Hydraulic main clutch mechanism of corn harvester

A corn harvester, main clutch technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of large operating force, short service life of the main clutch transmission belt, etc., to reduce labor intensity, improve transmission efficiency and effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

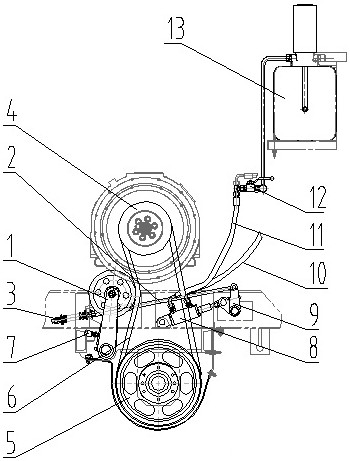

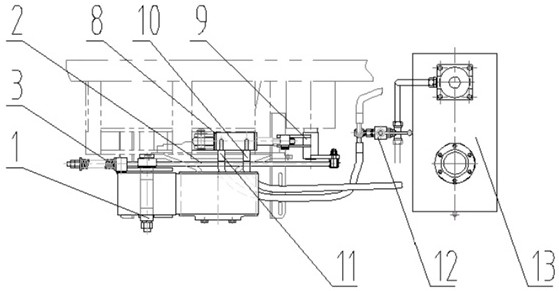

[0031] Such as figure 1 , 2As shown, the embodiment of the present invention provides a hydraulic main clutch mechanism for a corn harvester, including a storage box 14, a tensioner assembly 1, a pull rod 2, a return spring 3, an engine pulley 4, a main drive pulley 5, a drive belt 6, Safety switch 7, main clutch oil cylinder 8, clutch rocker arm 9, oil pipe 1 10, oil pipe 2 11, high pressure valve 12, hydraulic oil tank 13, the inside of storage box 14 is provided with tensioner assembly 1, the front end of tensioner assembly 1 Fixedly connected with pull rod 2, the lower rear end of pull rod 2 is rotatably connected with the inner wall of storage box 14 by bolts, and the surface of main drive pulley 5 is connected with drive belt 6 in one circle rotation, and the top of main drive pulley 5 is connected with the surface of drive belt 6. The engine pulley 4 is rotatably connected, and the side of the tensioner assembly 1 near the main drive pulley 5 is rotatably connected to ...

Embodiment 2

[0033] Such as figure 1 , 2 , 5, the embodiment of the present invention provides a hydraulic main clutch mechanism for a corn harvester, the top of the main clutch oil cylinder 8 is fixedly connected with a clutch rocker 9, and the top of the clutch rocker 9 is fixedly connected with the top of the return spring 3, reset The surface of the spring 3 runs through and connects with the rear end of the tensioner assembly 1 and the drive belt 6, and the front end of the main drive pulley 5 is provided with an air outlet groove with the main drive pulley 5 as a circular axis, and the rear top of the main clutch cylinder 8 runs through Oil pipe one 10 is connected, one side of oil pipe one 10 is in contact with the air, the top of oil pipe two 11 set at the junction of oil pipe one 10 and main clutch oil cylinder 8 is fixedly connected with the bottom end of high-pressure valve 12, and the top of high-pressure valve 12 passes through oil pipe Two 11 are connected through the bottom...

Embodiment 3

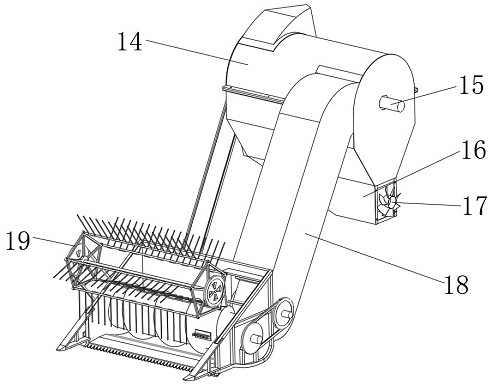

[0035] Such as image 3 , 4 , shown in 5, the embodiment of the present invention provides a kind of hydraulic main clutch mechanism of corn harvester, one side of support 25 is fixedly connected with harvesting frame 19, and the bottom end of harvesting frame 19 and the top distance of support 25 are one meter, harvesting frame One week of the surface of 19 is fixedly connected with harvesting pipe 26, and harvesting pipe 26 is provided with a length of eighty centimeters, and harvesting pipe 26 is arranged at equal intervals on the surface of harvesting frame 19 to be five rows, and the inside of storage box 14 is provided with motor 23, harvesting One side of the lower bracket 25 of the frame 19 is rotatably connected with a winch bucket 20, and the surface of the hoist bucket 20 is fixedly connected with a rotating scale 21, and the end of the engine pulley 4 away from the storage box 14 is fixedly connected with a wheel set 24, and the wheel set 24 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com