Highly toxic powder transportation and feeding equipment and method

A powder and highly toxic technology, which is applied in the field of highly toxic powder transportation and feeding equipment, can solve the problems of difficulty in on-site placement, high labor intensity, and easy leakage, etc., to achieve easy placement and transportation, ensure labor safety, and facilitate maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

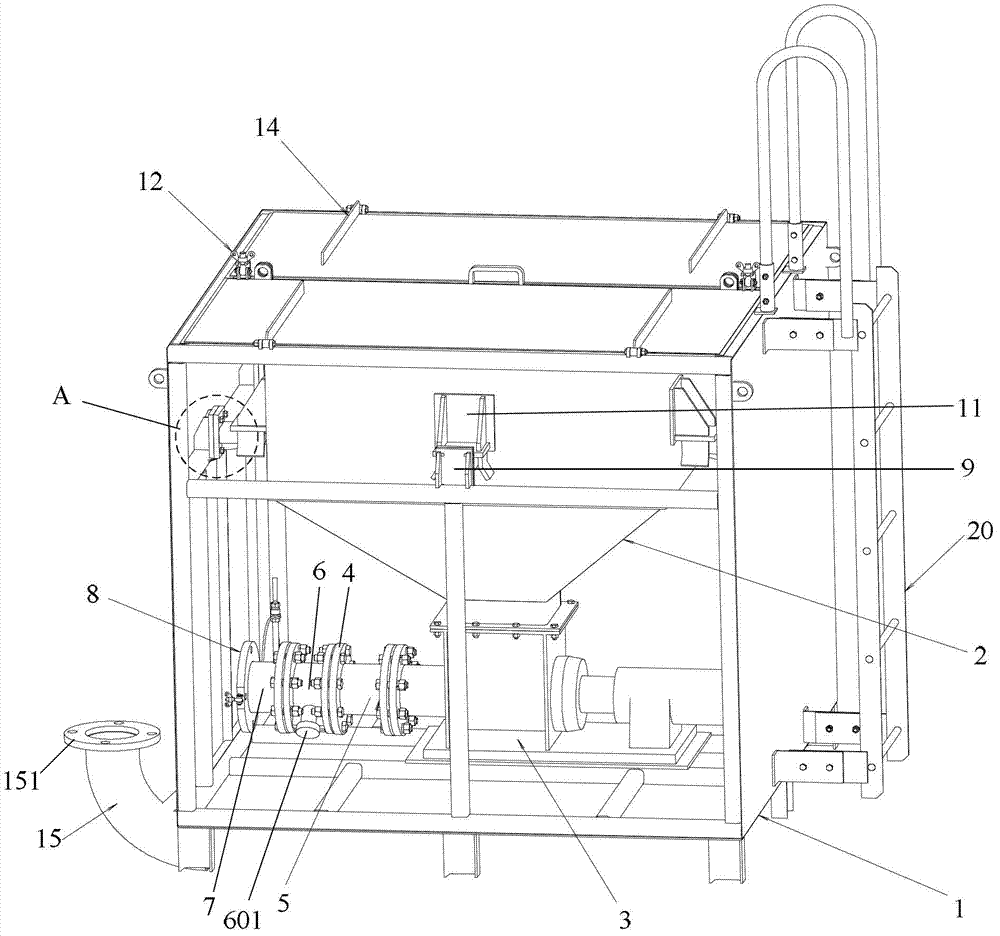

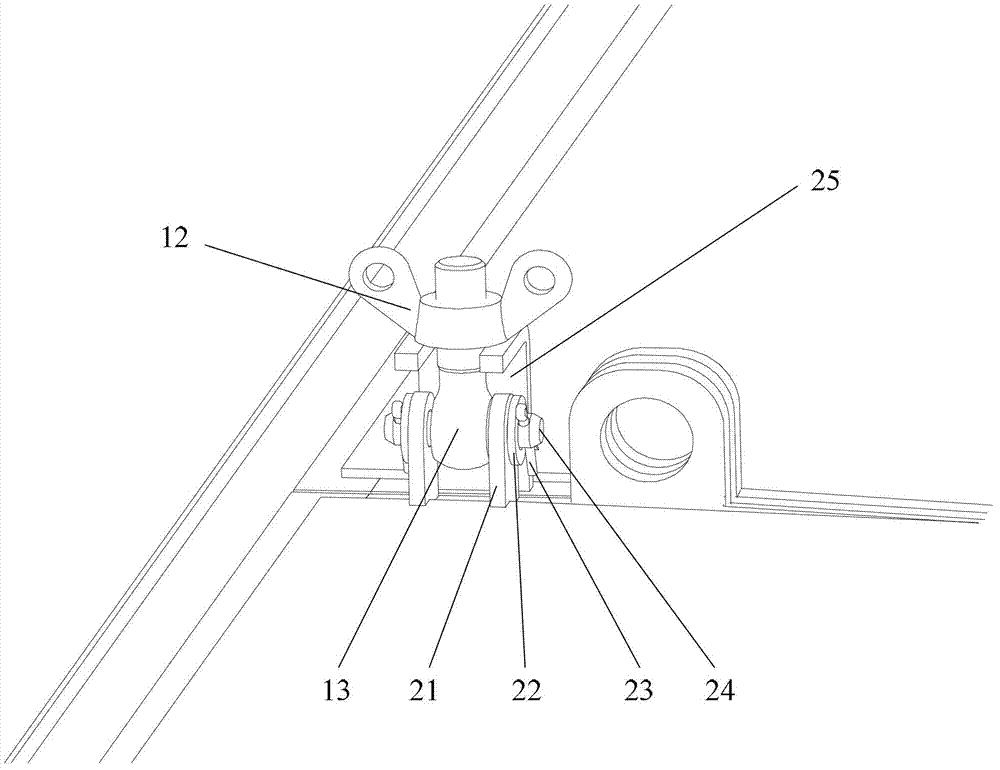

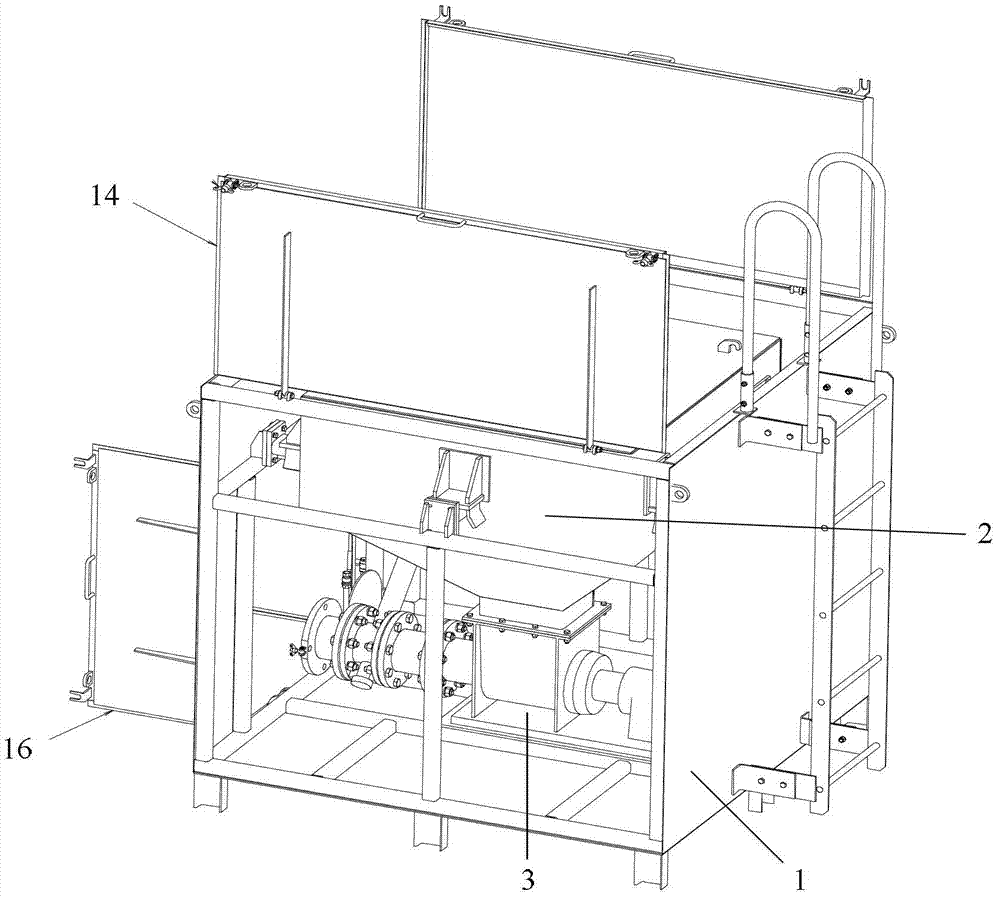

[0037] The following will combine Figure 1 to Figure 7 The highly toxic powder transportation and feeding equipment and method provided by the present invention are described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can use common knowledge without changing the spirit and content of the present invention. Modify and polish it within the scope.

[0038] Please refer to figure 1 , the present embodiment provides highly toxic powder transportation and feeding equipment, used to feed into the solution tank, including an inner silo 2, a screw feeder 3 and a transport box 1, the inner silo 2 and the screw feeder Machines 3 are all located in the transport box 1, the inner silo 2 is connected with the screw feeder 3, the output end of the screw feeder 3 is connected with a conveying pipeline, and the conveying pipeline is used To connect with the solution tank.

[0039] In this embodiment, the combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com