Fabric cutting and fetching method

A cloth and cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc., can solve the problems of low efficiency and increased labor costs, and achieve the effect of reducing labor costs, ensuring work efficiency, and realizing automatic picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

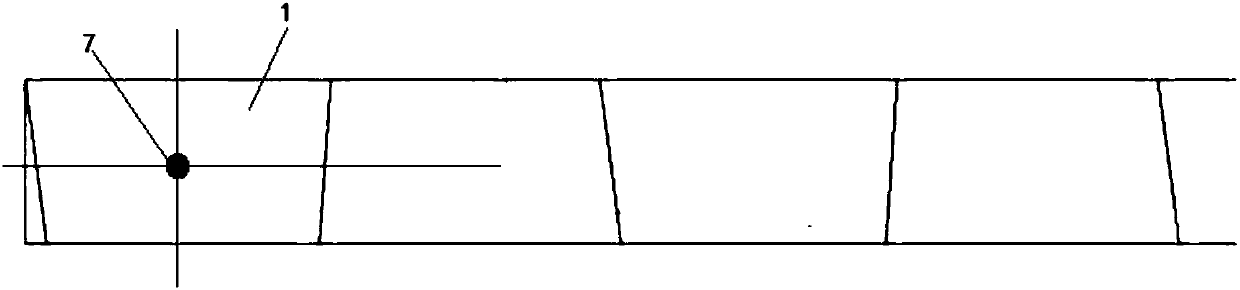

[0028] A method of fabric cutting, such as figure 1 As shown, the following steps are included to achieve the cutting of trapezoidal pieces of the same height:

[0029] 1.1 The first trapezoidal pieces 1 with the same height to be cut are distributed and designed in the form of lateral complementation to minimize the range of waste 8, and the distribution design results are imported into the cutting machine control system;

[0030] 1.2 The control system divides the distribution design into sections, in which each section can be completely covered by the cutting range of the cutting machine during the cutting process, and ensures that there is only one row of cut pieces in each section in the direction of fabric conveying. This implementation In the example, the width of the trapezoidal first piece 1 is equal to the width of the cloth, so only one piece is arranged in each column;

[0031] 1.3 Determine the positioning point 7 of the above-mentioned first cut piece 1. The pos...

Embodiment 2

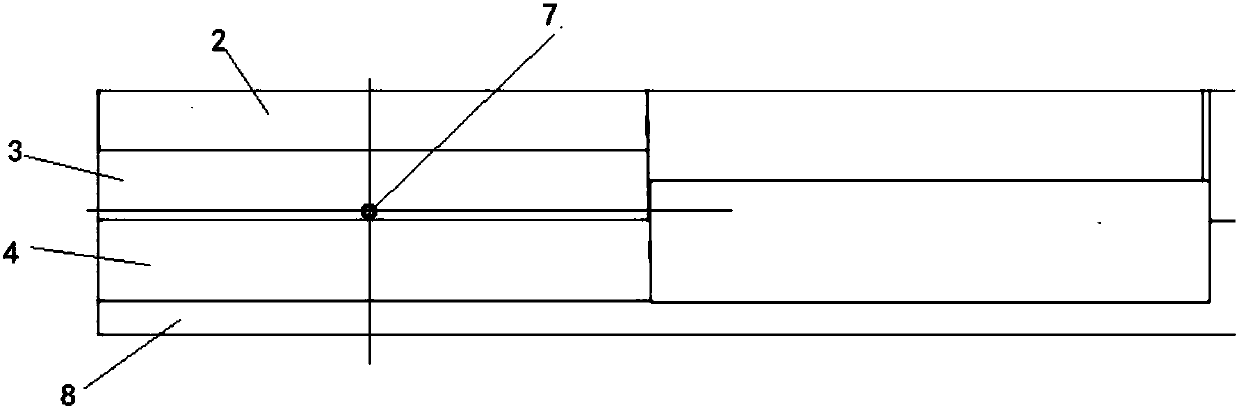

[0037] A fabric cutting method, which is used to realize the cutting of various pieces of constant length but different widths, wherein the width of each piece is smaller than the width of the fabric to be cut, comprising the following steps:

[0038] 1.1 Distribute and design various pieces of constant length but different widths in a complementary form. The design method is to set the length direction of the pieces to be consistent with the length direction of the fabric, and arrange them in sequence along the width direction of the fabric. Try to fit as much as possible to minimize the range of waste 8, and import the distribution design results into the cutting machine control system;

[0039] 1.2 The control system divides the distributed design into segments, such as figure 2 As shown, each section can be completely covered by the cutting range of the cutting machine during the cutting process, and it is ensured that there is only one row of cutting pieces in each secti...

Embodiment 3

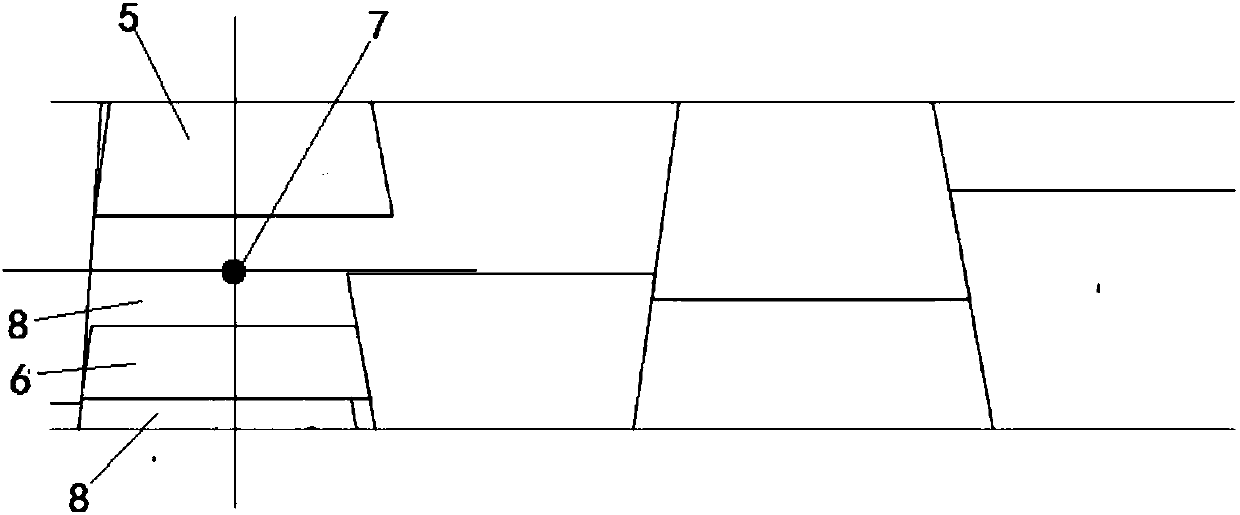

[0045] A fabric cutting method, which is used to realize the cutting of each cut piece that is different in length and width but similar in length and whose shape is approximately rectangular, wherein the width of each cut piece is smaller than the width of the fabric to be cut, including The following steps:

[0046] 1.1 Distribute and design the pieces with different lengths and widths but similar lengths and their shapes are similar to rectangles. The design method is to set the length direction of the pieces to be consistent with the length direction of the fabric, and sequentially along the width direction of the fabric. Arrange to form several columns, reduce the range of waste 8 to a minimum by fitting as much as possible, and import the distribution design results into the cutting machine control system;

[0047] 1.2 The control system divides the distribution design into sections, in which each section can be completely covered by the cutting range of the cutting mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com