Device and process for hot-working forming of aviation transparent material

A technology of thermal processing and forming, transparent materials, applied in glass forming, glass re-forming, glass manufacturing equipment, etc., can solve the problems affecting the accuracy of the press furnace, non-optimal performance of wire materials, and the lifting mechanism is not fully automated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

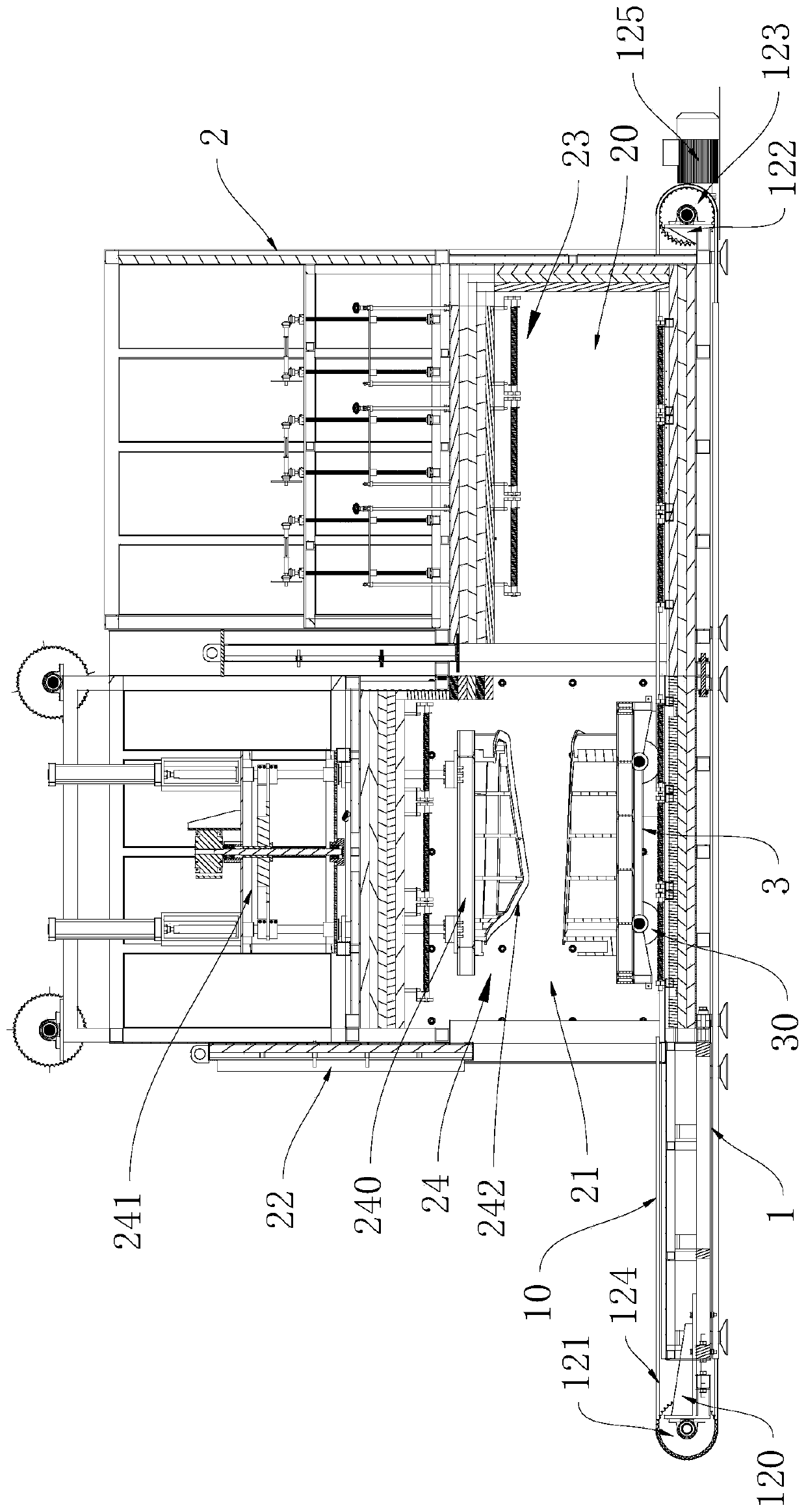

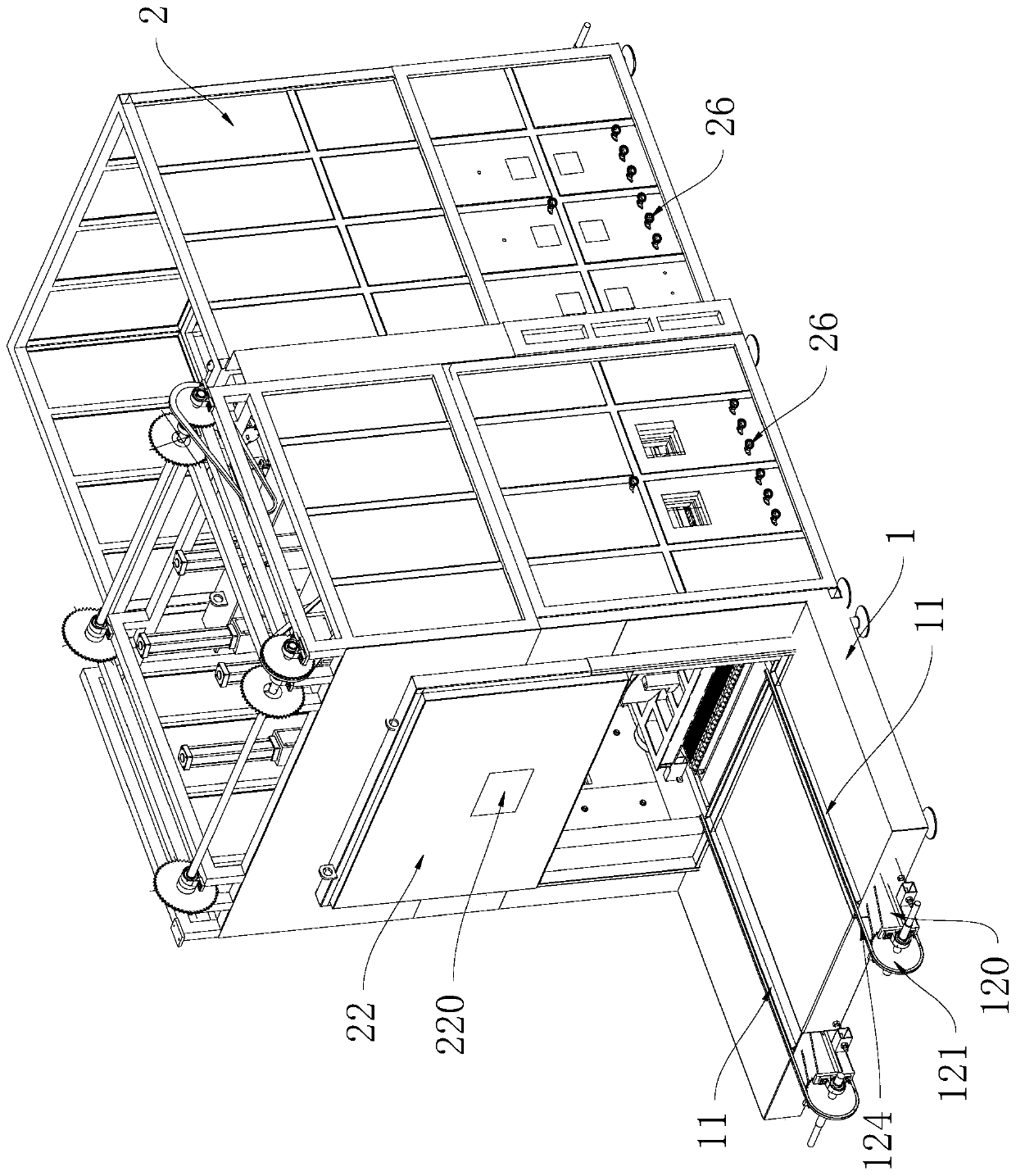

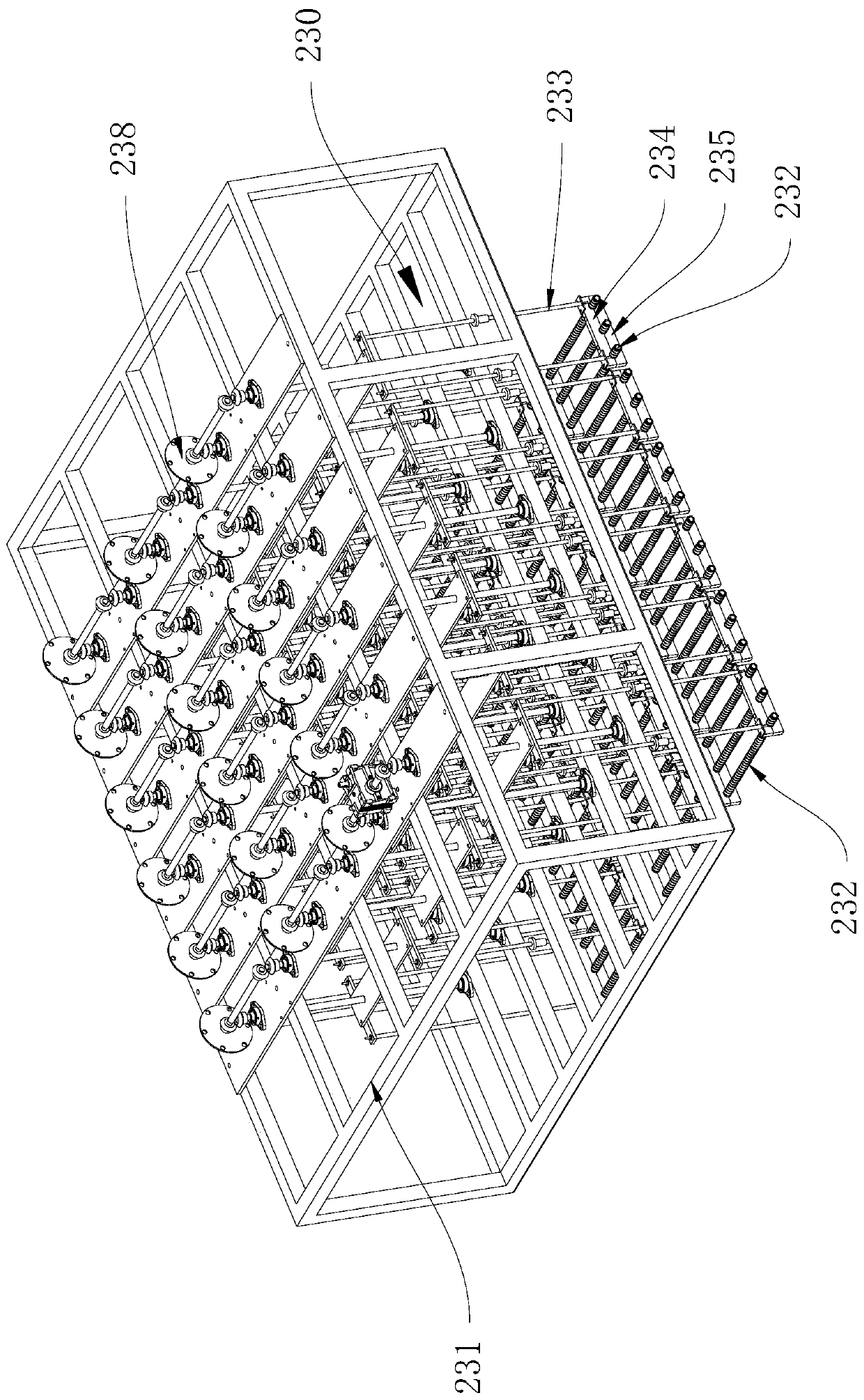

Embodiment 1

[0052] In this embodiment, the thermal processing and forming equipment for aviation transparent materials adopts a fully automatic lifting mechanism, an automatic heating system and a cooling system for production operations. The overall length of the fuselage is 7.7 meters, the width is 3.07 meters, and the height is 4.25 meters. It is 2.2 meters long and 4 meters long. It consists of seven parts, including furnace body, bracket, lifting system, heat preservation system, transmission system, electrical system, and servo system, and is placed horizontally. Among them: the equipment bracket is made of Fangtong, and holes are drilled in the welding places to communicate. At the same time, there are two air inlets and air outlets, which are connected to the air compressor to form a cooling system. In this way, the temperature of the furnace body can be safely lowered, and the time for starting the furnace can be shortened. The height of the furnace conveying chain is lowered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com