A bga placement system

A mounting system and mounting technology, applied in the direction of assembling printed circuits with electrical components, electrical components, printed circuit manufacturing, etc., can solve the problems of manual mounting of IC devices such as BGA, etc., to solve the problems of precise mounting and operation. High precision and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

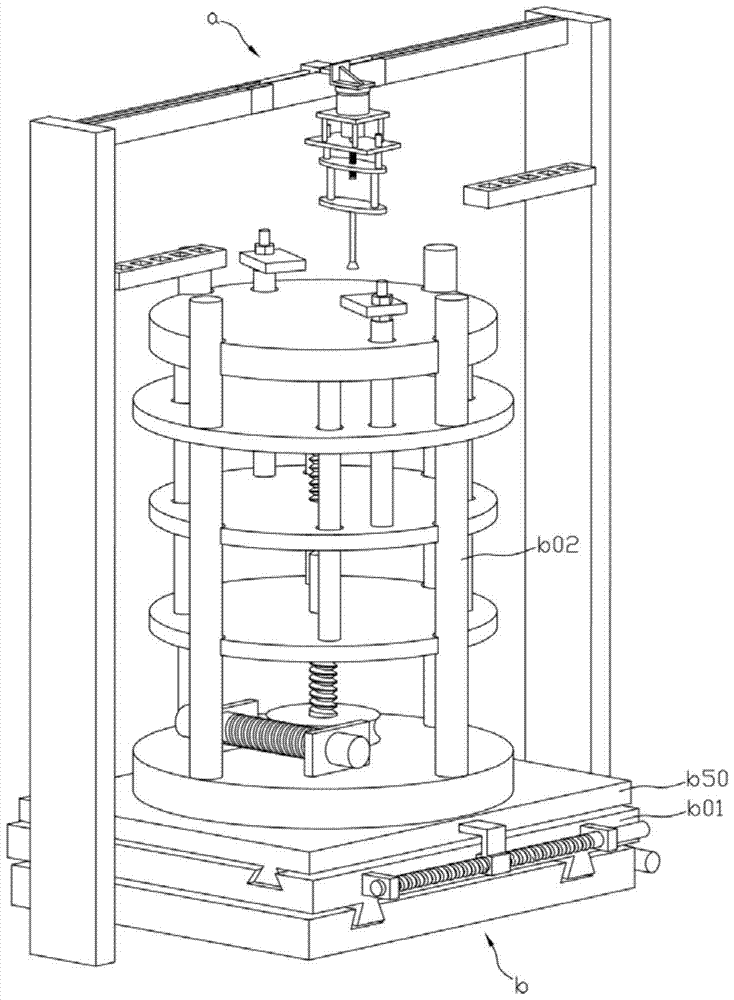

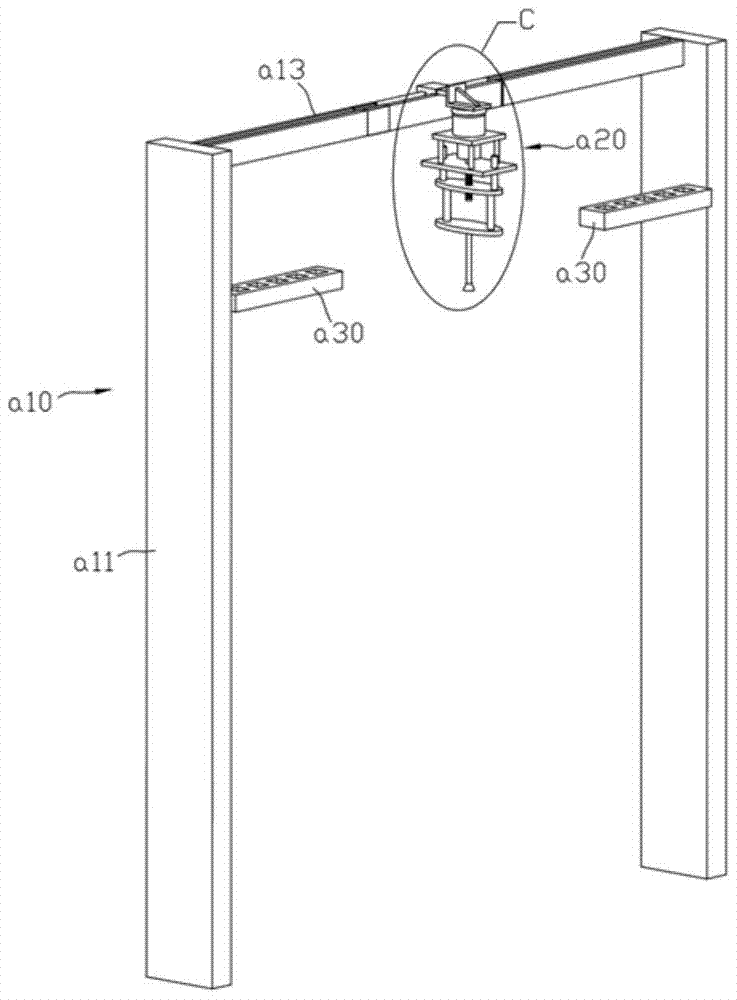

[0054] Such as figure 1 , a BGA placement system, comprising a placement mechanism a, and a PCB board positioning adjustment mechanism b.

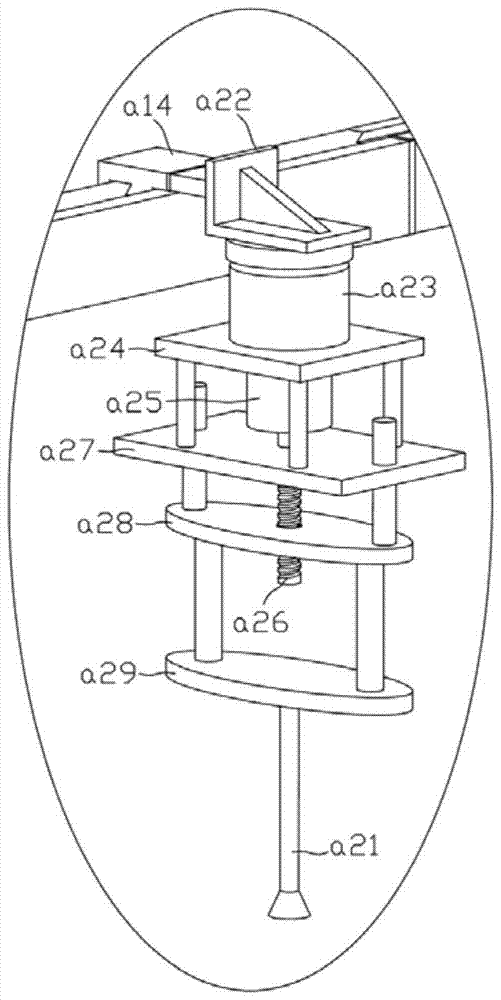

[0055] combine Figure 2 to Figure 5 , the mounting mechanism a includes a mounting frame a10, the mounting frame includes a pair of vertical mounting support plates a11, the top of the mounting support plate is fixedly installed with a crossbeam a13, and the crossbeam is provided with There is a horizontal slideway, the sliding block a14 is slidably fitted on the horizontal slideway, the drive unit that drives the sliding block to move along the horizontal slideway is installed on the beam, the mounting assembly a20 is installed on the sliding block, and the mounting assembly It includes a picking mechanism for picking up BGA devices and an alignment adjustment mechanism for adjusting the alignment of the picking mechanism; both sides of the mounting frame are provided with BGA storage tables a30 for placing BGA devices to be mounted.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com