Device for automatically covering tarpaulin of truck

A sheet cloth and automatic technology, which is applied in the field of automatic cover sheet cloth devices for trucks, can solve the problems of high difficulty, danger, high work intensity, etc., and achieve the effects of increasing safety and reliability, improving work efficiency, and being convenient and quick to assemble and maintain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

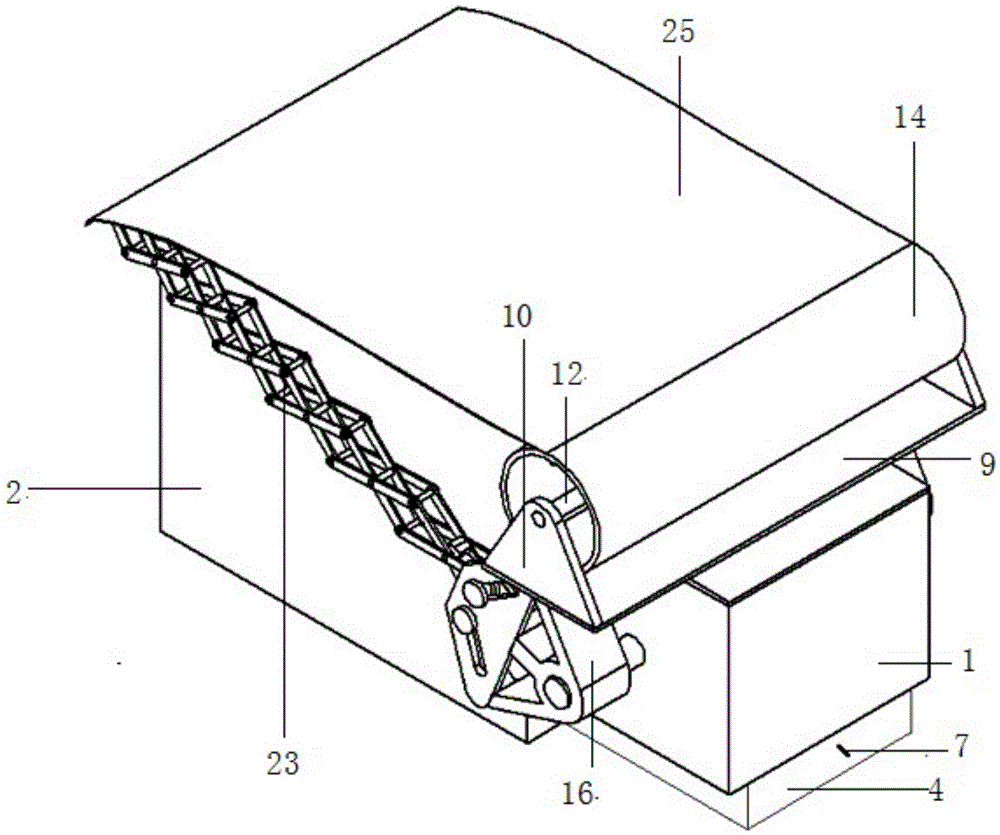

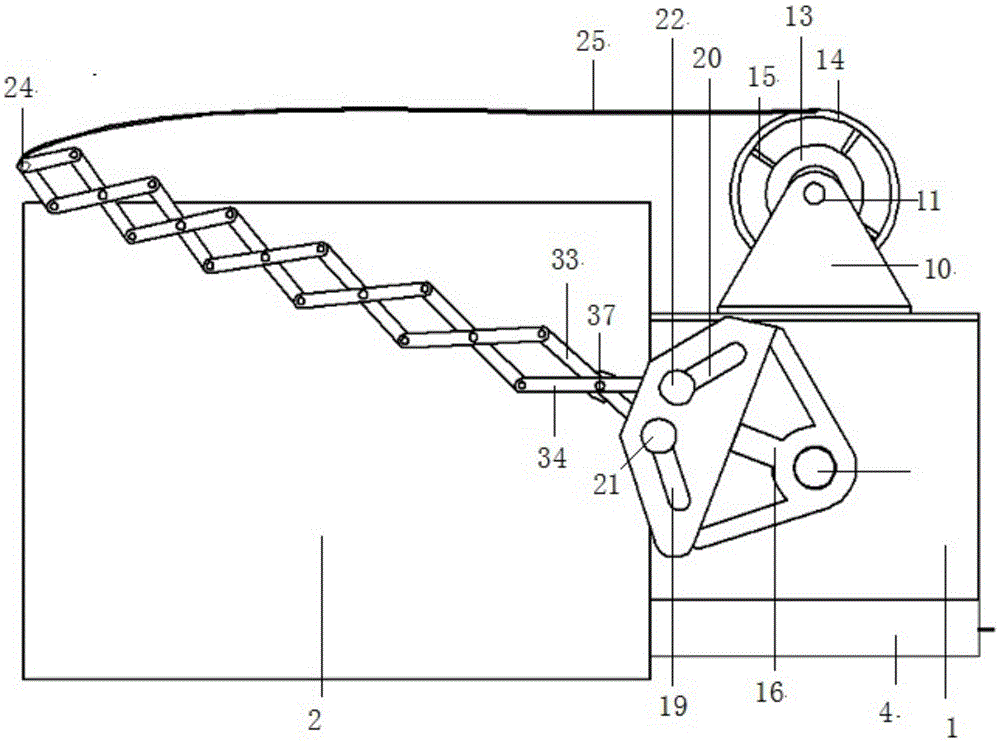

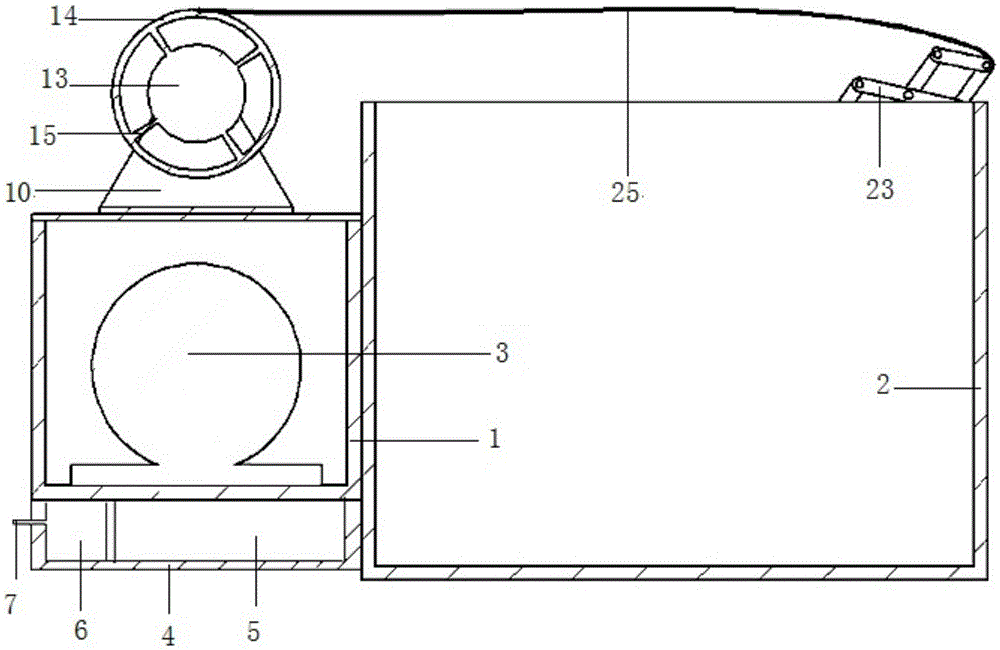

[0021] Specific implementation method: combined Figure 1-8 As shown, it includes a motor box 1 and a cargo box 2. A stepping motor 3 is installed in the motor box 1, and the stepping motor 3 is connected with the bottom of the inner side of the motor box by bolts; a battery box 4 is installed on the lower surface of the motor box 1; The box 4 and the motor box 1 are connected by bolts; the motor box 1 and the cargo box 2 are connected by bolts; the battery box 4 is installed with a battery 5 and a control device 6; 6 and the remote control receiving head 7 are connected through a circuit; the control device 6 is equipped with a remote controller 8; the upper surface of the motor box 1 is provided with a bottom plate 9, and the bottom plate 9 is connected with the motor box 1 by bolts; both sides of the bottom 9 plate are welded with bases in the length direction 10. The base 10 is provided with a through hole 11; the through hole 11 is matched with a fixed shaft 12, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com