Sintered ore FeO content on-line detection device and method with automatic blockage treatment function

A technology of automatic processing and detection device, applied in the direction of measurement device, automatic feeding/discharging weighing equipment, material magnetic variable, etc. The maintenance volume remains high and other problems, to achieve the effect of reducing maintenance volume and operating costs, reducing labor economic costs, and improving labor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

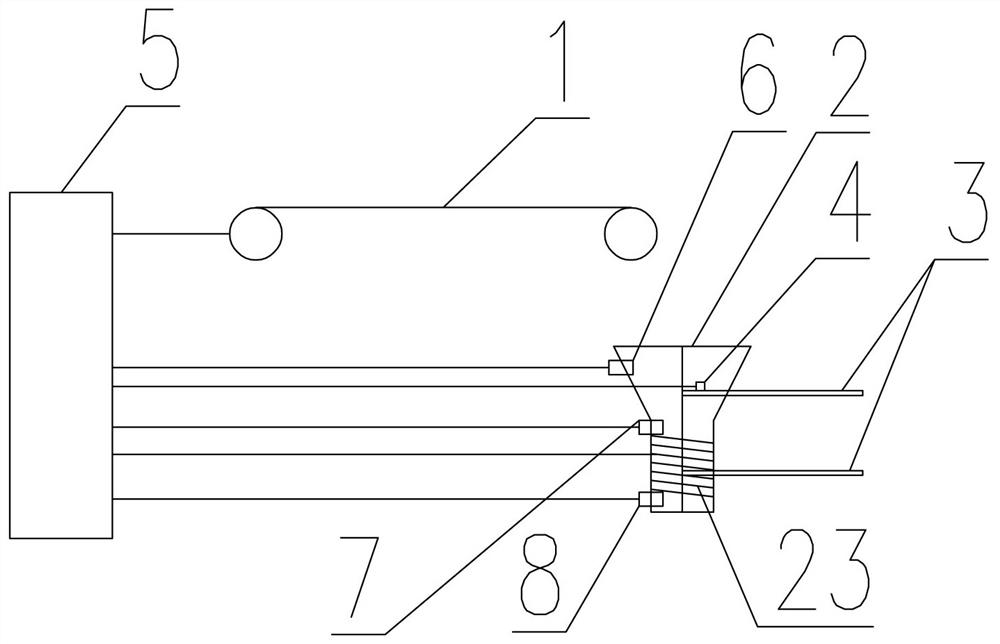

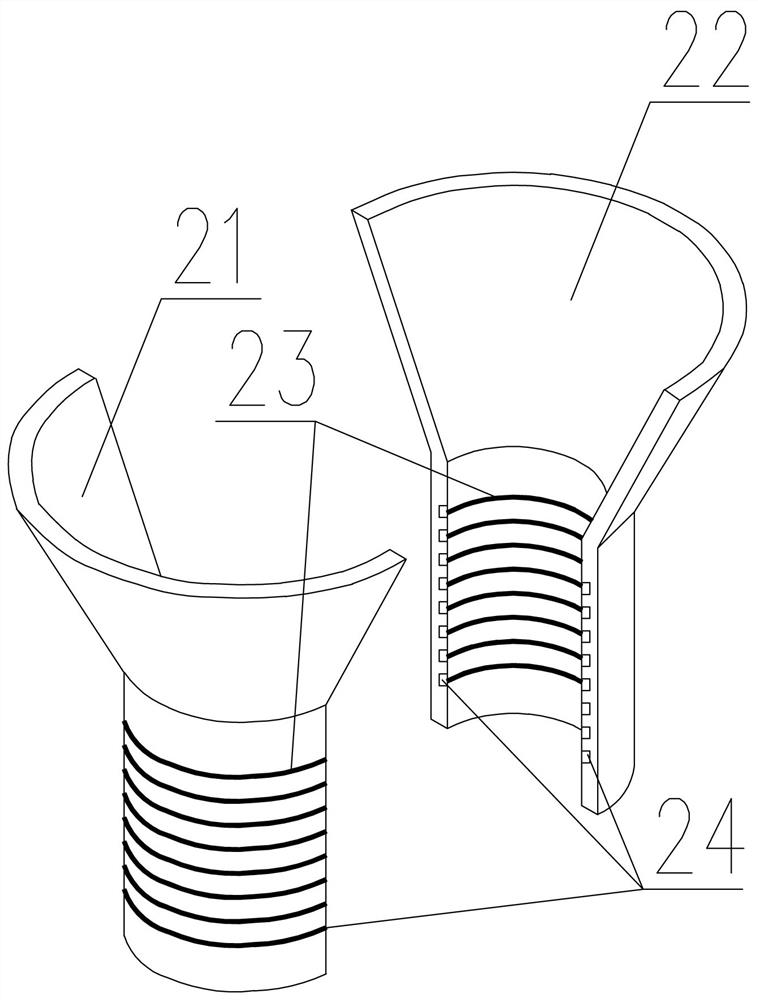

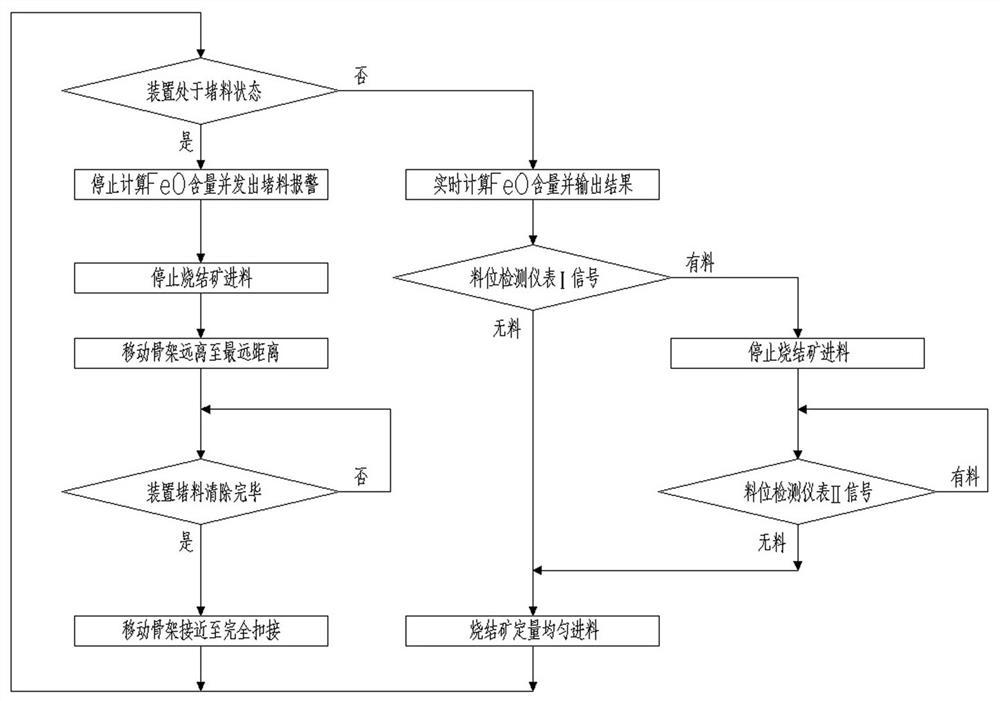

[0026] Such as figure 1 , 2 Shown in and 3, the sintered ore FeO content online detection device of the blocking material automatic processing function of the present invention is characterized in that it comprises an electric control system 5, a feed batching scale 1, and is arranged below the feeding point of the feed batching scale 1 The moving frame 2, the magnetic induction coil 23 arranged on the moving frame 2, the moving track 3 carrying the moving frame 2, the electric mechanism 4 arranged on the moving track 3, the material level set on the moving frame 2 Detection instrument Ⅰ6, material level detection instrument Ⅱ7 and material flow detection instrument 8,

[0027] The upper part of the mobile frame 2 is an inverted circular platform tube and the lower part is a cylindrical tube. The mobile frame 2 includes a mobile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com