Double-headed terminal installer

A technology of punching machine and rack, applied in the direction of electrical components, circuits, connections, etc., can solve the problems of low efficiency and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

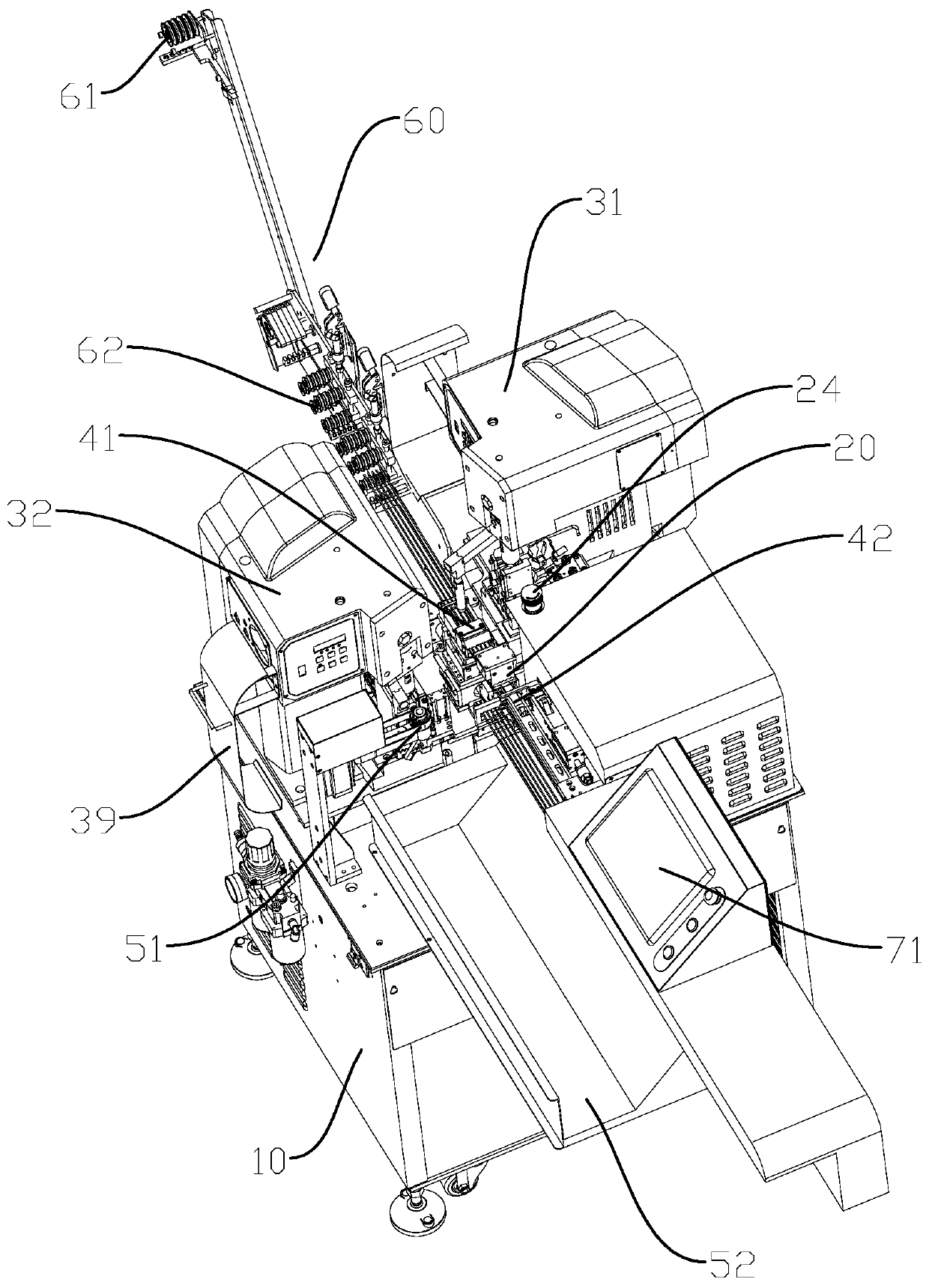

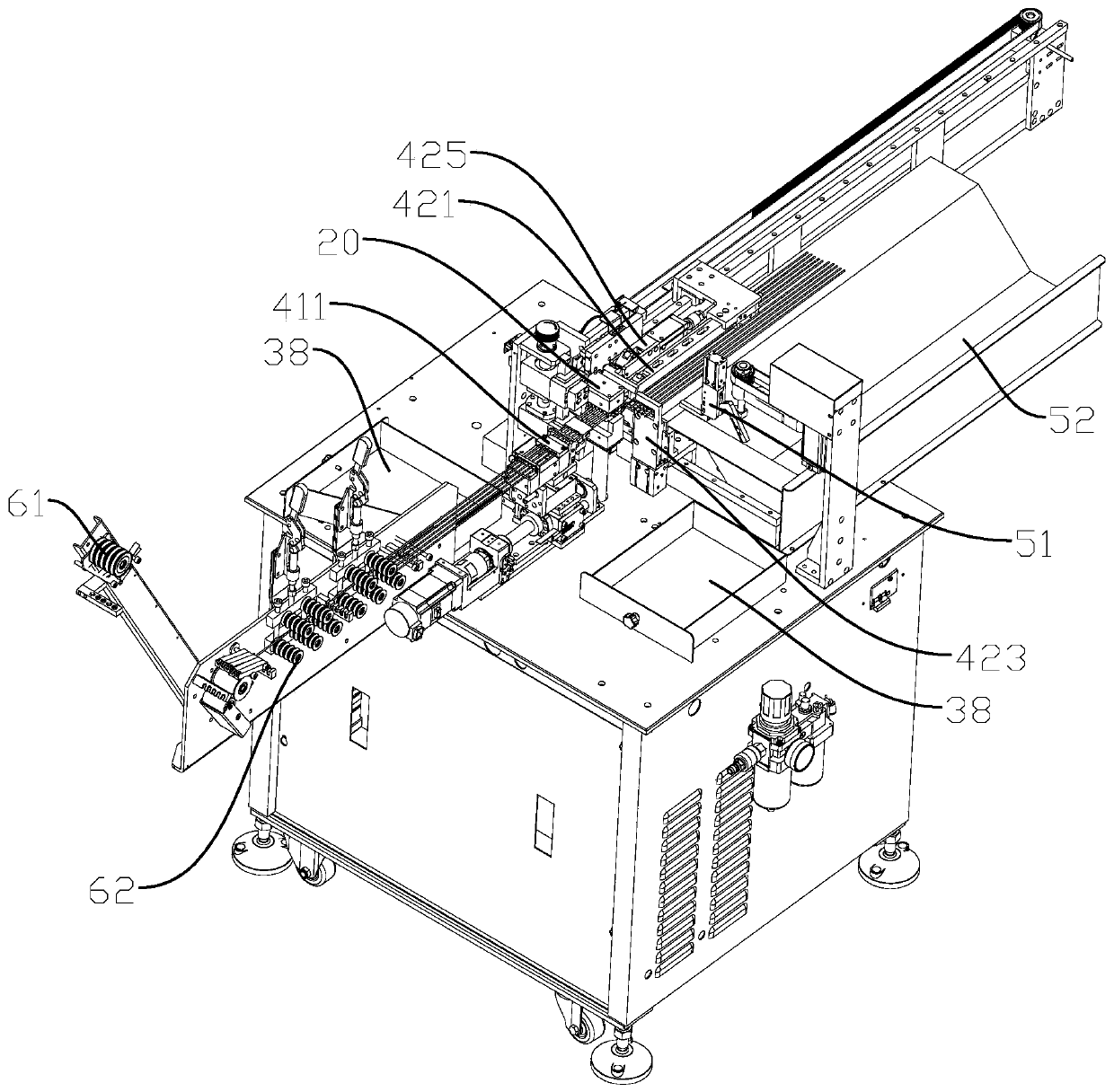

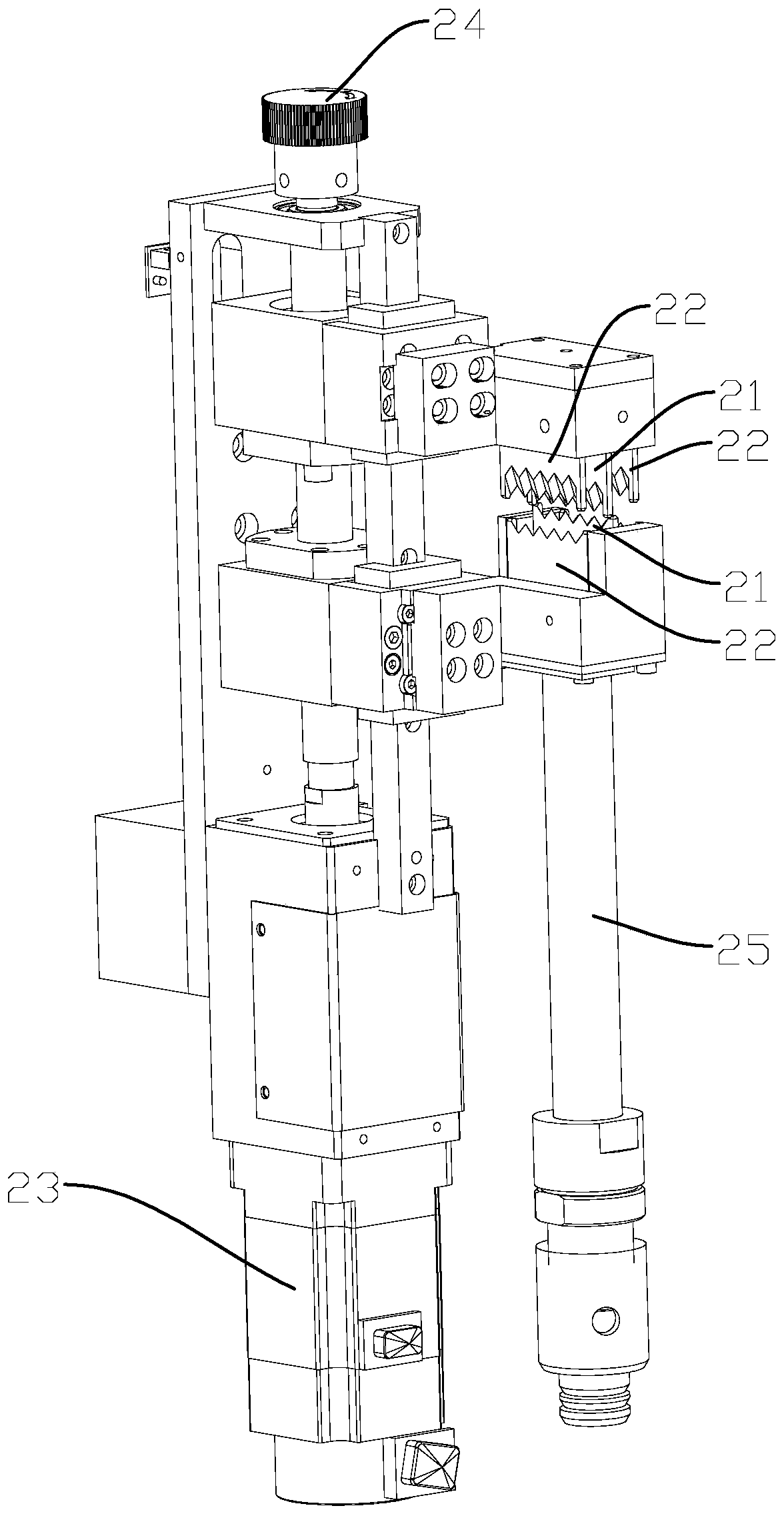

[0044] refer to Figure 1 to Figure 11, a double-headed end-tying machine, including: a frame 10; a cutting device 20, which is arranged on the frame 10, and is used to cut off the wire rod and place the wire sheath on the wire rod at a distance in front of the cutting opening and at a distance behind the cutting opening. Cutting; the first end-playing device 31 and the second end-playing device 32 are all arranged on the frame 10, wherein the first end-playing device 31 is used to carry out end-playing operations to the end of the wire at the rear of the cut-off of the wire, and the second end-playing device The device 32 is used to end the thread end in front of the wire cutting opening; the first wire moving device 41 and the second wire moving device 42 are both arranged on the frame 10, and the first wire moving device 41 can clamp the cutting device 20 and move the wire back and forth relative to the cutting device 20 to perform peeling operations on the wire together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com