Connection dismantling robot

A technology of robots and connectors, applied in the field of robots, can solve the problems of high labor intensity, low efficiency, dust entry, etc., to ensure labor safety, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

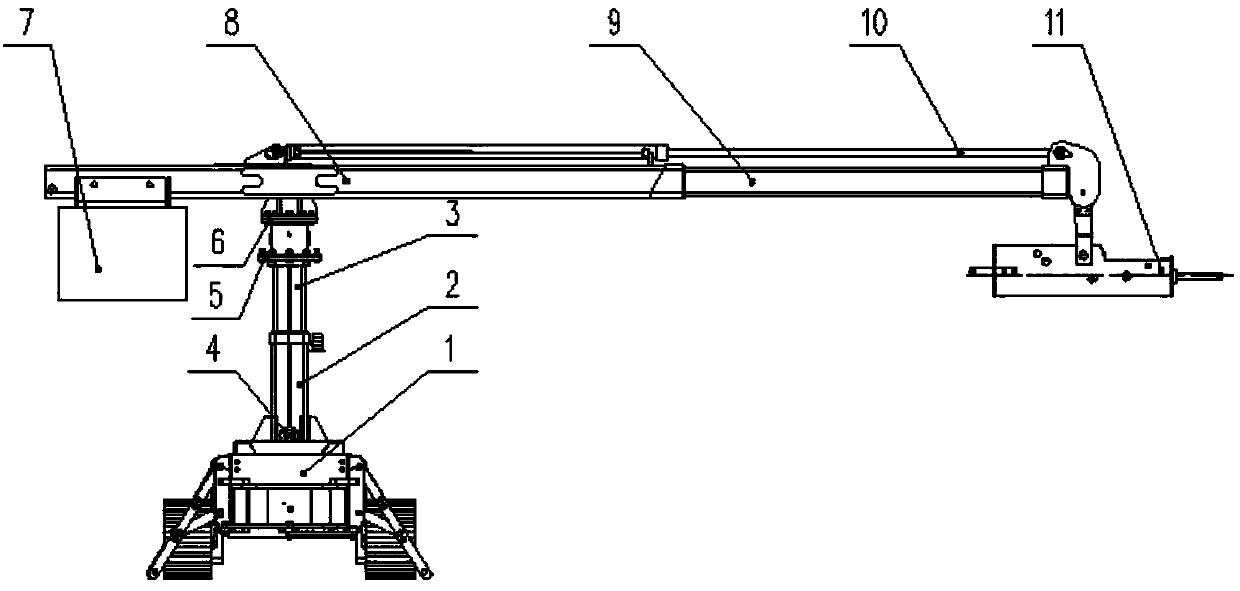

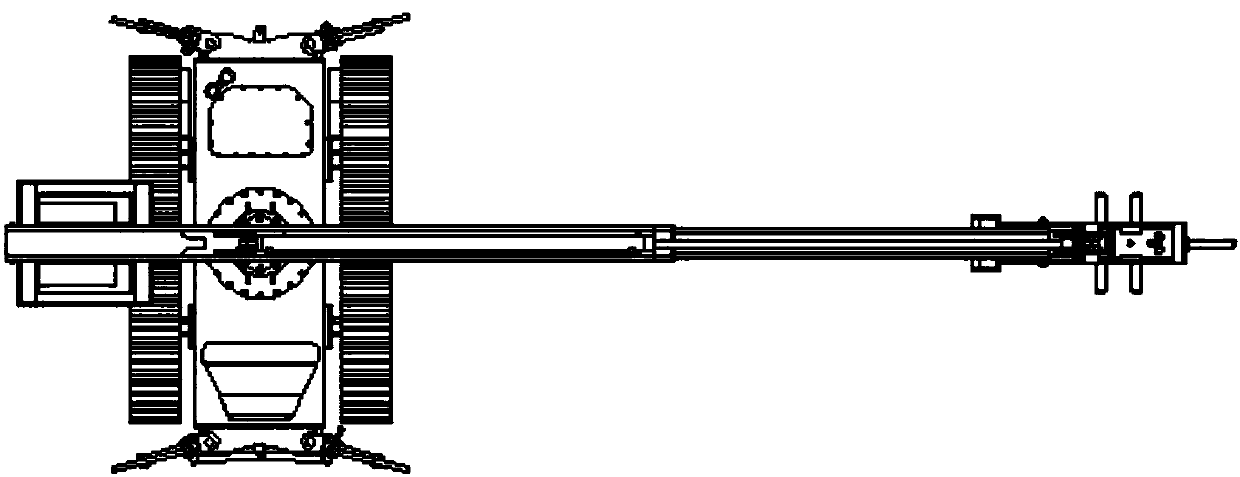

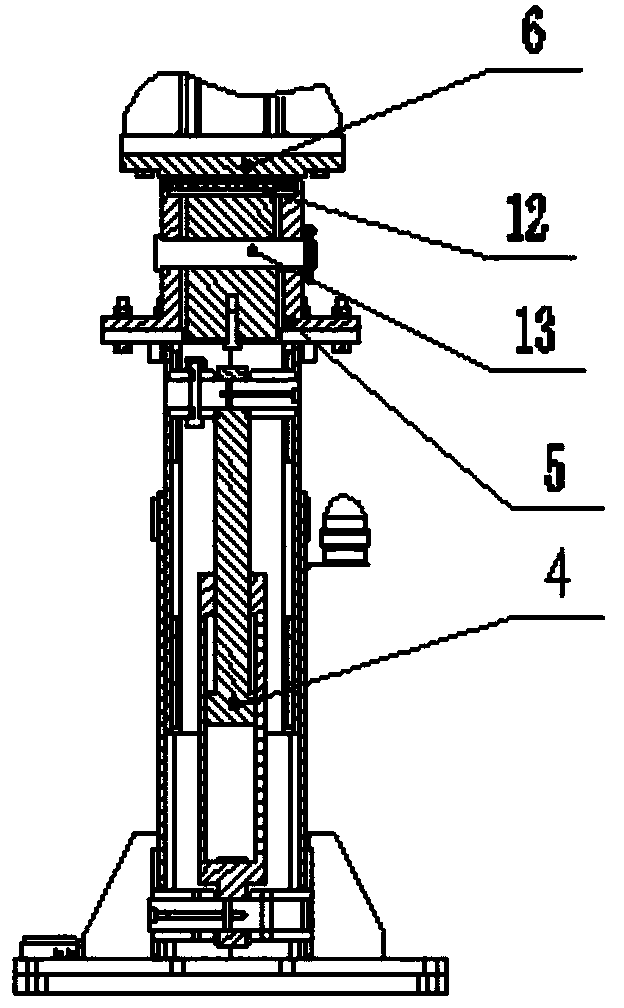

[0015] from figure 1 , figure 2 , image 3 It can be seen that the bolt removal robot device of the present invention includes a walking chassis 1, a lifting mechanism, a telescopic arm mechanism, and a punching body 11. The lifting mechanism is respectively connected with the telescopic arm mechanism and the walking chassis 1 up and down, and the punching body 11 is installed on the telescopic arm mechanism. ; The walking chassis 1 is equipped with four left-right and symmetrical outrigger mechanisms, which are used to support the body or fix the body during work.

[0016] Wherein, lifting mechanism comprises boom outer arm 2, boom inner arm 3, boom oil cylinder 4; Moving up and down, the boom oil cylinder 4 is arranged inside the boom, and its cylinder end is hinged with the boom outer arm 2, and the rod end is hinged with the boom inner arm 3; the telescopic arm mechanism includes the telescopic boom outer arm 8 and the telescopic boom inner arm 9 1. Telescopic arm oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com