Laser template cutting machine

A laser template and cutting machine technology, applied in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of inability to complete, large size, large platform, etc., and achieve short operation time, high production efficiency, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

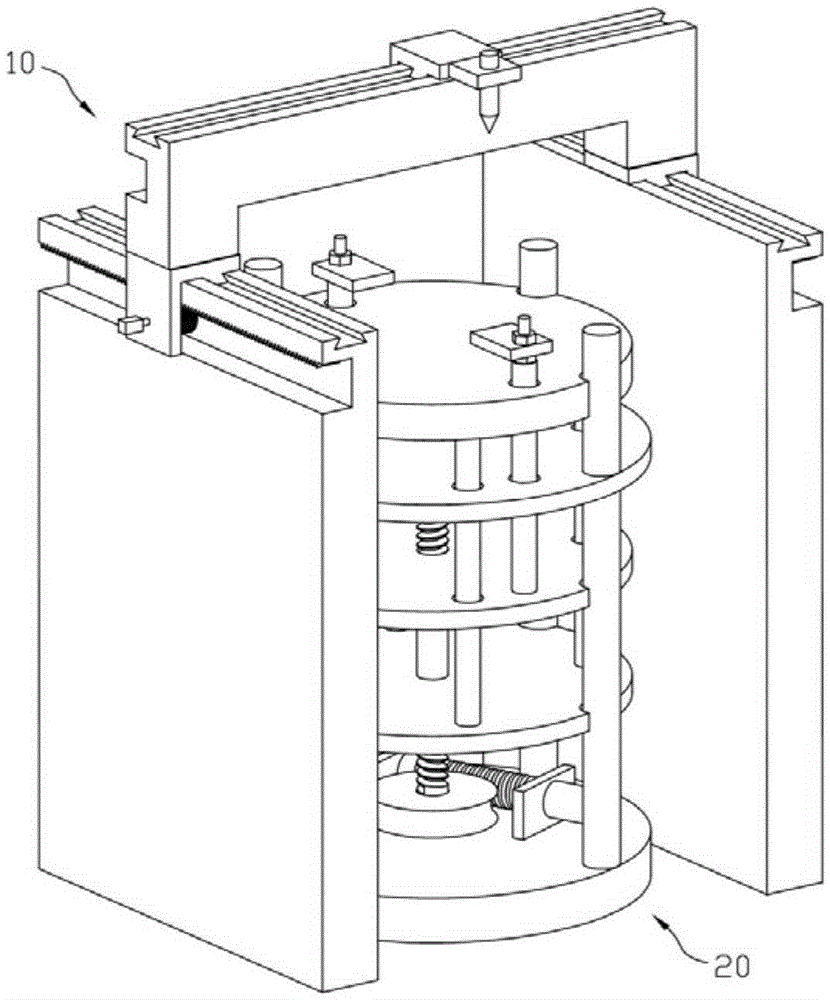

[0039] Such as figure 1 , a laser template cutting machine, including a cutting mechanism 10 and a template clamp 20.

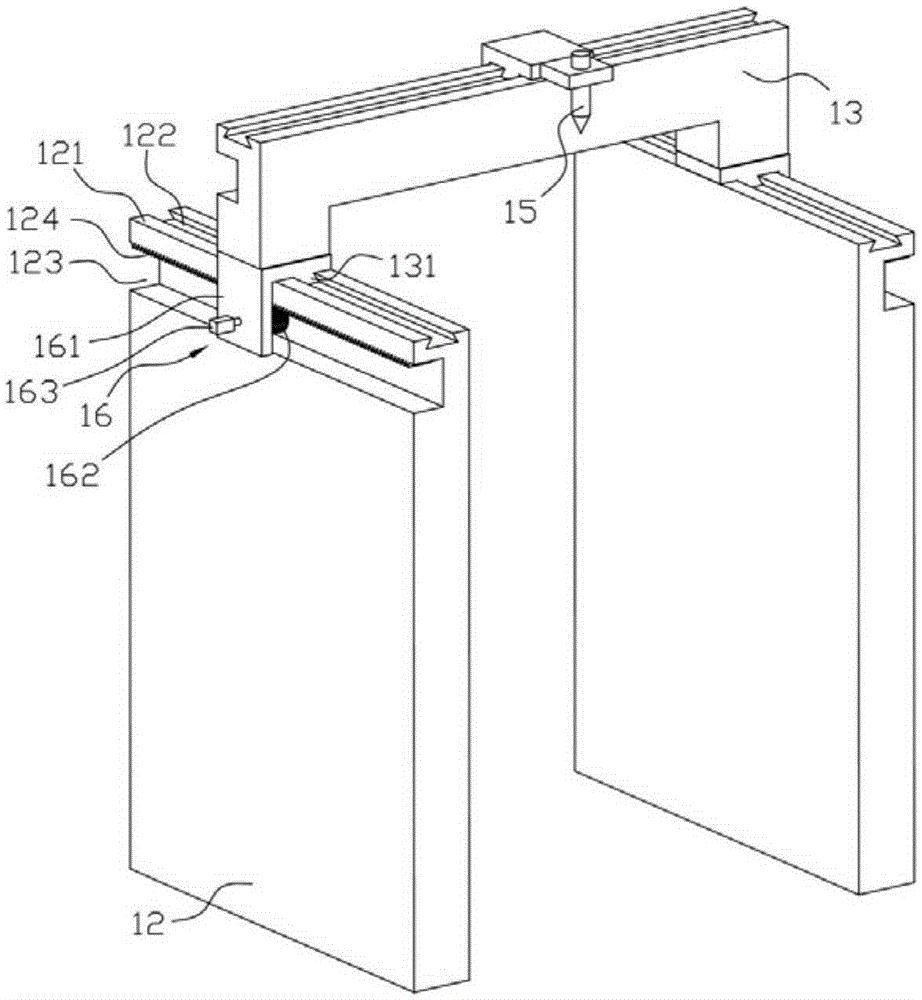

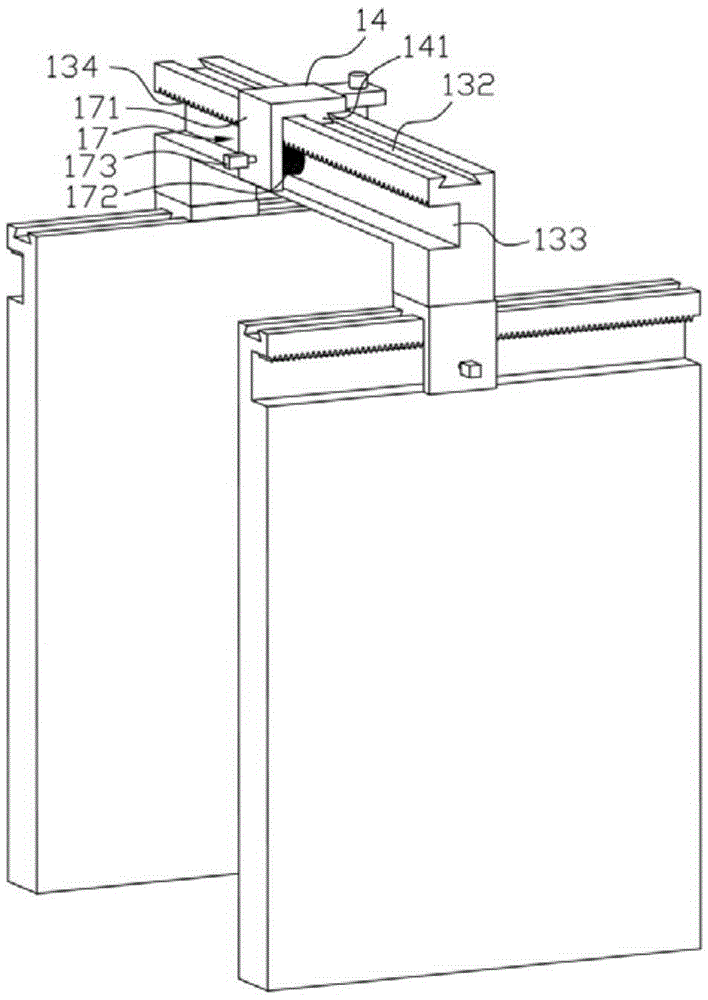

[0040] combine figure 2 , image 3 , the cutting mechanism 10 includes a pair of frame plates 12 arranged left and right, a beam 13 spanning a pair of frame plates, a laser frame 14 installed on the beam, a laser head 15 installed on the laser frame; the pair A Y-direction slideway is provided on the frame plate, and an X-direction slideway is provided on the beam. On the X-direction slideway of the beam; the laser head is connected with the laser generator through the reflection device.

[0041] In the above-mentioned cutting mechanism 10, the pair of frame plates 12 includes a left frame plate and a right frame plate, the first Y-direction slideway 121 is provided on the left frame plate, and the first Y direction slideway 121 is provided on the right frame plate. Two Y-direction slideways; a first Y-direction chute 122 with a trapezoidal cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com