Biological wood adhesive and preparation method therefor

A wood adhesive, bio-based technology, applied in the field of fine chemicals, can solve the problems of poor adhesive viscosity, long curing time, lack of elasticity, etc., and achieve high bonding strength, low price, and good aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

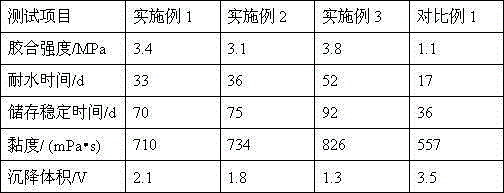

Examples

Embodiment 1

[0018] Bio-based wood adhesive, the components and the mass parts of each component are as follows: 30 parts of corn starch, 10 parts of tapioca starch, 18 parts of sucrose, 8 parts of pectin, 5 parts of methyl cellulose, 8 parts of propylene glycol alginate, 3 parts of succinic anhydride, 5 parts of potassium permanganate, 10 parts of polyvinyl alcohol, 0.09 parts of nano silicon dioxide, 0.08 parts of calcium carbonate, 5 parts of sodium hydroxide, 6 parts of epichlorohydrin, 3 parts of urea, twelve 3.5 parts of sodium alkyl sulfate, 7 parts of dibutyl phthalate, 5 parts of cis-pentadiene, 3 parts of butyl acrylate, 0.8 parts of benzoyl peroxide, and 70 parts of water.

[0019] The preparation method comprises the steps of:

[0020] 1) Mix starch and water, stir evenly, add sodium hydroxide, stir at 45rpm for 25min;

[0021] 2) Add potassium permanganate to the starch solution in step 1) and stir for 1 hour, then add the remaining components, raise the temperature to 100°C,...

Embodiment 2

[0023] Bio-based wood adhesive, the components and the parts by mass of each component are as follows: 10 parts of potato starch, 10 parts of corn starch, 10 parts of sucrose, 5 parts of pectin, 3 parts of methyl cellulose, 4 parts of propylene glycol alginate, 1 part of succinic anhydride, 2 parts of potassium permanganate, 5 parts of polyvinyl alcohol, 0.01 part of nano silicon dioxide, 0.02 part of calcium carbonate, 2 parts of sodium hydroxide, 1 part of epichlorohydrin, 1 part of urea, twelve 1 part sodium alkyl sulfate, 3 parts dibutyl phthalate, 1 part pentadiene, 1 part butyl acrylate, 0.1 part benzoyl peroxide, 50 parts water.

[0024] The preparation method comprises the steps of:

[0025] 1) Mix starch and water, stir evenly, add sodium hydroxide, stir at 45rpm for 25min;

[0026] 2) Add potassium permanganate to the starch solution in step 1) and stir for 1 hour, then add the remaining components, raise the temperature to 100°C, and react for 9 hours to obtain a b...

Embodiment 3

[0028] Bio-based wood adhesive, the components and the parts by mass of each component are as follows: 30 parts of corn starch, 14 parts of sucrose, 6 parts of pectin, 4 parts of methyl cellulose, 6 parts of propylene glycol alginate, 2 parts of succinic anhydride , 3 parts of potassium permanganate, 8 parts of polyvinyl alcohol, 0.05 parts of nano silicon dioxide, 0.06 parts of calcium carbonate, 4 parts of sodium hydroxide, 3.5 parts of epichlorohydrin, 2 parts of urea, 2.6 parts of sodium lauryl sulfate parts, 5 parts of dibutyl phthalate, 3 parts of cis-pentadiene, 2 parts of butyl acrylate, 0.4 parts of benzoyl peroxide, and 60 parts of water. The preparation method comprises the steps of:

[0029] 1) Mix starch and water, stir evenly, add sodium hydroxide, stir at 45rpm for 25min;

[0030] 2) Add potassium permanganate to the starch solution in step 1) and stir for 1 hour, then add the remaining components, raise the temperature to 100°C, and react for 9 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com