Insulating rod withstand voltage test testing device and locating method

A technology of testing device and withstand voltage test, which is applied in the direction of measuring device shell, testing dielectric strength, etc., can solve the problems of unrealizable structure and poor fixing effect of insulating rods, and achieves labor safety, labor intensity reduction, and normal power supply. effect of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

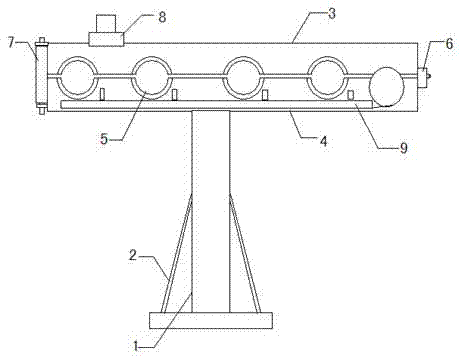

[0012] combined with Figure 1-2 , to further describe the present invention:

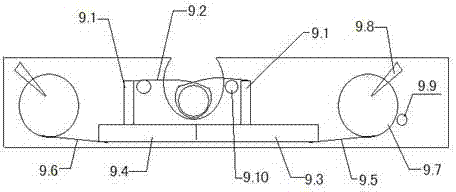

[0013] The present invention includes a support rod 1, a jacket, a hinge 6, and a screw rod 7. The bottom of the support rod 1 is provided with a side support frame 2, and the top of the support rod 1 is connected to a jacket, and the jacket includes an upper jacket 3 and a lower clamp. Cover 4, one end of the upper jacket 3 and the lower jacket 4 is hinged by a hinge 6, the other end of the upper jacket 3 and the lower jacket 4 is connected by a screw 7, and the upper jacket 3 and the lower jacket 4 are provided with There are semicircular grooves that cooperate with each other. The semicircular grooves inside the upper jacket 3 and the lower jacket 4 are closed to form an insulating rod through hole 5. The upper jacket 3 is provided with conductive bolts 8, so A bracket electrode closer 9 is provided between the two semicircular grooves of the lower jacket 4. The bracket electrode closer 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com