Intelligent gate-type coke feeder and control method

A smart door and coke machine technology, applied in the direction of electrical program control, program control in sequence/logic controller, coke oven, etc., can solve the problems of low automation and high labor intensity of operators, and achieve high automation, Realize the effect of automatic operation and remote monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

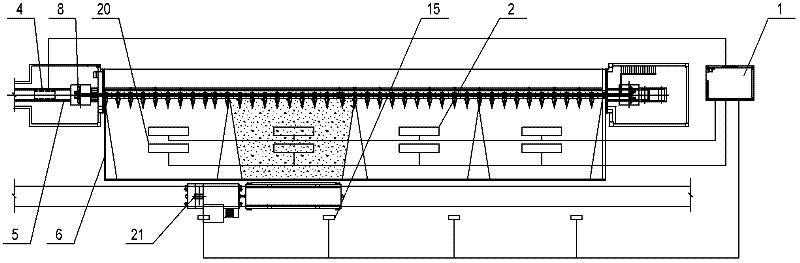

[0033] See figure 1 , an intelligent door-type focusing machine, including a door-type focusing machine 3, a PLC control system 1, a material detection device 2, a focusing positioning device 15, a red focus detection device 20, and an electronic scale 4.

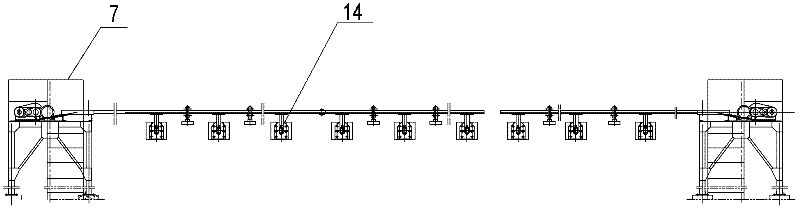

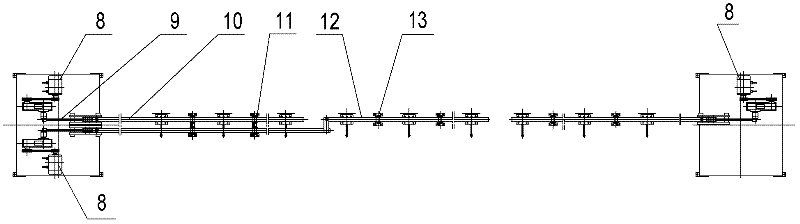

[0034] See figure 2 , image 3 , the door-type focusing machine includes a frequency conversion motor 8, an eccentric crank 9 with adjustable length, an end brace 10, a middle brace 12, a reciprocating opening door 14 with a flexible guide roller, an end brace 10 and a middle brace 12 It is a segmented and independent structure. There are multiple reciprocating opening doors 14 with flexible guide rollers arranged at intervals on the brace; the lower part of the brace is provided with a brace support guide roller. 10 and the bottom part of the end portion of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com