A rim and wheel with asymmetrical design of rims on both sides

An asymmetrical and rim-based technology, which is applied to rims, vehicle parts, transportation and packaging, etc., can solve the problems of reduced tire service life, tire partial wear, and large tire wear, so as to eliminate tire partial wear, uniform force, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

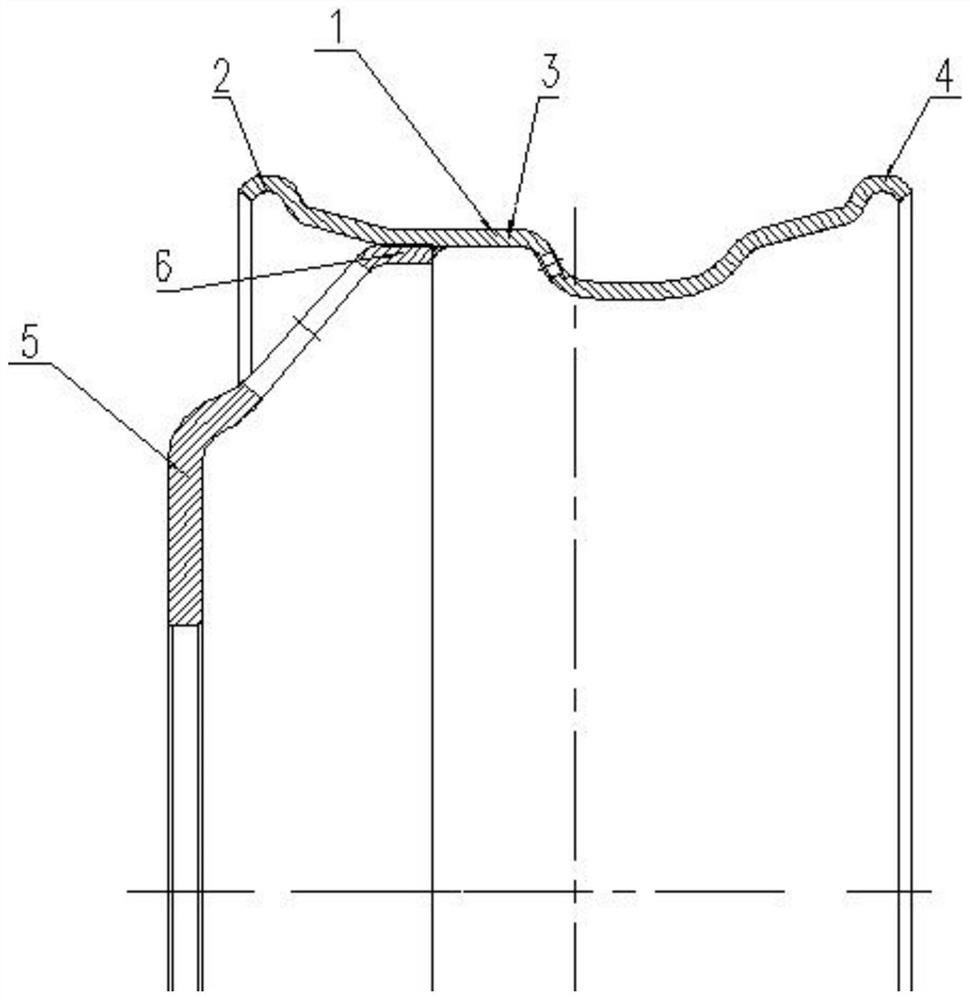

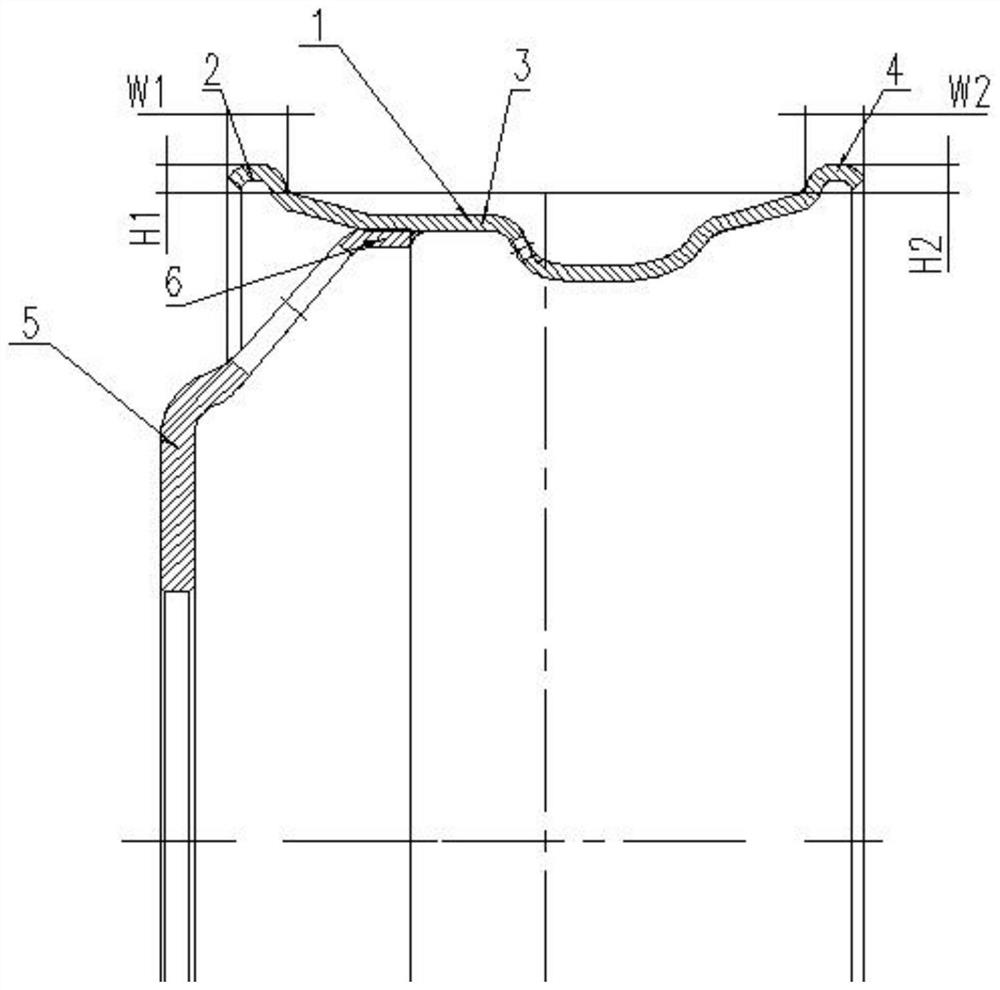

[0029] figure 2 , W1 is the width of the proximal rim 2, that is, the horizontal distance from the connection between the proximal rim 2 and the intermediate portion 3 to the end of the proximal rim 2; H1 is the height of the proximal rim 2, that is, the close The vertical distance from the junction of the end rim 2 and the middle part 3 to the top of the proximal rim 2 .

[0030] W2 is the width of the distal rim 4, that is, the horizontal distance from the connection between the distal rim 4 and the intermediate portion 3 to the end of the distal rim 4; H2 is the height of the distal rim 4, that is, the distal rim The vertical distance from the junction of the rim 4 to the intermediate portion 3 to the top of the distal rim 4 .

[0031] like figure 2 As shown, the nominal diameter and hook length of the proximal rim 2 and the distal rim 4 are equal, but the width W2 of the distal rim 4 is 105%-130% of the width W1 of the proximal rim 2, and the distal The height H2 of t...

Embodiment 2

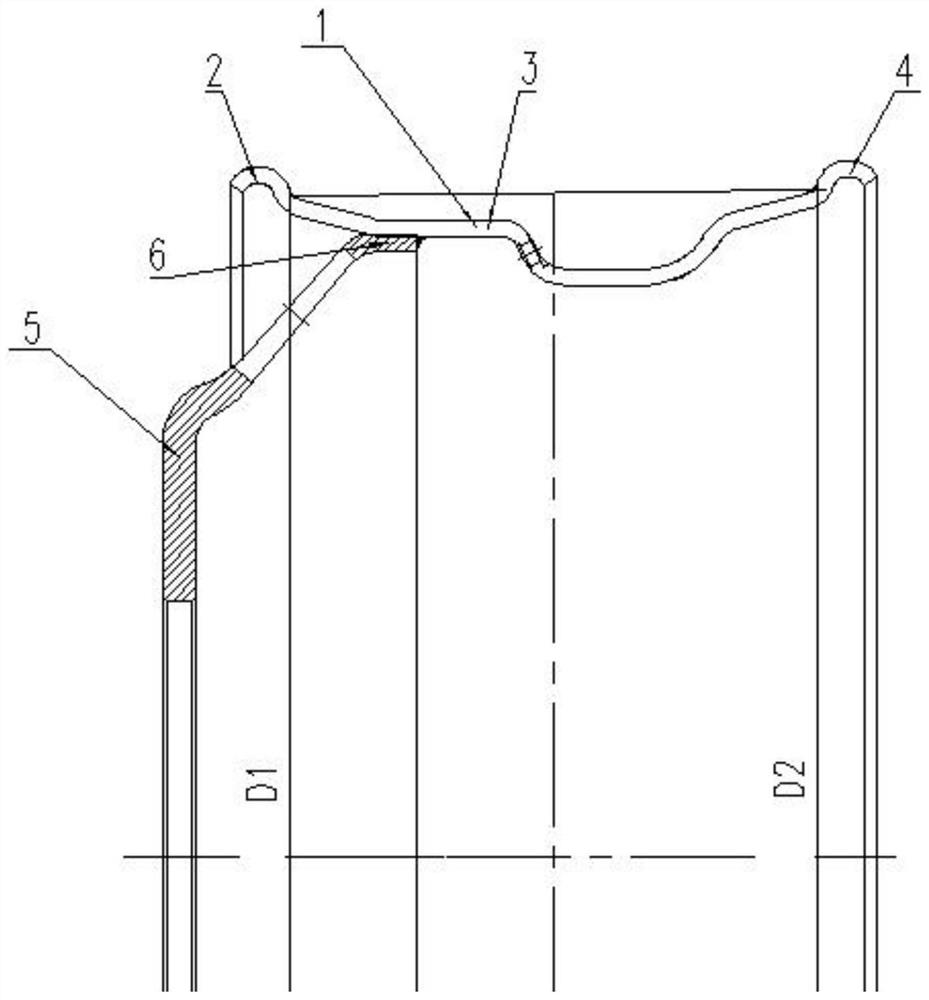

[0033] image 3 , D1 is the calibrated diameter of the proximal rim 2, that is, the outer diameter of the connection between the proximal rim 2 and the middle part 3; D2 is the calibrated diameter of the distal rim 4, that is, the distal rim 4 and the middle part 3 outside diameter of the junction.

[0034] like image 3 As shown, the width, height and hook length of the proximal rim 2 and the distal rim 4 are equal, but the nominal diameter D2 of the distal rim 4 is 1-2 mm larger than the nominal diameter D1 of the proximal rim 2 . Taking a 22.5X9.00 15° deep groove rim as an example, the calibrated diameter D2 of the distal rim 4 is set to Φ573.0±0.4mm, and the calibrated diameter D1 of the proximal rim 2 is set to Φ571.5±0.4mm.

Embodiment 3

[0036] Figure 4 , L1 is the hook length of the proximal rim 2, the vertical distance from the end of the proximal rim 2 to the top of the proximal rim 2; L2 is the hook length of the distal rim 4, the distal rim The vertical distance from the end of the rim 4 to the top of the distal rim 4 .

[0037] like Figure 4 As shown, the width, height and nominal diameter of the proximal rim 2 and the distal rim 4 are equal, but the hook length L2 of the distal rim 4 is 140%-180% of the hook length L1 of the proximal rim 2 %. Taking a 22.5X9.00 rim with a 15° deep groove as an example, the hook length L2 of the distal rim 4 is set to 17 mm, and the hook length L1 of the proximal rim 2 is set to 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com