PTC thermistor ceramic aluminum spraying carrier plate turnover device and aluminum spraying equipment

A technology of thermistor and turning device, which is applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problems of high labor intensity, affecting the quality of spraying, and high noise, so as to ensure labor safety and sanitation, reduce Labor intensity, the effect of improving the quality of sprayed aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

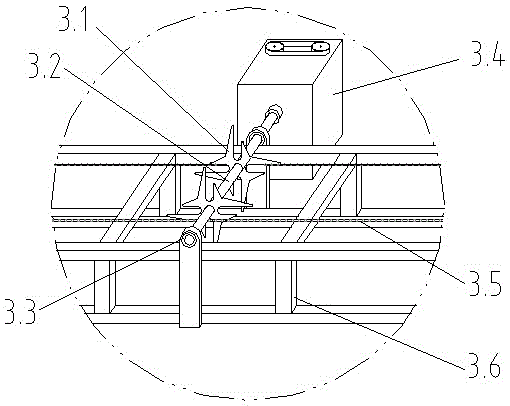

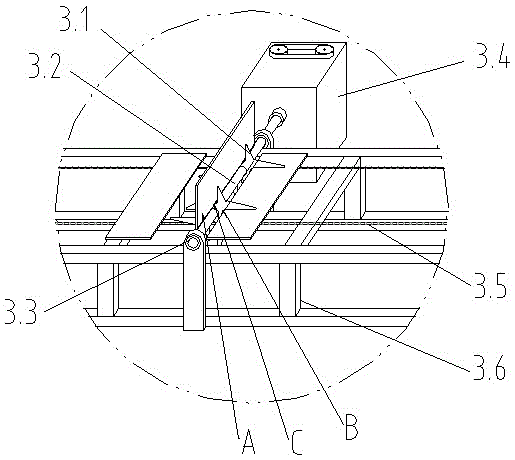

[0016] Such as figure 1 and figure 2 As shown, a PTC thermistor ceramic sprayed aluminum carrier plate flipping device includes a mechanical part and a control system. The mechanical part includes a synchronous motor, a reducer 3.4 and a cross claw mechanism. The cross claw mechanism includes a main shaft 3.2 and a bearing 3.3 and A pair of cross claws 3.1 set on the main shaft; the control system includes a driver, a sensor and a relay; the synchronous motor realizes the transmission through the reducer 3.4 and the cross claw mechanism; the sensor senses the position of the sprayed aluminum carrier plate, and the driver is connected to the sensor and the relay Under the coordinated control of the system, the synchronous motor is driven to run to control the operation of the cross jaw mechanism. The flipping device of the sprayed aluminum carrier board is installed on the frame 3.6, and the position of the sprayed aluminum carrier board is sensed by the sensor. When the fir...

Embodiment 2

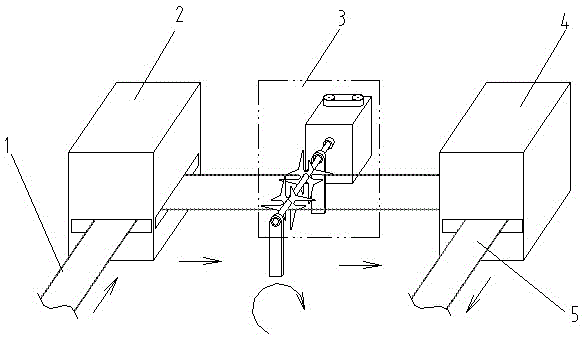

[0018] Such as image 3 As shown, an aluminum spraying equipment using a PTC thermistor ceramic spraying aluminum carrier plate flipping device includes an input conveyor belt 1, a first aluminum spraying room 2, an intermediate conveyor belt 3.5, a second aluminum spraying room 4, an output conveyor belt 5 and a set The aluminum-sprayed carrier plate flipping device 3 on the middle conveyor belt; the input conveyor belt 1 sends the aluminum-sprayed carrier plate into the first aluminum spraying room 2, and the first aluminum spraying room 2 completes the aluminum spraying of the first surface of the PTC thermistor ceramics, and the middle conveyor belt 3.5 The aluminum-sprayed carrier board is transferred and turned over by the aluminum-sprayed carrier board turning device 3 and then sent to the second aluminum spraying chamber 4. The second aluminum spraying chamber 4 completes the aluminum spraying on the second side of the PTC thermistor ceramics, and the output conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com