Packaging bag cutting machine

A cutting machine and packaging bag technology, applied in the field of packaging, can solve the problems of increasing labor intensity of workers, unfavorable collection and sorting of packaging bags, and reducing production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

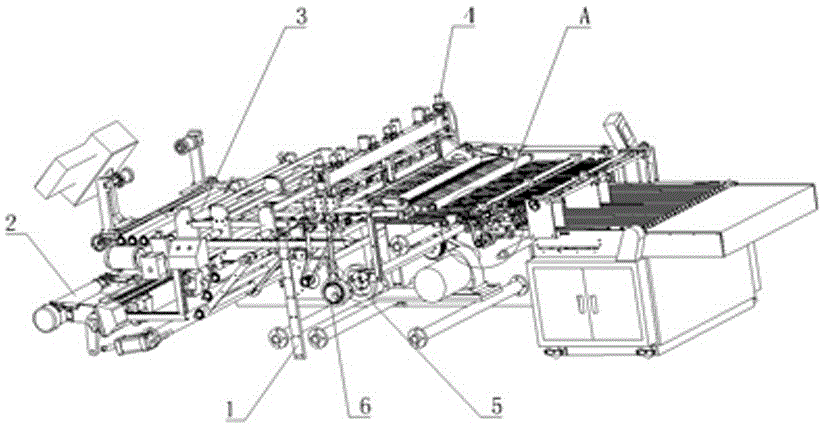

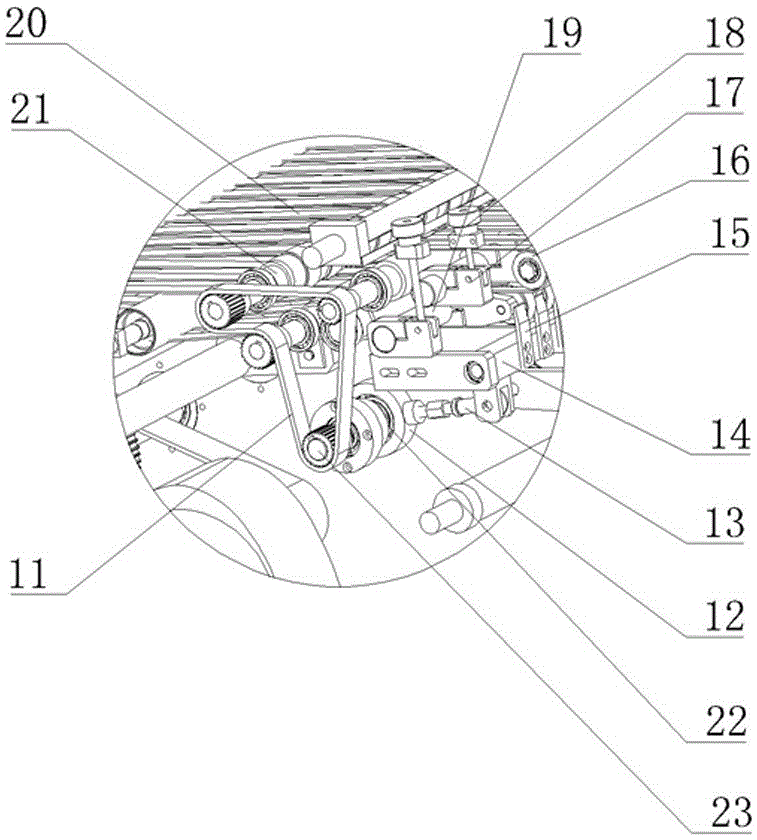

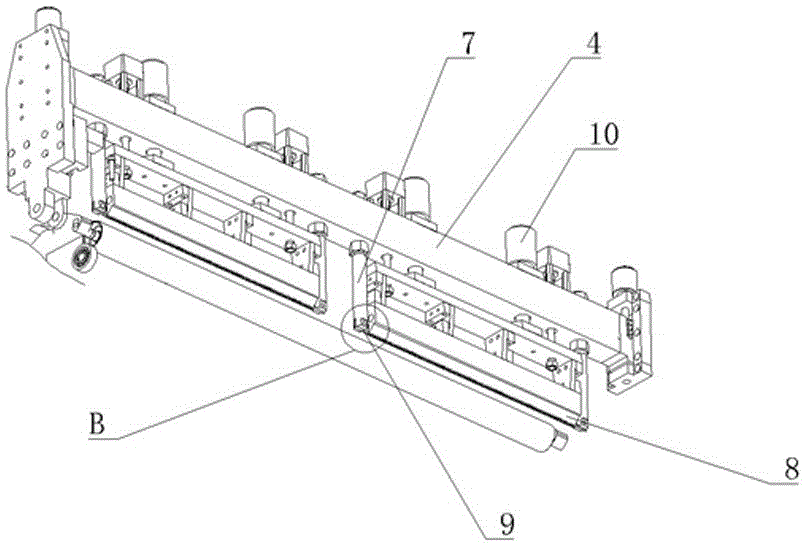

[0017] As shown in the figure, this packaging bag cutting machine has a frame 1, and the frame 1 is provided with an input mechanism 3, a cutting mechanism and an output mechanism in turn from left to right, and the bottom of the frame 1 is provided with a support Shaft 2, the support shaft 2 is used to place the packaging roll to be cut, the cutting mechanism has a cutter, the cutter is used to cut the packaging bag, the output mechanism has a conveying belt 20, a conveying roller 21, conveying The belt 20 is wrapped around the conveying roller 21, the cutting mechanism is movably installed on the frame 1, the cutting mechanism has a mounting seat 4, and the mounting seat 4 is provided with a cylinder 10, the cylinder 10 The piston rod is connected to the toothed cutter 8, the toothed cutter 8 can cut out lace, the toothed cutter 8 can move up and down under the action of the cylinder 10, and the toothed cutter 8 is arranged symmetrically and has a gap. A plane cutter 9 is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com