Material-fetching method and automatic material-fetching machine for implementing the method

An automatic reclaimer and reclaimer technology, applied in optics, loading/unloading, instruments, etc., can solve the problems of the complex structure of the automatic reclaimer and the long stroke of the reclaimer, so as to reduce waiting time, work compactly, and save money. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

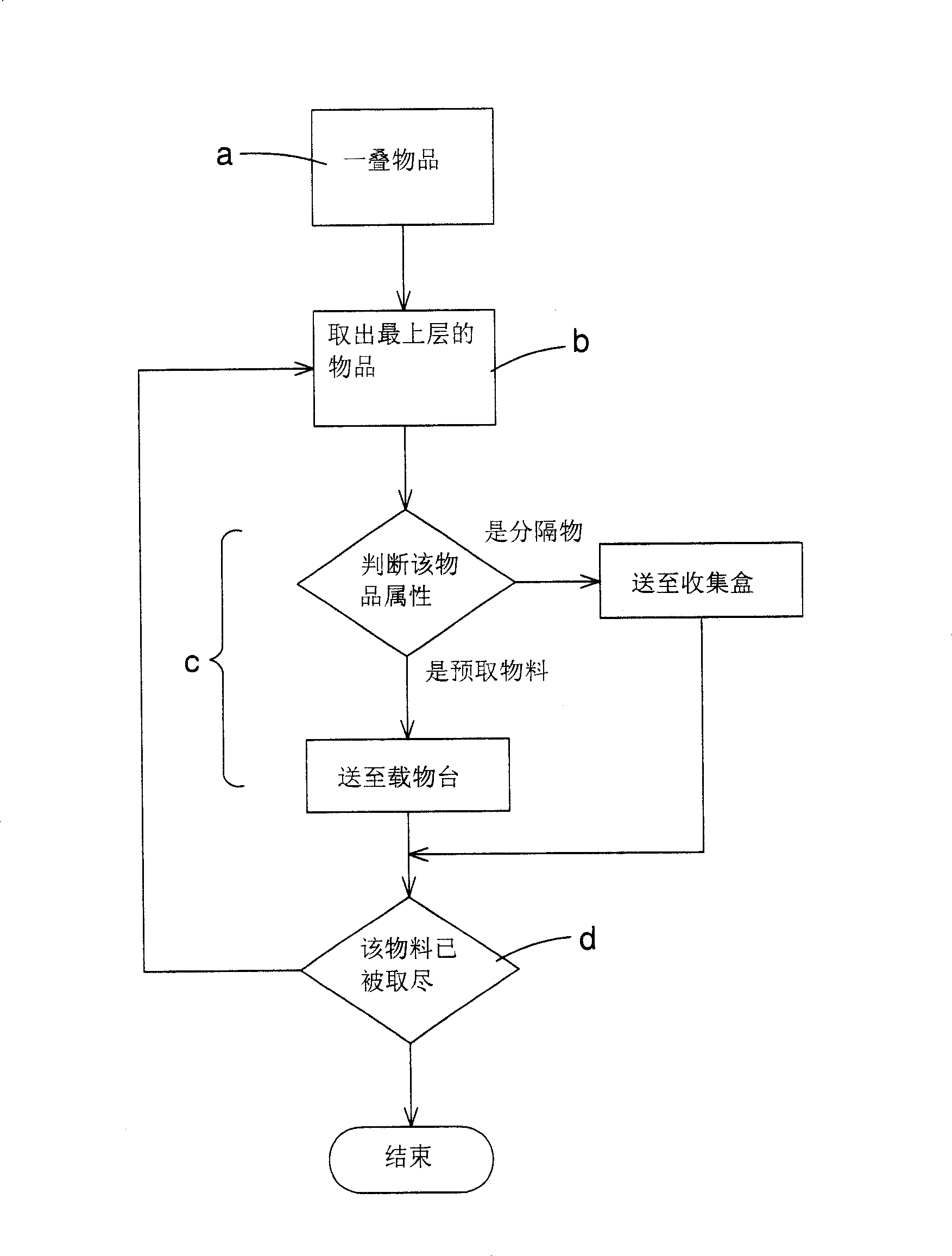

[0036] See attached figure 1 And attached image 3 , a kind of reclaiming method, it comprises the steps:

[0037] a) Move a stack of items to a pick-up position, the stack of items includes a plurality of materials stacked layer by layer, and the plurality of materials are separated from each other by spacers. In this embodiment, the above-mentioned materials are liquid crystal panels, and The spacer is made of cushioning material;

[0038] b) Take out the item located on the uppermost layer, in this embodiment, vacuum suction is used to absorb the item, such as using several suction cups to absorb the item;

[0039] c) Determine the property of the item, place the item in a corresponding position according to the property of the item, if the item is a spacer, move the collection box for containing the spacer to the bottom of the spacer, and The spacer falls and is placed in the collection box; if the item is a pre-fetched material, the material is first moved horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com