Top cover and bottom cover overturn mold closing device

A mold clamping device and bottom cover technology, which is applied in the field of bottom cover flip clamping device and top cover, can solve the problems of easy personal injury, poor working environment for workers, and low production efficiency, so as to improve labor safety and improve labor efficiency. The effect of high environmental and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

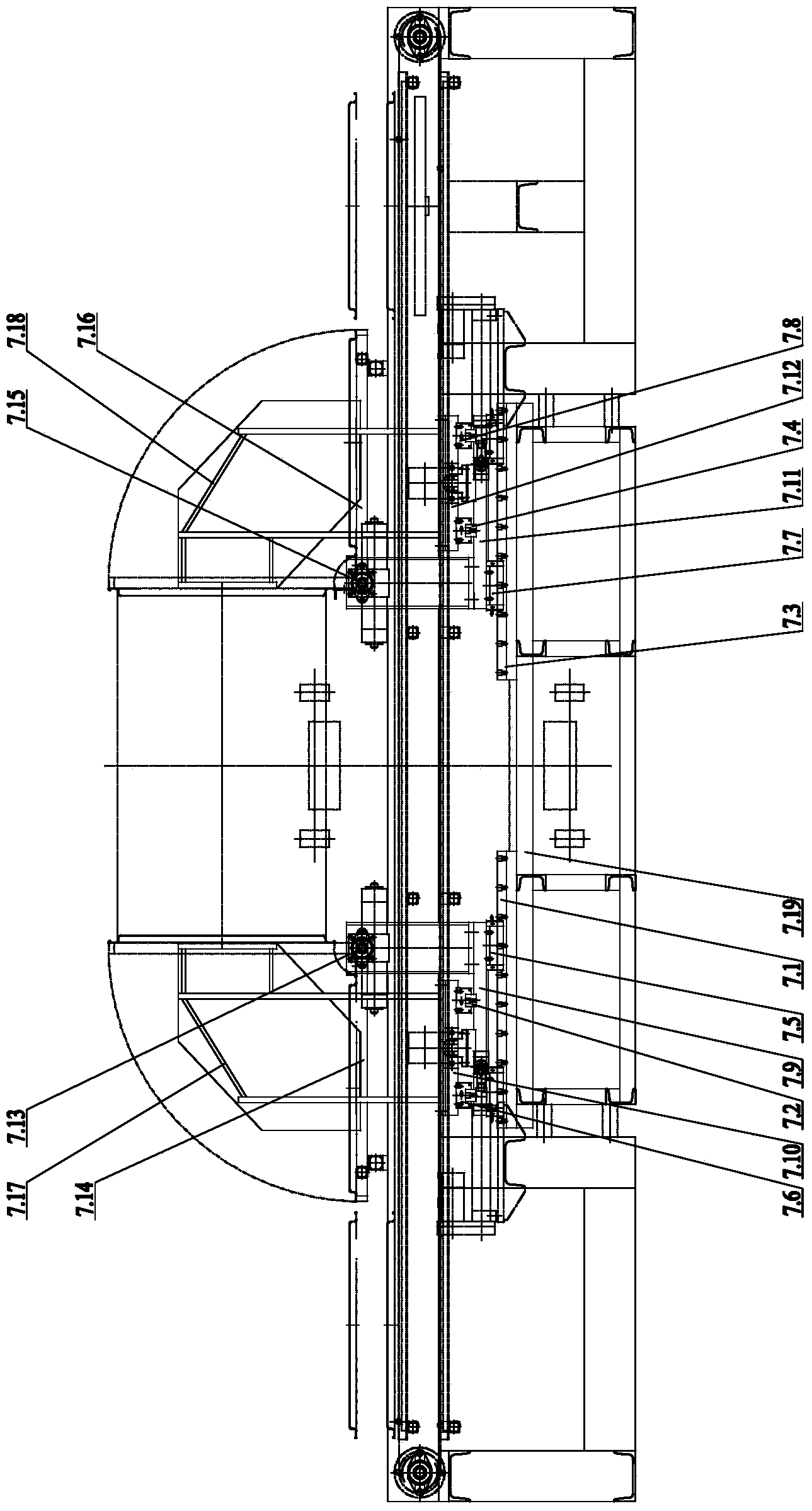

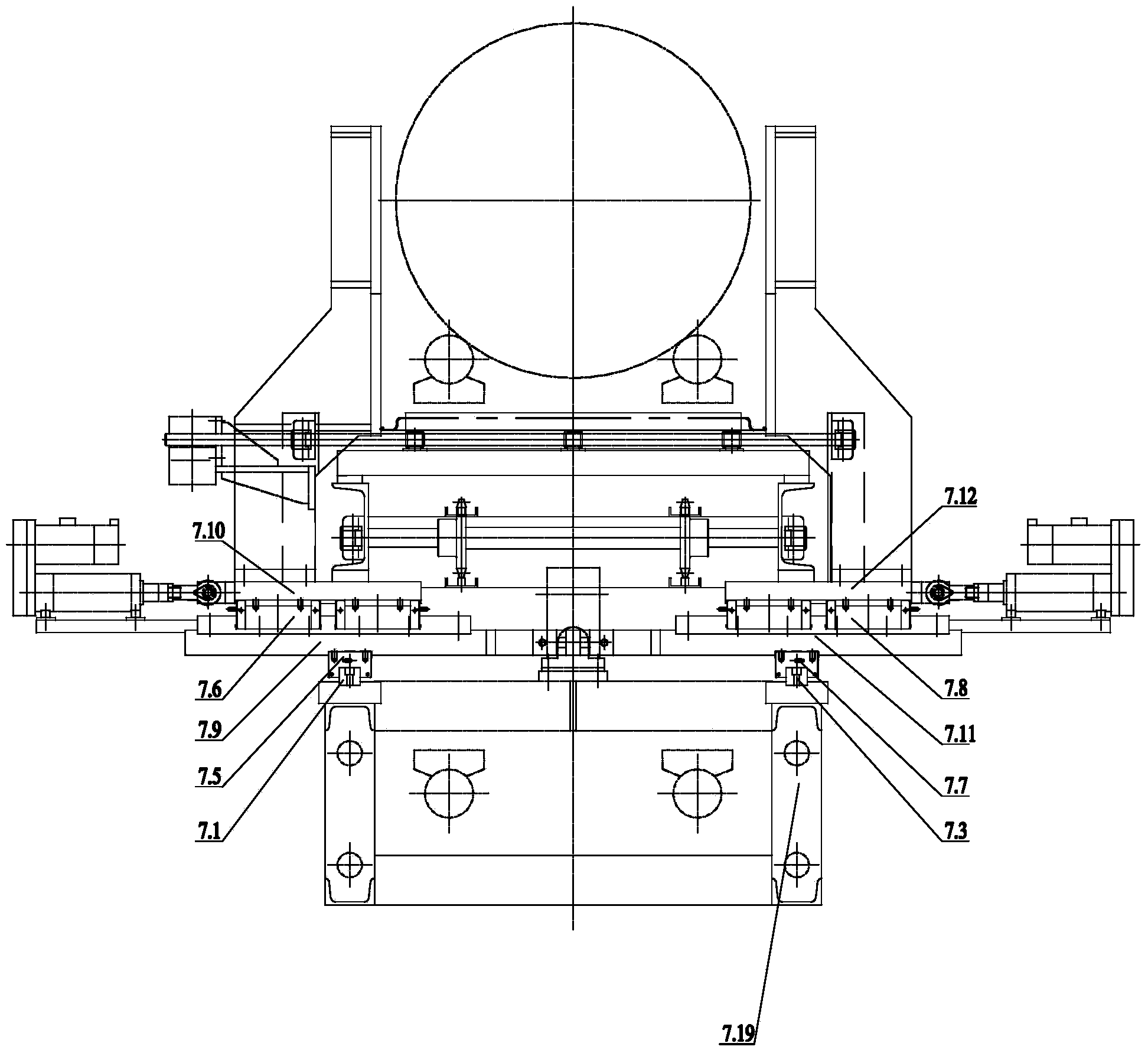

[0011] The top cover and the bottom cover turn over the mold clamping device, which includes a mold clamping frame 7.19, and a first slide rail 7.1 is fixed on the mold clamping frame 7.19 on one side of the bucket body conveyor chain 1, and slides on the first slide rail 7.1 The first slide block 7.5 is connected, the first slide table 7.9 is fixed on the first slide block 7.5, the second slide rail 7.2 is fixed on the first slide table 7.9, and the second slide rail 7.2 is slidably connected The slide block 7.6 is fixed with the second slide table 7.10 on the second slide block 7.6, the first overturn frame 7.14 is hinged on the first slide table 7.9 through the first overturn shaft 7.13, and the length direction of the first slide rail 7.1 is in line with the The axis direction of the barrel to be conveyed by the barrel conveying chain 1 is consistent, and the length direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com