Patents

Literature

67results about How to "No elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

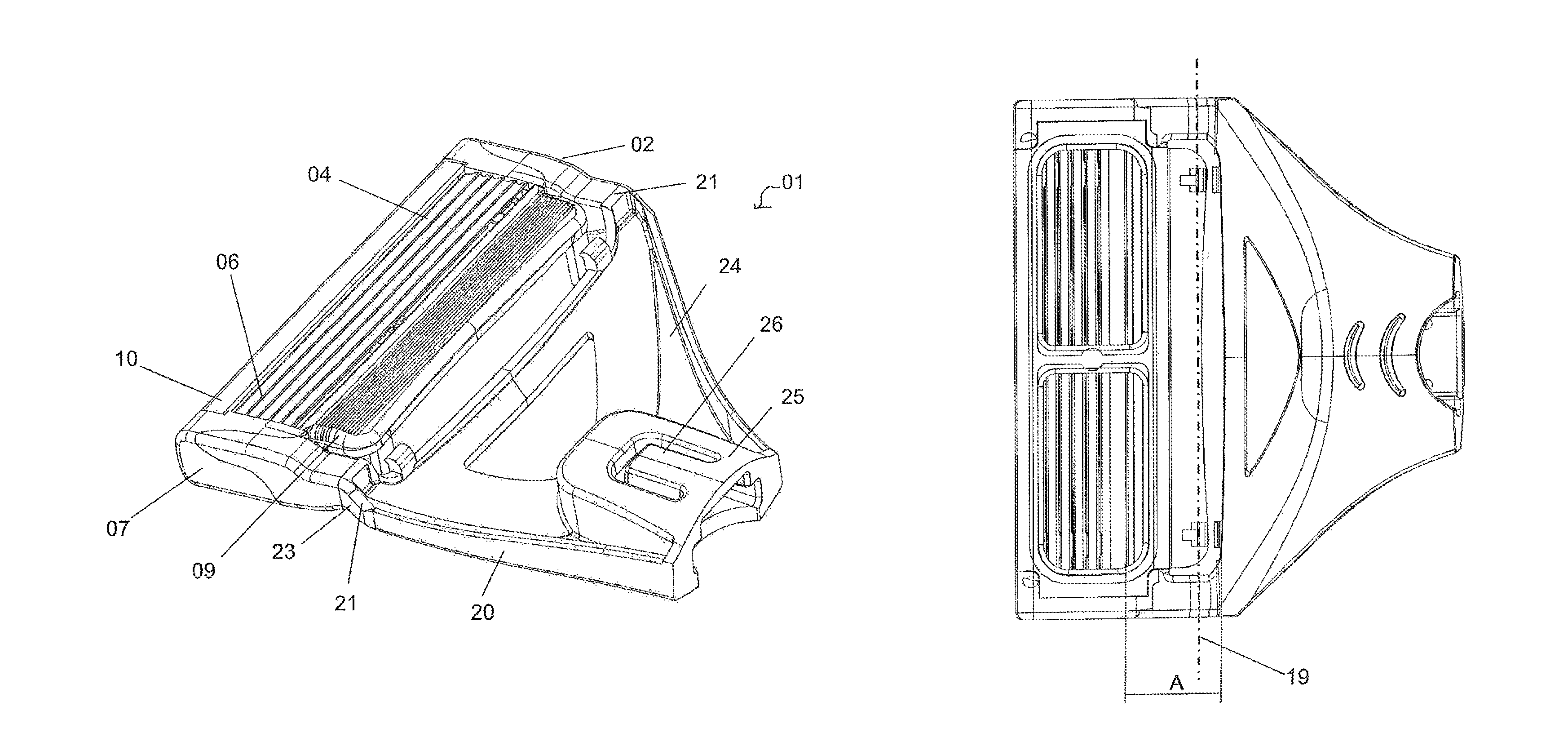

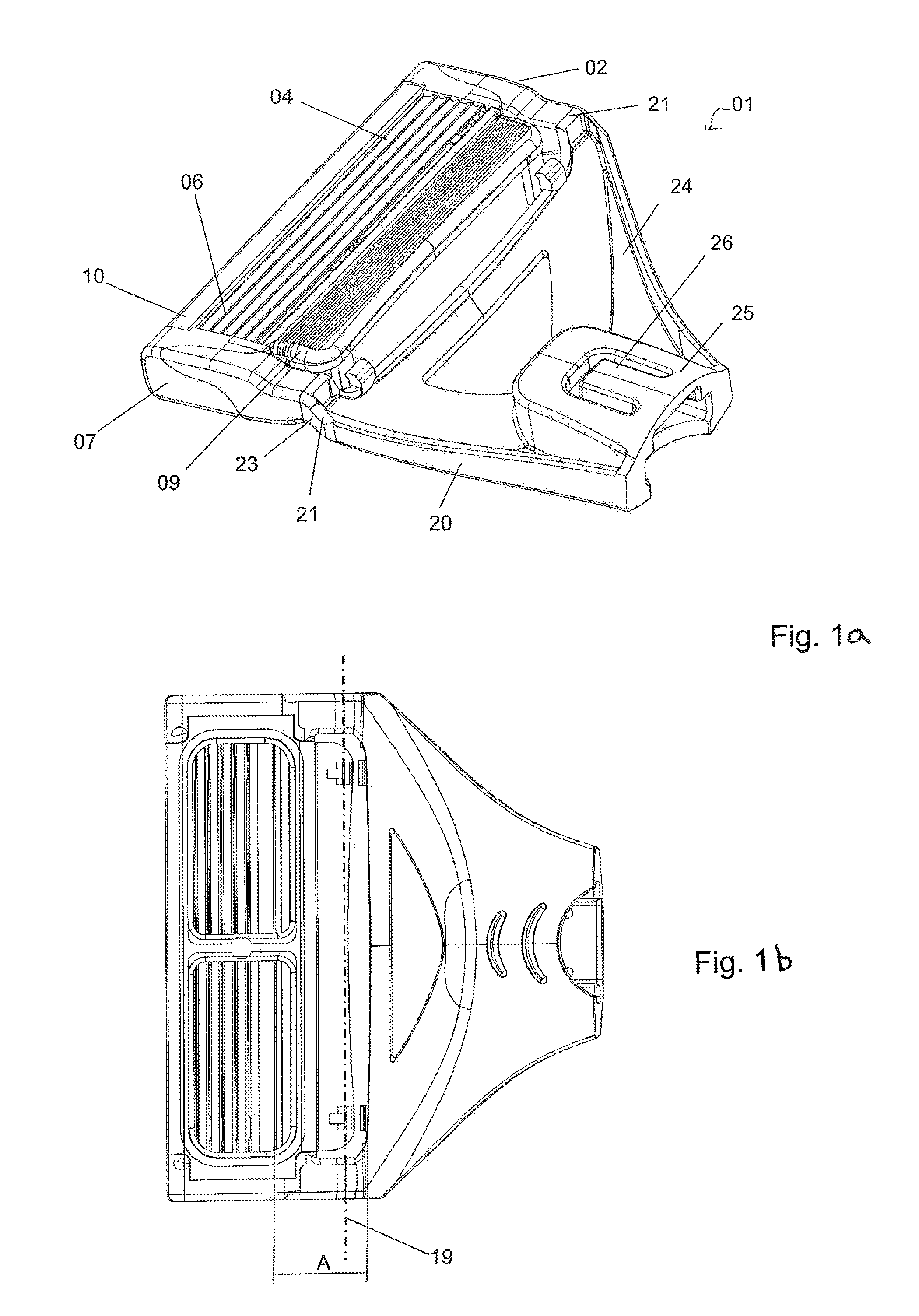

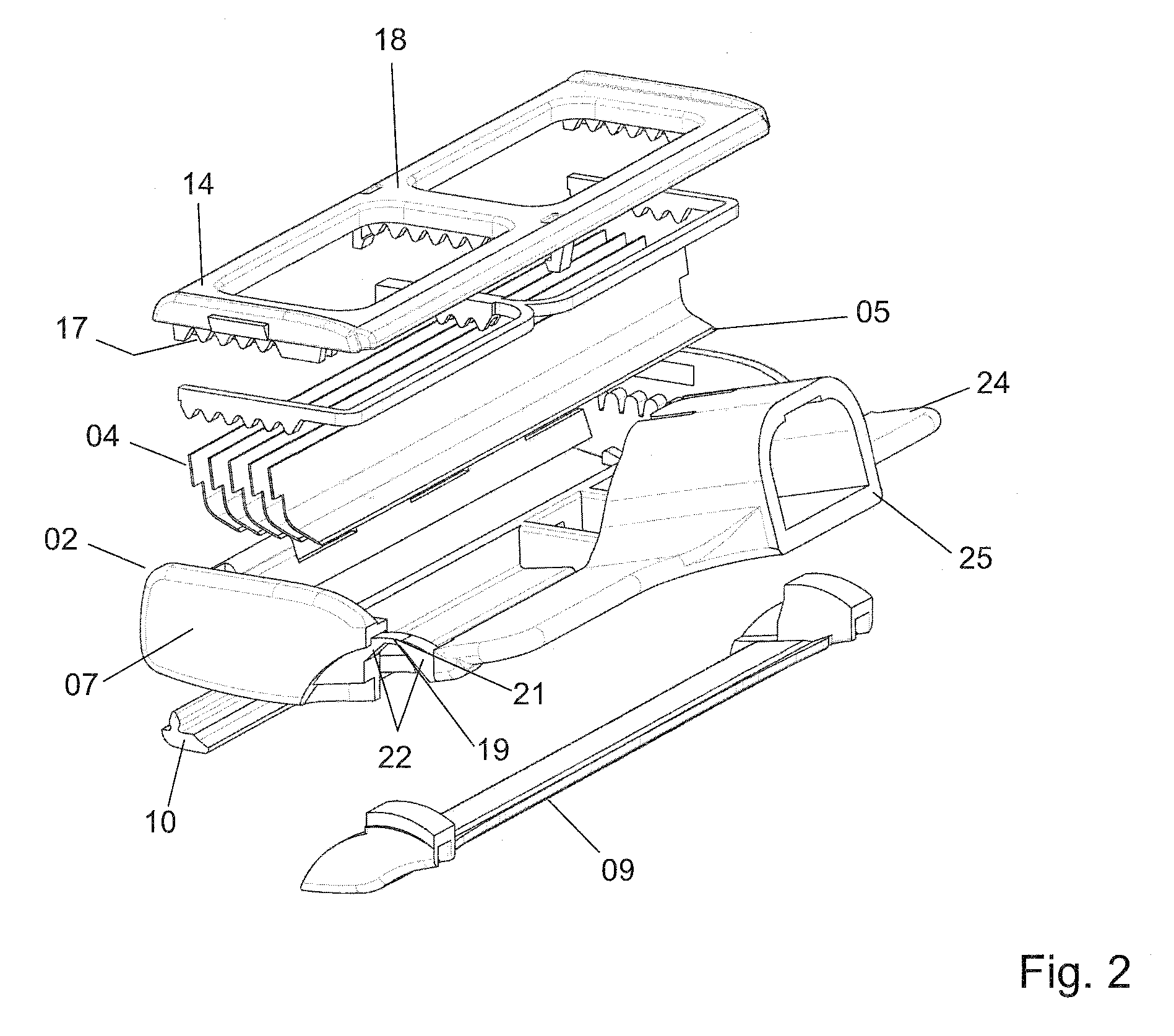

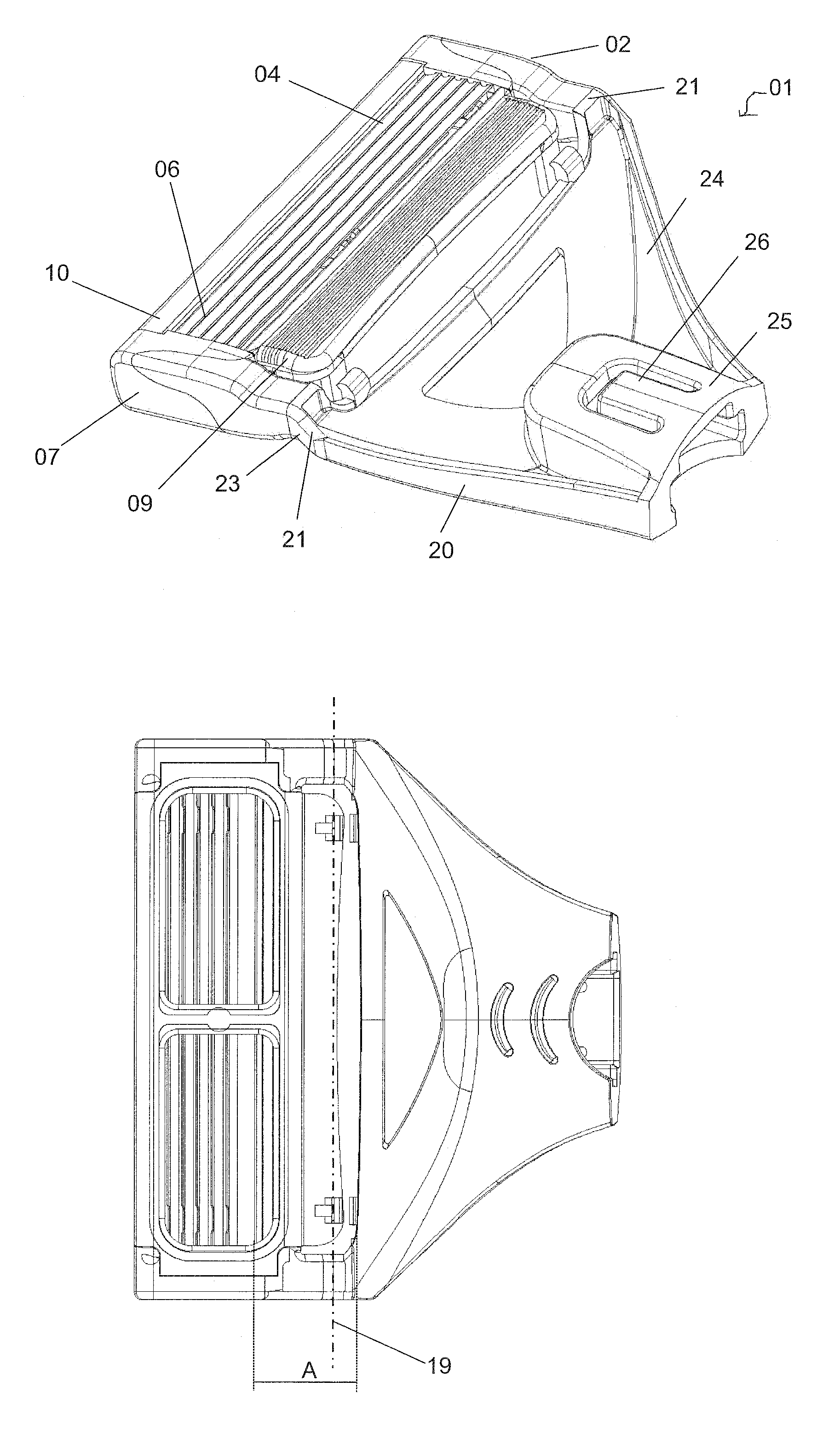

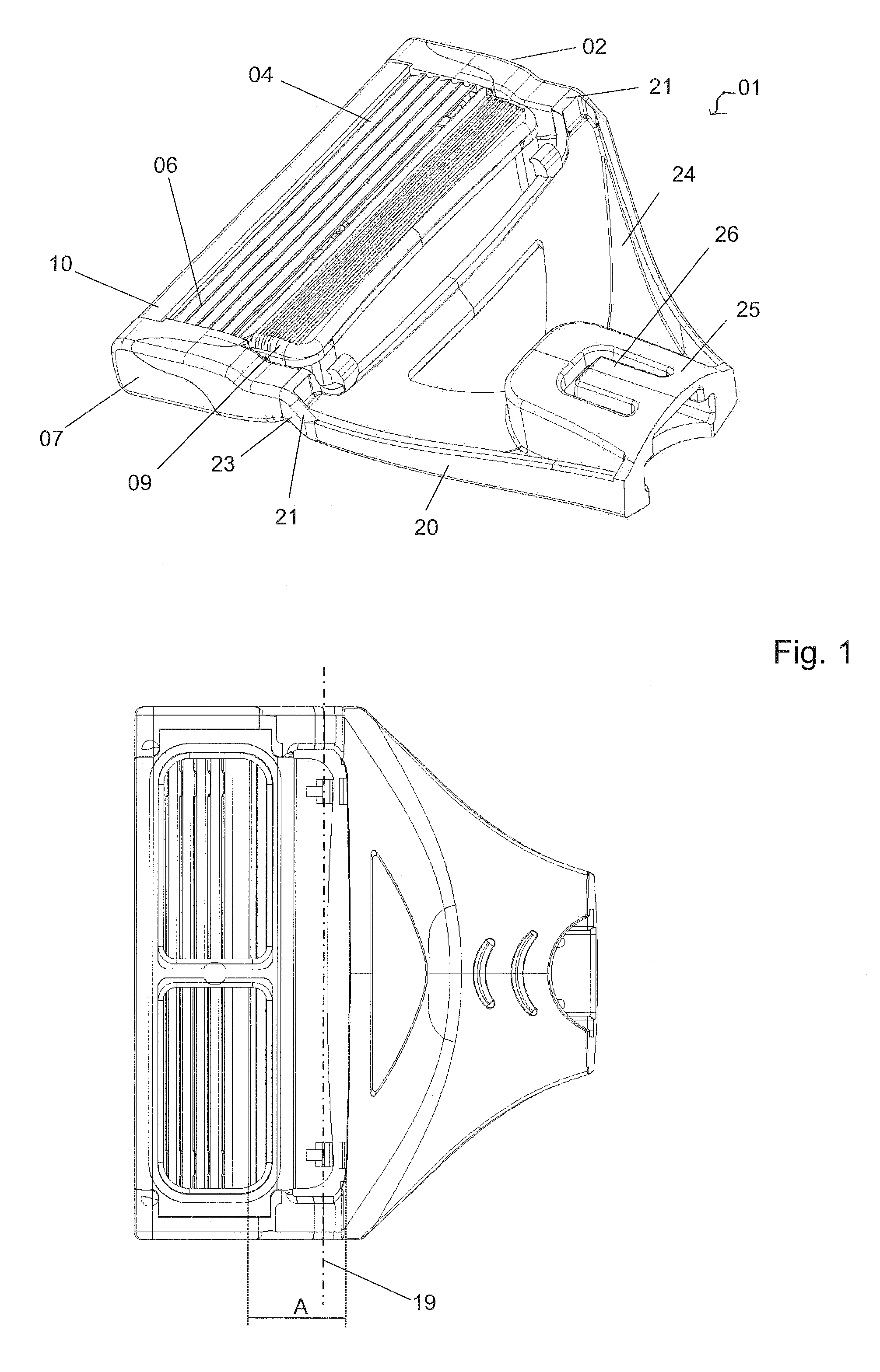

Razor blade unit with film hinge

A razor blade unit with a blade housing, in which several blades with cutting edges lying parallel to a skin contact plane are arranged, a coupling section, which can be connected preferably in a detachable manner to a handle, and a connecting section. The connecting section includes at least one film hinge between the blade housing and the coupling section, which hinge defines a pivot axis extending parallel to the skin contact plane, and an elastic damping component, which surrounds one or more sides of the film hinge and is formed both on the blade housing and on the coupling section. The razor blade unit also has a foam edge, arranged in front of the cutting edges (with respect to the shaving direction) of the blades to pretension the skin during shaving. The pivot axis extending through the film hinge is positioned between the forward boundary (with respect to the shaving direction) of the foam edge and the cutting edge lying closest to the foam edge.

Owner:FEINTECHN EISFELD

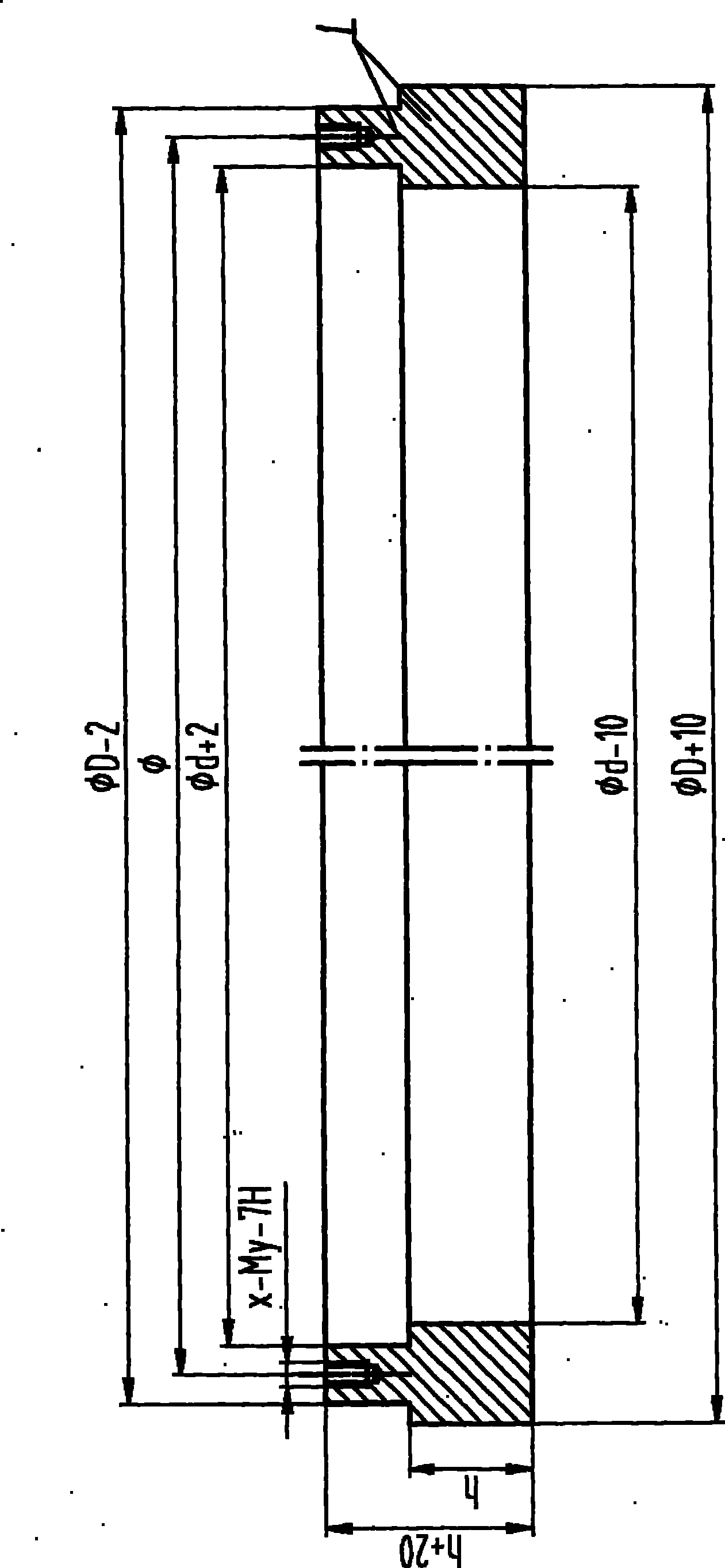

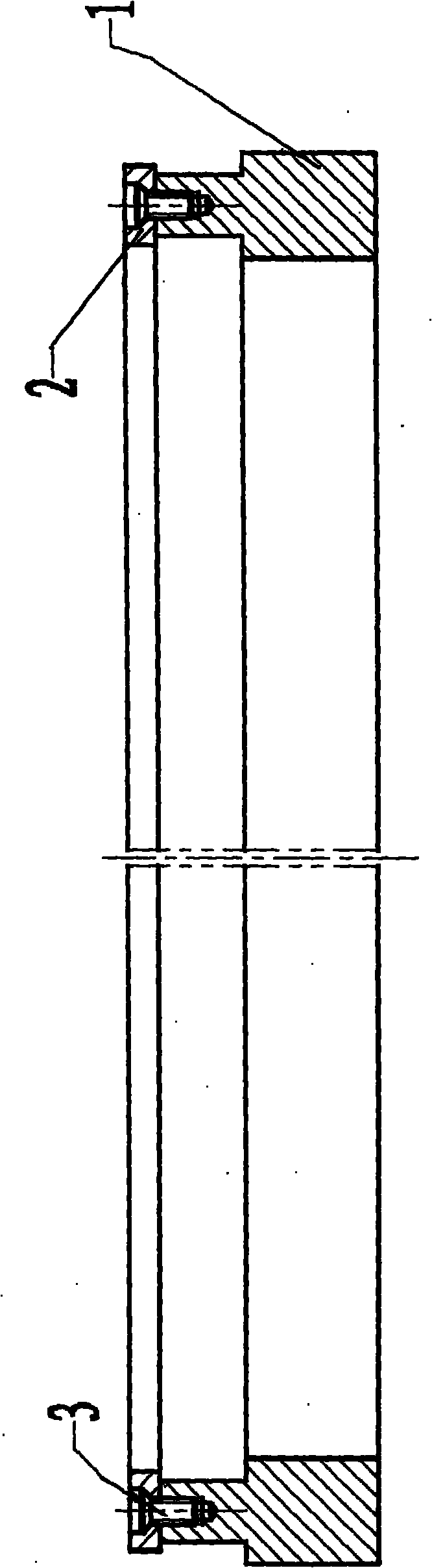

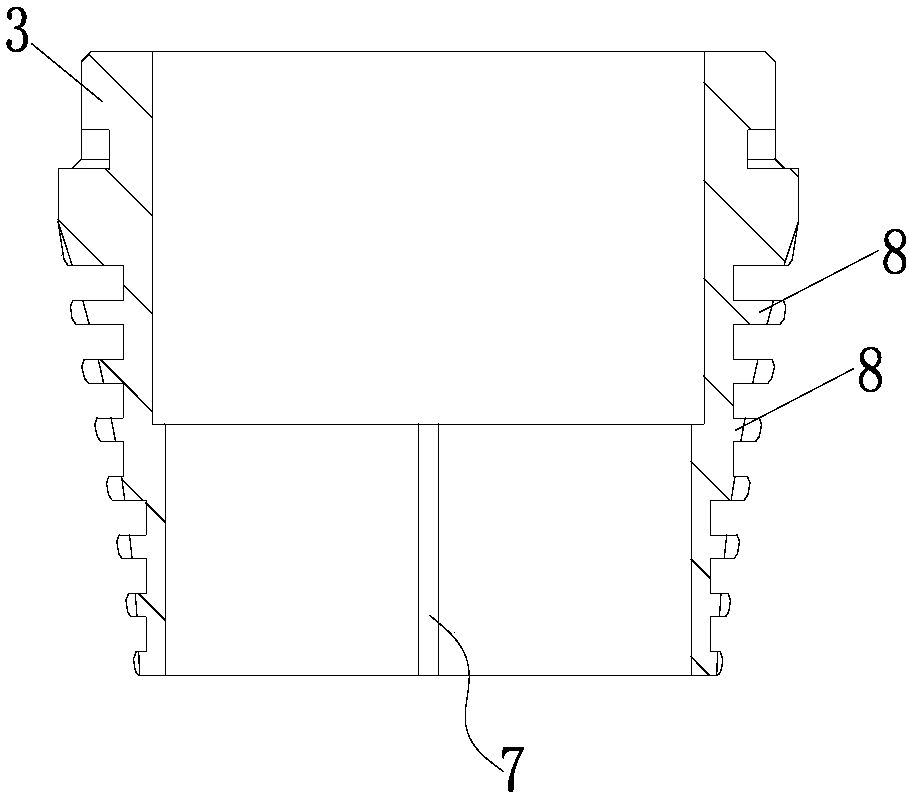

Processing method of ultra-thin annular pieces

InactiveCN101774111AImprove rigidityNo elasticityPositioning apparatusMetal-working holdersSheet steelWork in process

The invention relates to a processing method of ultra-thin annular pieces. The method comprises the following process flows of: (1) cutting a blank; (2) roughly turning; (3) drilling; (4) dividing single pieces; (5) manufacturing a tool clamp; (6) combining and fine turning; and (7) turning or grinding planes. 4-10 ultra-thin annular pieces are combined together, and meanwhile, steel plate flames are used for cutting and integrally blanking so as to improve the rigidity and ensure that no deformation occurs in the processing process. Semi-finished ultra-thin annular piece products to be processed, which are cut and blanked into single pieces, need to be combined together with the tool clamp, wherein the tool clamp is an annular piece with inner and outer steps between an upper section and a lower section. The circumference on the upper end surface of the tool clamp is uniformly provided with threaded holes according to the mounting hole sizes of the ultra-thin annular pieces, and then the single semi-finished products of the ultra-thin annular pieces to be processed are combined with the tool clamp into a whole by using bolts so as to enhance the rigidity of the semi-finished ultra-thin annular piece products, guarantee non-deformation during processing in subsequent working procedures, realize the localization of the ultra-thin annular pieces to replace imported pieces, greatly reduce the cost and meet the requirement of users.

Owner:MAANSHAN FANGYUAN SLEWING RING

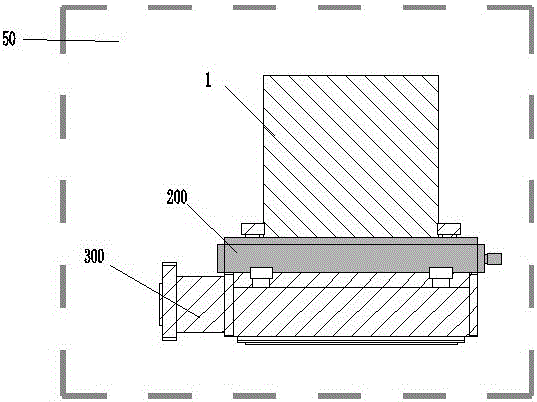

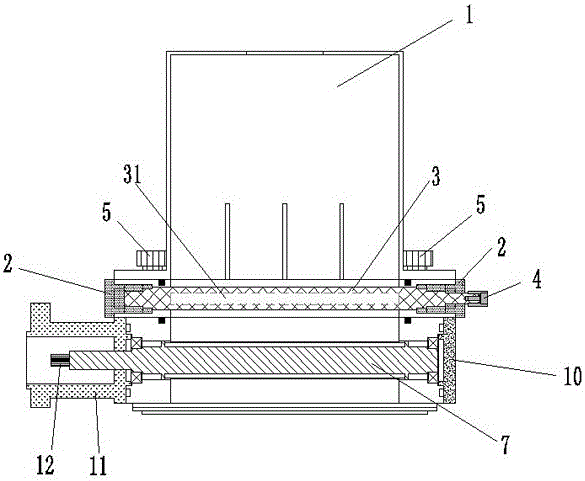

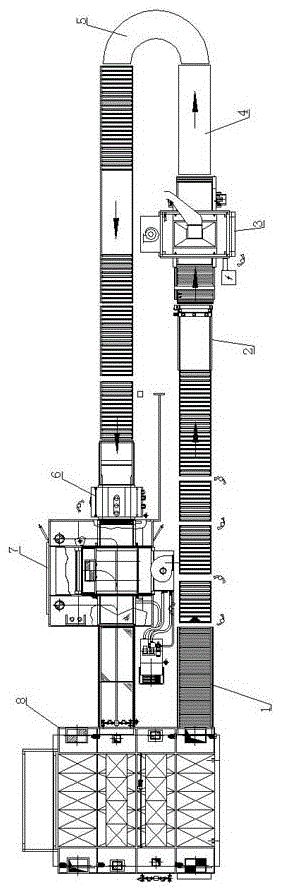

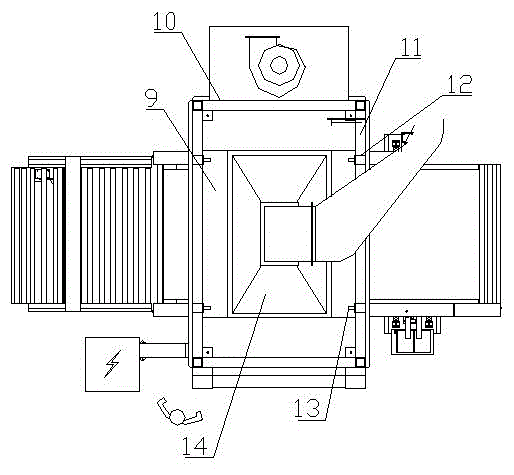

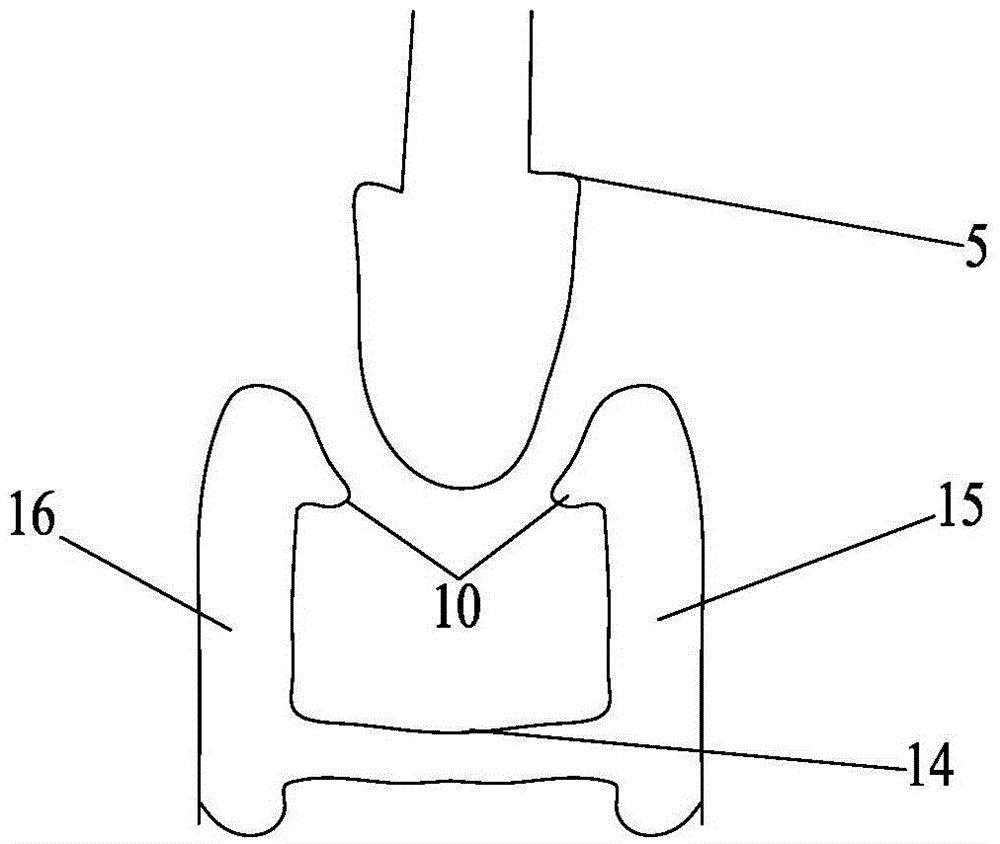

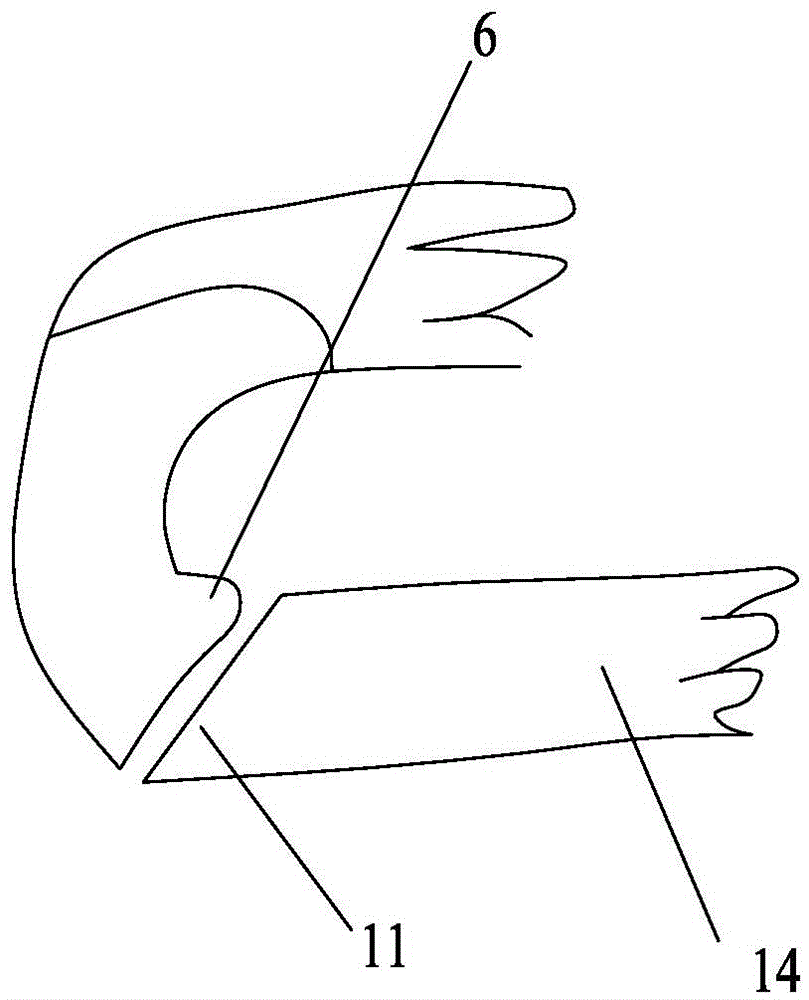

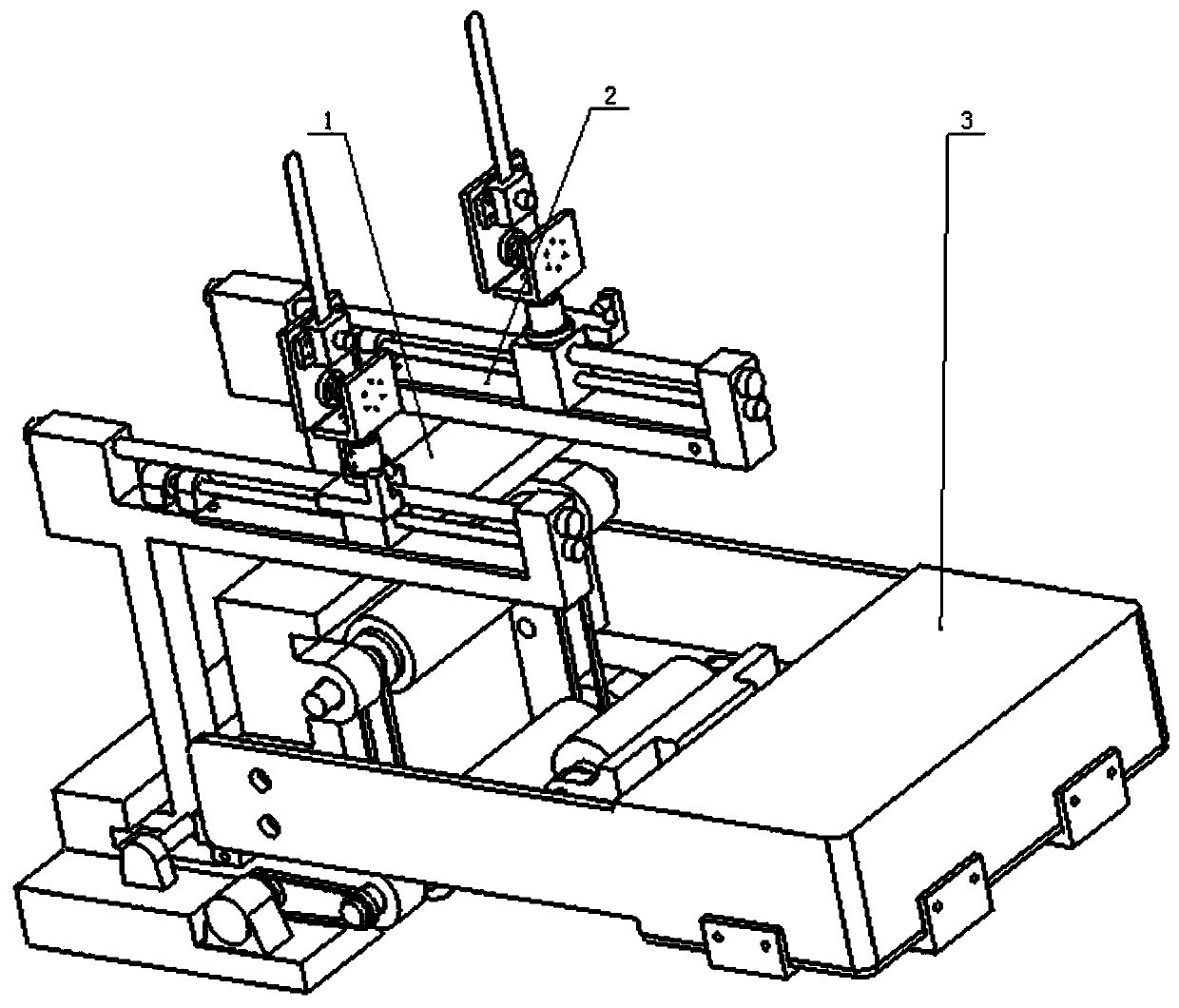

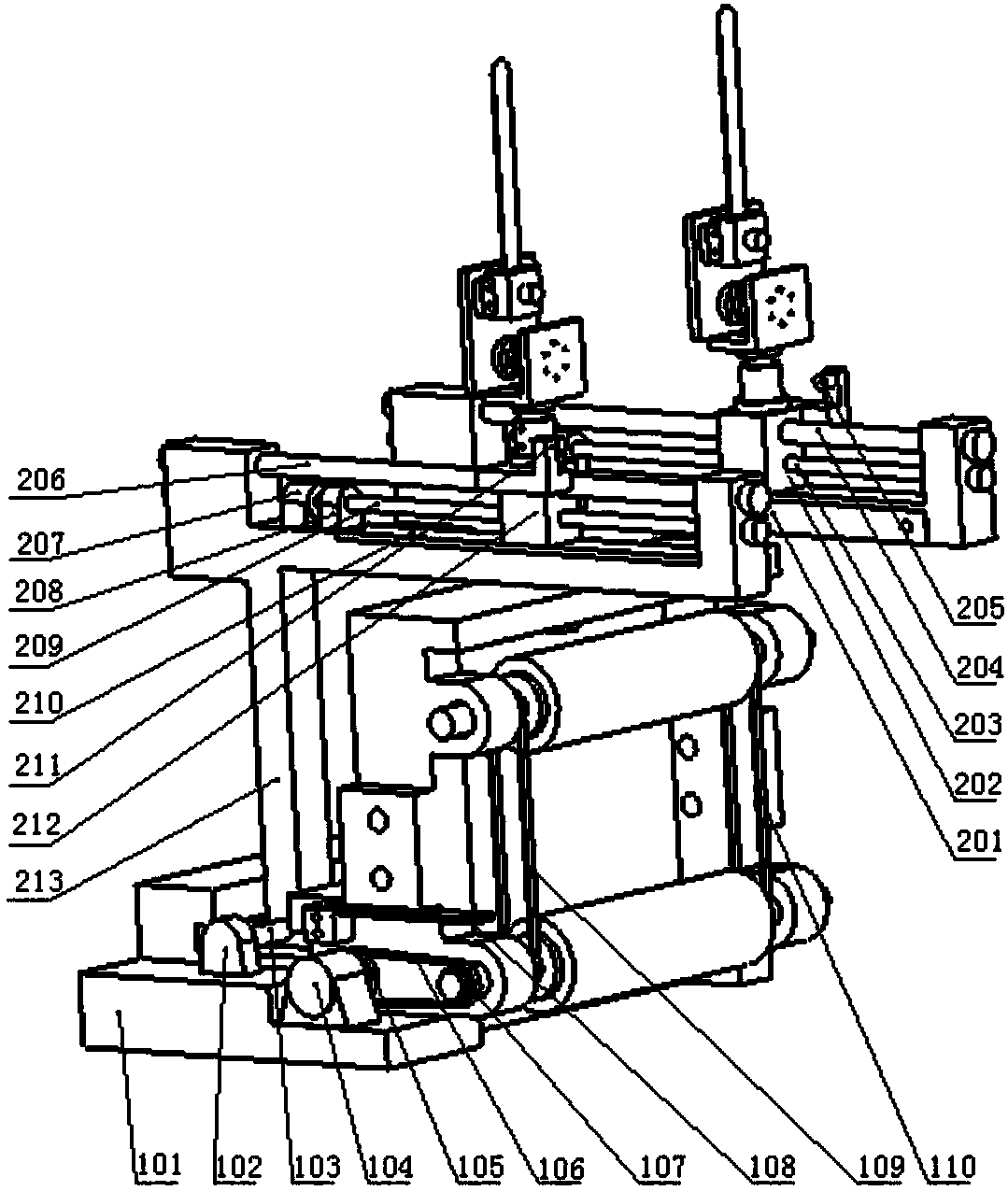

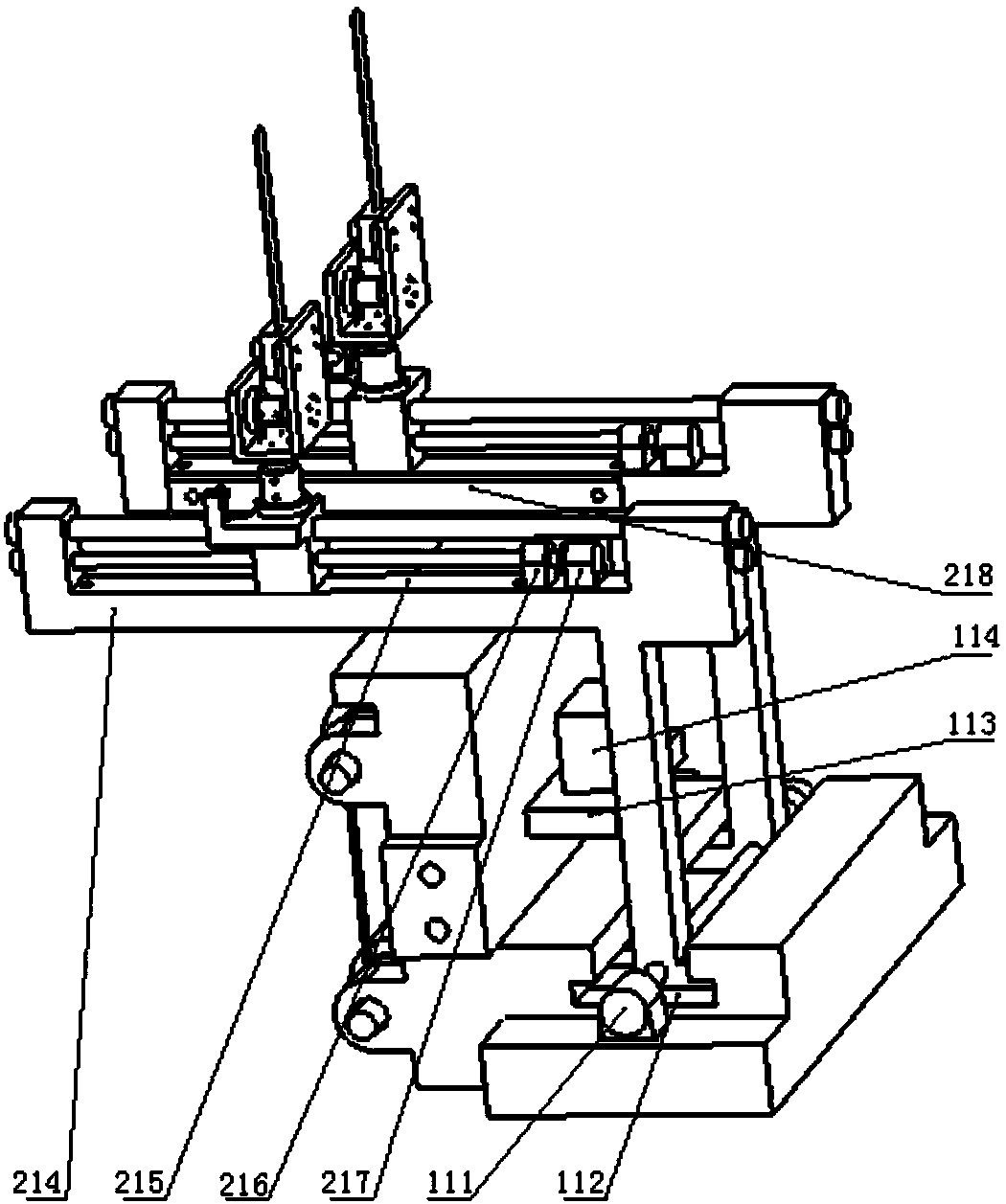

3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device and equipment

PendingCN106696260AReduce splashReduce wasteAdditive manufacturing apparatus3D object support structuresLinkage conceptMental detachment

The invention relates to a 3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device. The 3D printing powder delivery and paving linkage type bidirectional powder paving device comprises a worktable, a powder paving driving device, and a powder paving device, wherein the powder paving device is of a powder delivery and paving linkage structure and comprises a powder bin, a powder falling closing area, a quantitative powder delivery area and a powder paving part; the powder falling closing area is arranged at the bottom part of the powder bin, and a powder falling closing shaft is arranged in the powder falling closing area; a detachment and installation structure is arranged between an end cap of the powder bin and the bottom part of the powder bin; a powder bin pressing rotary button is arranged above a roller cylinder in the quantitative powder delivery area and is used for fixing the powder bin and the roller cylinder, a quantitative powder delivery roller is arranged in the quantitative powder delivery area, a powder falling port is arranged under the quantitative powder delivery roller, and the roller cylinder is detachably connected with the bottom part of the powder bin; a powder delivery and paving separation structure is arranged between the powder delivery and paving linkage structure and the powder paving driving device; the powder paving part is arranged at both sides of the roller cylinder, and each side is provided with a scraping knife. The 3D printing powder delivery and paving linkage type bidirectional powder paving device has the advantages that the whole structure is stable, the efficiency is improved by double scraping knives, the bidirectional powder paving function is realized, the aligning process of powder delivery and powder paving in working is not needed, the powder control accuracy is high, and the powder lifting and snapping are avoided; the structure is simple, and the detachment and cleaning are convenient.

Owner:安徽泰尔控股集团有限公司

Razor blade unit with film hinge

A razor blade unit with a blade housing, in which several blades with cutting edges lying parallel to a skin contact plane are arranged, a coupling section, which can be connected preferably in a detachable manner to a handle, and a connecting section. The connecting section includes at least one film hinge between the blade housing and the coupling section, which hinge defines a pivot axis extending parallel to the skin contact plane, and an elastic damping component, which surrounds one or more sides of the film hinge and is formed both on the blade housing and on the coupling section. The razor blade unit also has a foam edge, arranged in front of the cutting edges (with respect to the shaving direction) of the blades to pretension the skin during shaving. The pivot axis extending through the film hinge is positioned between the forward boundary (with respect to the shaving direction) of the foam edge and the cutting edge lying closest to the foam edge.

Owner:FEINTECHN EISFELD

Method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves

ActiveCN104814549ASimple processImprove cut resistanceProtective garmentSpecial outerwear garmentsUltra-high-molecular-weight polyethyleneFilament yarn

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

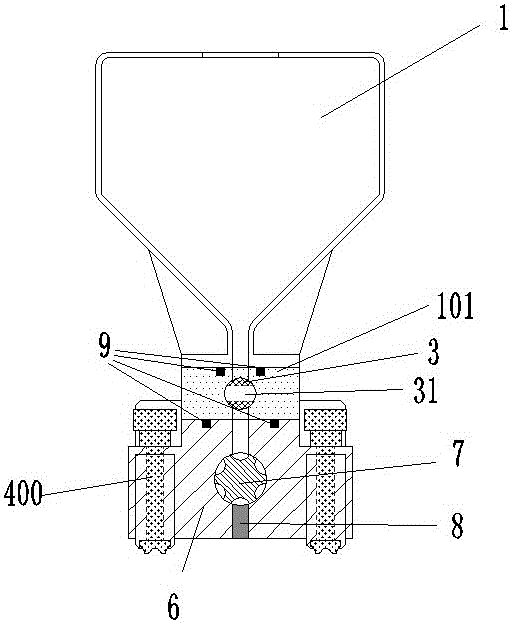

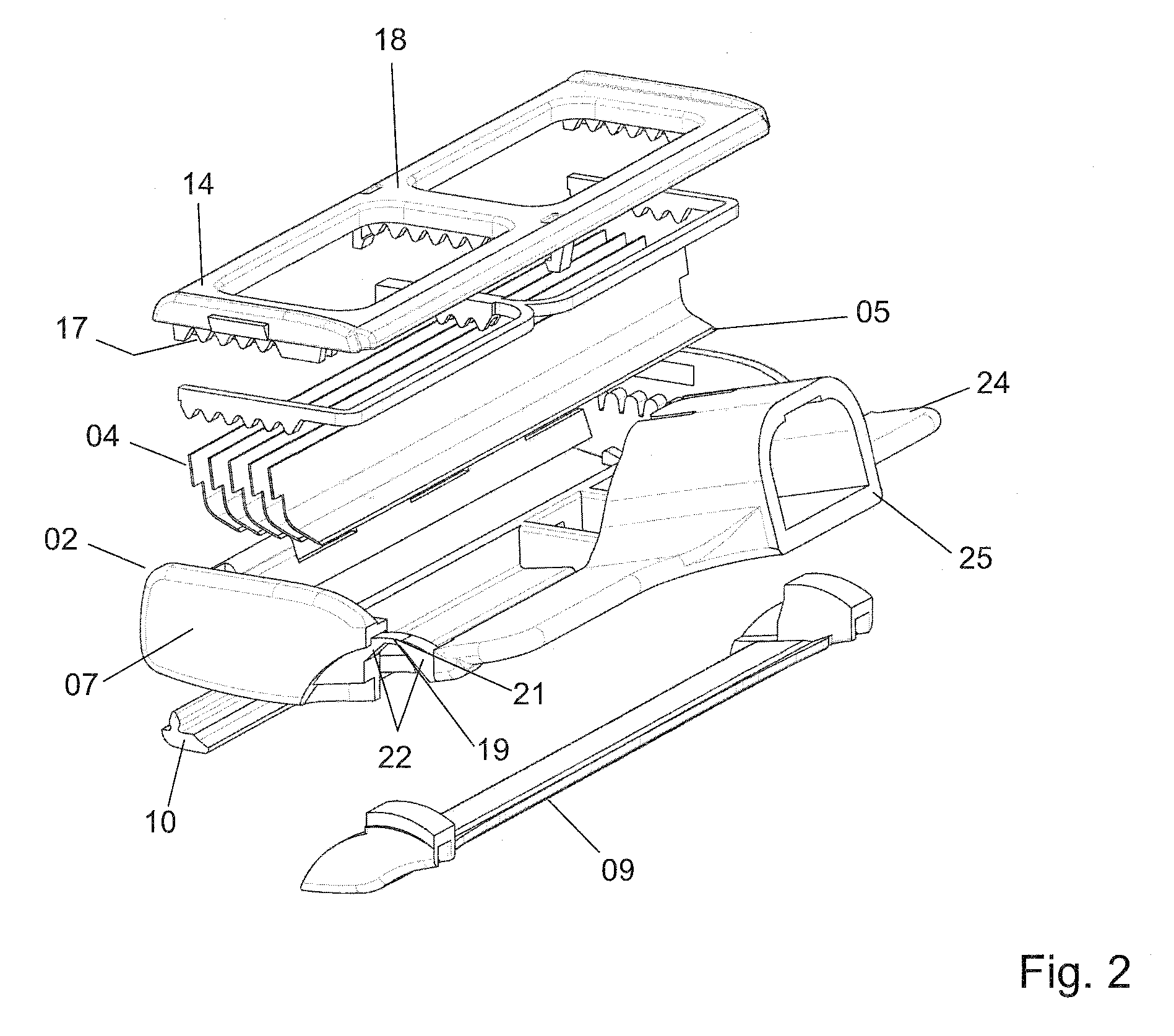

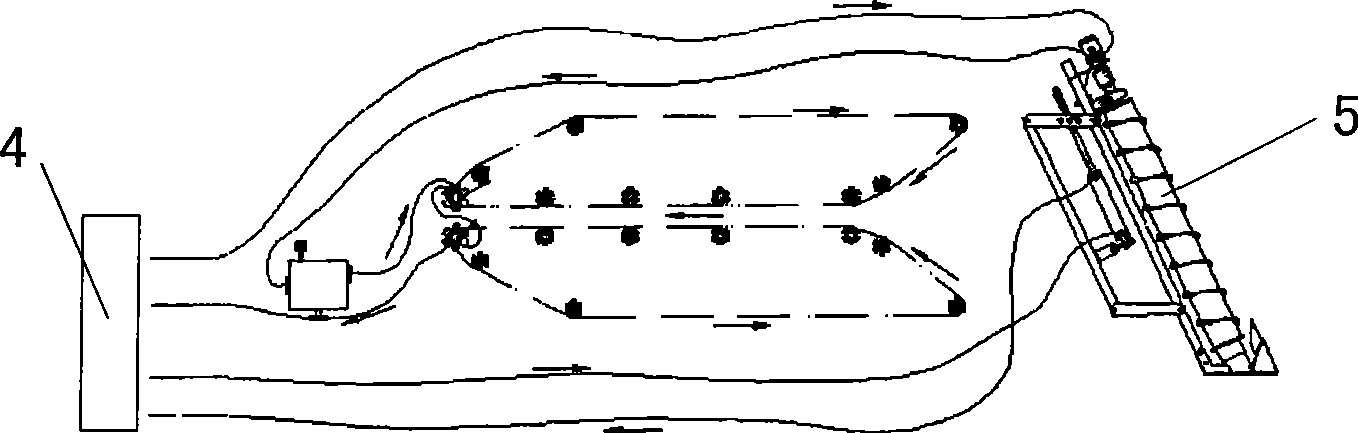

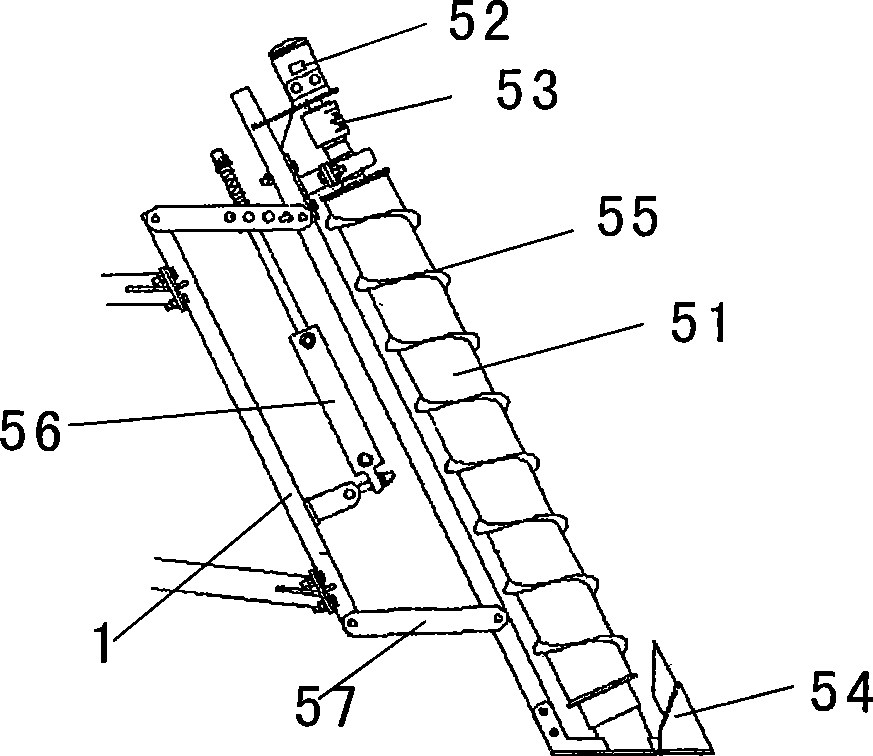

Sugar cane harvester

InactiveCN101427625ANo elasticityNo jumpingHarvestersAgricultural lifting devicesHydraulic motorControl system

The invention discloses a cane harvester, comprising a frame, a cutter, a transfer mechanism, a servo mechanism, a power hydraulic system and a corresponding control system, characterized in that: a lifting mechanism is set on the front end of the cane harvester. The lifting mechanism comprises a roll shaft, a hydraulic motor, wherein the roll shaft is mounted on the frame by a connection-rod mechanism and the connection-rod mechanism is driven by a hydraulic device mounted on the frame and the top end of the roll shaft is connected with the hydraulic motor by a connection axle device and a triangle wedge block is set on the lower end of the roll shaft and the hydraulic motor is driven by the power hydraulic system. The cane harvester can be used in sloping field, highland, cane lodging and bending occasion, with good cane-lifting effect and stable running and can normally work for 50-100m.

Owner:SOUTH CHINA AGRI UNIV

Novel two-component joint beautifying agent

InactiveCN106811166AIncrease elasticityStrong resistance to yellowingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent free

The invention relates to a novel two-component joint beautifying agent composed of components A and B. The component A comprises, by mass, 70-80 parts of polyaspartic acid ester, 5-15 parts of propylene carbonate, 5-10 parts of fumed silica and 2-5 parts of titanium dioxide, and the component B comprises, by mass, 70-85 parts of polyol and aromatic / aliphatic isocyanate polymer, 8-15 parts of 2, 2, 4-trimethyl-1, 3-pentanediol diisobutyrate and 1-15 parts of diethyl fumarate. The novel two-component joint beautifying agent is composed of polyaspartic acid ester resin and a high-elasticity prepolymer curing agent formed by polymerizing polyol and aromatic / aliphatic isocyanate and has the advantages of being high in yellowing resistance, elastic and solvent-free, the problem that an epoxy resin type joint beautifying agent is not resistant to yellowing and water, is subject to influence of air temperature during construction and cannot be used outdoors is solved, and a gap in domestic joint beautifying industry is filled in.

Owner:DONGGUAN COHUI IND MATERIALS

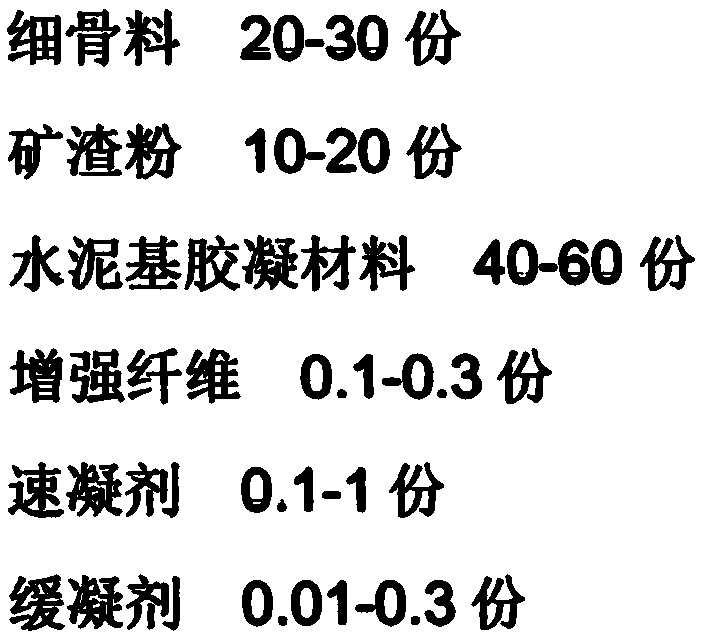

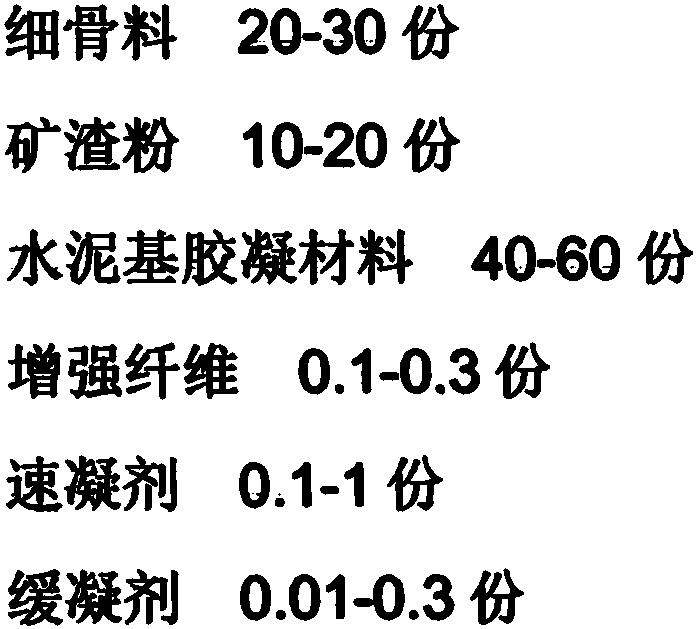

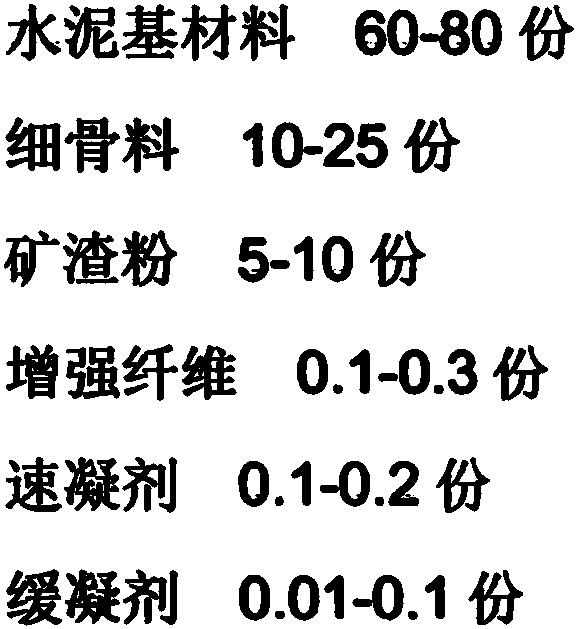

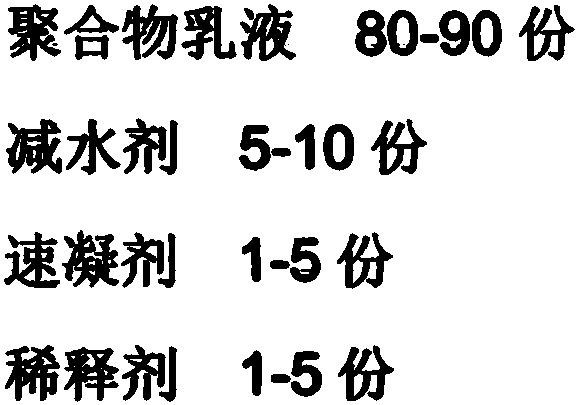

Flexible spraying material for mine laneway supporting and preparation method and application of flexible spraying material

ActiveCN111533518ANon-volatileEfficient use ofUnderground chambersTunnel liningSlagHazardous substance

The invention relates to a flexible spraying material for mine roadway support and a preparation method and application of the flexible spraying material, and belongs to the technical field of mine roadway supporting. The slag-based anchoring and shotcreting support guniting material prepared by the method is an organic-inorganic hybrid material and does not volatilize harmful substances and is safe and environment-friendly; a slag doped guniting material is adopted so that effective utilization of slag is developed, secondary pollution is relieved, and the cost is reduced; vertical face and top face spraying construction does not flow, the construction environment is friendly, and any springback and dust pollution problems are avoided; the curing temperature is low, and the flame-retardant property is realized.

Owner:赣州创可通科技有限公司

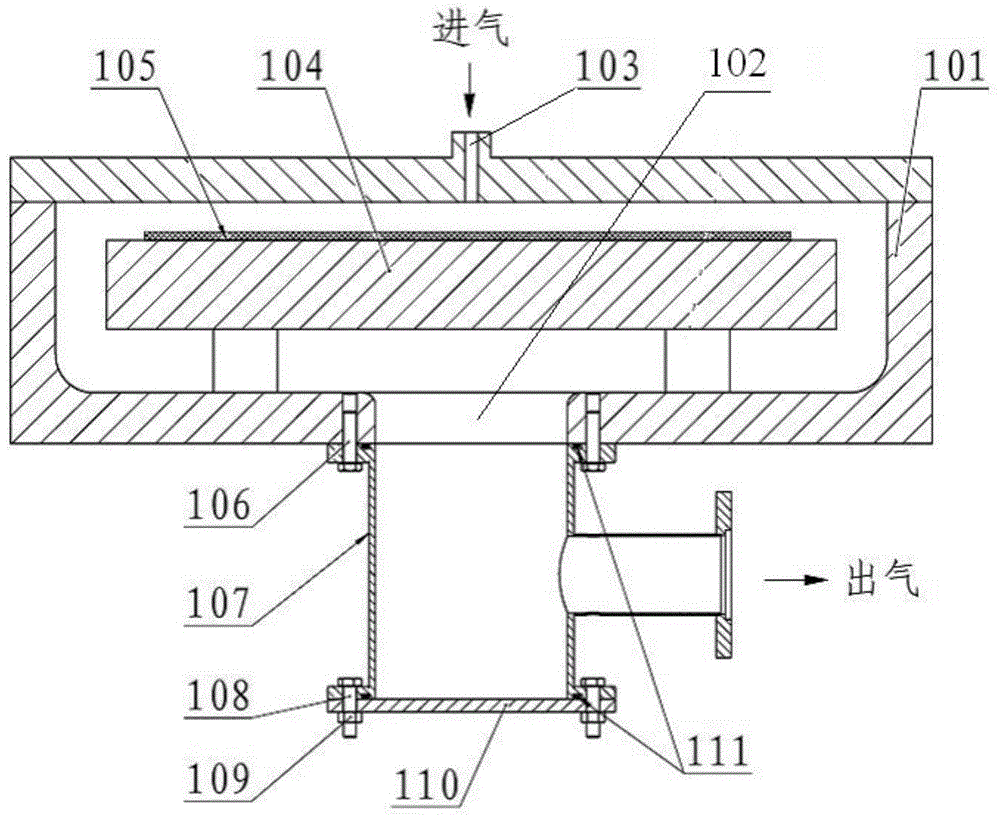

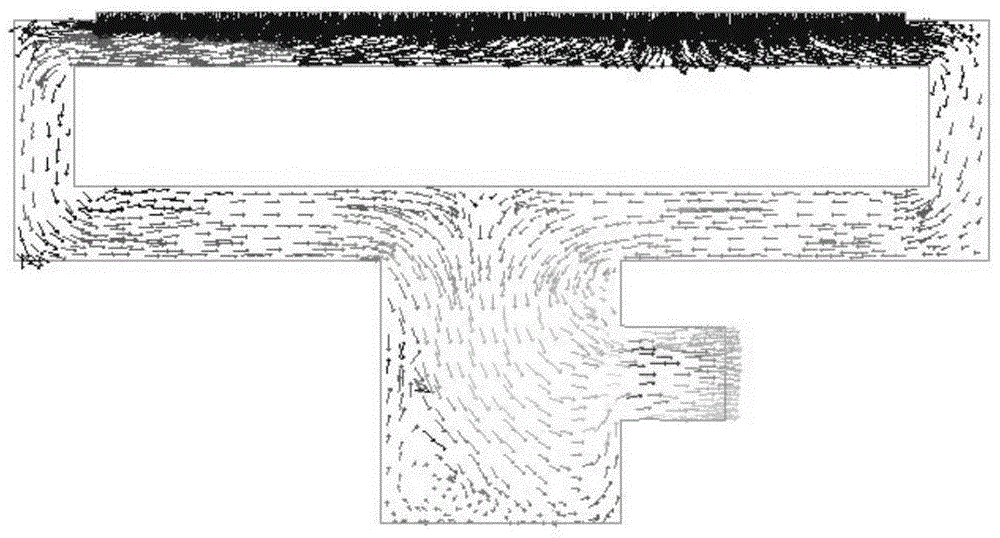

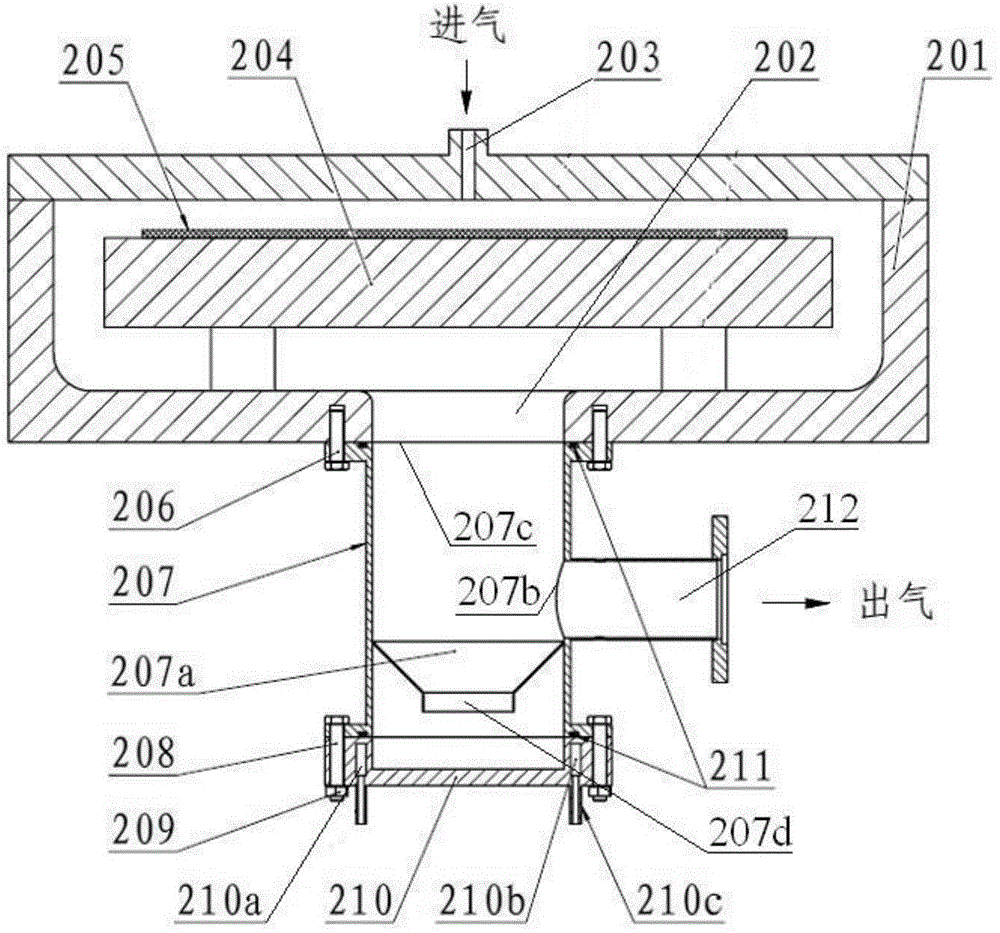

Semiconductor processing device

ActiveCN104979237ASpeed up the flowEfficient dischargeSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor processing device, comprising a reaction chamber (201) and an air extraction chamber (207) which is arranged at the bottom of the reaction chamber, wherein an air exhaust port (202) is provided at the bottom of the reaction chamber, an air inlet port (207c) is provided at the top of the air extraction chamber correspondingly, and the air inlet port is connected to the air exhaust port; an air outlet port (207b) is provided on a side wall of the air extraction chamber for exhausting air in the air extraction chamber; a funnel-shaped conical ring (207a) is provided in the air extraction chamber and is located below the air outlet port, wherein a lower port of the conical ring is smaller than an upper port thereof; and the conical ring is used for dividing the air extraction chamber into an upper chamber and a lower chamber, wherein the upper chamber is in communication with the lower chamber through a ring hole of the conical ring. The semiconductor processing device can reduce the accumulation of some by-product granules carried in an airflow, and can restrain the accumulated by-product granules from being raised by the airflow, thereby preventing the by-product granules from returning to the reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

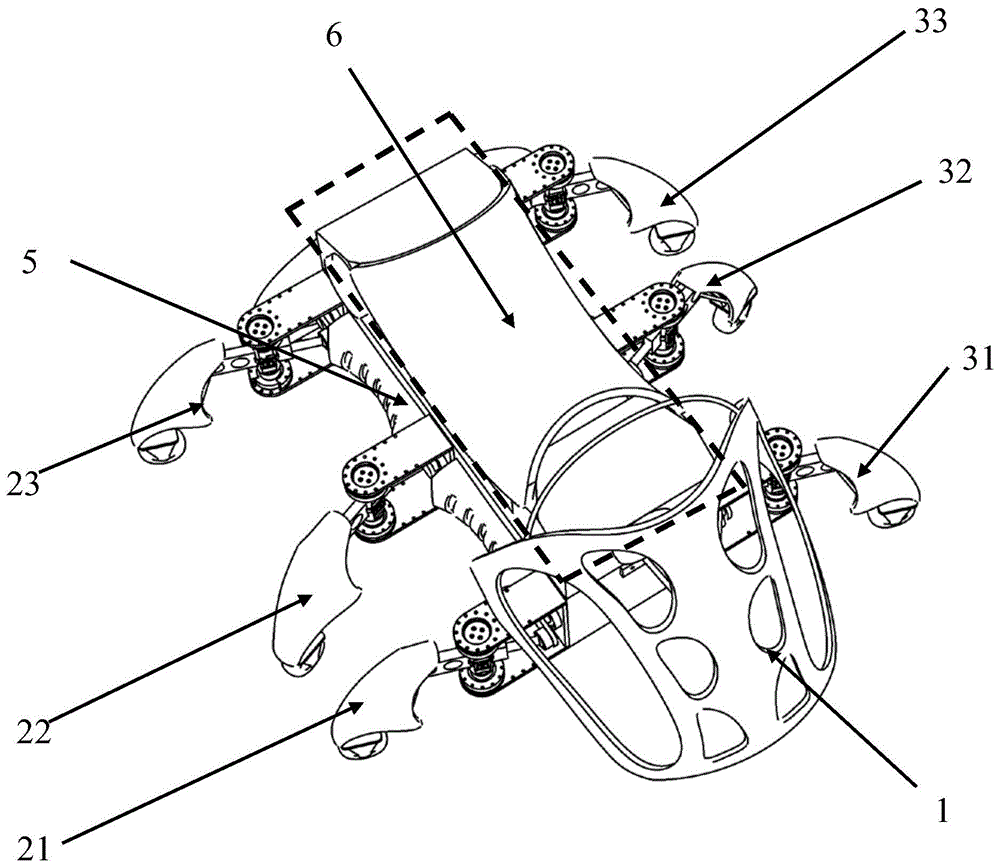

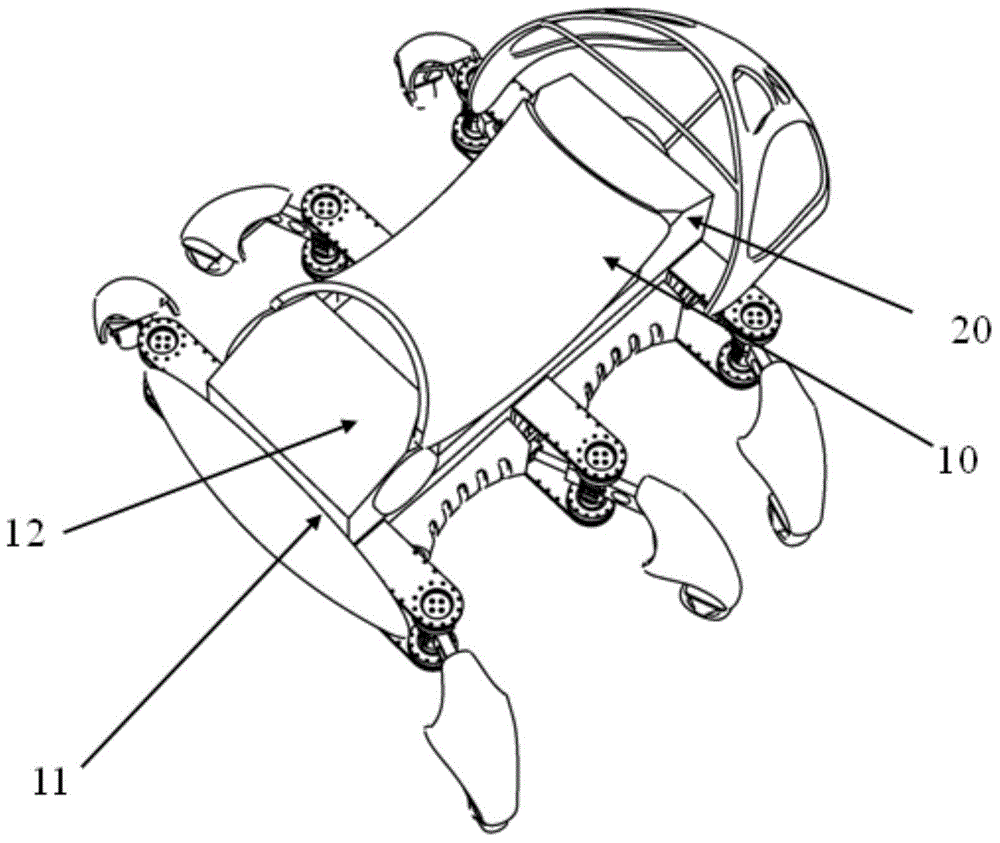

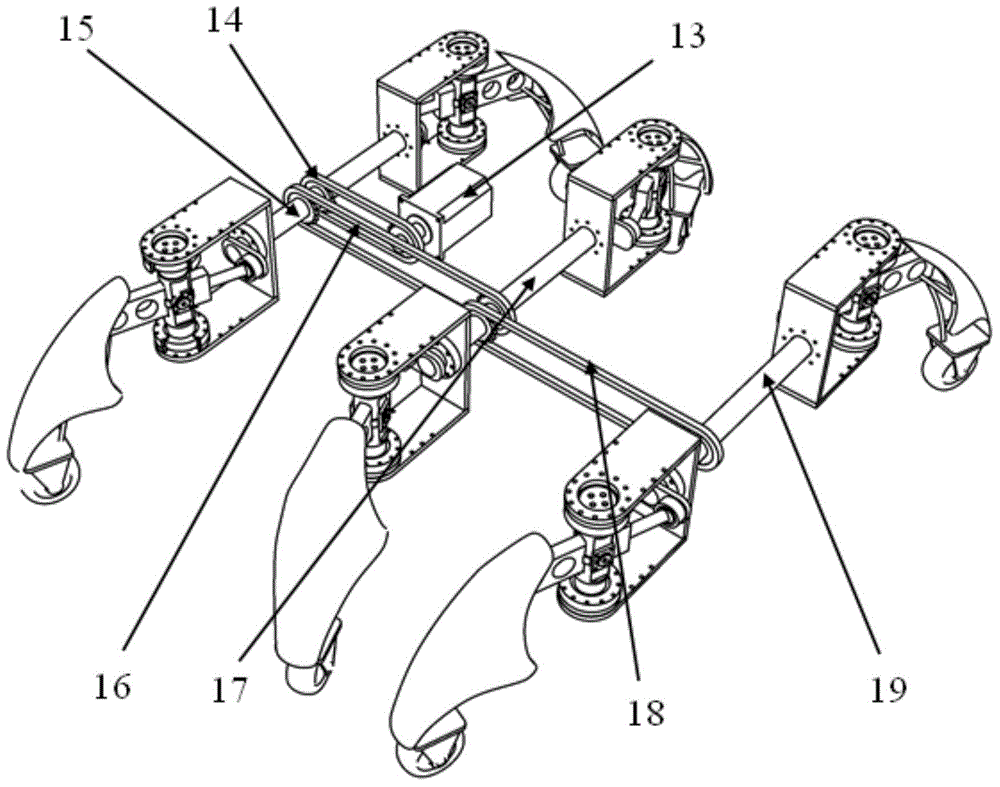

Hexapod robot

The invention discloses a hexapod robot. The robot comprises a head part, a body, a driving device, a transmission system and six mechanical legs. The hexapod robot is characterized in that the six mechanical legs are reversely and symmetrically mounted on both sides of the long edge of the body, and adopt the completely same structures; the driving device and the transmission system are arrayed at the inner part of the body; the driving device performs driving through a servo motor, and the transmission system performs transmission through sprocket chains; three output rods are also arranged at the inner part of the body, and the two mechanical legs are reversely and symmetrically mounted on both sides of each output rod; the six mechanical legs are divided into three groups, and the three groups of output rods are connected in a transmission manner by adopting the sprocket chains; the servo motor of the driving device designed at the inner part of the body simultaneously drives the six mechanical legs to move.

Owner:SHAANXI JIULI ROBOT MFG

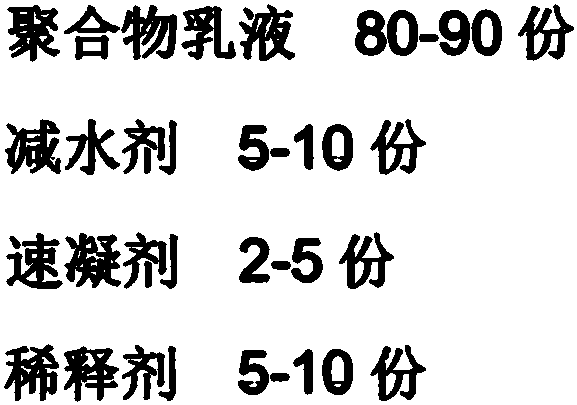

Flexible spraying material for tunnel roadway support and preparation method and application thereof

The invention relates to a flexible spraying material for tunnel roadway support and a preparation method and application thereof, and belongs to the technical field of tunnel roadway support. Vertical face and top face spraying construction does not flow, the construction speed is high, the construction environment is friendly, and any springback and environmental pollution problems are avoided;a spraying material can be subjected to long-distance spraying construction through conventional spraying equipment, the safety distance of manual operation is long, the time is short, and the construction process is safer and more reliable; and the material curing speed is high, the tensile strength and the bonding strength are increased rapidly, the problems that a guniting layer is large in thickness, prone to falling off and cracking and needing to be maintained repeatedly are solved, and the technology is particularly suitable for supporting and reinforcing, air leakage preventing and water leakage preventing treatment of key positions of tunnels or positions where surrounding rock is seriously broken.

Owner:赣州创可通科技有限公司

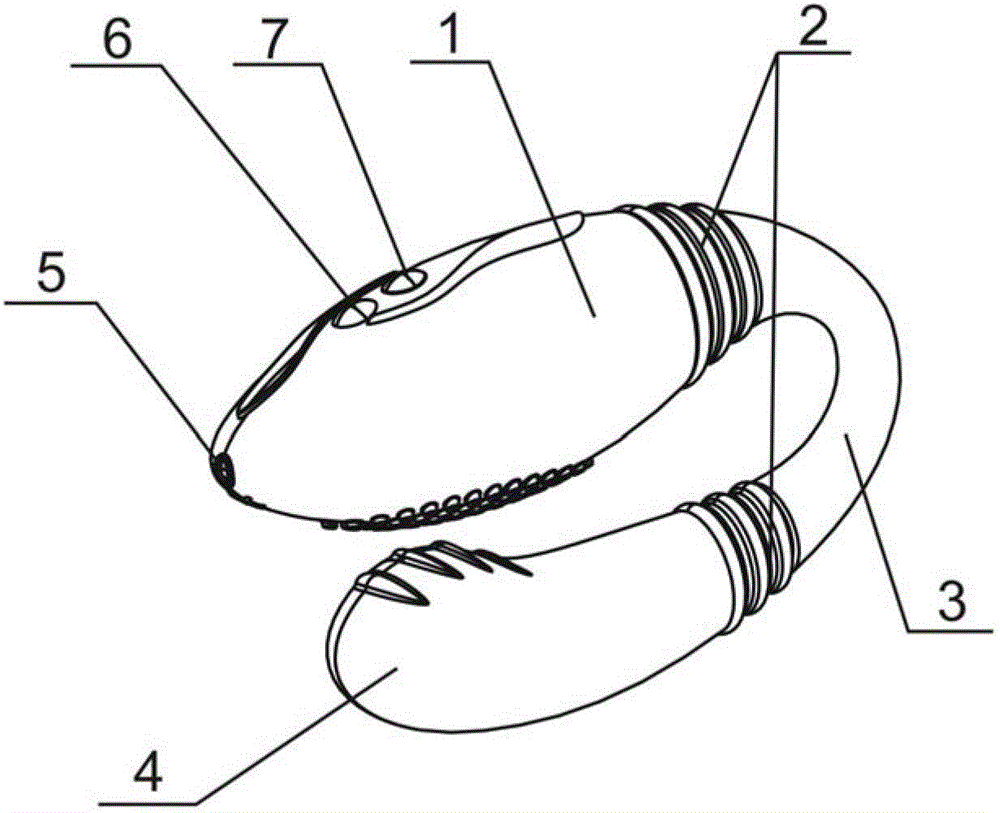

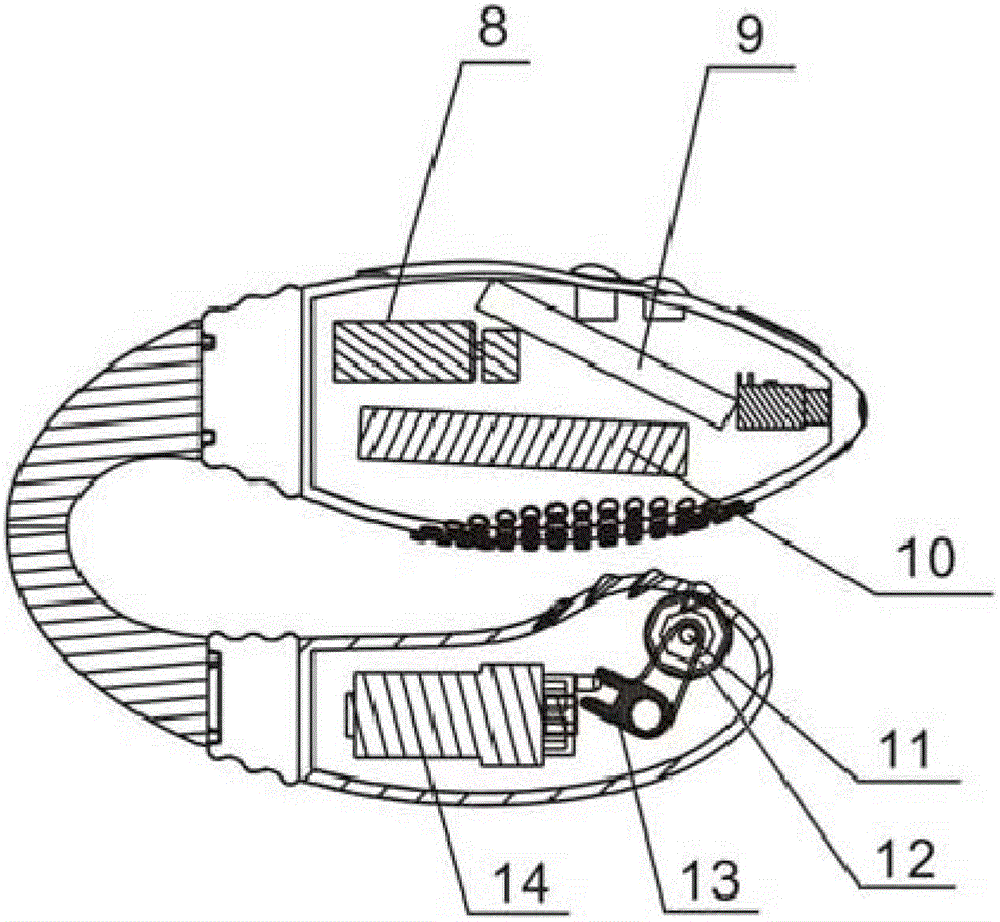

Function assisting massager for women or women and men

The invention relates to a function assisting massager for women or women and men. According to the function assisting massager for women or women and men, the outer surface of a main body is made of elastic silica gel and acrylonitrile butadiene styrene (ABS) plastic; a vibration motor, a circuit board, a gear motor and a peristalsis mechanism are arranged in the main body; the function assisting massager is characterized in that the main body is U-shaped; a vibration end, a peristalsis end and a connection part form a U-shaped elastic resetting structure.; the vibration end is connected with the peristalsis end through the connection part; the vibration motor and the circuit board are arranged in the vibration end; and the gear motor and the peristalsis mechanism are arranged in the peristalsis end. The function assisting massager has the advantages that due to the unique shape design of the U-shaped main body, the massager can be tightly attached to the sensitive parts of internal and external sexual organisms of men and women, and meets a body structure well; the massager is reasonable in structural design; the vibration motor and the gear motor are arranged in the massager, so that the technology-based and intelligent massager is provided and is convenient to operate; and meanwhile, the vibration motor and the gear motor have seven different frequency modes, so that the massager is high in temperament and interest.

Owner:LIAOYANG BAILE HEALTH CARE PROD CO LTD

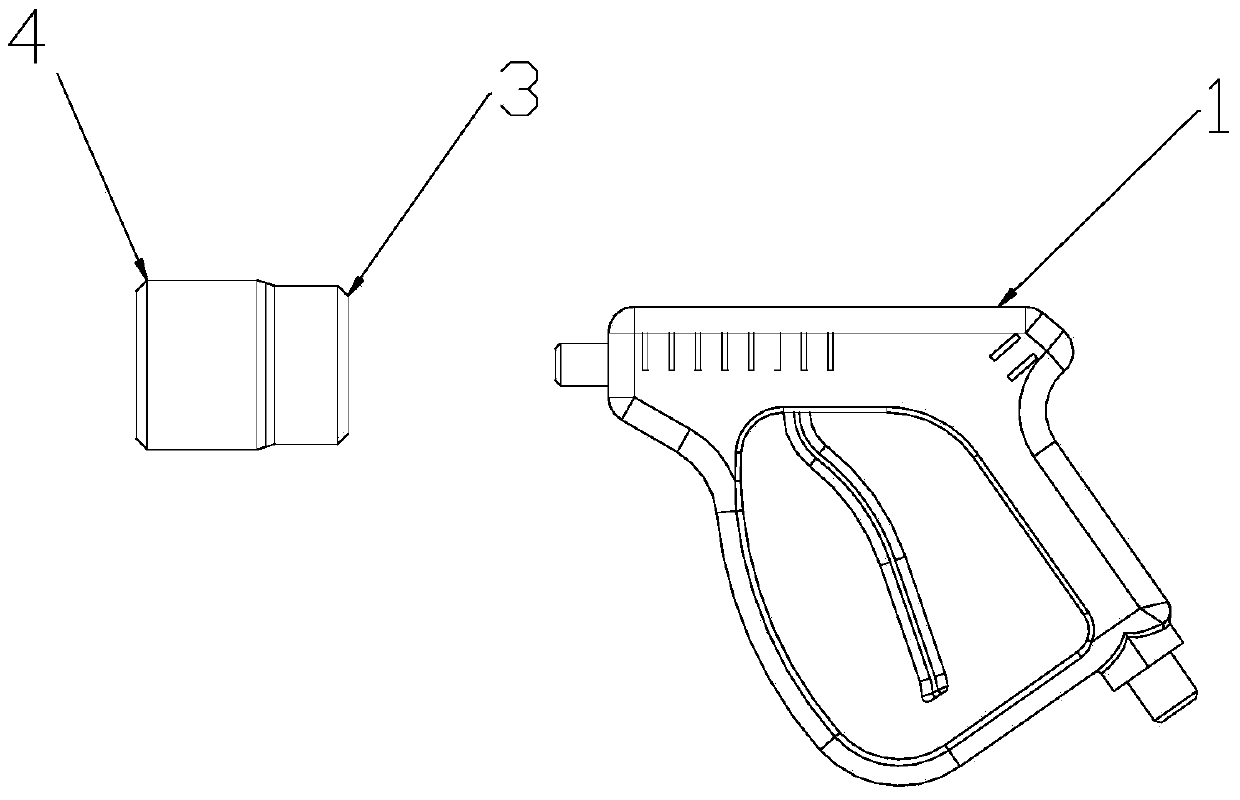

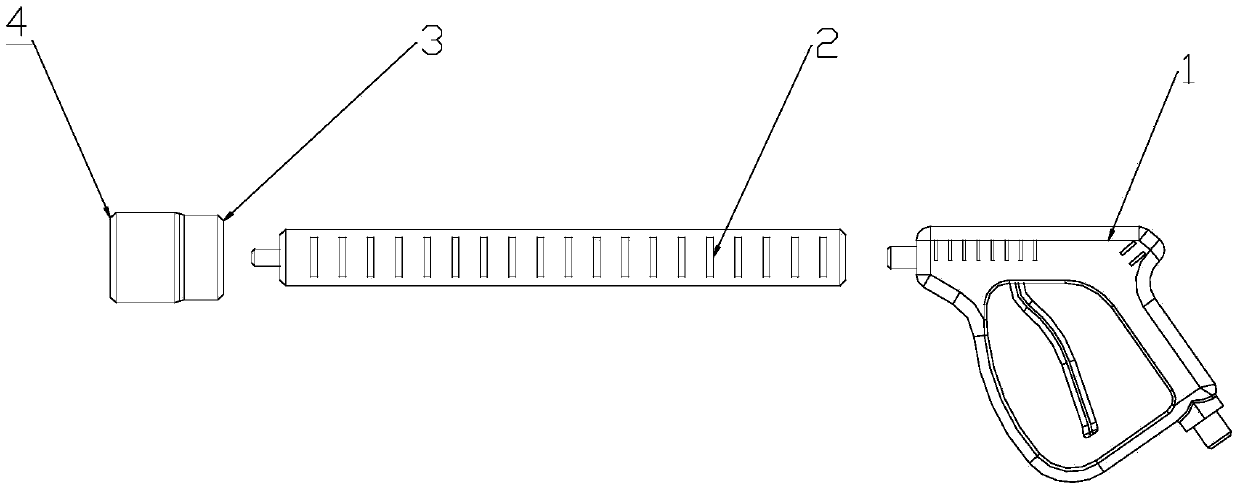

High-pressure airless spray gun without blind spraying corner

InactiveCN103464324AStable forceEliminate the problem of harsh working environmentSingle-unit apparatusDiaphragm pumpSpray coating

The invention discloses a high-pressure airless spray gun without a blind spraying corner. The high-pressure airless spray gun comprises a gun grip and a high-pressure spray nozzle. A pressure-regulating valve is mounted on the high-pressure spray nozzle, an access end of the high-pressure spray nozzle is a connector matched with an exit end of the gun grip, and the exit end of the gun grip is connected with the access end of the high-pressure spray nozzle. The high-pressure airless spray gun further comprises a diaphragm pump driven by a motor. During a spraying operation, the high-pressure airless spray gun sprays coatings directly on the surface of a workpiece to be sprayed and processed by means of taking static pressure generated from the diaphragm pump as driving force to spray the coatings. Due to the fact that compressed air is not taken as the driving force to spray the coatings, rebounding and splashing of the coatings during the spraying process are basically avoided, and coating fog particles sprayed out can smoothly enter corner cracks and edges of the workpiece with less spraying pollution and no dead corner. The high-pressure airless spray gun has the advantage that a sprayed coating is compact, uniform, glossy, high in flatness and the like.

Owner:SHANDONG URBAN MINING ENVIRONMENTAL PROTECTION GRP

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

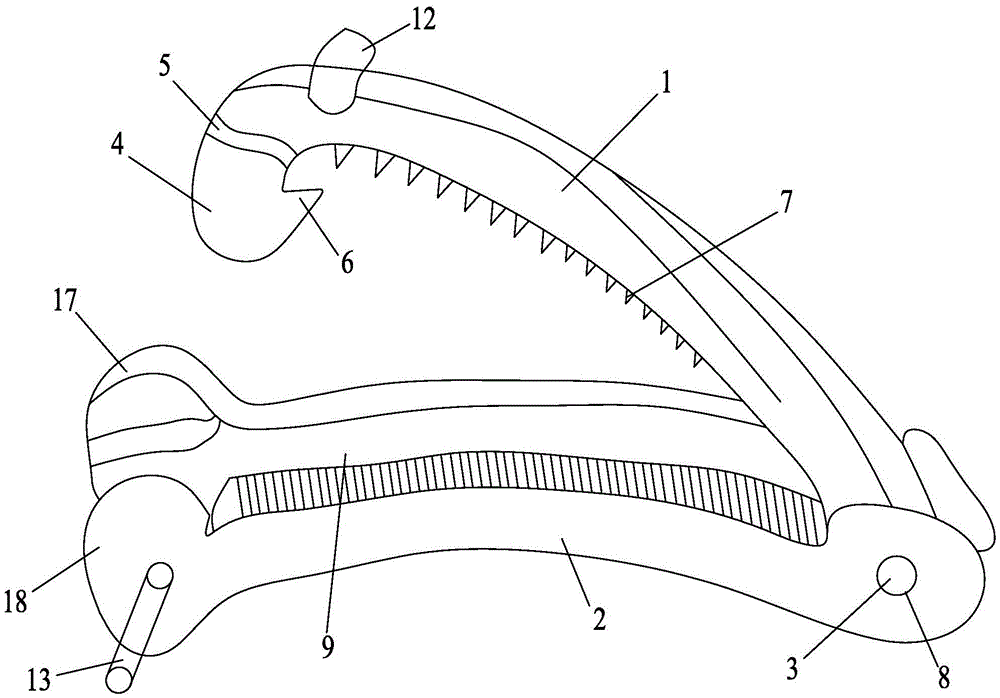

Vascular clamp

InactiveCN105534558APrevent sliding playPrevents risks from stuffing fixed teethWound clampsEngineeringBlood vessel

The invention belongs to the field of medical instruments, and relates to a vascular clamp. The vascular clamp comprises a first clamping arm and a second clamping arm; the end of one side of the first clamping arm and the end of one side of the second clamping arm are hinged, the second clamping arm is provided with a groove, a first guiding seat and a second guiding seat are upwards formed on the two sides of the front end of the groove respectively, and the side, facing the groove, of the first guiding seat and the side, facing the groove, of the second guiding seat are each provided with a protrusion; the locking end of the first clamping arm is bent downwards to form a puncturing lock head, upper fixing teeth are formed at the two ends of the upper portion of the puncturing lock head, and a lower fixing tooth is formed on the inner side of the puncturing lock head; a groove bottom plate is arranged at the bottom of the groove, and a groove bottom tooth is arranged at the front end of the groove bottom plate; after the first clamping arm and the second clamping arm are closed, the lower fixing tooth is locked at the groove bottom tooth, and the upper fixing teeth are clamped under the protrusions. The vascular clamp is reliable and stable in locking.

Owner:徐斌

Intelligent automatic branches pruning device

InactiveCN107926332AImprove pruning efficiencyImprove versatilityCuttersMotor driven pruning sawsAgricultural engineeringPruning

The invention discloses an intelligent automatic branch pruning device, which is composed of a climbing mechanism, a pruning mechanism and a pressing mechanism, and is characterized in that a pruning mechanism is installed on the climbing mechanism, and a pressing mechanism is installed on the climbing mechanism . The advantage is that the intelligent automatic branch pruning device can replace manual branch pruning, which improves the efficiency of branch pruning and reduces the labor intensity of garden workers. Moreover, the device can realize the pruning of tree branches of different thicknesses. Different, the intelligent automatic branch pruning device can automatically adjust the internal spacing to meet the pruning work for trees of different thicknesses, avoiding the difficulty that the same branch pruning device cannot complete the job due to different tree thicknesses, improving the versatility of the branch pruning device, reducing pruning costs.

Owner:李洪龙

Thermoplastic elastomer composite material

The invention relates to a thermoplastic elastomer (TPE) composite material, which consists of a polyolefin thermoplastic elastomer (TPO), a styrene thermoplastic elastomer (SBC) and a polyurethane thermoplastic elastomer (TPU), wherein each 100 weight portions of the thermoplastic elastomer (TPE) comprise 30 to 70 portions of the polyolefin thermoplastic elastomer (TPO), 1 to 50 portions of the styrene thermoplastic elastomer (SBC) and 1 to 50 portions of the polyurethane thermoplastic elastomer (TPU). The material has stable chemical properties, is difficult to decompose after being processed, has no smog, and does not pollute the environment due to production of carbon dioxide after burning treatment; and a transfusion system manufactured does not need to be added with low molecular compounds such as a stabilizer, a lubricant and pigment. The thermoplastic elastomer (TPE) composite material has a reasonable formula, stable performance and good flexibility, elasticity and toughness, does not pollute the environment when being destroyed, and is a special material which can be used for mass production of portable thermoplastic elastomer transfusion systems in a cleaning shop.

Owner:威海威高创新有限公司

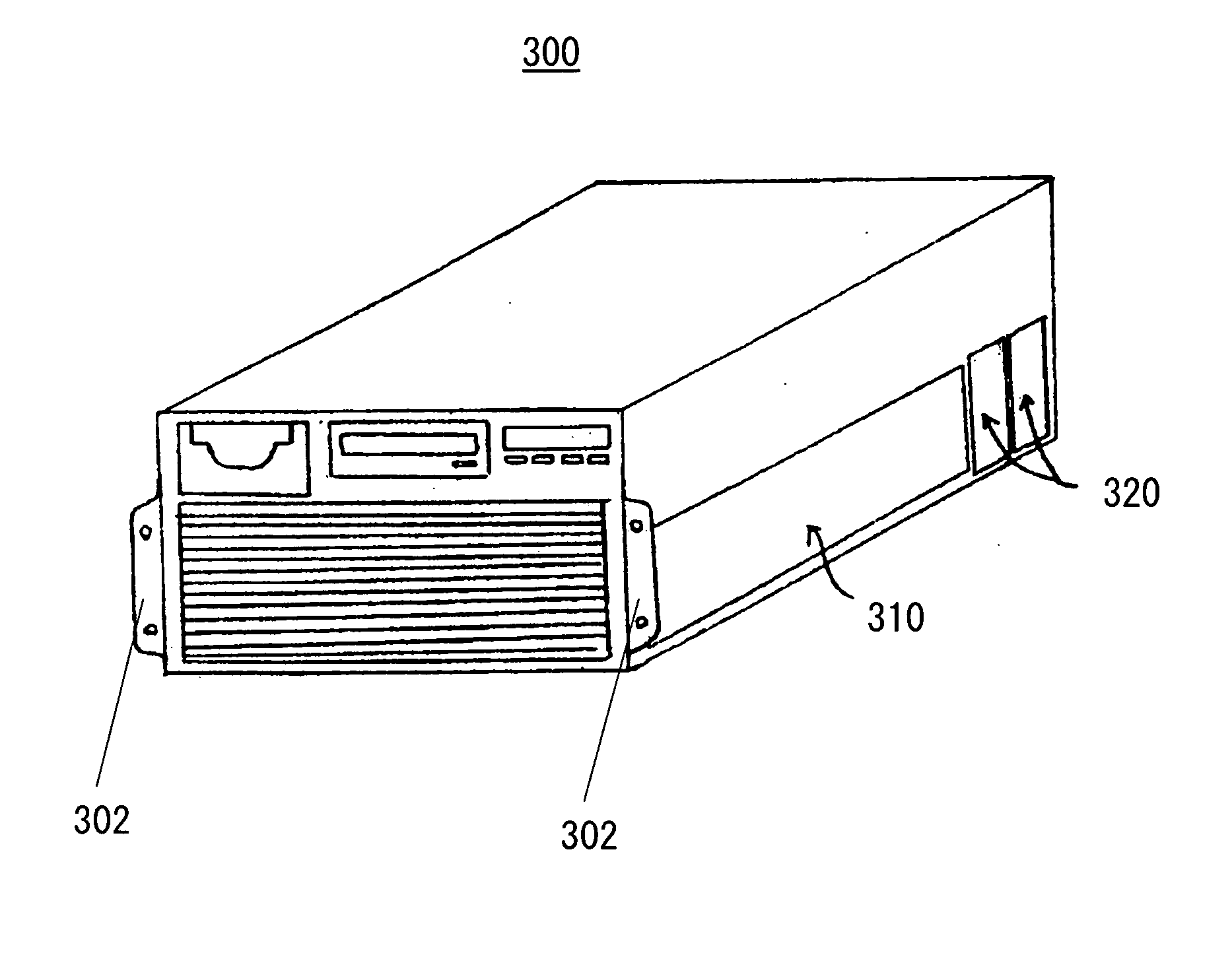

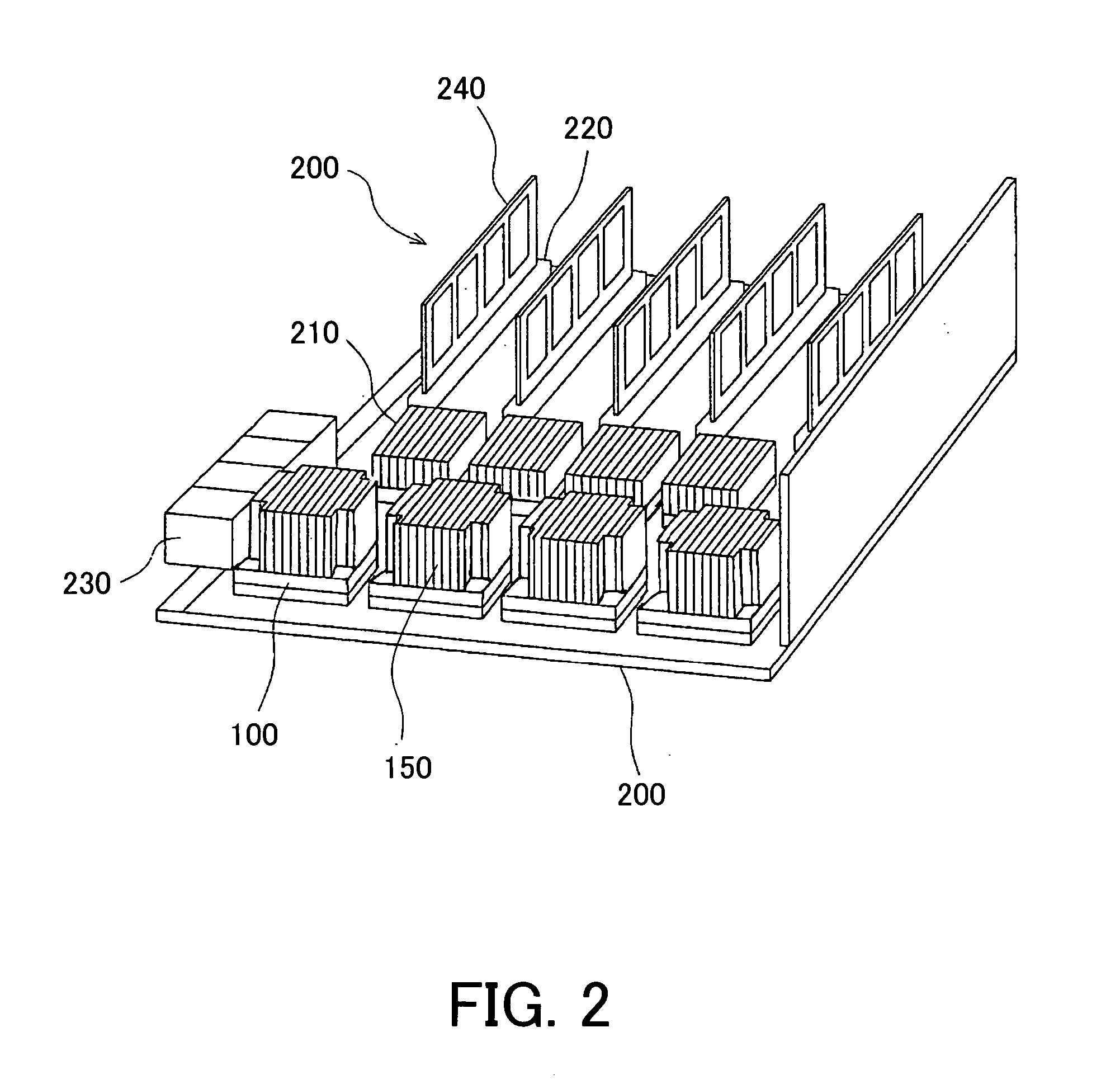

Semiconductor package, printed board mounted with the same, and electronic apparatus having the printed board

InactiveUS20060033202A1Good effectEasy to transformSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectronic equipment

A holding fixture that holds a component and mounts the component on an electronic circuit board includes a holding member that holds the component at a side of a first surface of the electronic circuit board, a first fixing member that includes a first base that is engageable with the holding member, and an elastic member that is pivotally attached to the base, sandwiches the electronic circuit board at a side of a second surface of the electronic circuit board, and elastically supports the holding member at the side of the first surface, the second surface opposing to the first surface, and a second fixing member that includes a second base that is engageable with the holding member, and a projection member that projects from the second surface of the electronic circuit board and is engageable with the elastic member.

Owner:FUJITSU LTD

Automatic duck shell cutting device

The invention provides an automatic duck shell cutting device and belongs to the technical field of food processing. The technical scheme of the automatic duck shell cutting device is as follows: theutomatic duck shell cutting device comprises a cross beam arranged on a ceiling, the cross beam is provided with a driving mechanism, and the lower part of the driving mechanism is provided with a workbench and a control console, and both the workbench and the control console are provided with cutting mechanism. The automatic duck shell cutting device has the beneficial effects that manual operation cost is saved, a duck meat splashing phenomenon caused by manual cutting is avoided, the labor efficiency is high, the cutting quality is reliable, duck neck joints are free from injury, the problem that the duck neck joints are not uniform in length is solved, and the bone spur rate of duck necks is reduced.

Owner:东阿六和绿佳食品有限公司

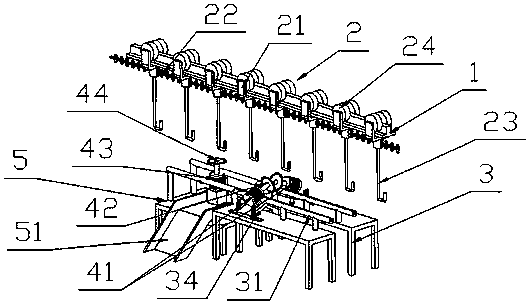

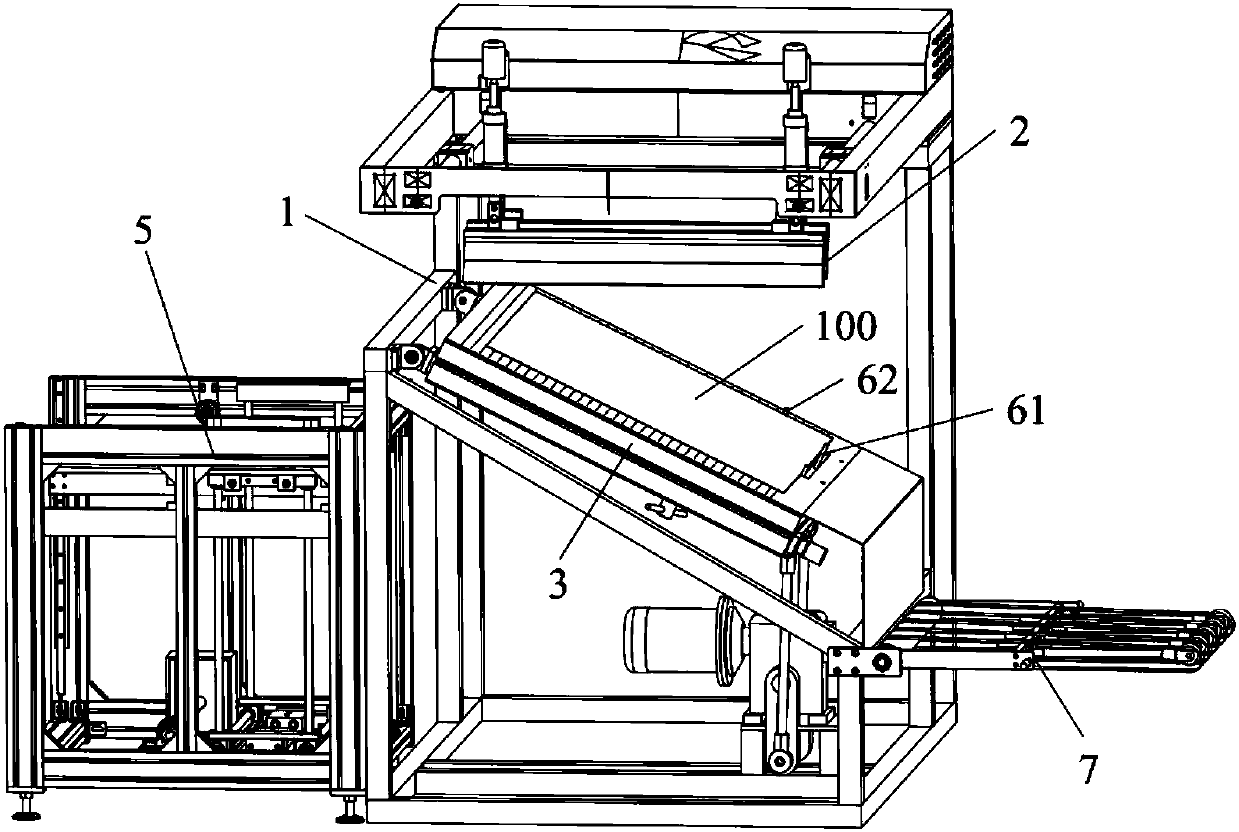

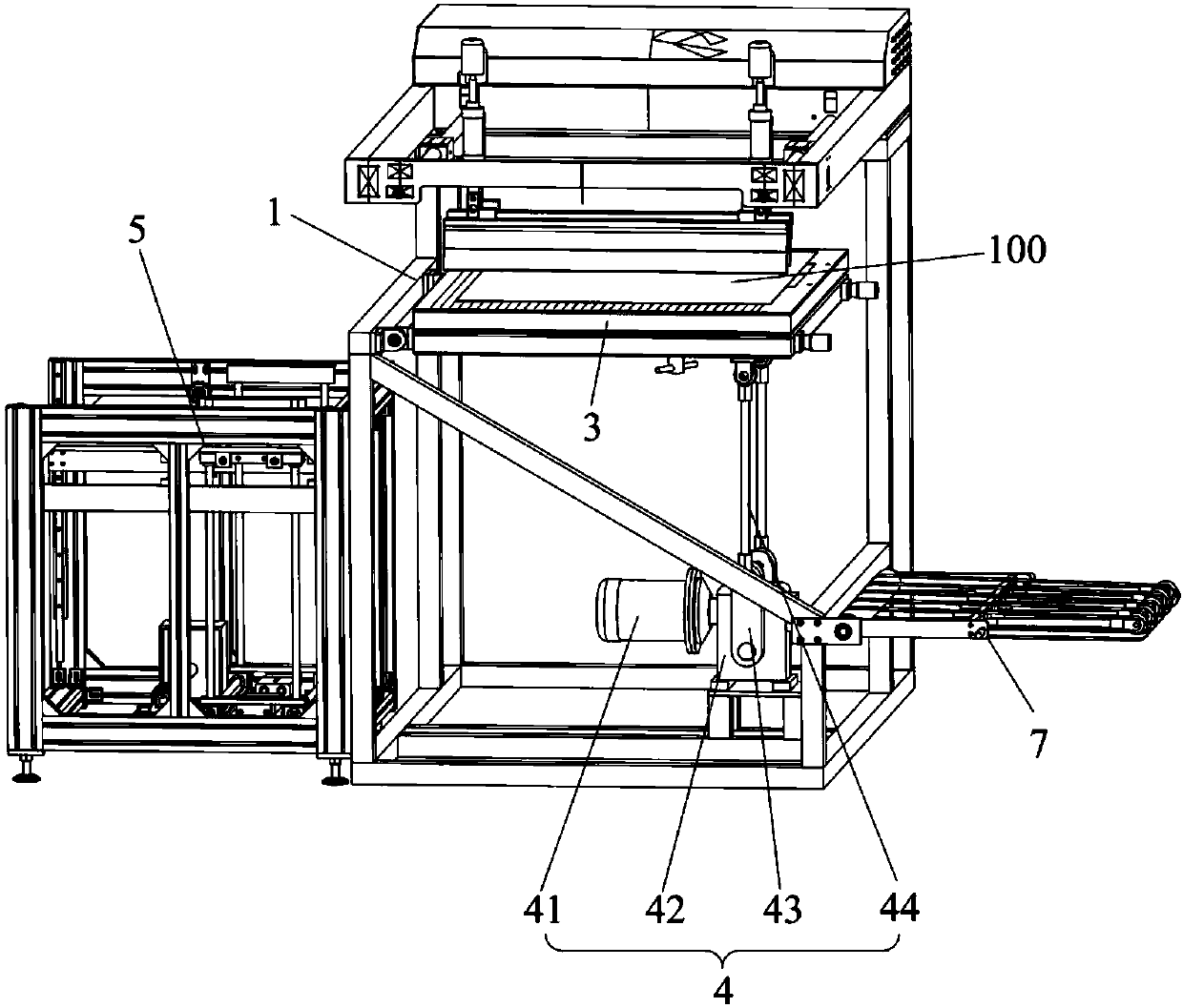

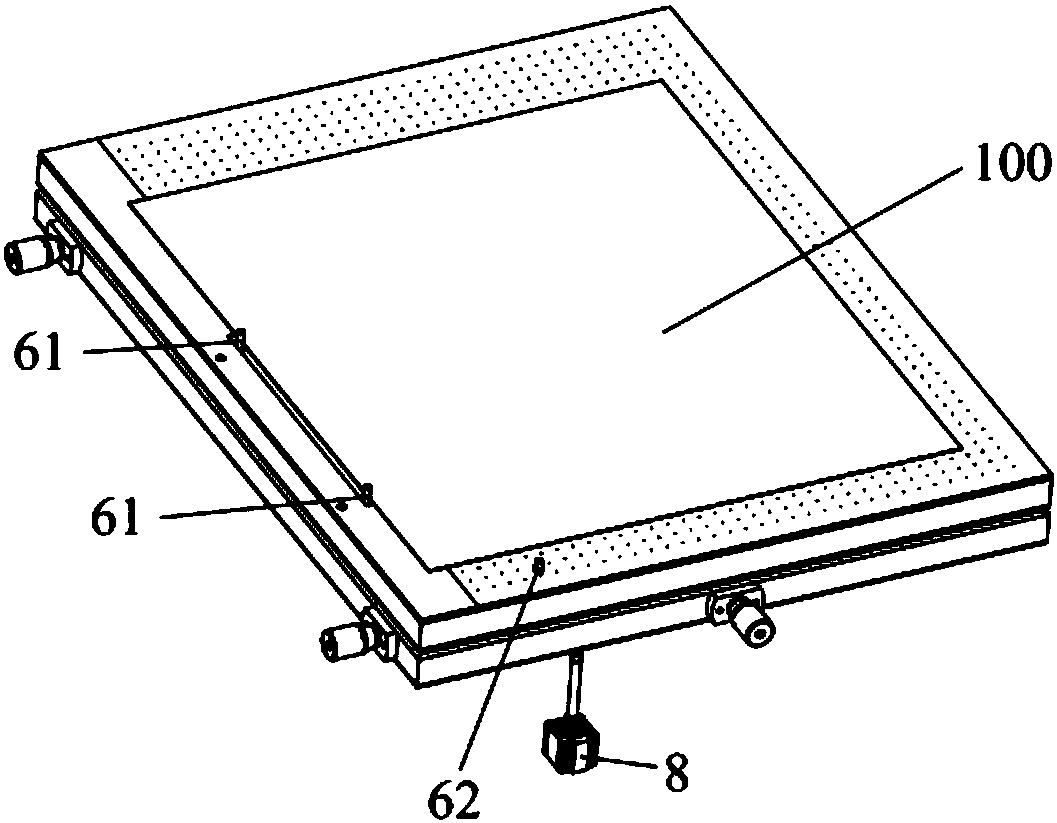

Parallel halftone automatic printer

The invention discloses a parallel halftone automatic printer, and belongs to the technical field of printing. The parallel halftone automatic printer comprises a frame, a printing mechanism, a printing platform, a loading mechanism, a positioning mechanism and a discharge mechanism; the printing mechanism is fixedly mounted on the frame; the printing platform is mounted at the lower end of the printing mechanism; one end of the printing platform is rotationally connected with the frame, and the other end is connected with a driving mechanism for driving the printing platform to rotate; the loading mechanism is positioned on one side of the frame, and is near the end, rotationally connected with the frame, of the printing platform; a feeding roller of the loading mechanism conveys printedmatters to the printing platform; the positioning mechanism comprises a first positioning mechanism for positioning first side edges of the printed matters, and a second positioning mechanism for positioning second side edges of the printed matters; included angles are formed between the first side edges and the second side edges; the discharge mechanism is positioned on the other side of the frame, and comprises a discharge roller, a roller, and a belt for connecting the discharge roller with the roller; and the printed matters are sent out after printing to realize automatic and accurate positioning of the printed matters.

Owner:SHENZHEN SCIEN JC PRINTING MACHINERY MFG CO LTD

Water recycling process of corn starch process

ActiveCN107265687AAvoid pollutionLow investment costOther chemical processesWater contaminantsUltrafiltrationSorbent

The invention belongs to the technical field of starch processing and discloses a water recycling process of a corn starch process. The water recycling process includes following steps: enabling wastewater generated in the corn starch processing technique to flow through multiple grids; enabling the wastewater to enter a precipitation tank, and standing; enabling the wastewater to enter a chemical adsorption tank, adding a chemical adsorbent, and stirring; stopping stirring, and performing adsorption treatment; filtering through an ultrafiltration membrane to obtain permeate; enabling the permeate to enter a corn starch processing water system for reusing. The water recycling process has the advantages of low investment expense, simplicity in operation and maintenance, capability of allowing outgoing water to stably reaching standards and capability of recycling the wastewater, and the wastewater can be recycled, so that water resources are saved, environment pollution caused by the wastewater is avoided, and the water recycling process kills two birds with one stone.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Compound fertilizer granulating agent

InactiveCN106927954AImprove adhesionQuality improvementMatrix fertilisersFertilizer mixturesLignosulfonatesUltimate tensile strength

The invention belongs to the technical field of compound fertilizer granulating agents, and provides a compound fertilizer granulating agent. The compound fertilizer granulating agent is prepared from, by weight, 25-38 parts of molasses, 5-15 parts of lignosulfonate, 8-20 parts of polyoxyethylene ether, 16-23 parts of starch, 8-17 parts of modified attapulgite and 25-38 parts of water. The compound fertilizer granulating agent is high in adhesiveness and low in use level, and made fertilizer is high in granule strength.

Owner:ANHUI BOSHUO TECH

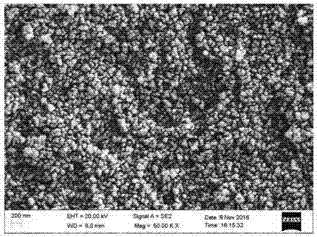

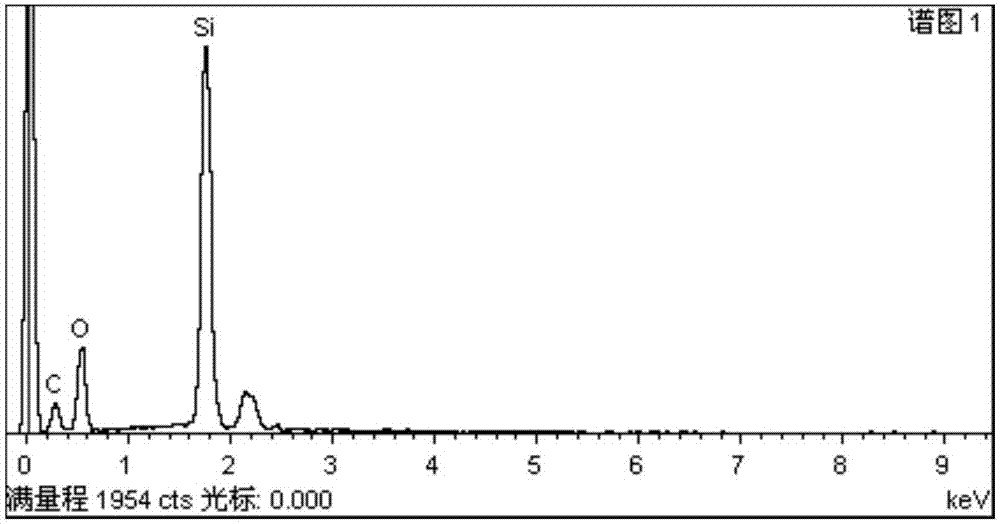

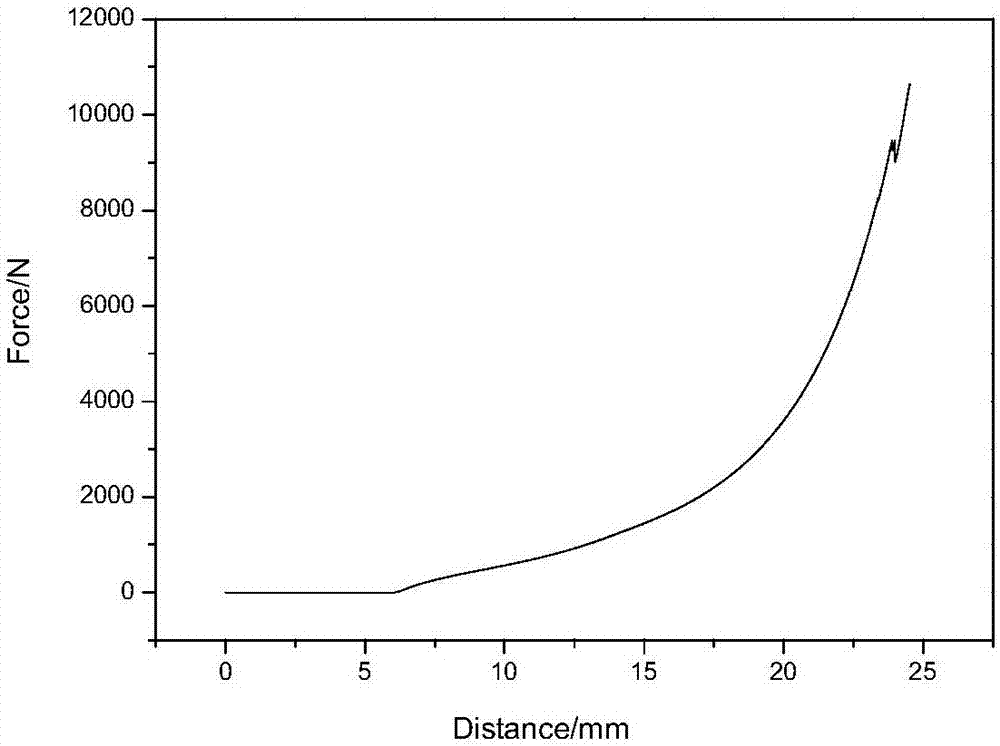

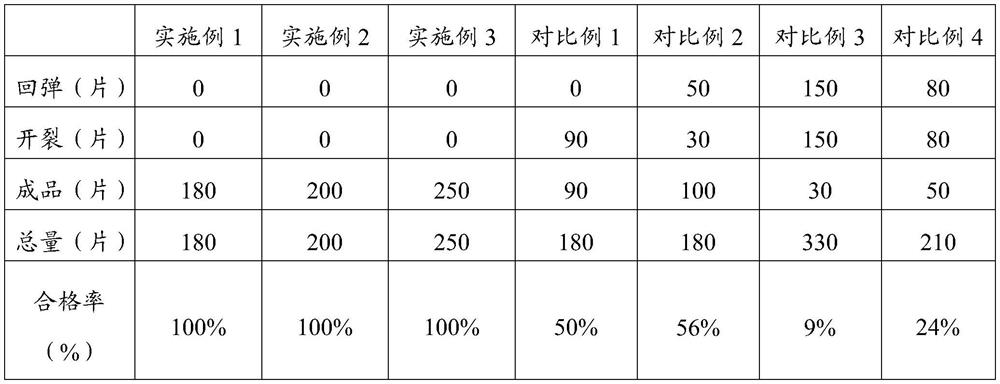

Flexible silica aerogel material and preparation method thereof

InactiveCN107159067AGood deformabilityGood flexibilityAerogel preparationColloidal chemistry detailsSilica gelOrganic molecules

The invention relates to a flexible silica aerogel material and a preparation method thereof and belongs to the technical field of preparation of nanometer materials. The preparation method of the flexible silica aerogel material provided by the invention comprises the following steps: adding an amino-containing silane coupling agent in frozen acidic silica sol, and controlling the amino-containing silane coupling agent to react with the silica sol so that active amido is introduced onto the surface of the wet silica gel; soaking the modified wet silica gel into a solution containing organic epoxy molecules, introducing a flexible organic molecule layer into the surface of the wet silica gel through an addition reaction between the amino on the surface of the wet silica gel and the epoxy organic molecules; and finally, purifying and drying, thus obtaining the dried flexible silica aerogel material.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

Medicine for treating comedo and acne on face

InactiveCN1586567AGood treatment effectQuick resultsUnknown materialsDermatological disorderSide effectCurative effect

The medicine for treating comedo and acne of face is ointment prepared with 13 kinds of Chinese medicinal materials including red peony root, dittany bark, gypsum, talcum, dahurian angelica root, etc. The present invention compounds the externally applied ointment based on the comedo and acne forming mechanism and Chinese medicine theory of treating internal medicine externally with the medicine materials possessing functions of clearing away heat, cooling blood, dispelling wetness, toxic matter and wind evil. The medicine may be used directly in the affected part and has high curative effect and no side effect and recurrence.

Owner:YANGCHUNTANG CHINESE MEDICINE HONGKONG

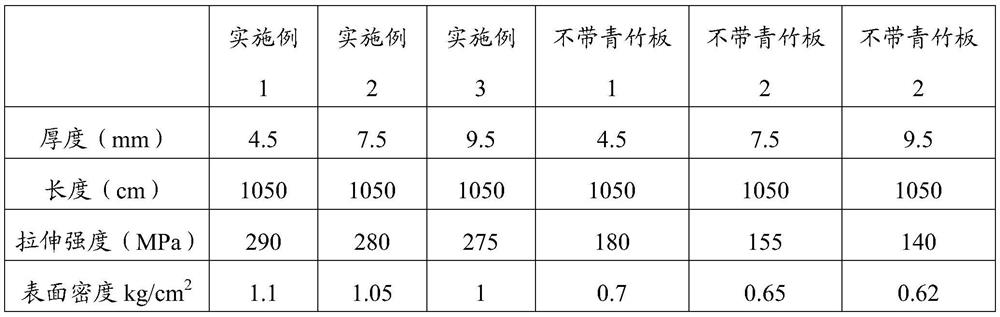

Unfolding process of green bamboo strips

PendingCN113927685AHigh strengthUniform thicknessWood treatment detailsCane mechanical workingPulp and paper industryComposite material

The invention discloses an unfolding process for green bamboo strips, and belongs to the technical field of bamboo processing. The unfolding process comprises the following steps that bamboos are segmented and sectioned bamboo strips with cambered sections; the bamboo strips are expanded in an equal-arc and fixed-thickness mode after being pressurized, heated and softened; then, double-face protection gradual flattening is conducted under the heat preservation condition till the bamboo strips are completely flattened, and a bamboo board is obtained; and the bamboo board is continuously cooled, then subjected to ballasting, shaping and drying until the moisture content is 6-10%, and then subjected to fixed-width trimming to obtain a green bamboo board finished product. According to the unfolding process for the green bamboo strips, the green bamboo strips can be unfolded on the premise that oblique notching and green planing are not conducted, the problems of cracking and rebounding cannot occur in the unfolding process, the obtained green bamboo strips are smooth and flat, the obtained green bamboo strips have the characteristic of high strength, and the application range and field of the bamboo wood are further widened through the unfolding process.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

Vulcanized black jean garment washing process

ActiveCN110117898AReduce riskSafe operating environmentLight resistant fibresDry-cleaning apparatus for textilesHydroxylamine sulfateDeodorant

The invention relates to a vulcanized black jean garment washing process. The vulcanized black jean garment washing process comprises the following steps of placing preprocessed jean garments into desizing solution for desizing treatment at 0-60 DEG C for 10-30 minutes, draining the desizing solution and washing the desized jean garments in clean water at room temperature; placing the desized jeangarments into enzyme solution for treatment at 30-40 DEG C for 15-60 minutes, draining the enzyme solution and washing the treated jean garments in clean water at room temperature; placing the treated jean garments in rinsing solution for treatment at 40-50 DEG C for 10-50 minutes, draining the rinsing solution and washing the rinsed jean garments in clean water at room temperature; adding dechlorinating deodorant into the rinsed jean garments for treatment at 30-40 DEG C for 5-15 minutes, draining the dechlorinating deodorant and washing the treated jean garments in clean water at room temperature; dewatering and drying the first-neutralized jean garments, spraying PP (polypropylene) solution onto the surface of the jean garments, then washing the jean garments in clean water; treating the PP-processed jean garments with hydroxylamine sulfate at 20-50 DEG C for 5-15 minutes, draining the hydroxylamine sulfate, and washing the treated jean garments in clean water at room temperature;processing, dewatering and drying the second-neutralized jean garments. Compared with the prior art, the vulcanized black jean garment washing process is environmentally friendly and safe, and the processed jean garments can be higher in performance.

Owner:FIBER CHEM BIOLOGICAL CHEM

Preparation method of ultra-high molecular weight polyethylene cotton type cut-resistant gloves

ActiveCN104814549BImprove cut resistanceIncrease elasticityProtective garmentSpecial outerwear garmentsGlass fiberPolymer science

The invention discloses a method for producing ultra-high molecular weight polyethylene cotton-type anti-cutting gloves. The gloves are formed by mixing and weaving of yarns such as ultra-high molecular weight polyethylene / polyester staple fiber blended yarns, polyester spandex wrap yarns, polyvinyl chloride (PVC) coated glass fiber spandex filament yarns and elastic yarns, cuffs of woven gloves are closed up by knitted rib cuffs, hot melting edge wrapping and one-time forming are achieved through a hot melting machine at the temperature from 120 DEG C to 180 DEG C, and surface chemical processing is performed through water-proof finishing agents so that finished products can be obtained. According to the method for producing the ultra-high molecular weight polyethylene cotton-type anti-cutting gloves, the process is simple, large-scale automatic production can be achieved, the anti-cutting performance of the gloves is high, the elasticity is good, a user can conveniently and comfortably wear the gloves, and the operation is flexible. Besides, the dust-proof effect is good, and harm to products due to falling of fibers of the gloves can be avoided. The gloves can be widely applied to people in special industries such as automobile assembly industry, glass industry, metal rolling sheet industry, cutting industry, recovery processing industry, police and the like.

Owner:JIANGSU HANVO SAFETY PROD CO LTD

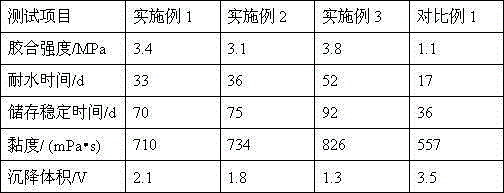

Biological wood adhesive and preparation method therefor

InactiveCN105086894AModerate viscosityImprove wettabilityGraft polymer adhesivesEpoxyBenzoyl peroxide

The invention discloses a biological wood adhesive and a preparation method therefor. The biological wood adhesive is prepared from the components in parts by weight: 20-40 parts of starch, 10-18 parts of saccharose, 5-8 parts of pectin, 3-5 parts of methylcellulose, 4-8 parts of propylene glycol alginate, 1-3 parts of butanedioic anhydride, 2-5 parts of potassium permanganate, 5-10 parts of polyvinyl alcohol, 0.01-0.09 part of nano silicon dioxide, 0.02-0.08 part of calcium carbonate, 2-5 parts of sodium hydroxide, 1-6 parts of epoxy chloropropane, 1-3 parts of urea, 1-3.5 parts of lauryl sodium sulfate, 3-7 parts of dibutyl phthalate, 1-5 parts of cis-pentadiene, 1-3 parts of butyl acrylate, 0.1-0.8 part of benzoyl peroxide and 50-70 parts of water. By taking abundant and recyclable biological resources starch and saccharose as raw materials, the adhesive is good in water resistance, heat resistance and aging resistance, and can be cured within a short time at a low pressure at normal temperature.

Owner:SUZHOU YOUJUN ENVIRONMENTAL SCI & TECH

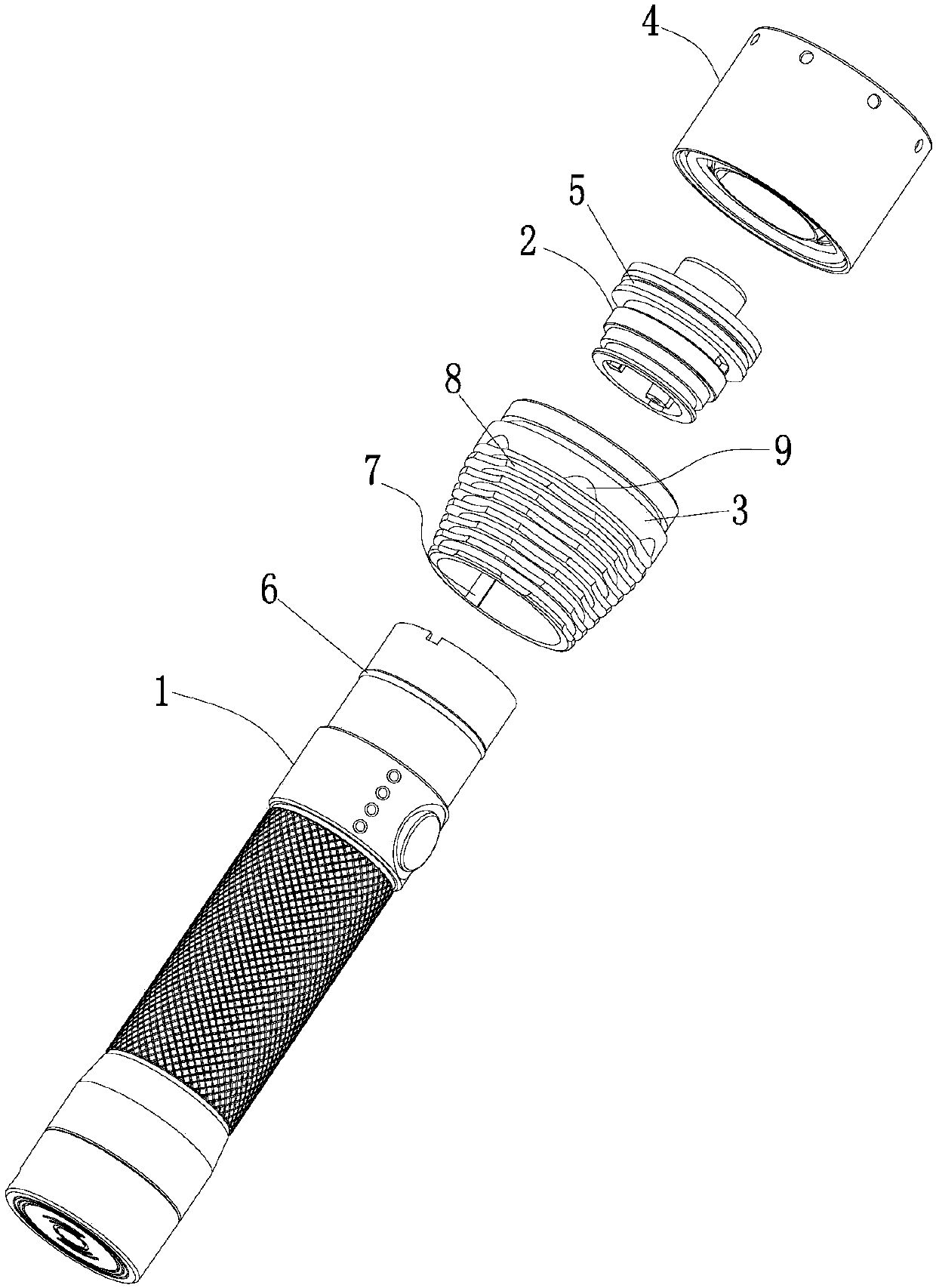

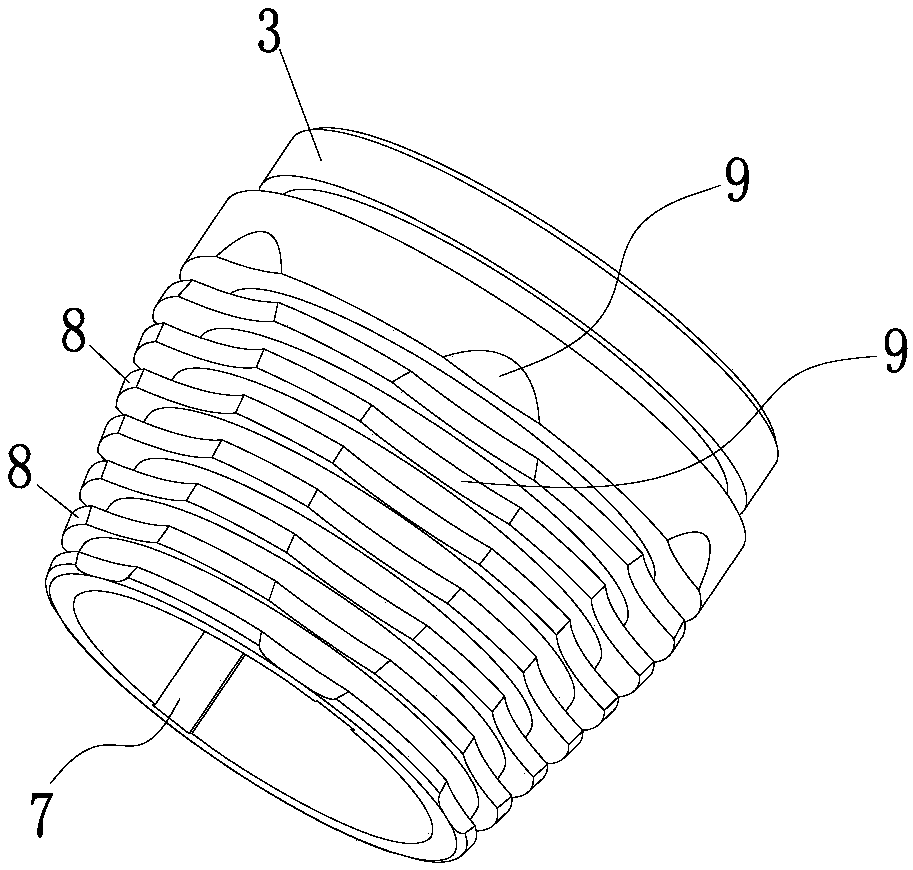

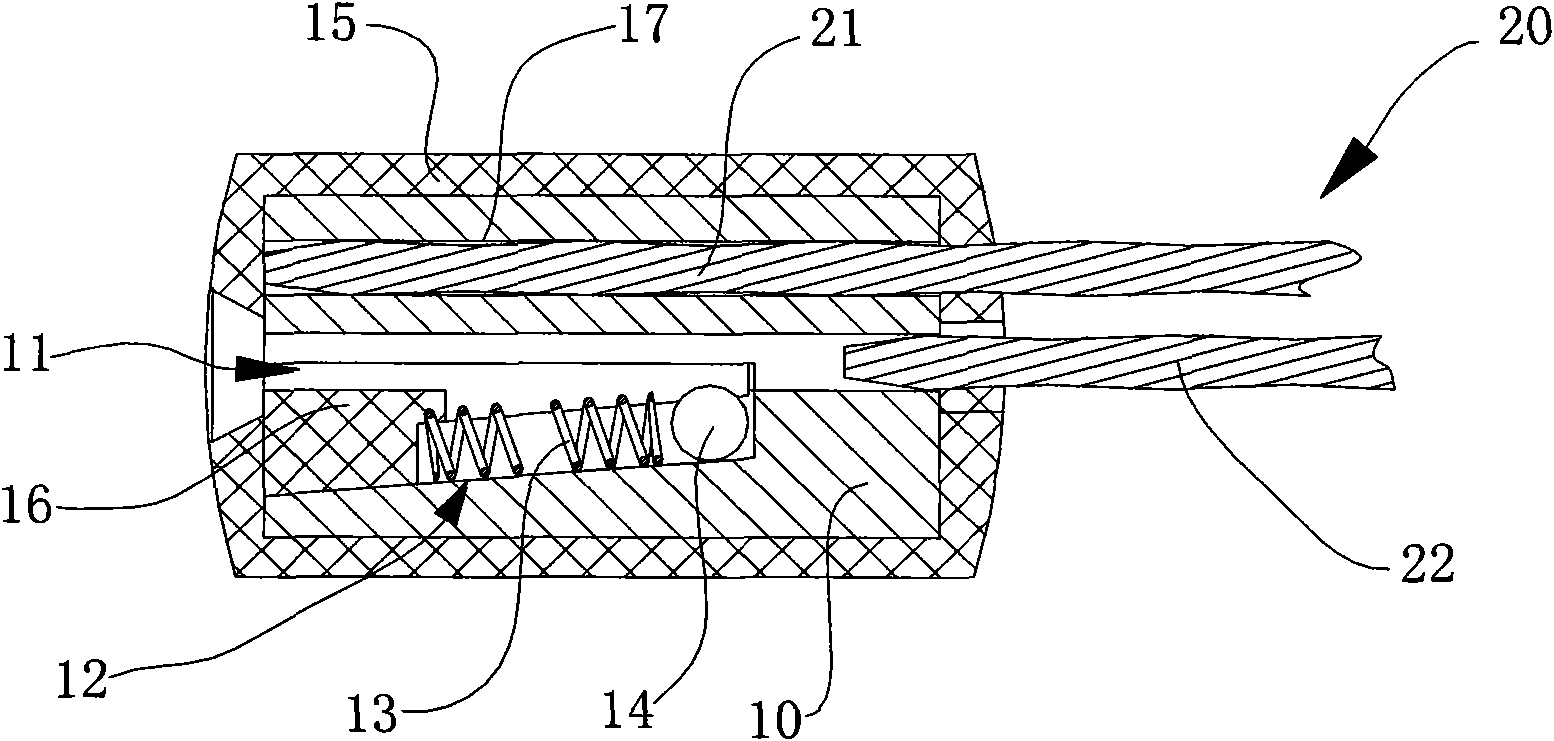

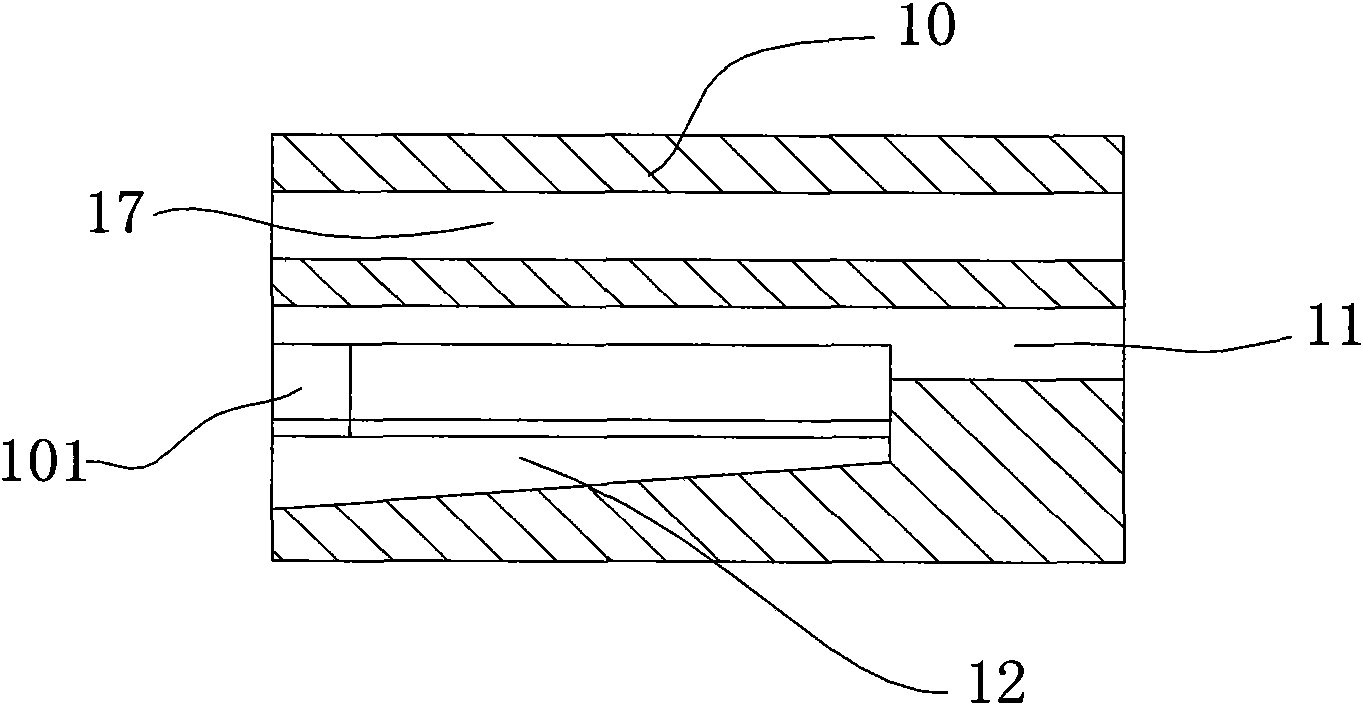

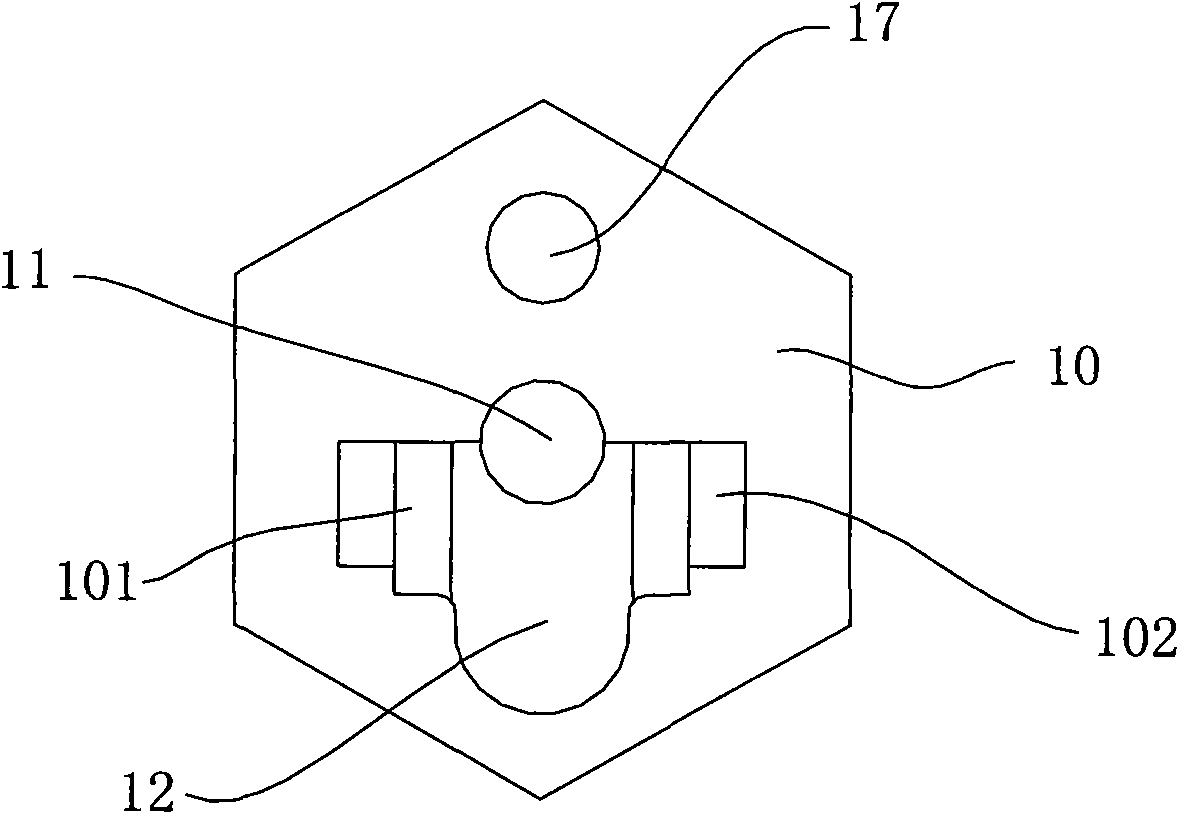

Flashlight

ActiveCN109668064ANo stuckNo elasticityElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringFlashlight

The invention provides a flashlight, and belongs to the field of lighting tools. The flashlight comprises a lamp barrel assembly, a lighting assembly connected with the front end of the lamp barrel assembly, a telescopic ring sleeving the periphery of the lamp barrel assembly and lighting assembly, and a lamp cap assembly connected with the front end of the telescopic ring, a first damping ring which is used for abutting against the inner wall of the telescopic ring is arranged on the periphery of the lighting assembly, a second damping ring which is used for abutting against the inner wall ofthe telescopic ring is arranged on the periphery of the lamp barrel assembly, a ventilation groove which is used for communicating the inner cavity of the telescopic ring with external air is arranged on the inner wall of the telescopic ring, and the opening direction of the ventilation groove faces to the inner part of the telescopic ring. According to the flashlight, when the focusing is carried out, the air pressure in the telescopic ring can be consistent with the air pressure of the external air, the telescopic ring does not have the phenomenon of locking or rebounding in the telescopicprocess, focusing can be carried out by using a single hand, the operation is simple, and a stepless telescopic focusing function can be achieved, the adjusting range is more flexible and the focusingeffect is better.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +2

Tensioning steel wire seal and processing method thereof

The present invention provides a steel wire seal, comprising a lock head and a steel wire with one end connected on the lock head. The lock head is provided with a lock cylinder hole for inserting the steel wire and a marble hole for containing the marble and a spring; the hole diameter of the marble hole is matched with the diameter of the marble; the front part of the marble hole is obliquely penetrated through the middle part of the lock cylinder hole; the size of an area of which the marble hole and the lock cylinder hole penetrate is less than the diameter of the marble. The seal is characterized in that the lock cylinder hole and the marble hole are composed by enclosing a hole wall on the lock head and the surface of an internal core; the internal core is located at the tail end between two holes and is fixedly connected with the lock head; the part where the internal core located at the tail end of the marble hole and the spring form a stop structure; the processing method comprises the steps as follows: compression molding the lock head, the parison comprising a big hole cavity, then filling with the marble and the spring and inserting in the big hole cavity by the specific internal core, and then fixedly connecting the lock head and the steel wire, thereby avoiding the secondary drilling process of the marble hole; the seal has the advantages of accurate size of eachhole, good performance and convenient process.

Owner:黄山亿利工贸集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com