High viscosity and scratch resisting PE wood-plastic plate composite production line and production technology

A wood-plastic board, scratch-resistant technology, used in wood processing appliances, veneer presses, manufacturing tools, etc., can solve problems such as bending, and achieve the effect of avoiding interference, keeping the size consistent, and facilitating positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

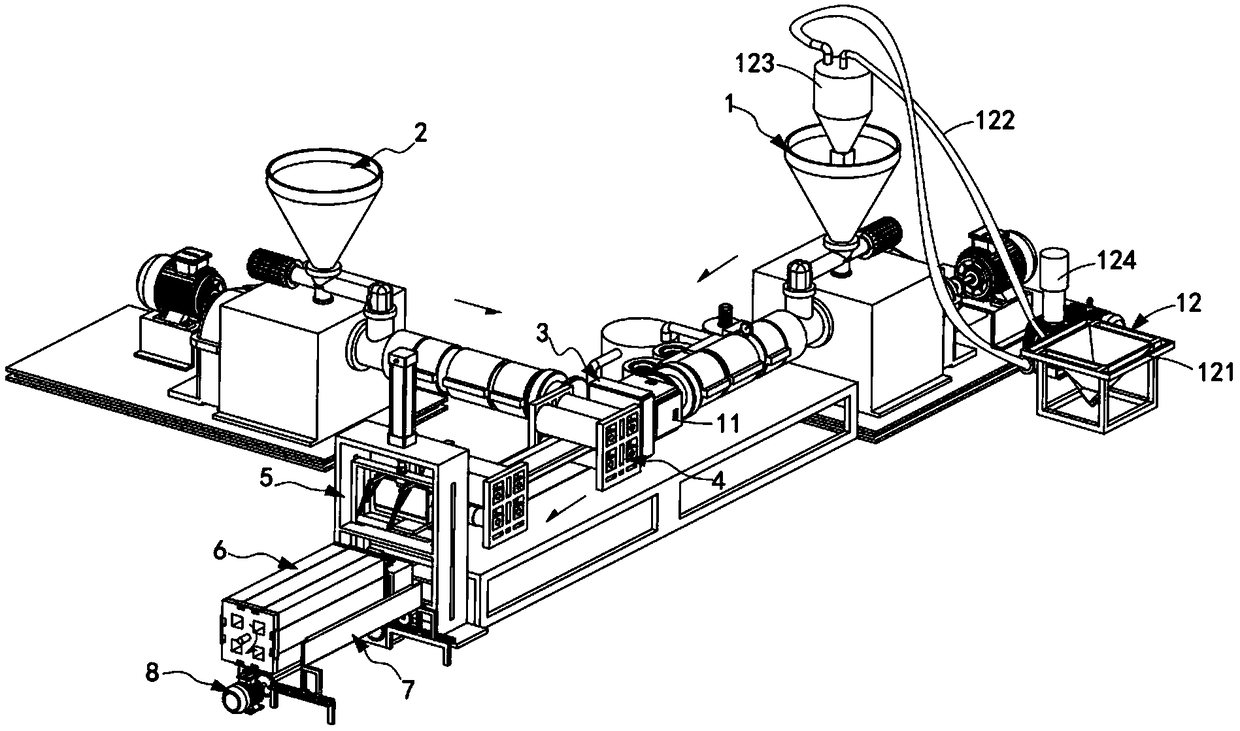

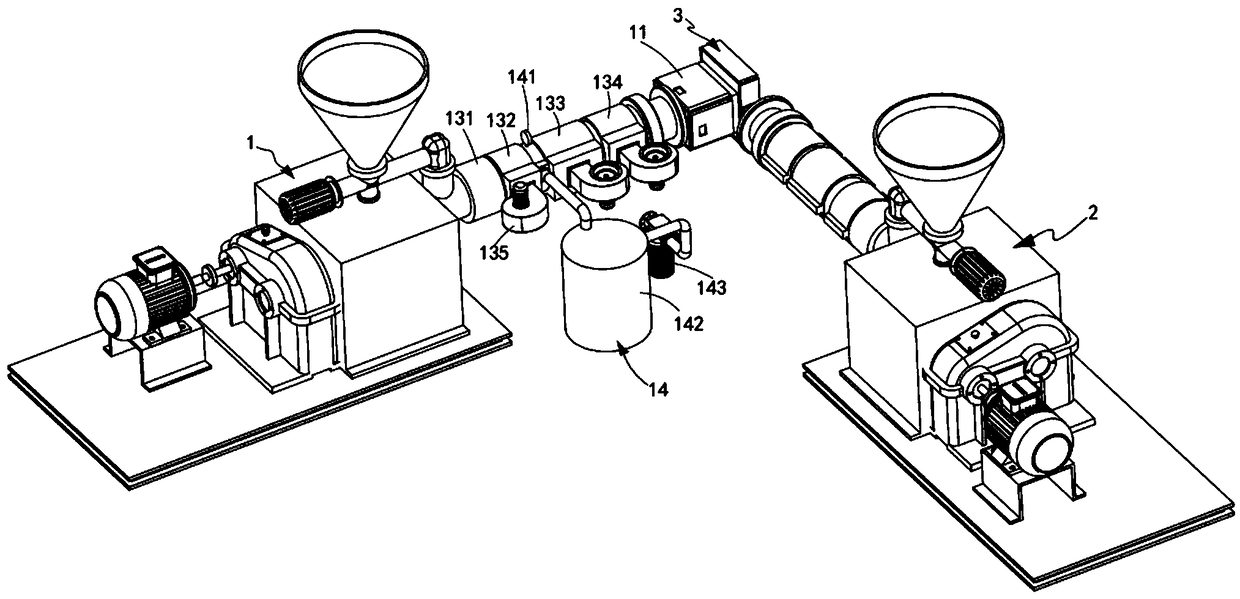

[0088] like Figure 1 to Figure 6 As shown, a high-viscosity scratch-resistant PE wood-plastic board composite production line includes a first extrusion device 1, a second extrusion device 2 and a composite mold 3, and the first extrusion device 1 and the second extrusion device 2. vertically arranged and intersected at the composite mold 3, and a forming mold 11 is provided between the first extruding device 1 and the composite mold 3, further comprising:

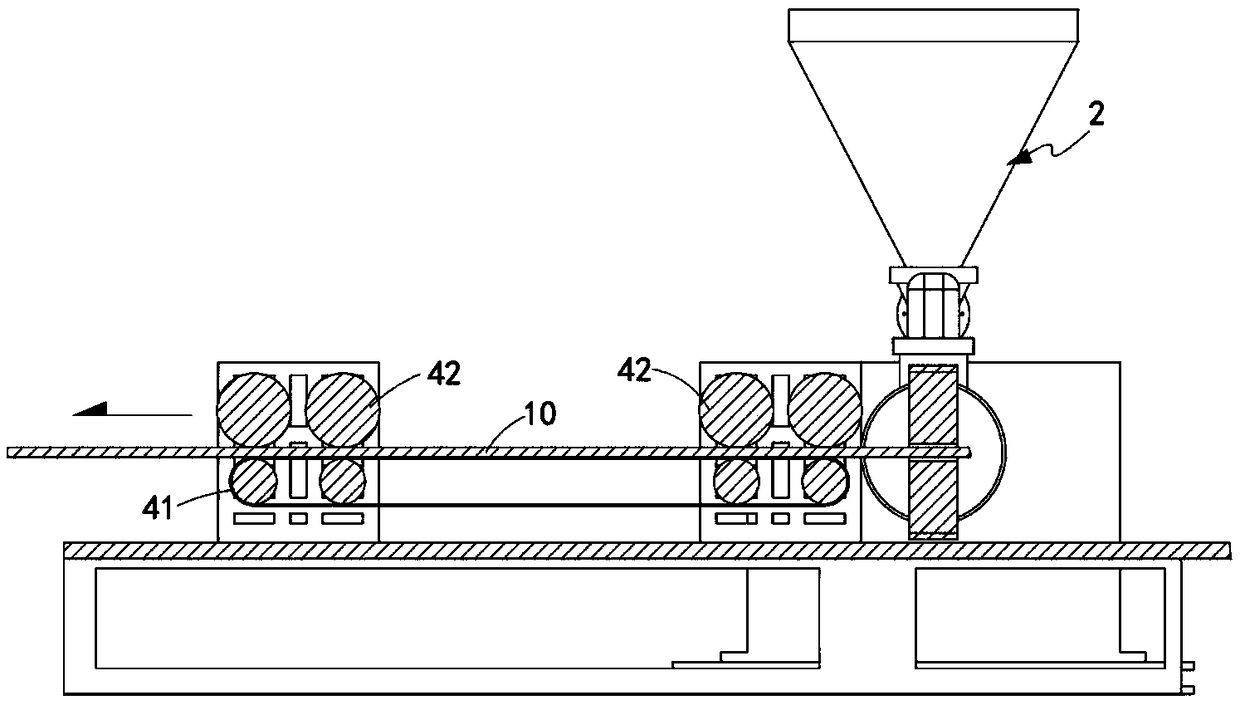

[0089] A rolling conveying mechanism 4, the rolling conveying mechanism 4 is arranged on the rear side of the composite mold 3, and it sequentially conveys the wood-plastic panels 10 output by the composite mold 3 backward;

[0090] Cutting and pushing mechanism 5, described cutting and pushing mechanism 5 is arranged on the rear side of described roller conveying mechanism 4, and it drives cutter 52 to the wood that described rolling conveying mechanism 4 outputs by the push cylinder 51 that is arranged vertically. The ...

Embodiment approach

[0134] like Figure 14 As shown, as a preferred embodiment, the cutting mechanism 8 includes:

[0135] Saw blade 81, the saw blade 81 is arranged below the workbench 60, it is arranged symmetrically along the length direction of the workbench 60, and it is correspondingly matched with the annular knife grooves 605 provided on both sides of the workbench 60 ;as well as

[0136] The drive motor 82 is arranged on one side of the workbench 60 , on which a drive shaft 83 is coaxially connected, and the drive shaft 83 drives the saw blade 81 to rotate through a gear set 84 .

[0137] It should be noted that the length of the wood-plastic panel product 10a will change due to the compression of the convex part after the shaping work is completed, and the two ends need to be cut to keep the length of the wood-plastic panel product 10a consistent. Therefore, by The driving motor 82 drives the saw blade 81 to cut the two ends of the wood-plastic board product 10a.

Embodiment 2

[0139] Figure 17 It is a structural schematic diagram of Embodiment 2 of a high-viscosity scratch-resistant PE wood-plastic board composite production line of the present invention; as Figure 17 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0140] like Figure 17 and Figure 18 As shown, a high-viscosity scratch-resistant PE wood-plastic board composite production line, the roller conveying mechanism 4 also includes an auxiliary push assembly 55 arranged below the wood-plastic board 10, and the auxiliary push assembly 55 includes:

[0141] A drive cylinder 551, the drive cylinder 551 is vertically arranged directly below the wood-plastic panel 10;

[0142] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com