Heating sorting equipment used in process of detecting asphalt content by combustion method

A technology of asphalt content and combustion method, which is applied in chemical analysis by combustion and weighing by removing certain components, can solve the problems of difficulty in estimating correction coefficients and complex labor costs, and achieves good human-computer interaction performance and improvement. Product quality, the effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

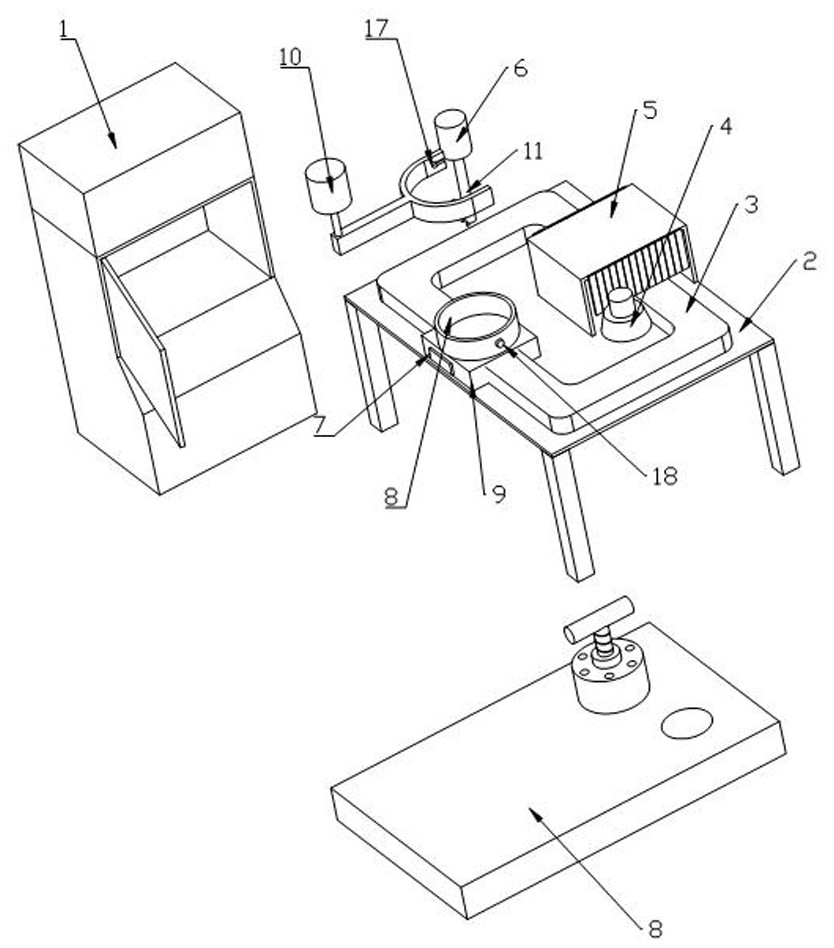

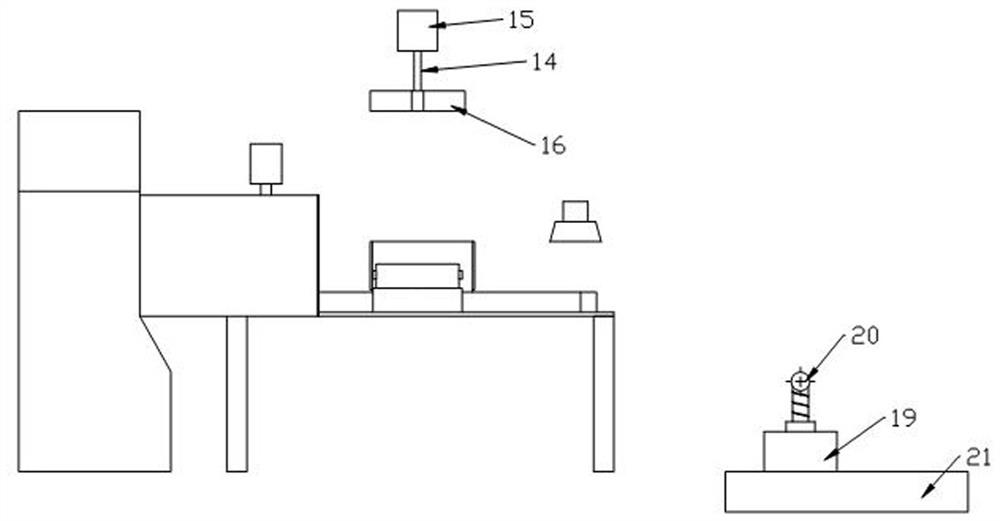

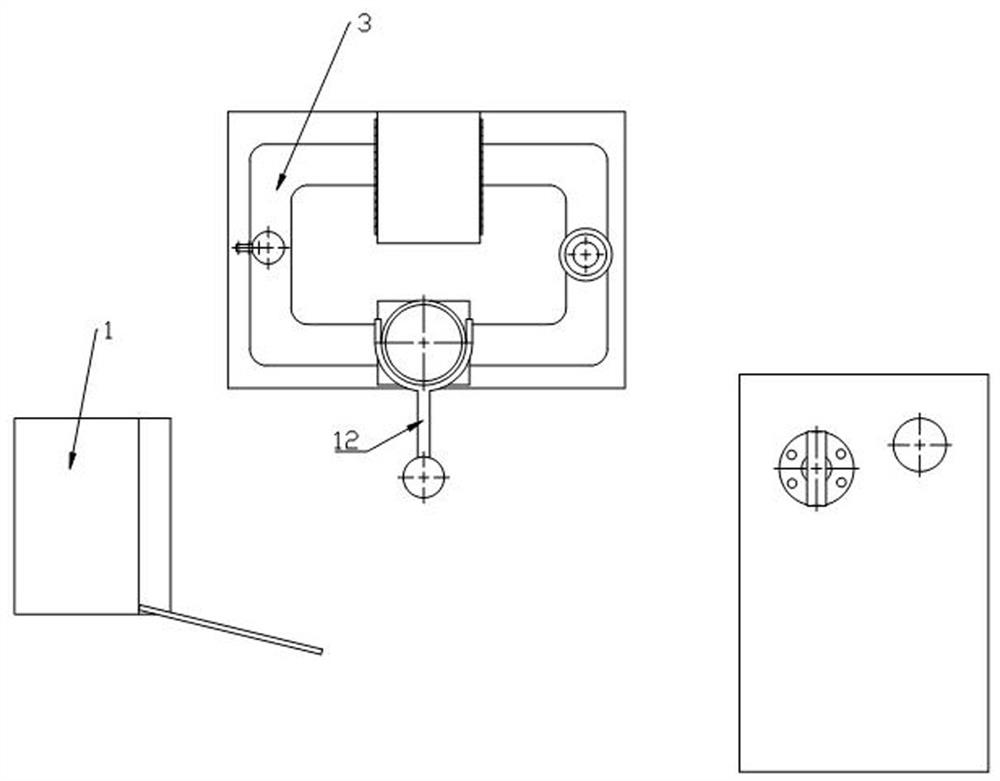

[0028] A kind of heating sorting equipment used in the process of detecting bitumen content by combustion method, see Figure 1 to Figure 4 , the design includes an asphalt detection furnace for the combustion method, the discharge port of the hoisting mechanism 10 is at the entrance of the asphalt detection furnace, the material inlet of the hoisting mechanism 10 is at the outlet of the pilot detection device, and the pilot detection device includes a feeding platform 2, a feeding platform 2 It is equipped with a word-shaped assembly line 3 and a power element that drives the assembly line 3 to run. Along the assembly line 3, a drying mechanism 4, a heating mechanism 5, a smoothing mechanism 6, an inspection mechanism, and a test block platform 9 are arranged in sequence. The table 9 includes a square platform and a cylindrical test block basket 8 installed on the square platform. Positioning columns 18 are arranged on both sides of the test block basket 8 , and a screw connec...

Embodiment 2

[0038]The working principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the pilot detection device is replaced by a feeding platform 2, and a mouth-shaped assembly line 3 is arranged on the feeding platform 2 along the direction of the assembly line 3. Drying mechanism 4, heating mechanism 5, smoothing mechanism 6 and inspection mechanism, each side of the heating mechanism 5 is provided with a test block platform 9, and the test block platform 9 includes a square platform and a cylindrical test block installed on the square platform Basket 8 and positioning columns 18 are arranged on both sides of the test block basket 8, and a backing plate for transitional placement of the cylindrical test block basket 8 is provided in the heating mechanism 5.

[0039] In this embodiment, the assembly line 3 includes a plurality of sliding rollers, the sliding rollers themselves are not connected to the power mechanism, and the movement of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com