Series connection non-crankshaft engine transmission mechanism and engine with series connection non-crankshaft engine transmission mechanism

A transmission mechanism and engine technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as low transmission efficiency, and achieve the effects of simple maintenance, reduced emissions, and reduced idle speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

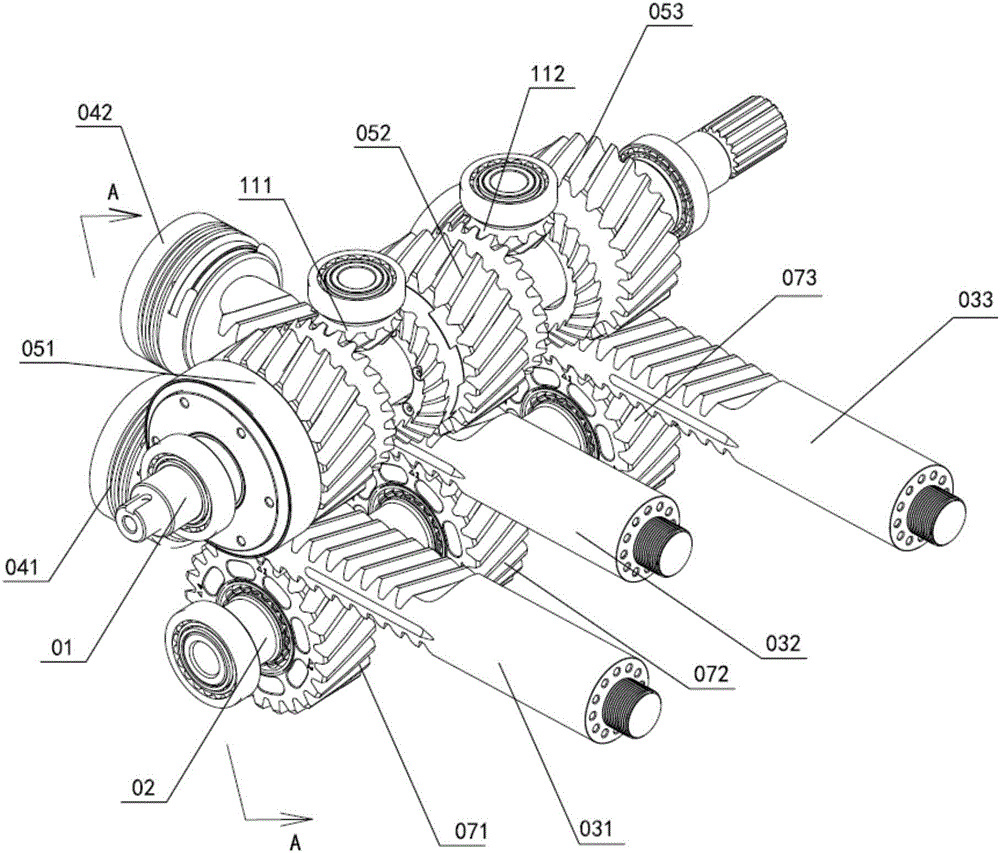

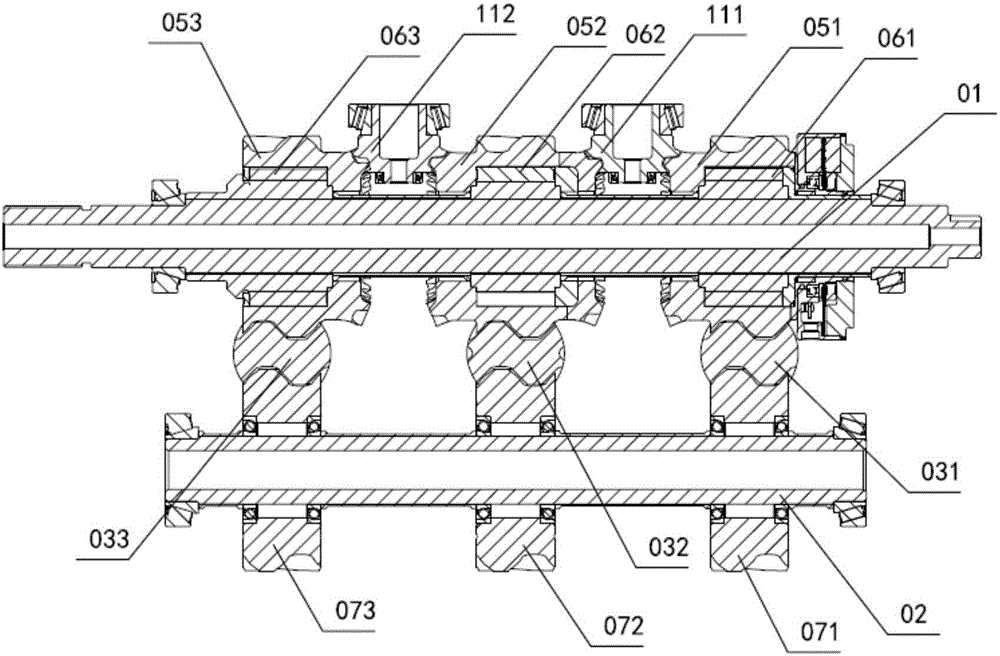

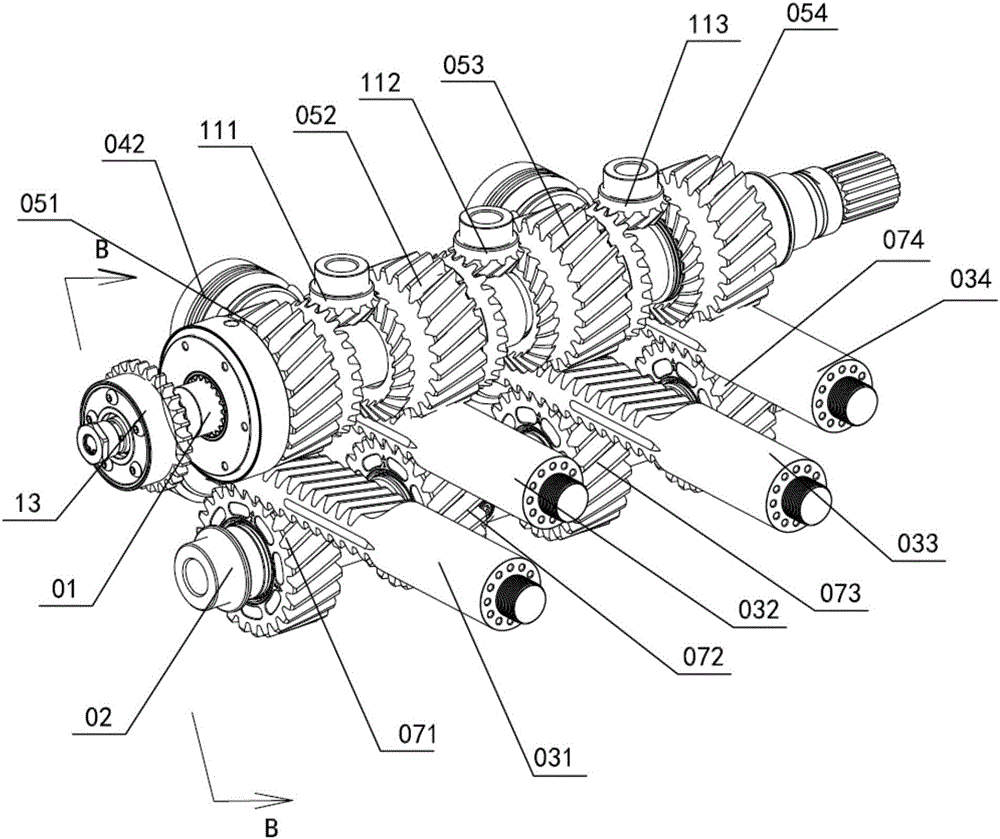

[0045] For the structure diagram of Embodiment 1 of the present invention, see figure 1 with figure 2 , a serial crankshaftless engine transmission mechanism, including a power shaft 01 and a countershaft 02, the power shaft 01 and the countershaft 02 are arranged parallel to each other, and at least three cylinder piston rods are arranged between the power shaft 01 and the countershaft 02, including the first cylinder piston Rod 031, the second cylinder piston rod 032 and the third cylinder piston rod 033; the same end of the three cylinder piston rods, that is, the end of the left end of the illustration is provided with a cylinder piston, and the end of the first cylinder piston rod 031 left end The first cylinder piston 041 is provided, and the second cylinder piston rod 032 is provided with a second cylinder piston 042; one side of each cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com