Processing method of ultra-thin annular pieces

A processing method and technology of ring parts, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as plastic and elastic deformation, and achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

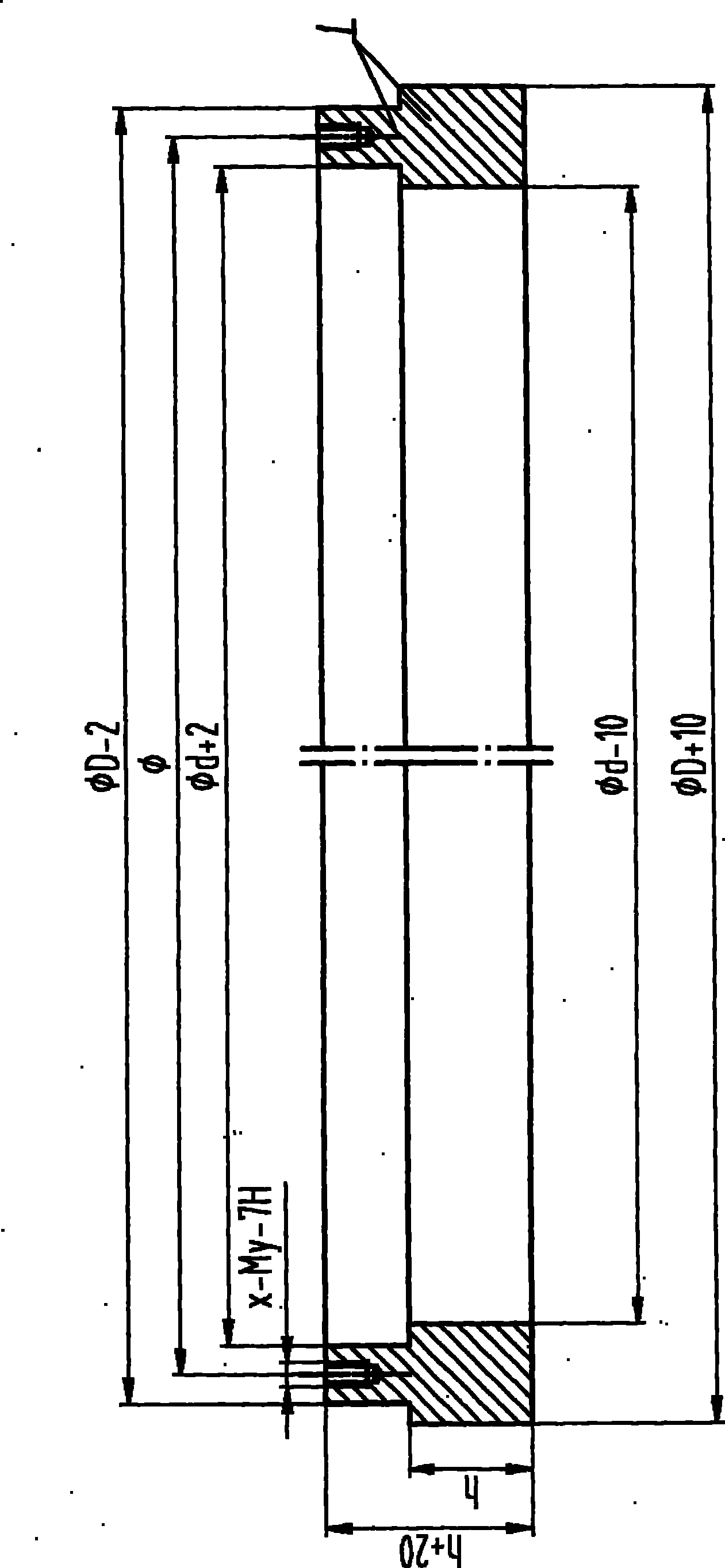

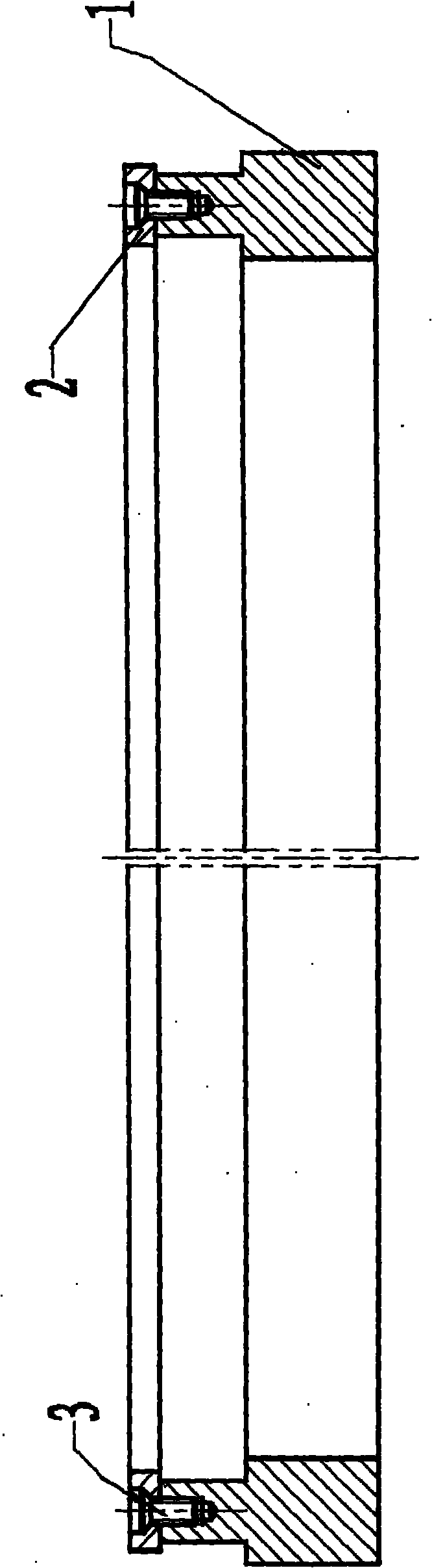

[0026] The slewing bearings on the machines imported by Yulong Company are ultra-thin ring parts. Since the production of ultra-thin ring parts is not yet mature in China, many units have not produced them. Our company uses the ultra-thin ring parts proposed by this invention to process method, and successfully produced ultra-thin ring parts on slewing bearings made in Germany, wherein: the size of part 1 is φ609 -0.175 0 / φ568 0 +0.175 ×3.5 -0.04 -0.01 mm, the size of piece 2 is φ617 -0.175 0 / φ561 0 +0.175 ×4.5 -0.04 -0.01 mm; and for the two surfaces, there are also geometric tolerance requirements for flatness less than 0.06mm and parallelism less than 0.06mm;

[0027] Process the above two products according to the processing technological process of the present invention:

[0028] 1) Cutting blank:

[0029] Part 1 is to produce four ultra-thin annular parts, and the steel plate is flame-cut and blanked, and the thickness of the blank is calculated according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com