Fully-automatic assembling machine of lighter heat shrinking tube sleeve

A lighter and fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as manual assembly troubles, achieve convenient operation, improve work efficiency, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

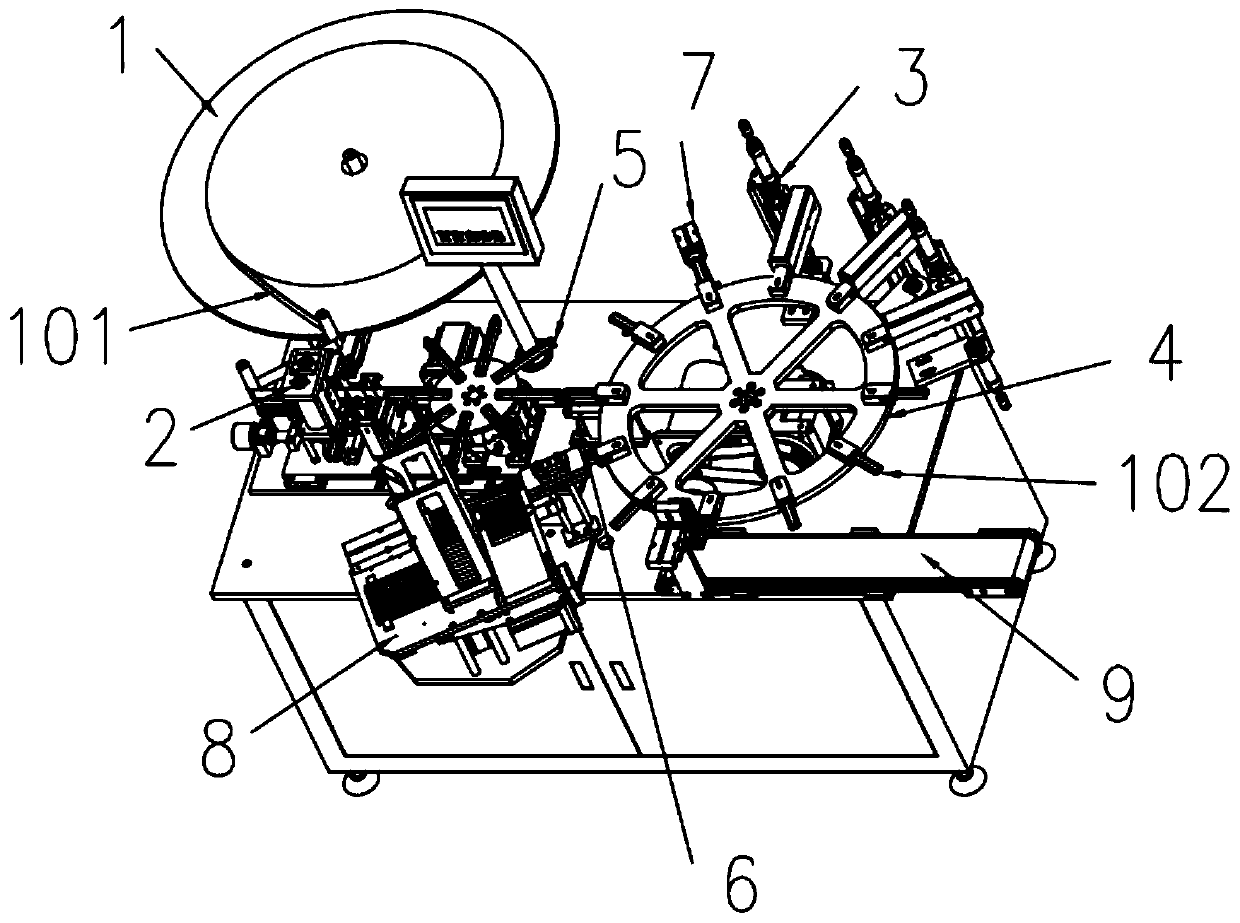

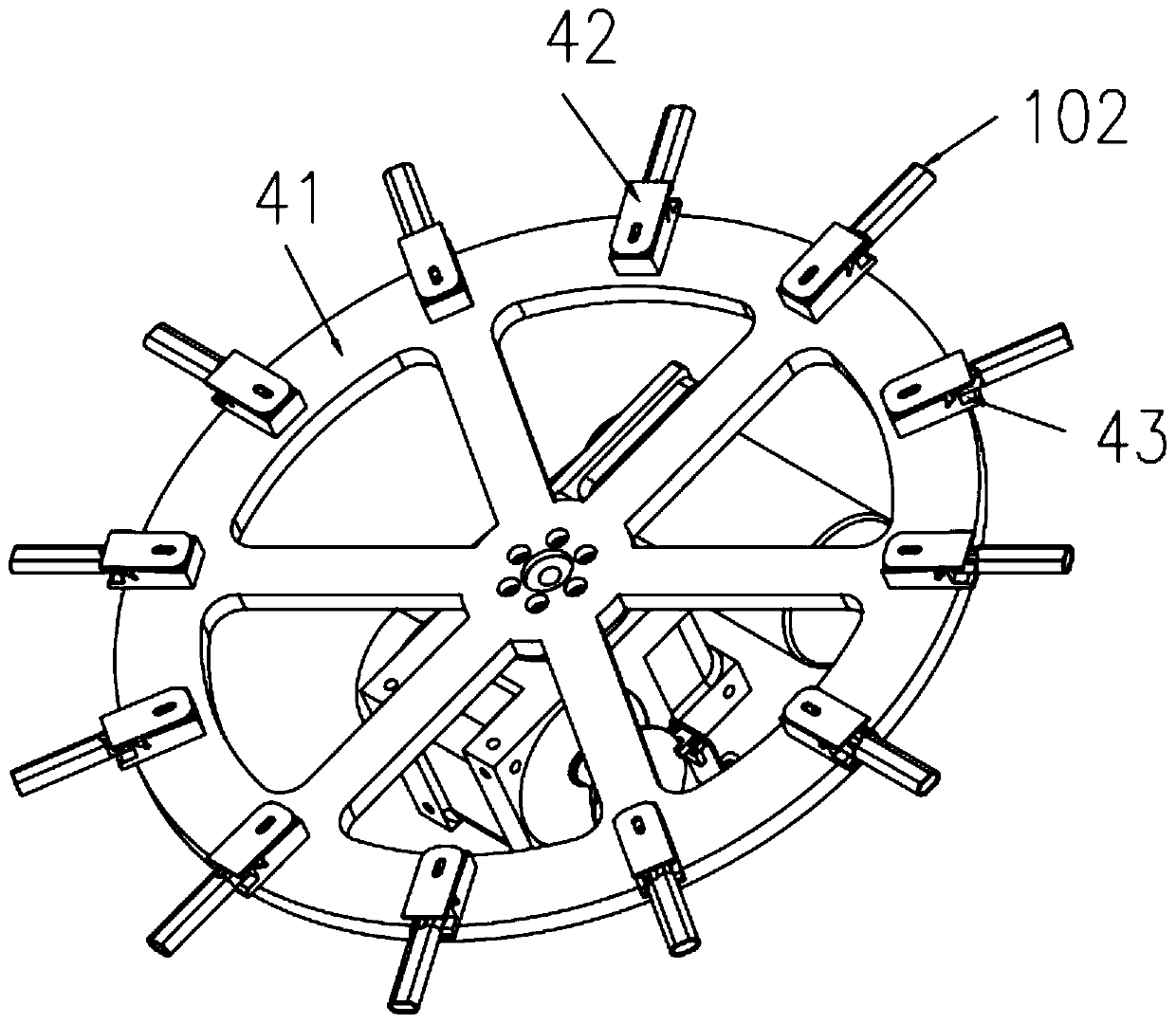

[0036] Example one: such as Figure 1-8 As shown, an automatic assembly machine for lighter heat shrinkable tube sleeves includes a feeding tray mechanism 1, an automatic tape feeding mechanism 2, a steam baking mechanism 3, a lighter feeding turntable mechanism 4, a tube bushing feeding turntable mechanism 5, and a nesting assembly 6. The lighter automatic distribution mechanism 8 and the finished product discharge mechanism 9;

[0037] The feeding tray mechanism 1 is provided with a rolled and flattened material belt 101,

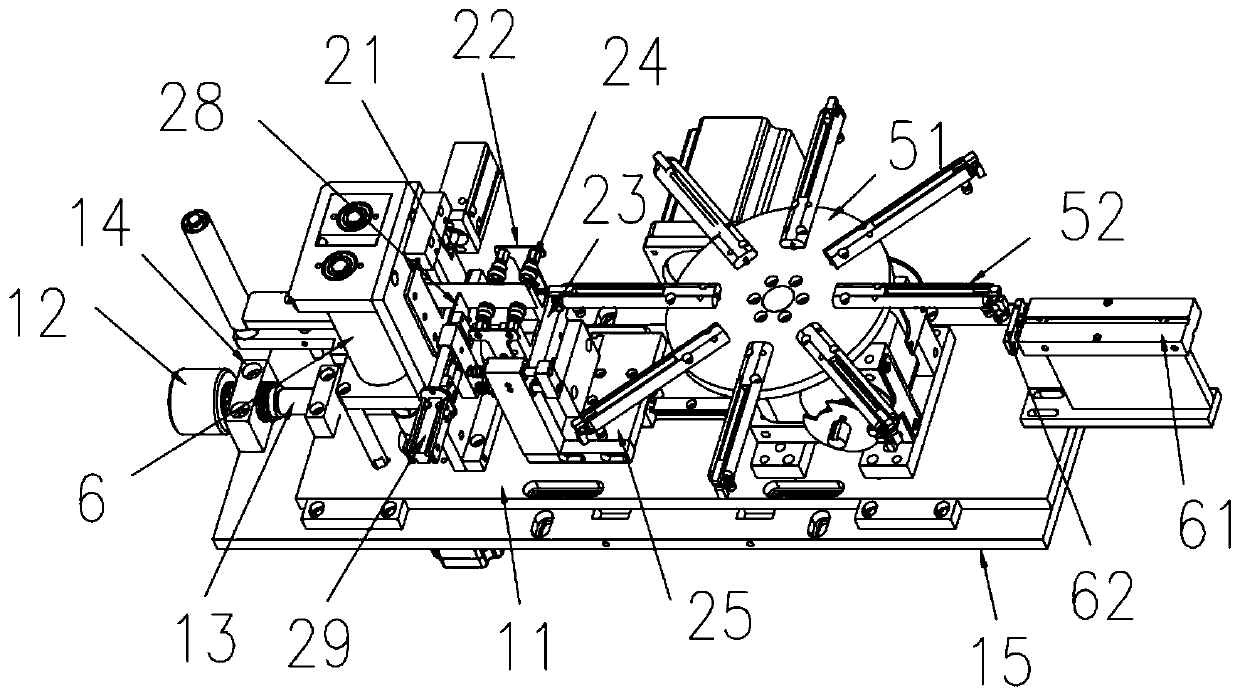

[0038] The tape automatic feeding mechanism 2 includes a cutting member 21, a tube sleeve opening member 22 and a tube sleeve pushing member;

[0039] The cutting member 21 includes a cylinder and a cutter,

[0040] The pipe sleeve opening member 22 includes a clamping jaw cylinder 23 and a suction cup 24. The pipe sleeve 102 is arranged between two clamping jaw blocks of the clamping jaw cylinder 23. The suction cup 24 is installed on the clamping jaw block and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com