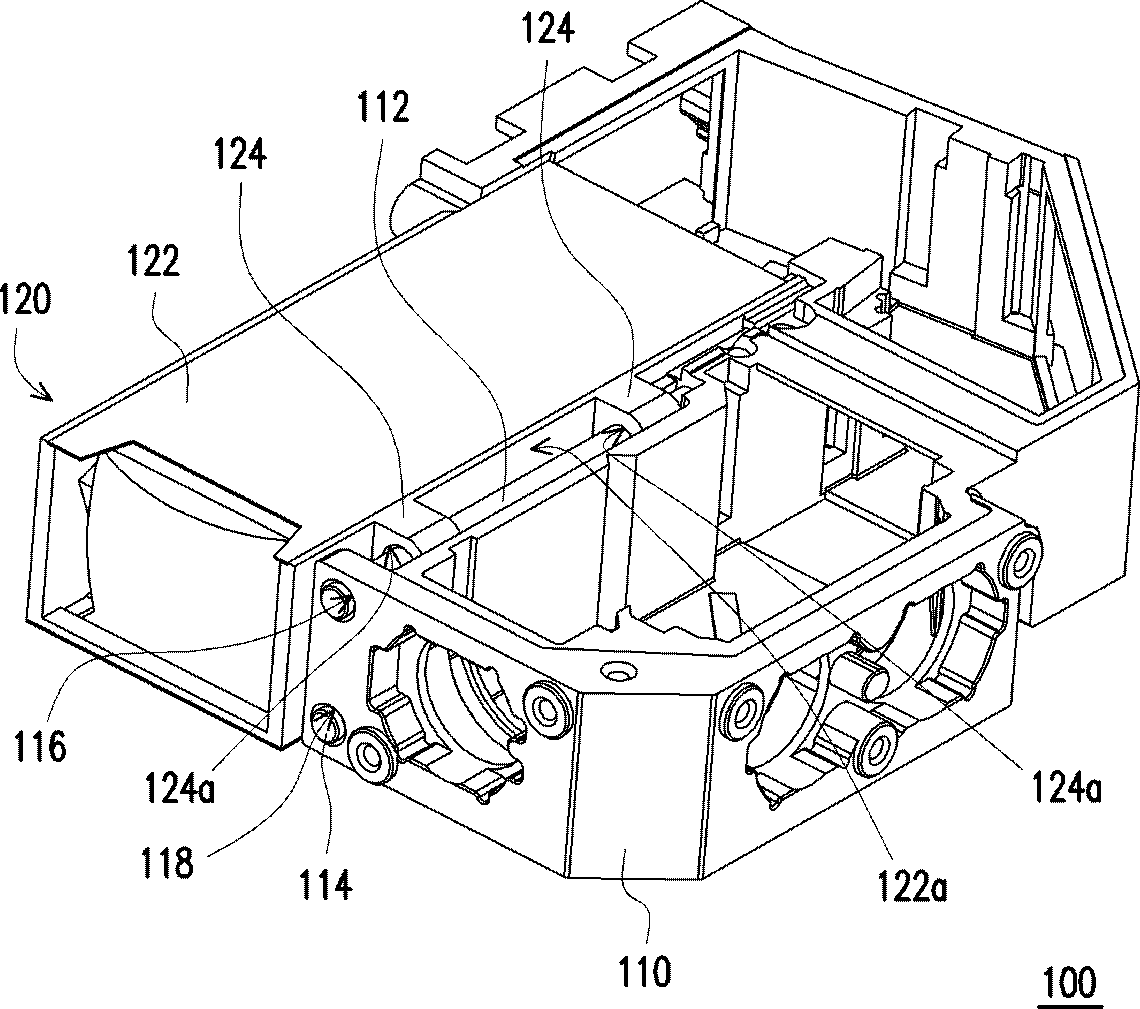

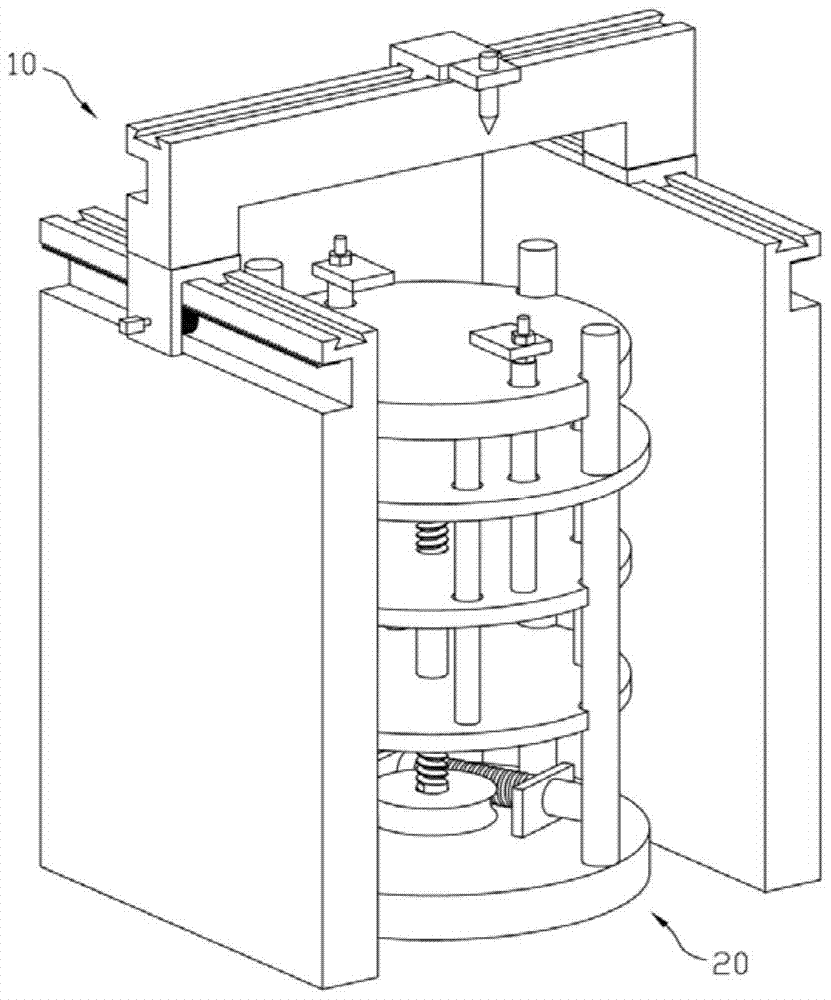

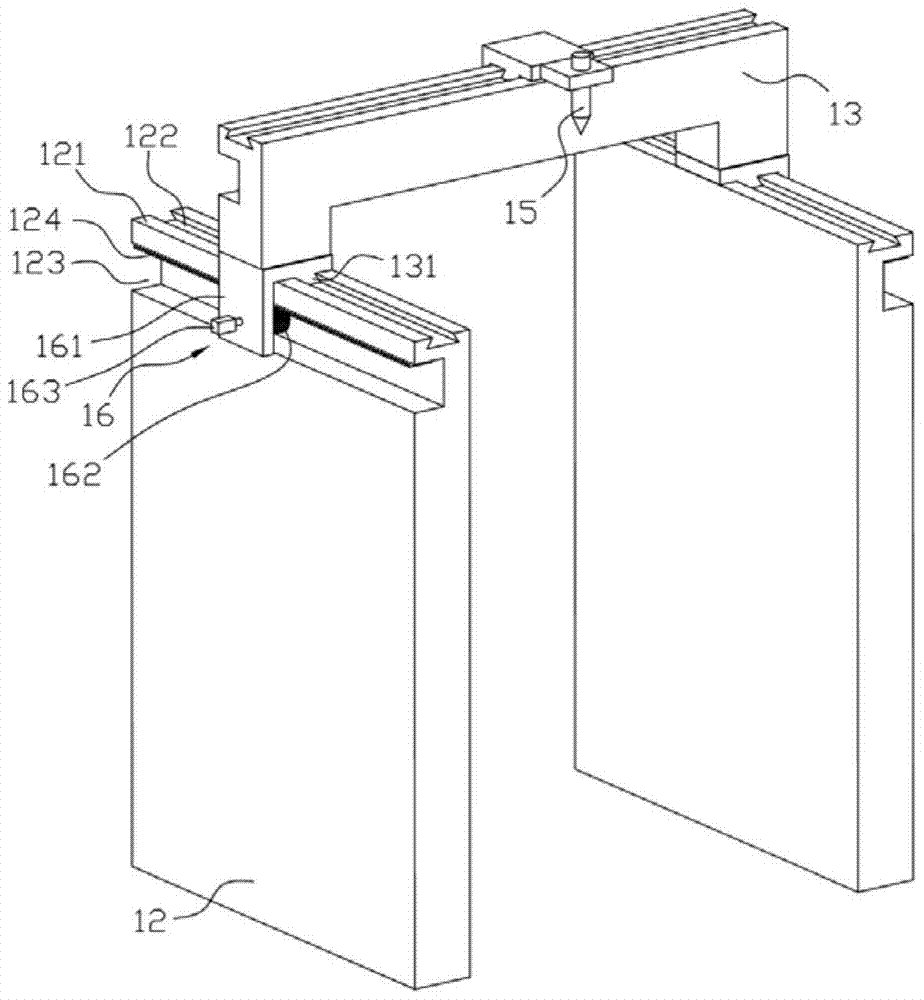

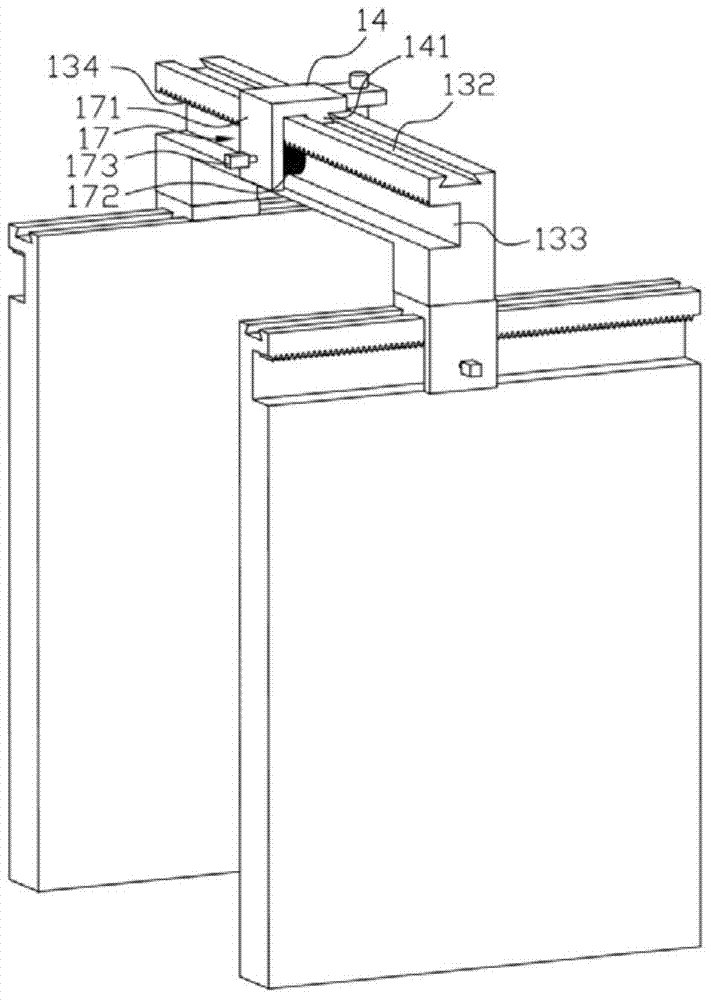

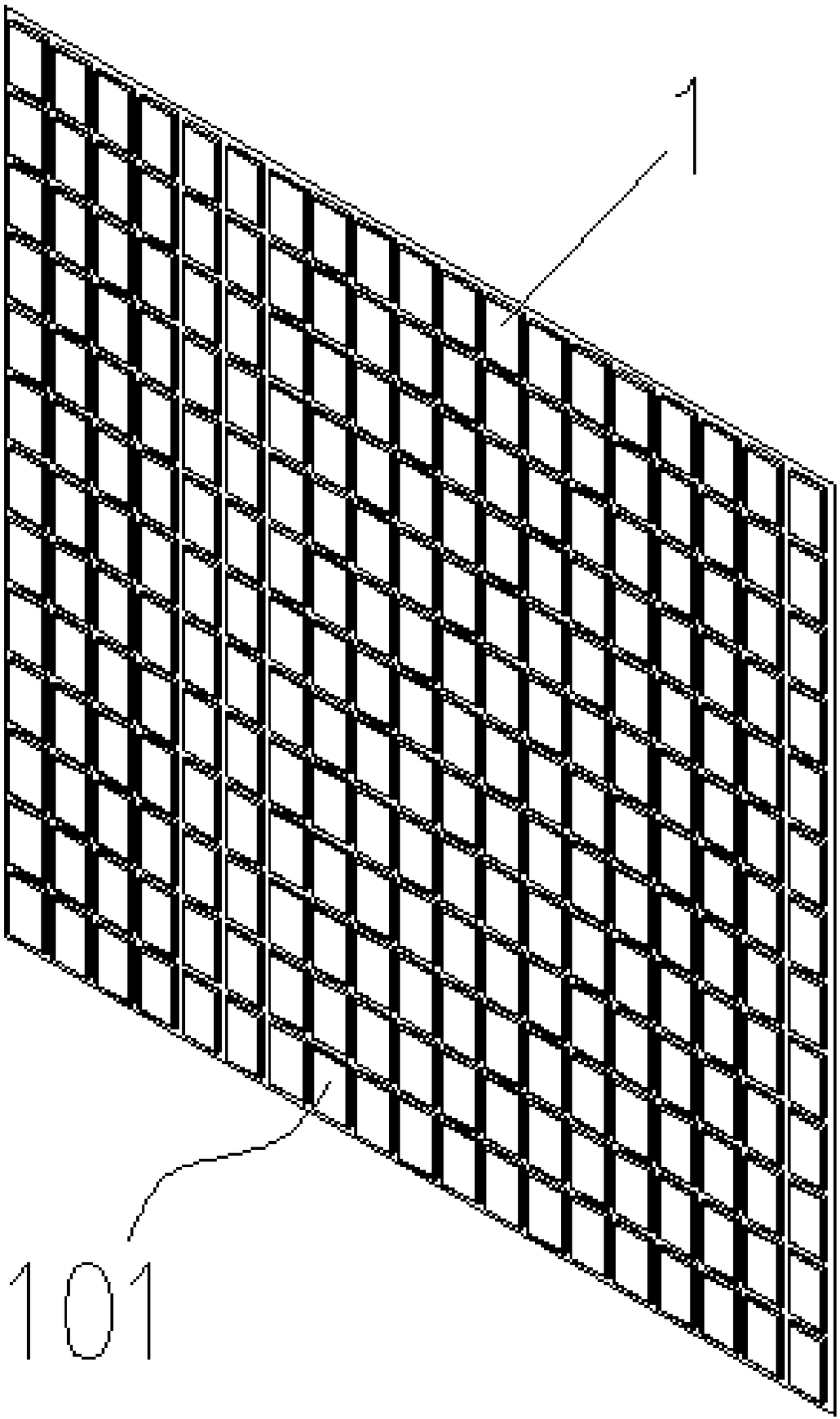

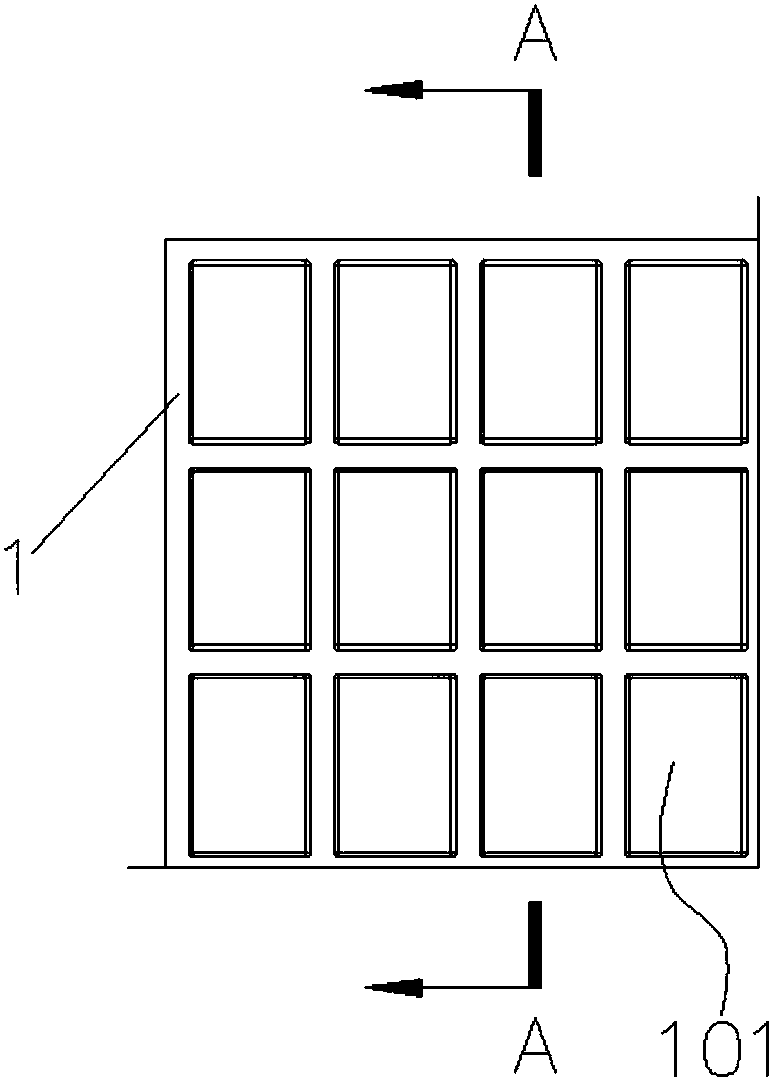

A bga placement system

ActiveCN105357898BSimple structureEasy to installPrinted circuit assemblingWork performanceSurface mounting

The invention discloses a BGA surface mounting system which comprises a surface mounting mechanism and a PCB positioning and adjusting mechanism. The PCB positioning and adjusting mechanism is placed under a crossbeam, and comprises a vertical and horizontal adjusting device and a positioning clamp mounted on the vertical and horizontal adjusting device; and in the positioning clamp, a fixation disk and locking blocks move up and down simultaneously to clamp a PCB on the fixation plate; the vertical and horizontal adjusting device moves the positioning clamp vertically and horizontally, so that BGA devices are in up and down correspondence with pad positions on the BCB, and then, reflow soldering is carried out. According to the technical scheme, the BGA surface mounting system is simple and reasonable in structure, convenient to install, simple in use and operation and high in working efficiency, the problem that BGA devices are hard to surface mount accurately on the PCB is effectively solved, the work performance is reliable, and the operation precision is high.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

Intelligent gate-type coke feeder and control method

ActiveCN102517045BRealize remote monitoringHigh degree of automationProgramme control in sequence/logic controllersDischarging devicesMotor driveAutomatic control

The invention relates to a coke feeder for a coke bench used for wet quenching in a coking plant and a control method for the coke feeder, in particular to an intelligent gate-type coke feeder. The intelligent gate-type coke feeder comprises a variable frequency motor, eccentric cranks, a brace, a plurality of reciprocating open doors with flexible guide rolls, wherein the brace adopts a structure with independent segments; the reciprocating open doors are arranged on the brace at intervals; each segment of the brace is connected with the variable frequency motor through an eccentric crank matched with the segment of the brace; the variable frequency motor drives the segment of the brace to move; a material detection device is arranged in a unit area of the coke bench; a plurality of cokeplacing positioning devices are arranged near a rail of a coke quenching vehicle; an electronic scale is arranged on the belt conveyor; and the material detection device, the coke placing positioningdevices, the electronic scale and the variable frequency motor are communicated with the PLC (Programmable Logic Controller) control system respectively. The method has the advantages that the degreeof automation is high; the automatic positioning of the coke quenching vehicle on the coke bench, the automatic control of delay coke feeding and the coke feeding quantity as well as unmanned operation can be realized; and the coke feeding quantity can be controlled effectively, so as to ensure uniform, safe and reliable coke feeding of a system.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Projection device and lens module

Owner:YOUNG OPTICS

Decoration line with groove embedding structure and production technology of decoration line

The invention discloses a decoration line with a groove embedding structure and a production technology of the decoration line. The decoration line comprises a line body and decoration strips; U-shaped grooves are formed in the line body; symmetric insertion grooves are formed in the two sides of the inner wall of each U-shaped groove; the decoration strips are inserted in the insertion grooves. By means of the decoration line, normalization, standardization and scale production can be achieved, the appearance is unified, moulding is uniform, the product dimension error is small, and the decoration line is convenient to install and low in manufacturing cost; the decoration line is free of chemical viscose, uniform in point of strength, healthy and environmentally friendly, and the phenomenon of bulging and shedding cannot occur.

Owner:麦耀伟

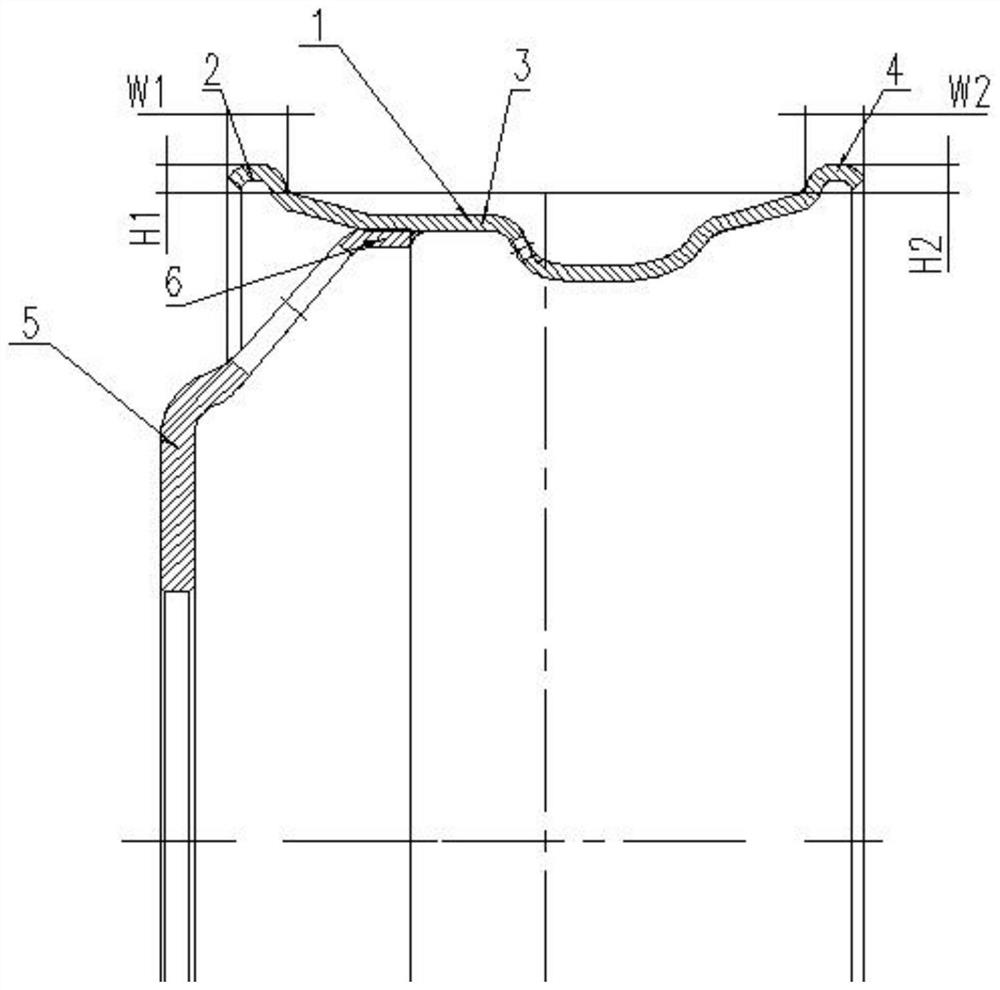

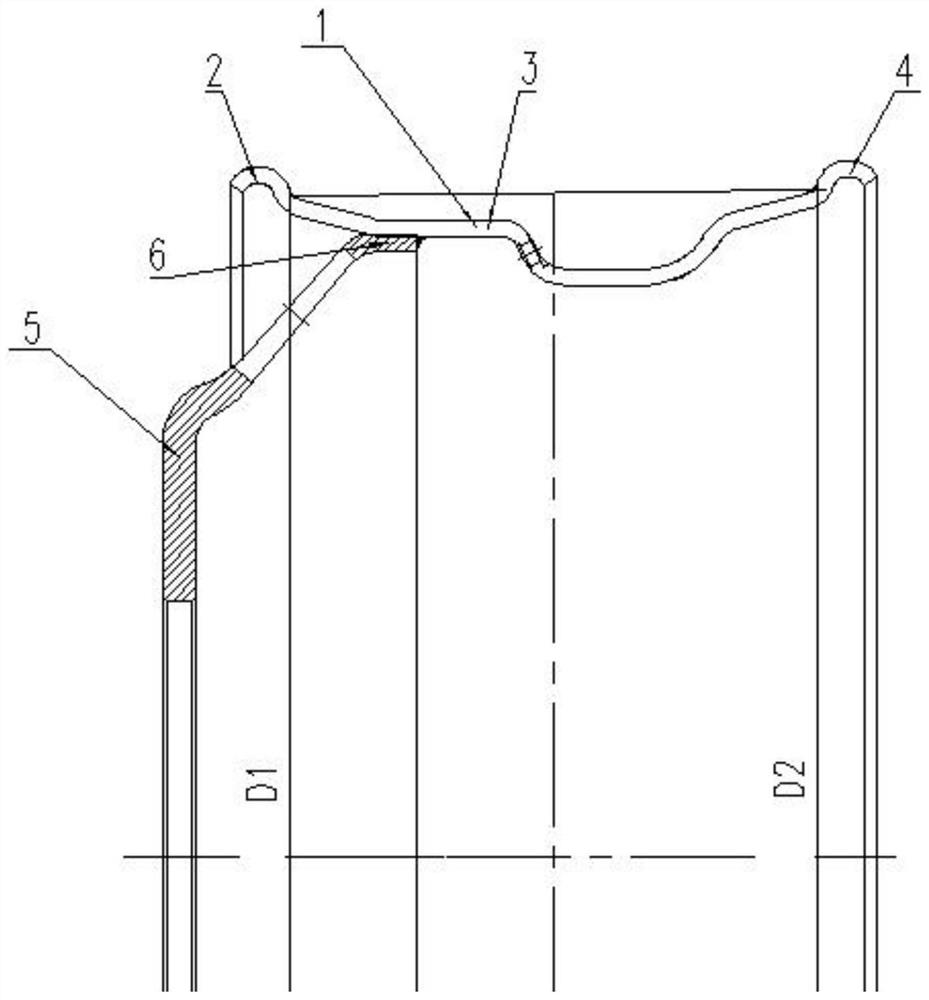

A rim and wheel with asymmetrical design of rims on both sides

Owner:东风汽车底盘系统有限公司

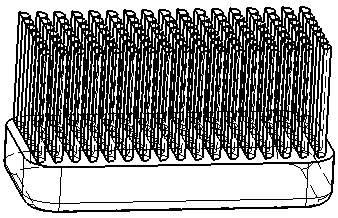

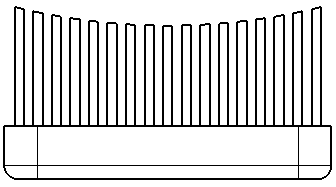

Brush hairs of toothbrush

The invention discloses brush hairs of a toothbrush. The brush hairs consist of two brush hair arrays, in an array structure that the long sides are configured as lines and the short sides are configured as columns, the central column is hollow, and the end surfaces of the two arrays are made into horizontal-lined planes, V-shaped inclined surfaces and V-shaped stepped surfaces, so that the brushhair arrays can form more contact surfaces which are in contact with teeth, so that the brush hairs can be more adhered with the teeth, and because of uniform stress, skewing and curling caused by stronger stress formed in the central column of the long lines of the brush hairs are reduced; moreover, the teeth can be cleaned more comfortably and high-effectively. The invention also discloses a manufacturing method of a brush hair mould and a brush hair molding method.

Owner:刘广

A laser template cutting machine

InactiveCN105397309BShort operating timeSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser beams

The invention discloses a laser template cutting machine which comprises a cutting mechanism and a template fixture, wherein the cutting mechanism comprises a laser head; the laser head performs two-dimensional motion through an X-direction slide and Y-direction slides; and the template fixture is positioned between a pair of rack plates of the cutting mechanism and is positioned below the laser head. According to the laser template cutting machine, workpieces to be cut are located through the template fixture, and templates are cut through laser beams, so that the speed is high, the efficiency is high, and the cutting is smooth, fluent and neat.

Owner:苏州市众鑫激光科技有限公司

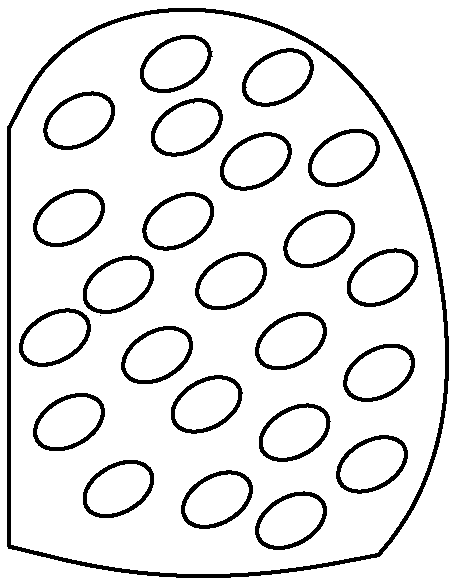

Plastic method of ear cavity and ear canal deformity

ActiveCN108743031AEvenly focusedComfortable to wearEar treatmentIndividualized treatmentCavum Conchae

The invention relates to a plastic surgery method, in particular to a plastic method of ear cavity and ear canal deformity. The method is to mix ear-print A material with ear-print B material to formear-print mixed material, the ear-print mixed material is injected into the ear cavity and the ear canal, after the ear-print mixed material is molded and the ear-print mixed material is removed, themodel precursor is formed, the ear canal part of the model precursors is pinched into a cylindrical, the ear-print mixed material is injected into the grooves of the ear cavity part, the groove is filled to form the plane, after molding, an ear cavity and ear canal mold is formed; the ear cavity and ear canal model is inserted into the ear cavity and the ear canal, and a base and an outer cover are used to fix. The plastic method of ear cavity and ear canal deformity adopts individualized treatment to customize the ear cavity and ear canal model for different patients, and the ear cavity and ear canal model is even and comfortable, which greatly reduces the incidence of complications such as ulcers, and can make perfect auricle and ear canal and solves the individual problem of each patient.

Owner:韩军宁

Focusing method and camera equipment based on shooting scene

ActiveCN105472248BImprove experienceEfficient focusTelevision system detailsColor television detailsComputer visionImaging data

Owner:成都全景智能科技有限公司

Automatic positive pressure thrombosis-resistant venous indwelling needle

PendingCN110812594AAchieve double anti-bleeding effectRealize cut-offInfusion needlesFlow controlThrombusEngineering

The invention belongs to the technical field of medical apparatuses, and discloses an automatic positive pressure thrombosis-resistant venous indwelling needle. The automatic positive pressure thrombosis-resistant venous indwelling needle comprises a front tee, a rear tee and a transfusion hose, wherein the front tee communicates with the rear tee through the transfusion hose; the automatic positive pressure thrombosis-resistant venous indwelling needle further comprises a liquid stopping clip, wherein a second lug is arranged on the inner side of the liquid stopping clip; the second lug is provided with a guiding route; and the transfusion hose penetrates through the liquid stopping clip. According to the automatic positive pressure thrombosis-resistant venous indwelling needle disclosedby the invention, automatic pressurization can be realized; and through combined action of the liquid stopping clip and the transfusion hose, the effect of preventing blood return can be realized, sothat formation of thrombosis is avoided.

Owner:薛玉民

Panel lamp lining pad of thin shell and convex curved surface arch-shaped structure

PendingCN109210390AEvenly focusedSolve problems that arise on a large scaleProtective devices for lightingLight fasteningsThin shellsLight guide

The invention belongs to the field of LED panel lamps, and particularly relates to a panel lamp lining pad of a thin shell and convex curved surface arch-shaped structure. The panel lamp lining pad comprises a lining pad body. A plurality of elastic protrusions are evenly distributed on the plate face of the lining pad body. The heights of all the elastic protrusions on the plate face of the lining pad body are equal. The panel lamp lining pad has the beneficial effects that a rear cover plate press a panel lamp in an abutting mode structurally, the elastic protrusions on the lining pad body can tightly press a light guiding plate into a profile frame structure in an abutting mode, thus the central lines of both a light emitting strip and the light guiding plate are always kept consistentwithout dislocation, light brightness is uniform, light leakage of the edge is avoided, and the light leakage problem caused by dislocation is solved accordingly; and the elastic protrusions are evenly distributed and arranged, thus force bearing of all the elastic protrusions can be even, all the elastic protrusions press a reflection film in an abutting mode, microscopic arching or rising and falling of the reflection film is avoided, accordingly the problem of large-area water ripples is solved, and it is ensured that the light surface is uniform and attractive.

Owner:JIANGSU SUN & MOON LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com