Material absorbing and dust removing method for packing material of carbon baking furnace as well as device

A carbon roasting furnace and filler technology, which is applied in the direction of combination device, separation method, chemical instrument and method, etc., can solve the problems of difficult construction and large investment, and achieve the effects of improving labor environment, low operating cost and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

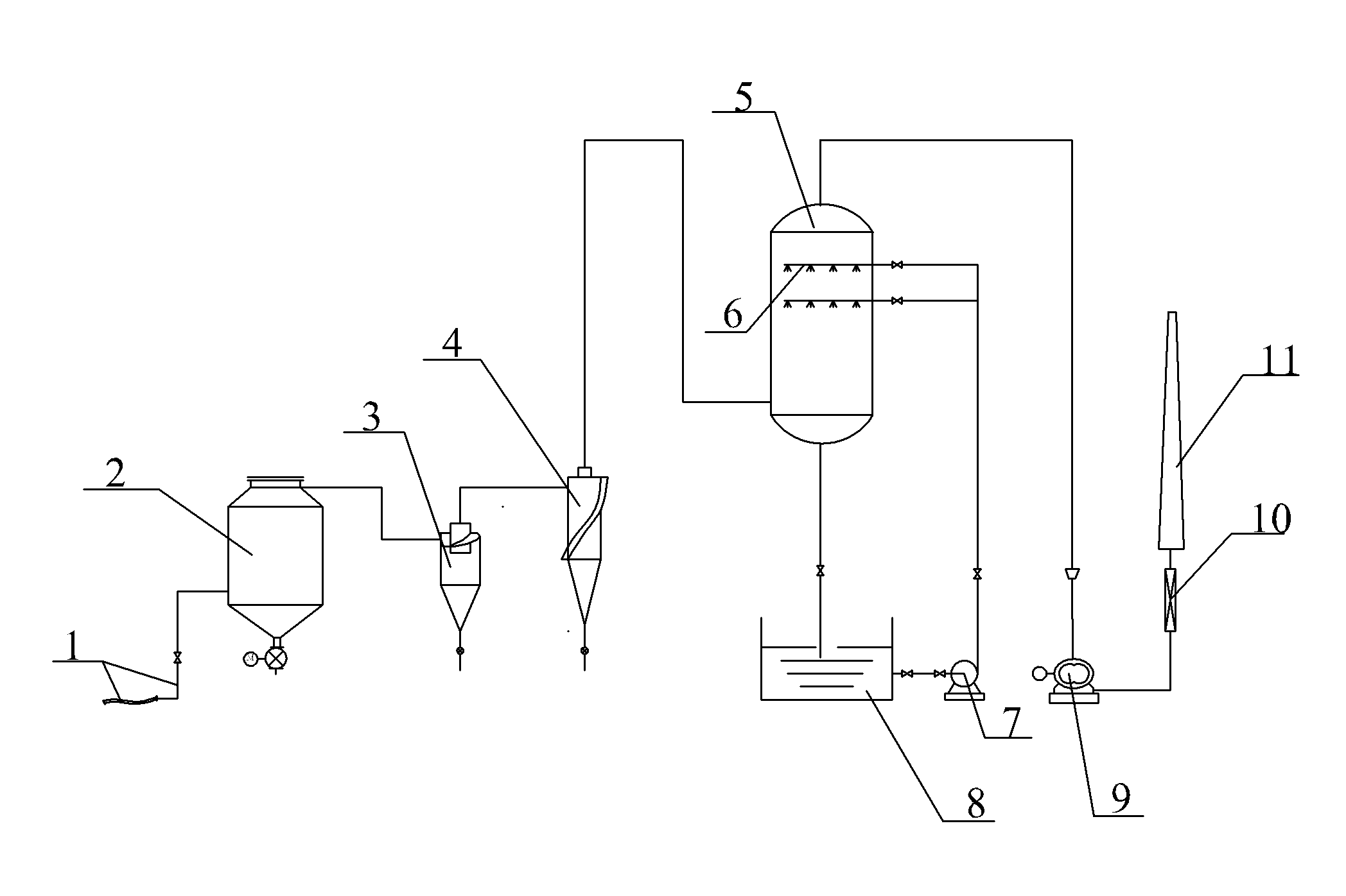

[0017] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0018] Such as figure 1 Shown, a kind of carbon roasting furnace filler dedusting, material suction method comprises the following steps: (1) material suction: extract carbon roaster filler with vacuum pipeline 1; (2) material separation: the filler that draws enters large Particle material separator 2, small particle material separator 3 and coarse powder separator 4 separate the filling material from the generated dust; (3) wet dust removal: the dust separated from the filling material enters the fine dust treatment device, and the dust is collected in the micro dust The dust treatment device cools down and removes dust by contacting with the liquid, and the dust after cooling and dust removal is mixed with the liquid and flows into the settling tank 8 for sedimentation and clarification;

[0019] The dust enters the micro-dust treatment device, is immersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com