Wheel type air pick energy storage coke removing machine

An energy storage, wheeled technology, used in lighting and heating equipment, etc., to achieve stable, firm, and excellent effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

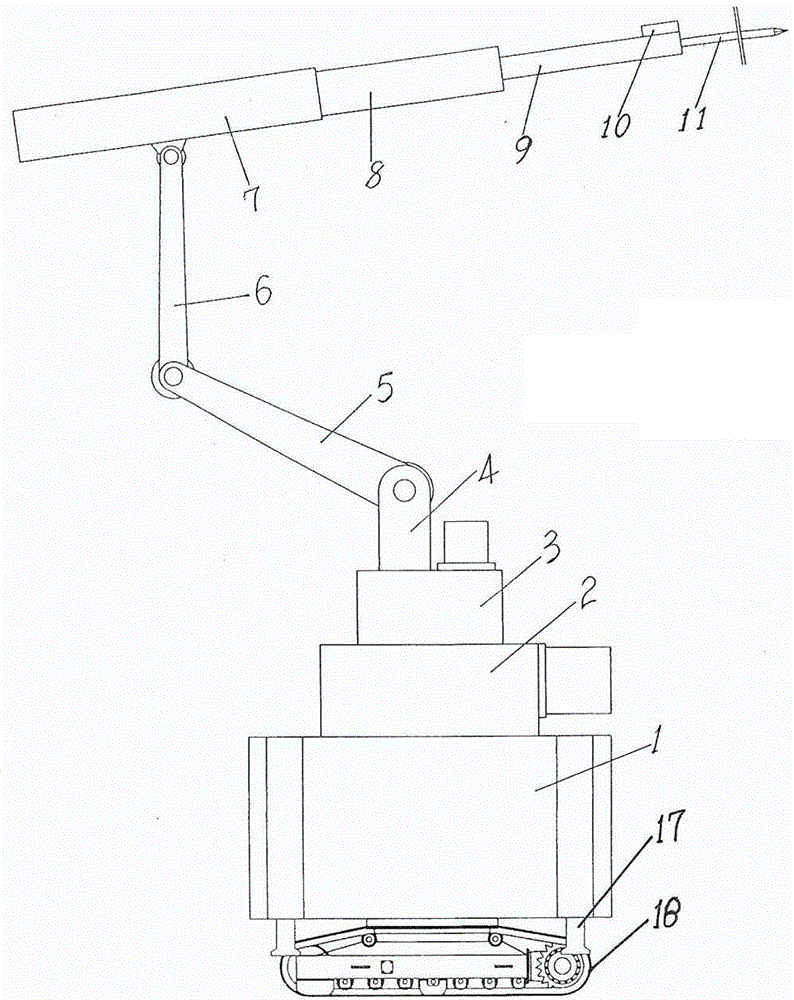

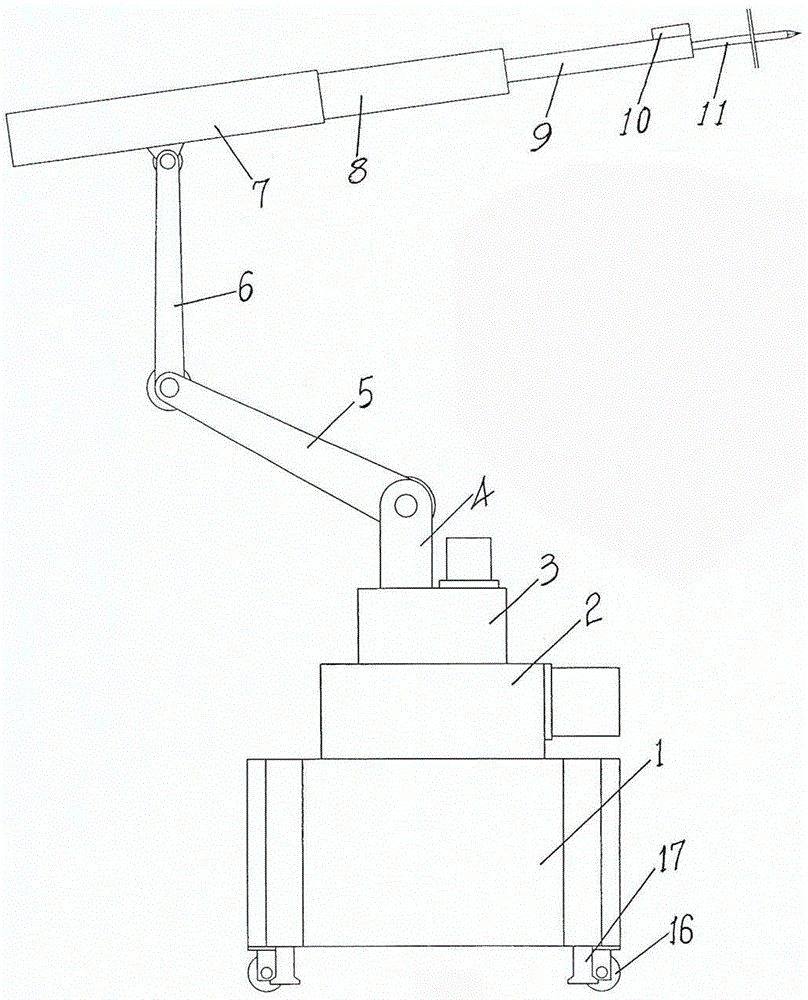

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 Shown:

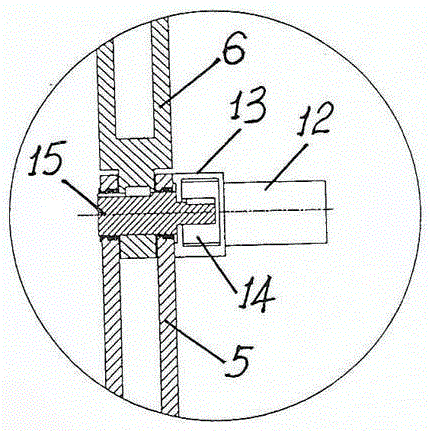

[0040] A wheel-type pneumatic pick energy storage coke machine, which consists of a frame plate 1, a rotating body 2, a frame body 3, a lifting arm 4, a main arm 5, a linkage arm 6, a sleeve 7, a telescopic tube 8, a pneumatic pick 9, and a camera 10. Steel drill 11, servo motor 12, reducer 13, reduction gear 14, rotating shaft 15, wheel 16, support 17, crawler belt 18;

[0041] The wheel-type pneumatic pick energy storage coking machine, the bottom end of its frame plate 1 is connected flexibly with the wheel 16, the frame plate 1 is fixedly connected with the pneumatic device, and the output end of the pneumatic device is connected with the upper end of the support 17. The ring gear on the disk 1 is engaged with the ring gear on the output shaft of the gearbox connected to the rotary motor on the rotating body 2, and...

specific Embodiment approach 2

[0051] Carried out on the basis of specific implementation mode 1 implementation, just as the description attached figure 2 , 3 Shown, just: described wheel 16 is replaced by crawler belt 18, and the bottom end of described frame dish 1 and wheel 16 rotation live connection are replaced by the bottom end of frame dish 1 and the supporting crawler belt shaft of crawler belt 18 rotation live connection, In this way, the key technology of "wheel type walking and pneumatic pick energy storage" has been transformed into the key technology of "crawler type walking and pneumatic pick energy storage". At the same time, the "wheel type pneumatic pick energy storage coking machine" has been transformed It has become another new product of "crawler type pneumatic pick energy storage coking machine". Good results were obtained as expected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com