Vacuum rake dryer

A rake dryer and drying machine technology, which is applied in the direction of dryers, drying solid materials, and dry goods processing, etc., can solve the problems of long residence time of materials, uneven drying, poor drying effect, etc., and achieve a small cleaning workload , Solve the effect of discontinuous production and constant vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

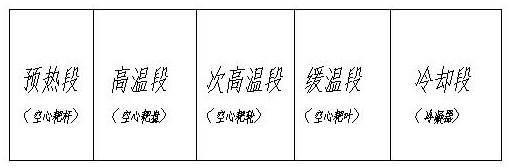

[0026] A vacuum rake dryer, the dryer is sequentially provided with a preheating section 1, a high temperature section 2, a subhigh temperature section 3, a slow temperature section 4 and a cooling section 5 from front to back;

[0027] The temperature of each section is determined by the characteristics of the object to be dried, the drying degree of the batch, and the drying requirements. Under normal circumstances, the temperature of the preheating section 1 is between 50 and 100°C, and the temperature of the high-temperature section 2 is between 50°C and 100°C. 120~250°C, the temperature of the secondary high temperature section 3 is between 110~160°C, the temperature of the slow temperature section 4 is between 60~110°C, the temperature of the cooling section 5 is between -10~ between 40°C.

[0028] Further, the preheating section 1 is provided with a hollow rake rod 11, the high temperature section 2 is provided with a hollow rake disc 21, the secondary high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com