Patents

Literature

40results about How to "Prevent pullback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

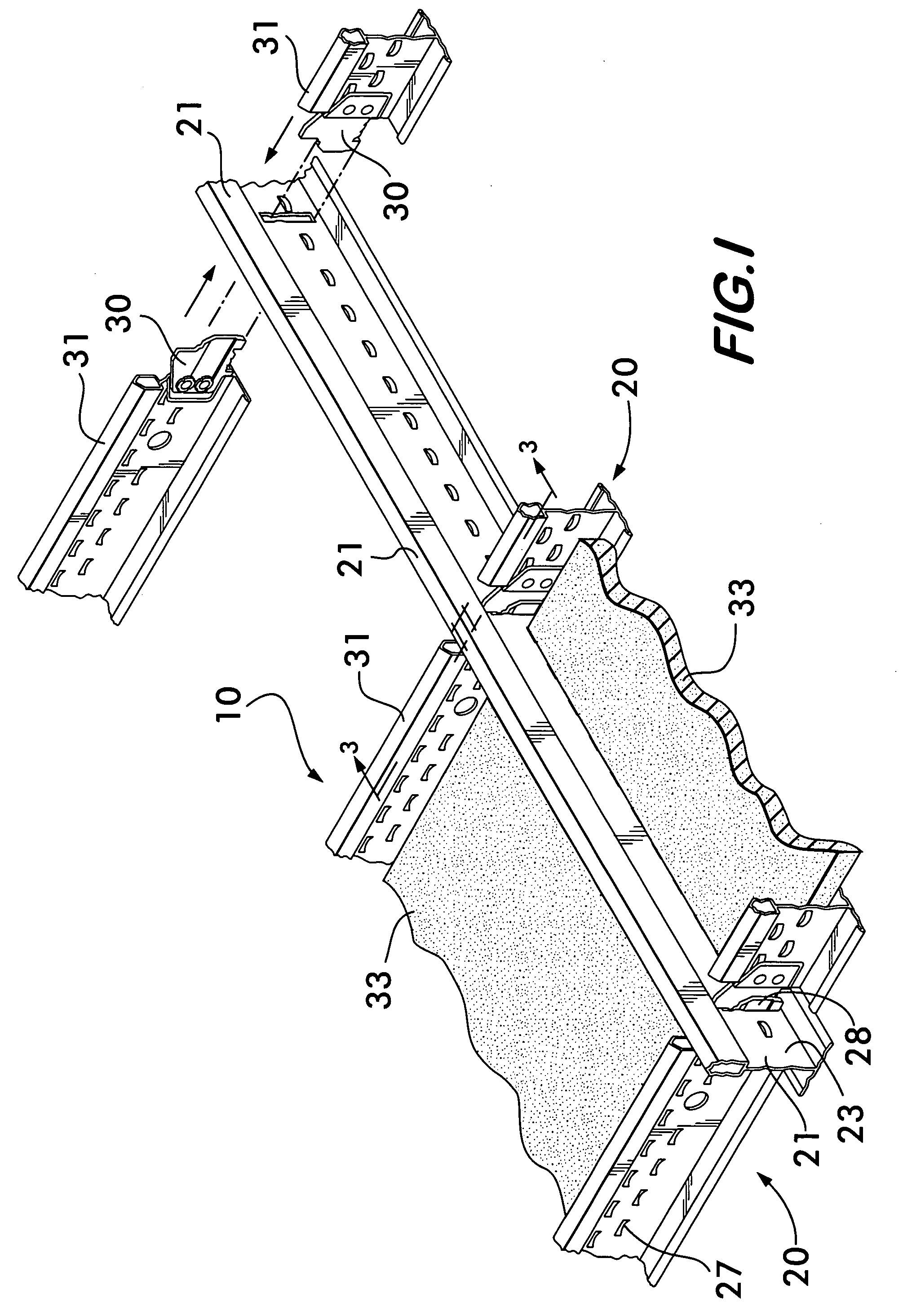

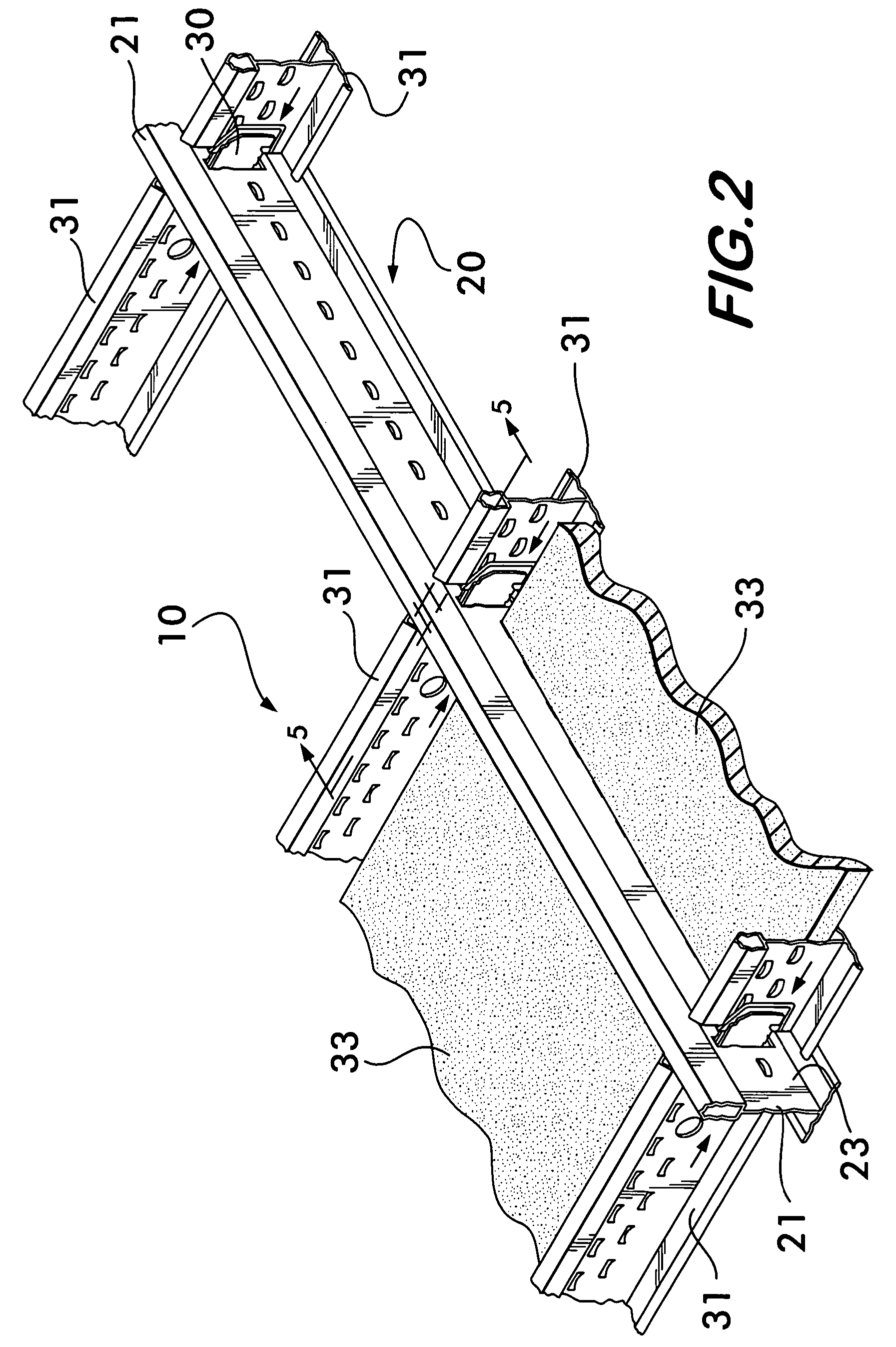

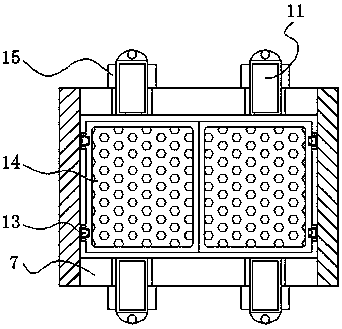

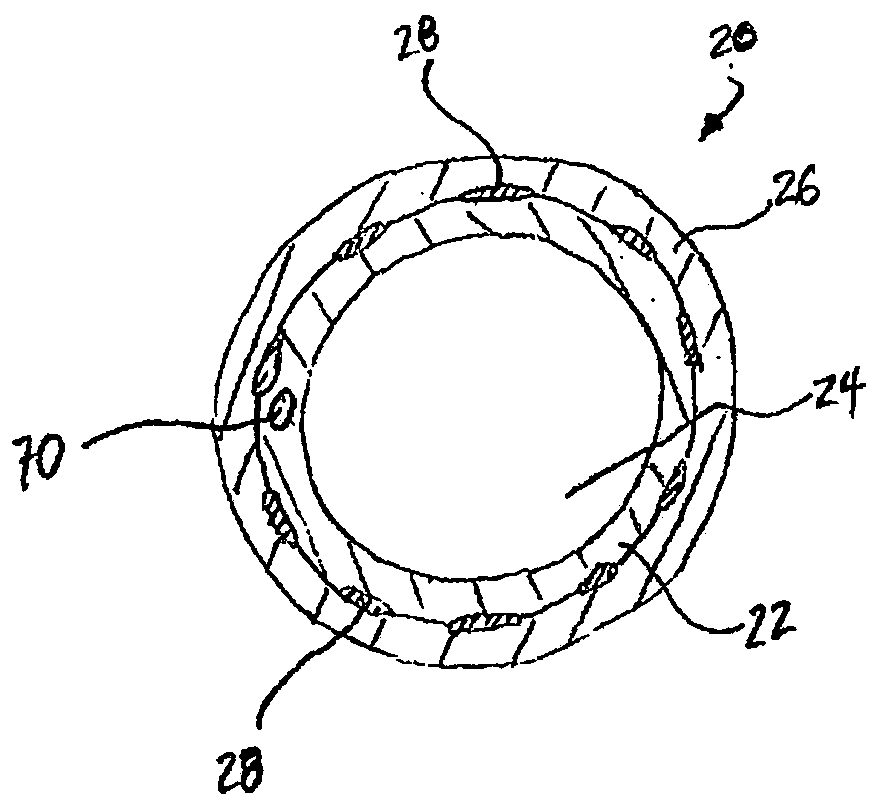

Hook connector with plastic fire relief

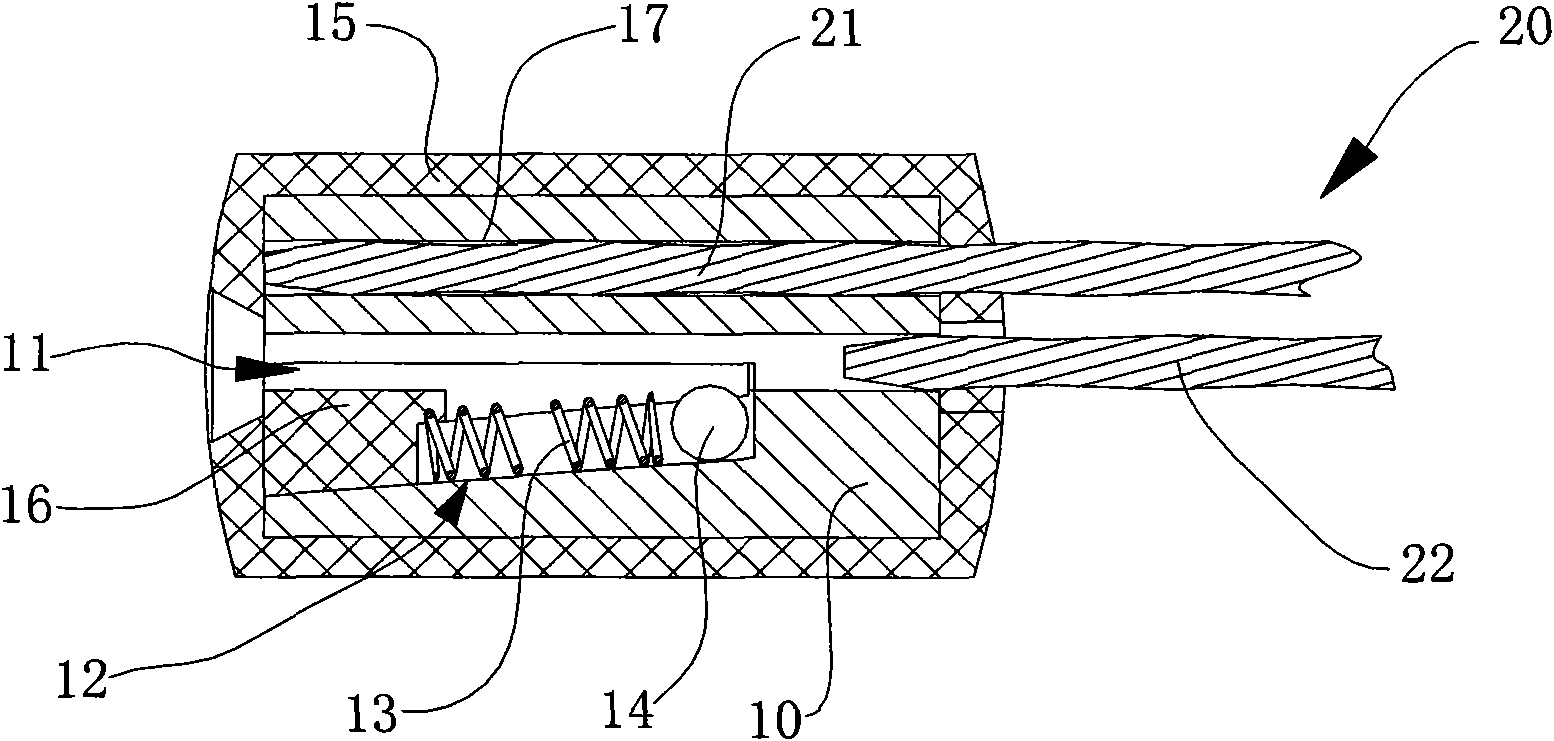

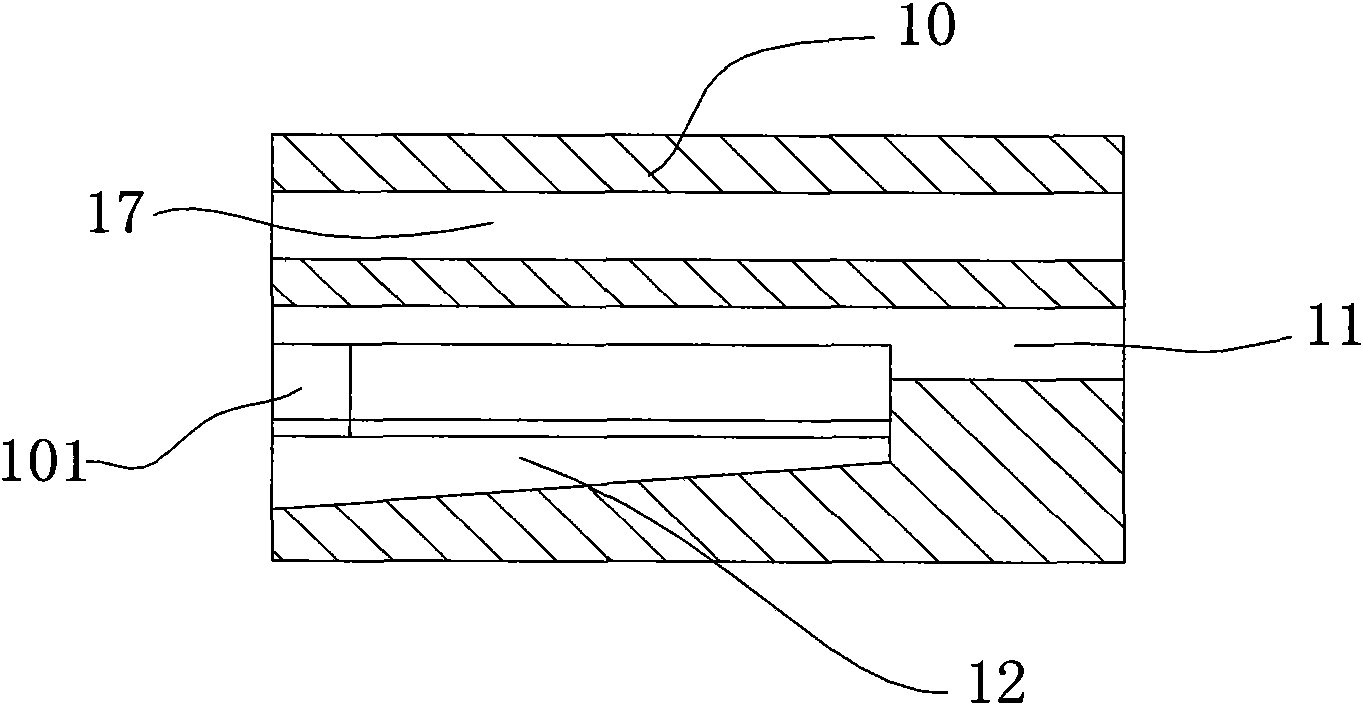

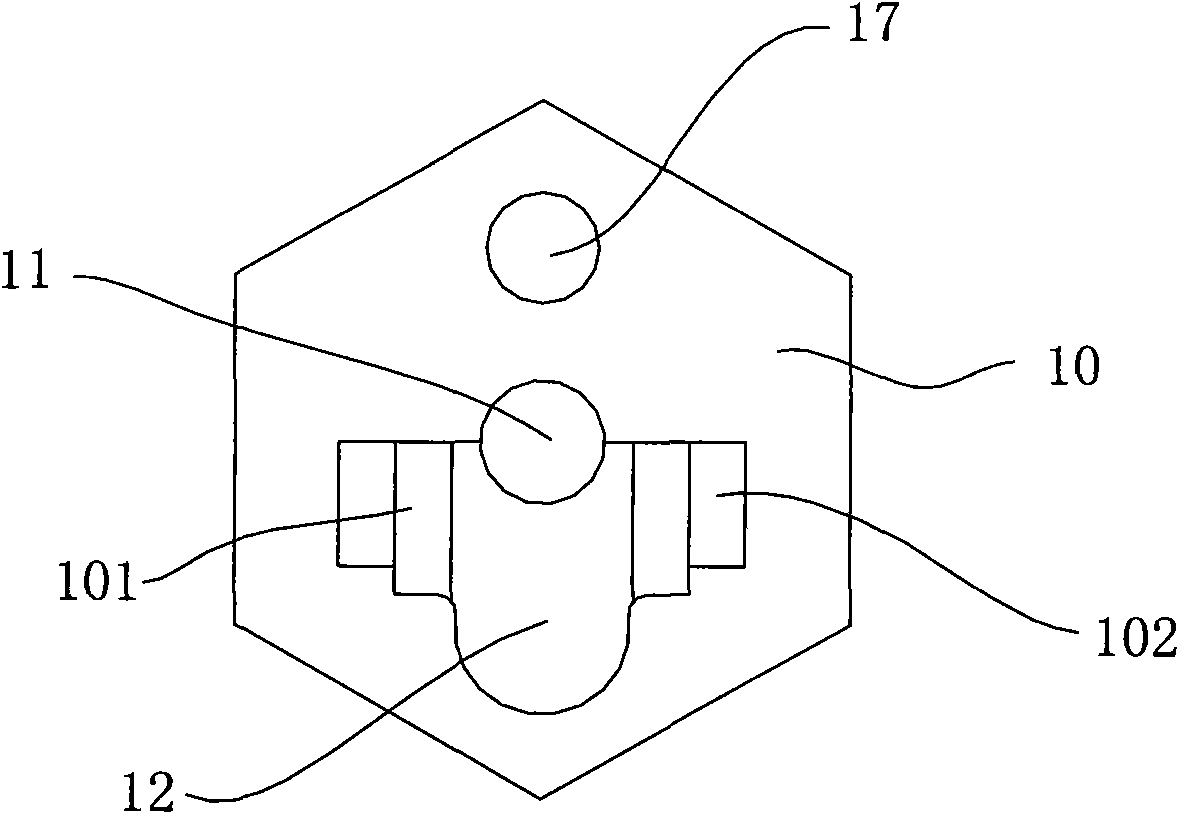

ActiveUS7520095B2Cross beams from sagging or droopingPrevent pullbackCeilingsConstruction materialEngineeringAbutment

Owner:WORTHINGTON ARMSTRONG VENTURE

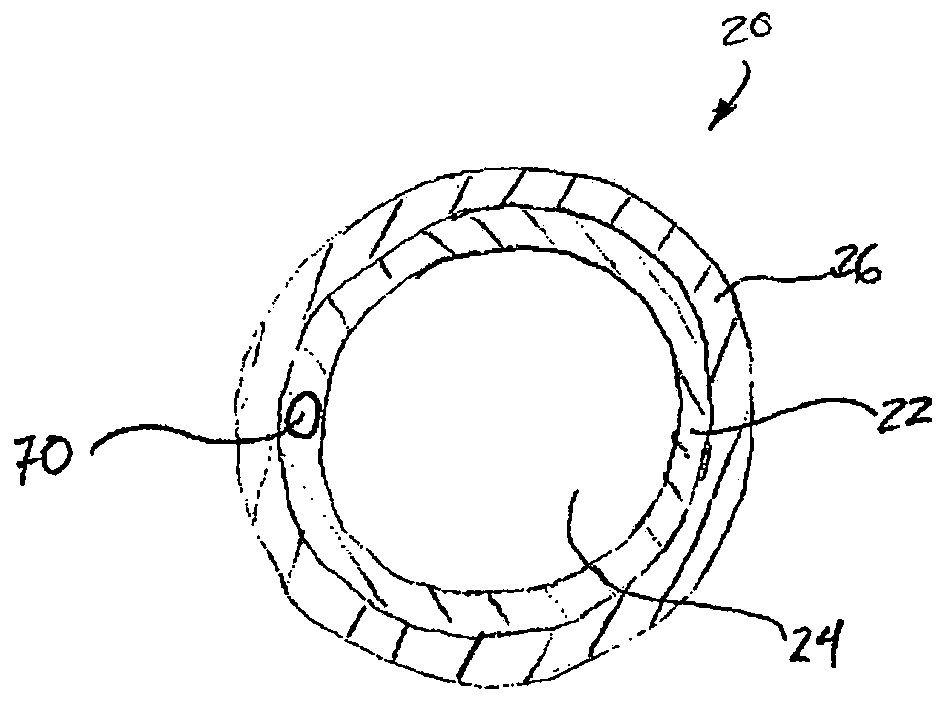

Hook connector with plastic fire relief

ActiveUS20060260244A1Cross beams from sagging or droopingPrevent pullbackCeilingsWallsNormal caseAbutment

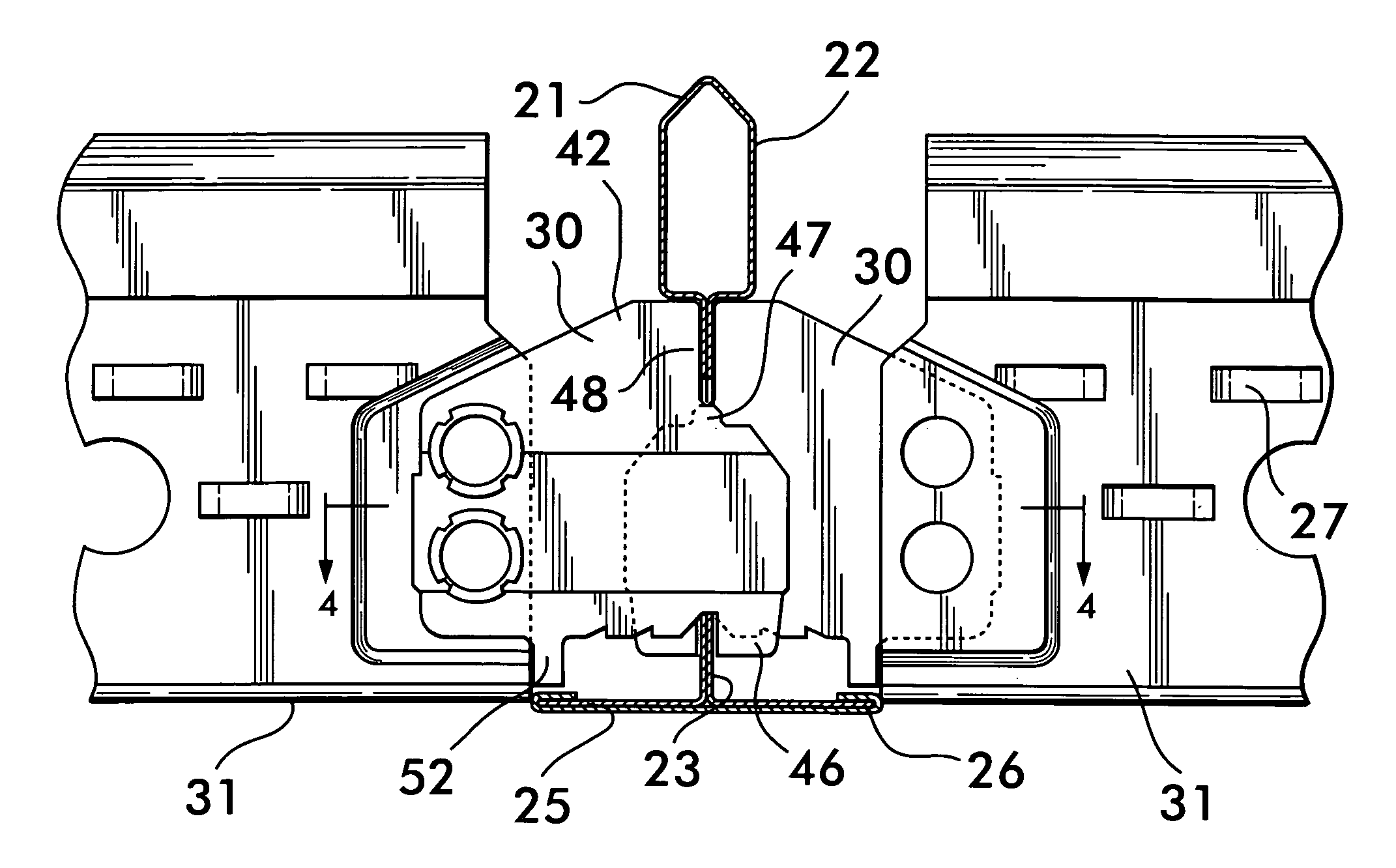

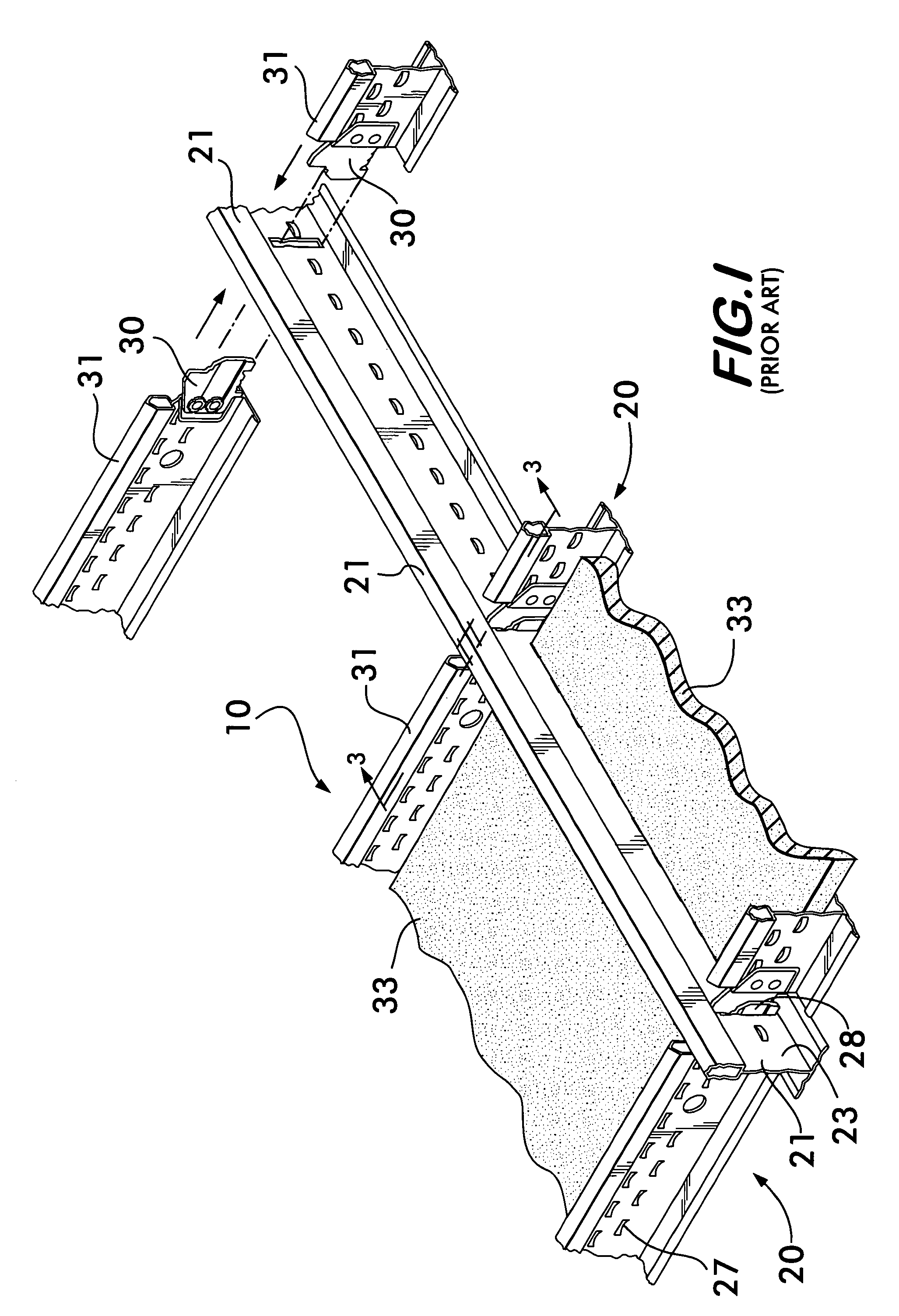

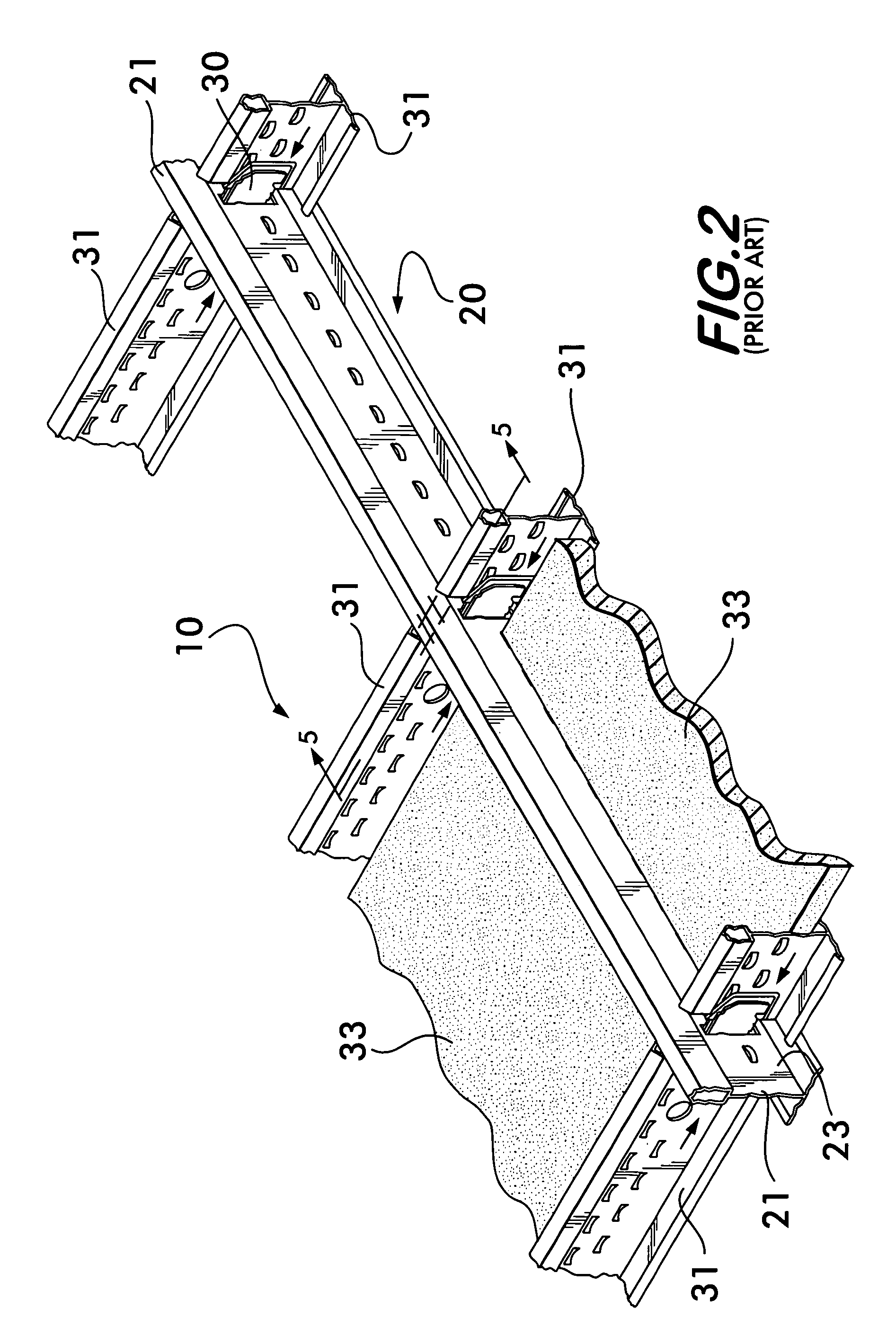

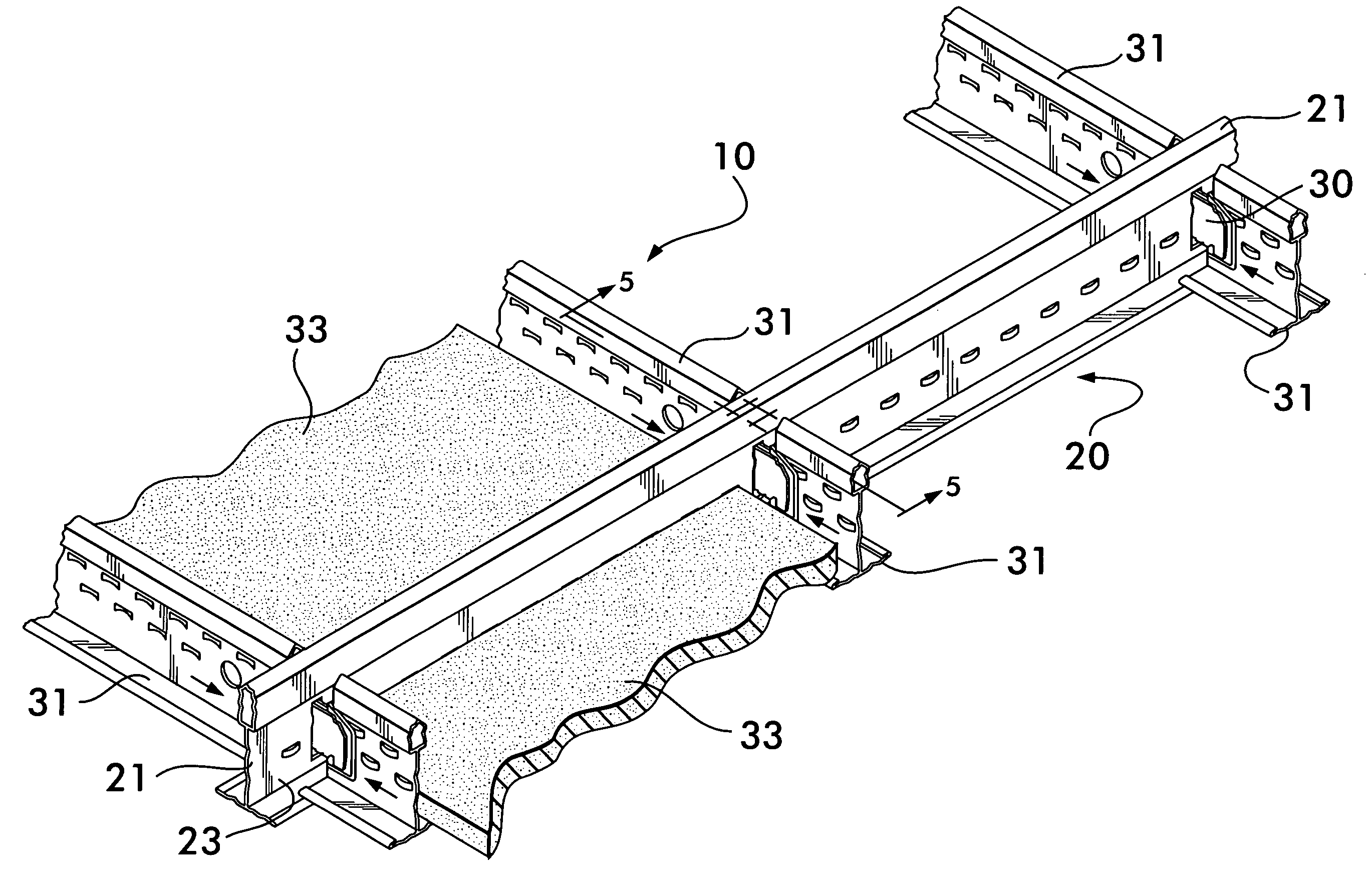

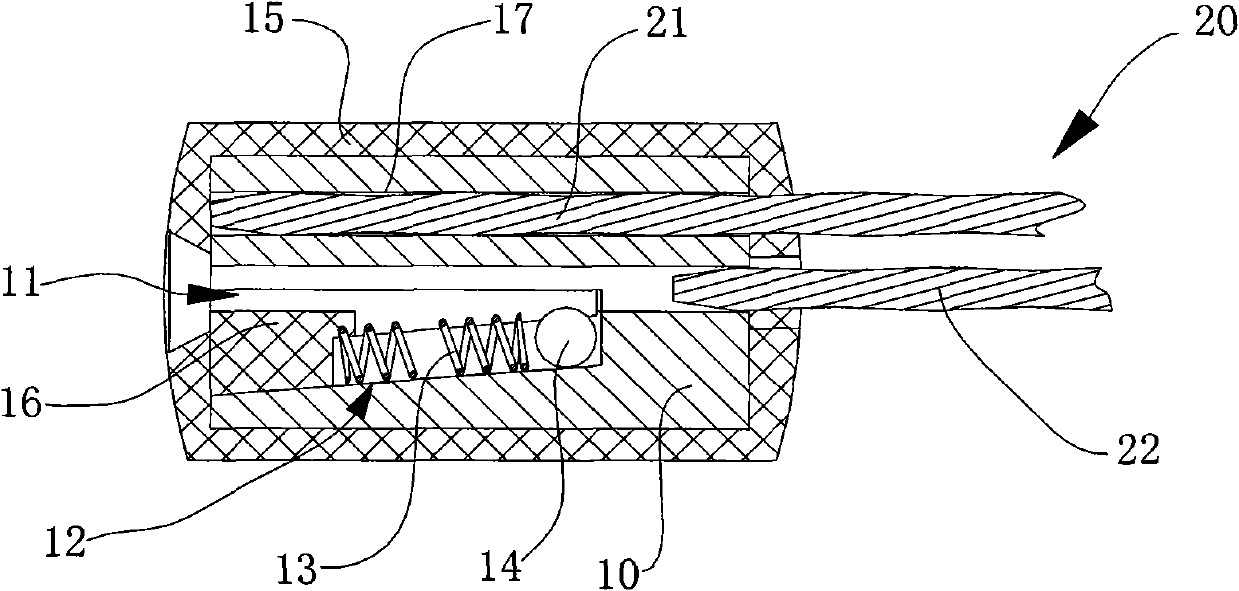

A connector for a cross beam that hooks into a slot in a main beam in the grid of a suspended ceiling. The connector has a plastic encasement that forms abutments about a metallic core. The abutments position the connector within the slot, and prevent further entry of the connector into the slot, under normal conditions. The plastic abutments melt away during a fire, so that the beam can expand longitudinally to relieve stresses in the beam, without the beam buckling. Ridges on the bottom of the metallic core prevent pullback of the connector from the slot, during a fire, to prevent the ceiling from sagging or drooping.

Owner:WORTHINGTON ARMSTRONG VENTURE

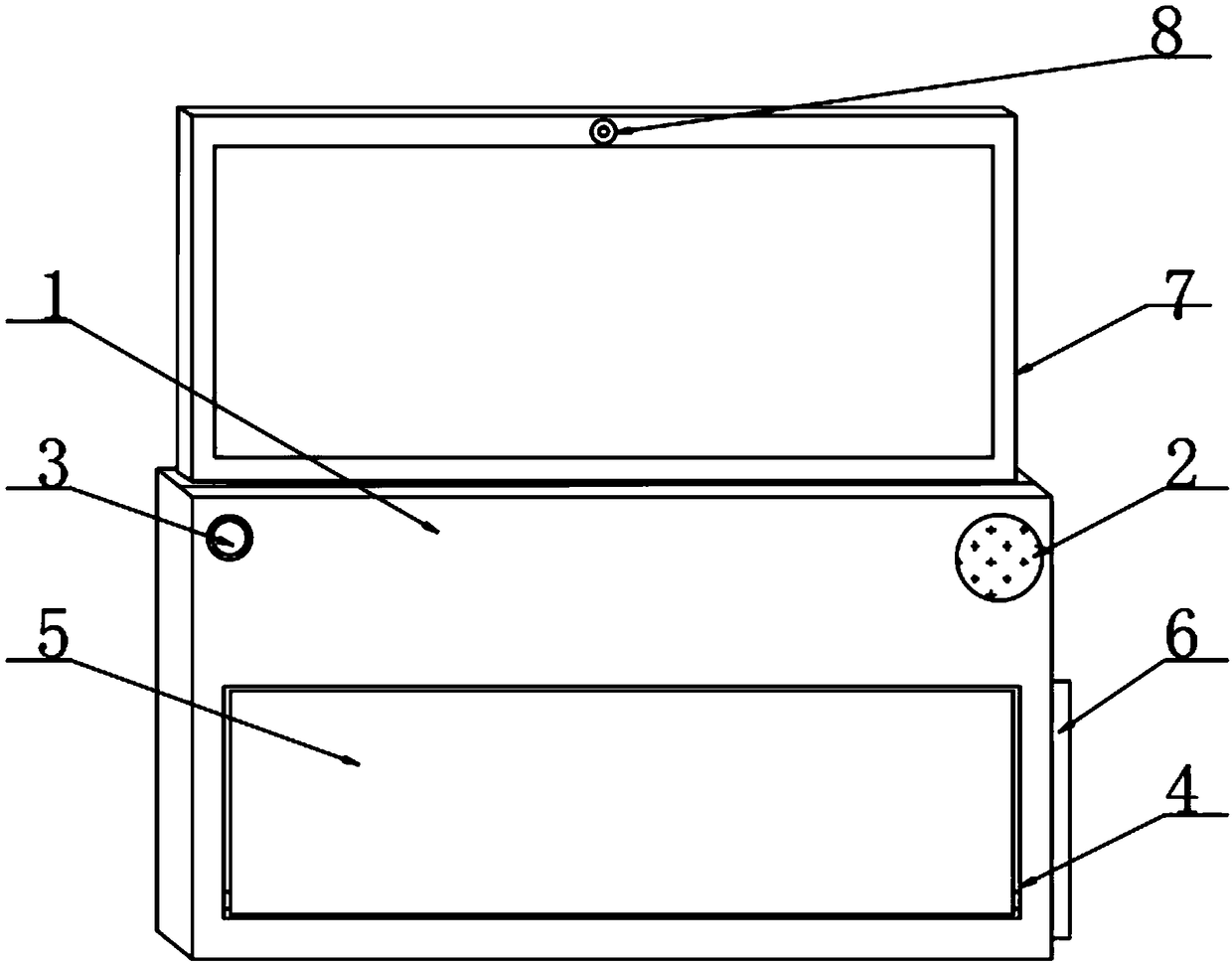

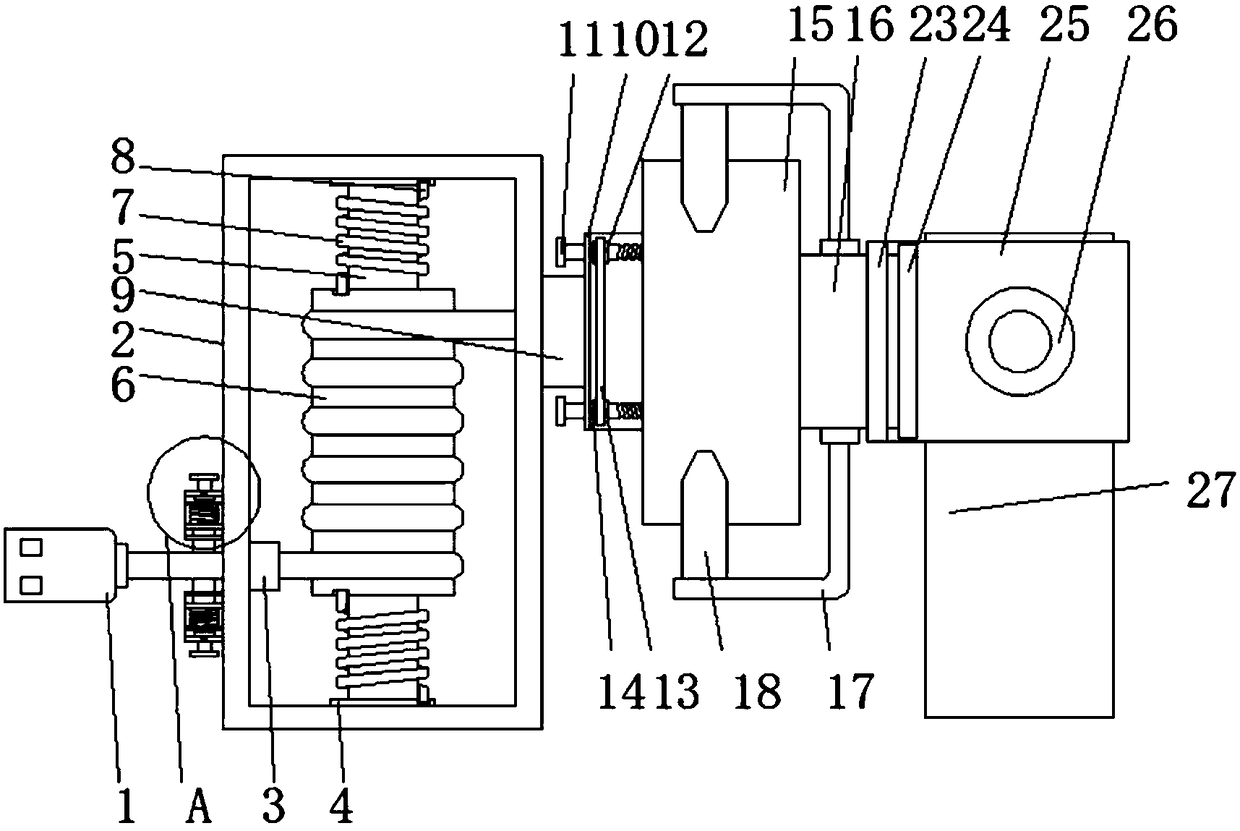

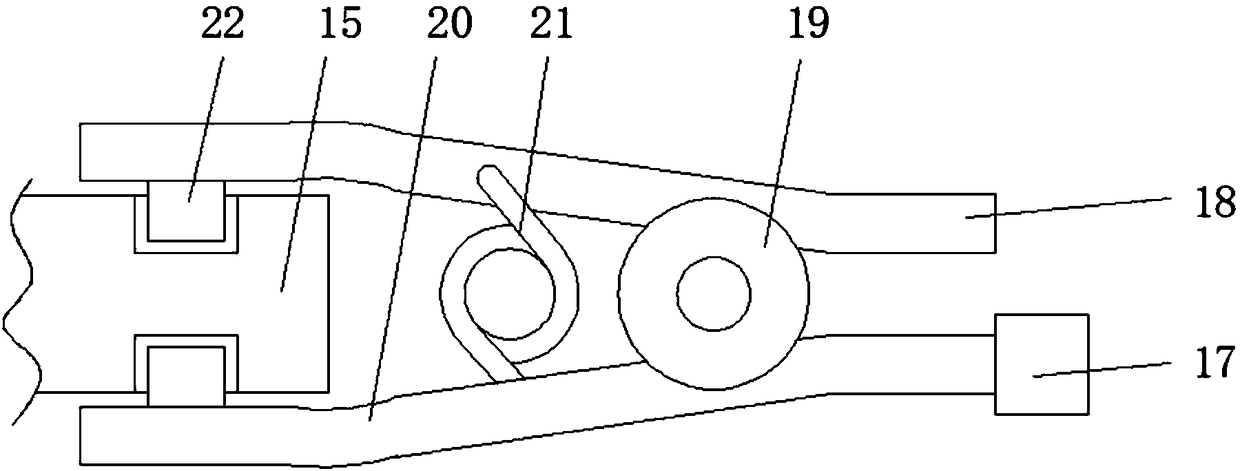

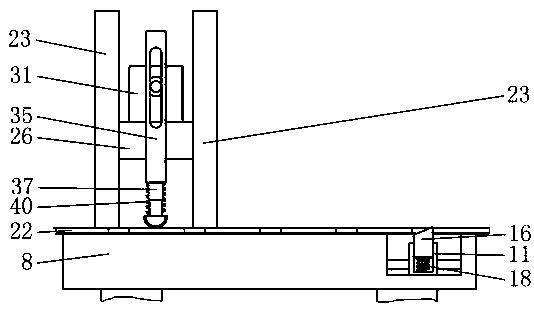

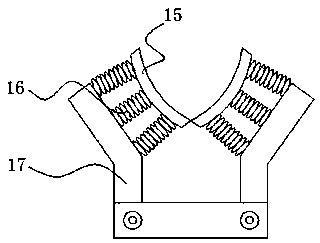

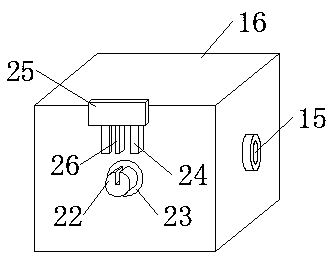

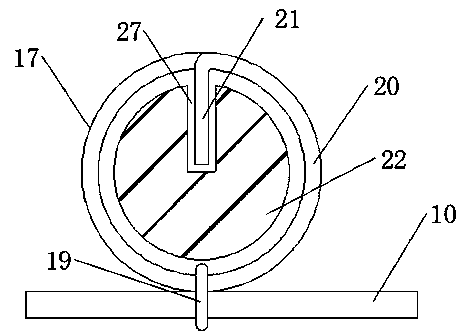

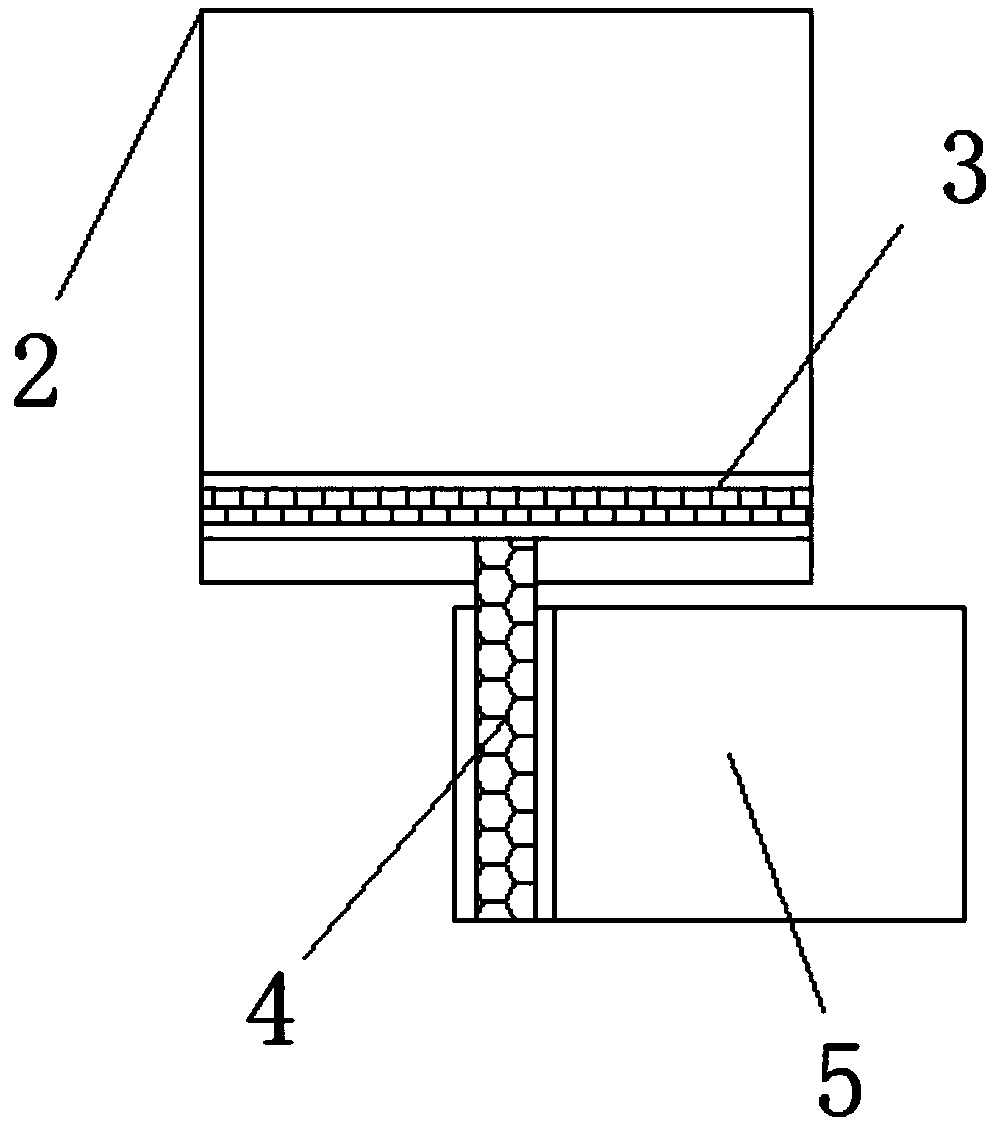

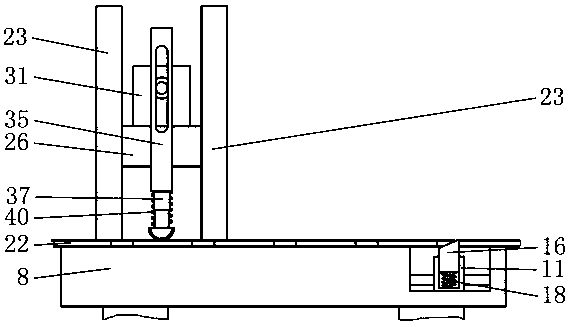

Letter spelling machine and protection method

PendingCN109377799APrevent pullbackAvoid secondary damageClamping/extracting meansElectrical appliancesPull forceEngineering

The present invention discloses a letter spelling machine and a protection method. The letter spelling machine comprises a main body casing. A speaker is fixedly installed to one side of the front endof the main body casing, and one side of the front end of the main body casing away from the speaker is provided with a start switch. According to the invention, slide rails, springs, connecting buttons, baffle plates and a protective plate are used, when people uses the letter spelling machine, the letter spelling machine can be pushed out along the sliding rails, when the letter spelling machine is completed pushed out, the baffle plates block the connecting buttons, the springs are prevented from pulling the connection buttons back, one end of each of the baffle plates is connected by a torsion spring, and the torsion force of the torsion spring is slightly larger than the pulling force of the spring when a display screen is pushed out. When equipment falls, the main body casing is vibrated, under the action of external force, the springs drive the connecting buttons to open the baffle plates, the connecting buttons are retracted, the display screen connected to one side of each ofthe connecting buttons, the display screen is retracted into the main body casing, the secondary damage to the display screen is avoided, and therefore, the safety of the equipment is improved.

Owner:大连派欧机电设备有限公司

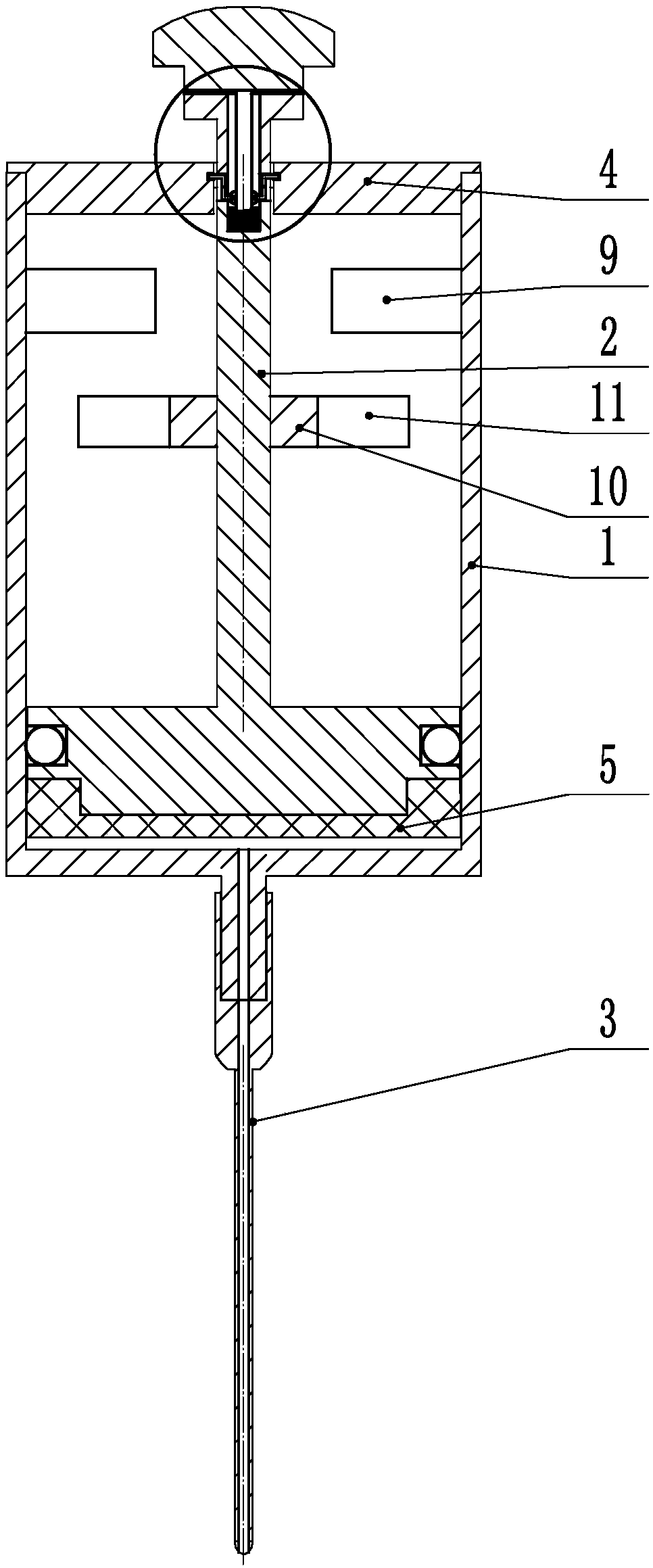

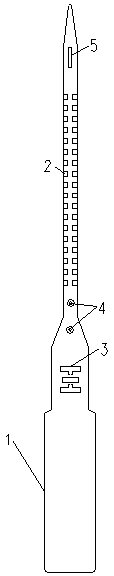

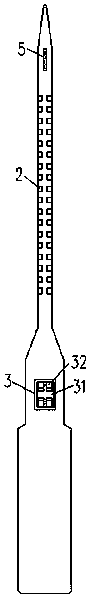

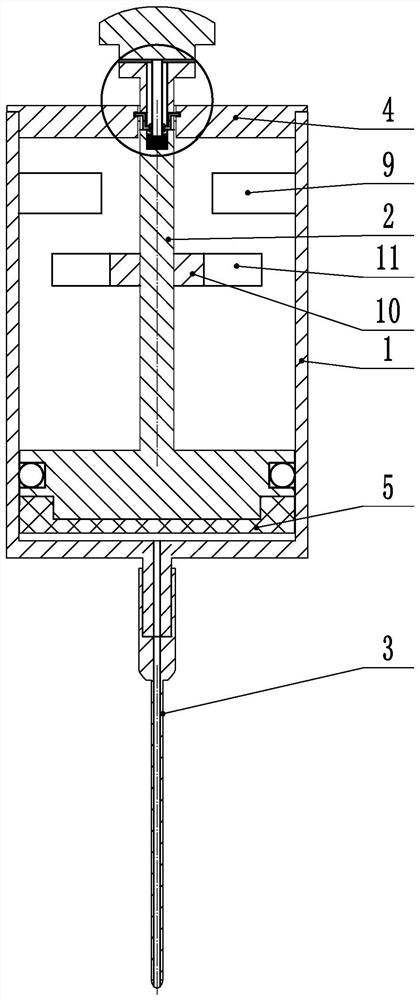

Gastric cancer full-thickness specimen sampling apparatus

ActiveCN108433752APrevent pullbackAvoid painSurgical needlesVaccination/ovulation diagnosticsStomach cancerSyringe needle

The invention discloses a gastric cancer full-thickness specimen sampling apparatus, which comprises a needle tube and a core rod, wherein the core rod is arranged in the needle tube; a syringe needleis arranged on the needle tube; a cap is arranged at the end, back away from the syringe needle, of the needle tube; a rod hole, in which the core rod can slide, is formed in the cap; a rubber coveris arranged on the core rod; a fixing structure is arranged on the core rod; the fixing structure comprises a control rod, a spring and a Z-shaped locating piece; a sliding hole is formed in the corerod; a mounting hole is formed in the sidewall of the sliding hole; and a locating hole, in which the locating piece is embedded, is formed in the hole wall of the rod hole. The locating piece is justaligned with the locating hole when a suction amount nearly reaches a required value during sampling, and the control rod is pushed to slide under the power of the spring, so that the locating pieceis driven to get inserted into the locating hole and the core rod and the needle tube are locked; therefore precise control over the suction amount can be achieved, and pain in a patient due to excessive suction can be prevented; and in addition, less suction can be prevented, and the accuracy of test can be reduced.

Owner:WENZHOU PEOPLES HOSPITAL

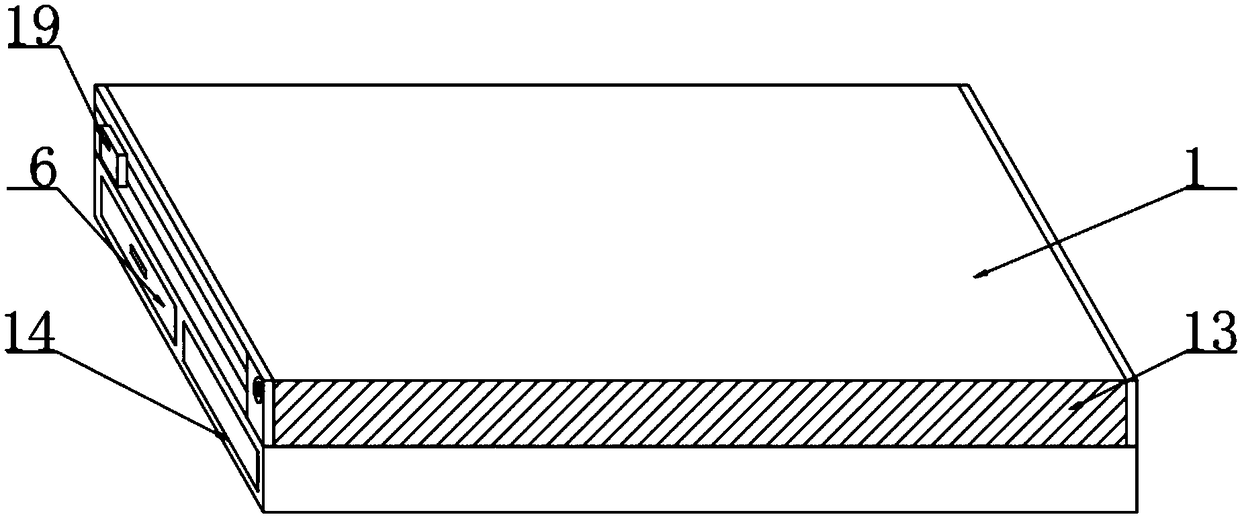

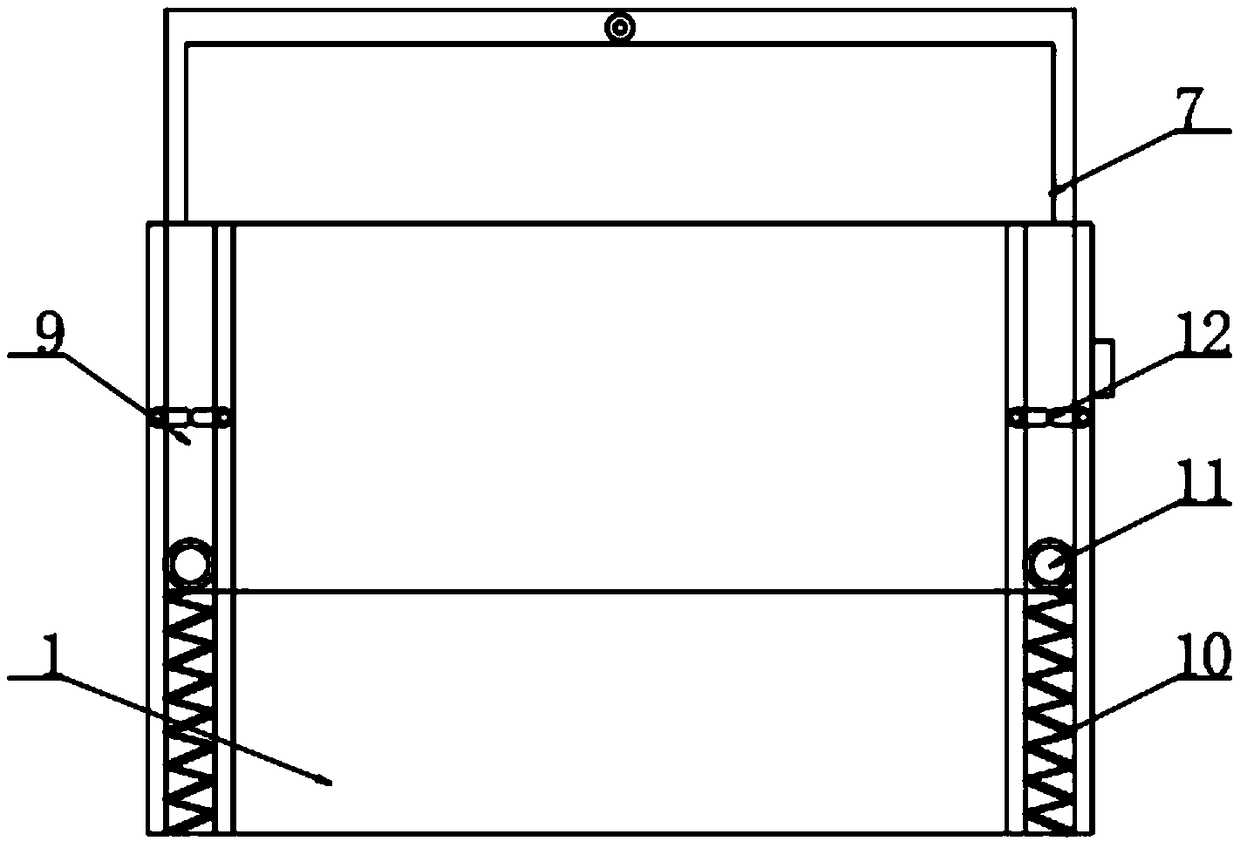

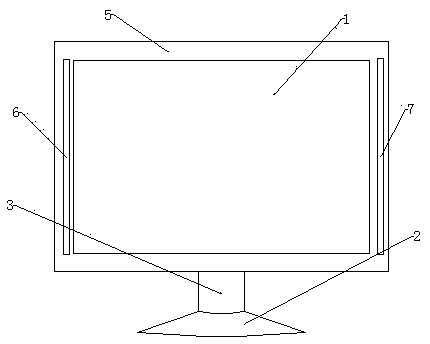

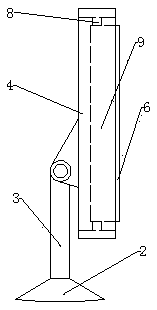

Dustproof display

InactiveCN105373192ASave effortCompact structureDigital data processing detailsInternal/peripheral component protectionSoftware engineeringDisplay device

Owner:CHONGQING CHENGSHUO TECH

Computer device capable of integrating multiple interfaces

InactiveCN108304337AEasy to place and useEasy to transferElectric digital data processingFlexible lead accommodationComputer deviceElectrical and Electronics engineering

The invention relates to the technical field of computer devices and discloses a computer device capable of integrating various interfaces. The computer device comprises a connector lug. One end of the connector plug is movably connected with a cable arranging device, one end of the connector plug runs through and extends to the inside of the cable arranging device, the inside of the cable arranging device is fixedly provided with a limit block, one end of the connector plug is movably connected to the inner wall of the limit block, and a positioning block is fixedly mounted on the inside thecable arranging device. Cables are prevented from being randomly placed during use. The problem that the cables are placed in confusion and easily entangled and affect the use of the connector plug issolved. The cables are prevented from swinging in the cable arranging device during use by means of the limit block. The cables are twisted on a cable arranging rod by means of matching of a connecting rod and the cable arranging rod to prevent cable staggering. By means of matching of a tension spring and a fixed rod, the cables can stretch freely, and placement and use of the cables are facilitated.

Owner:姚福泉

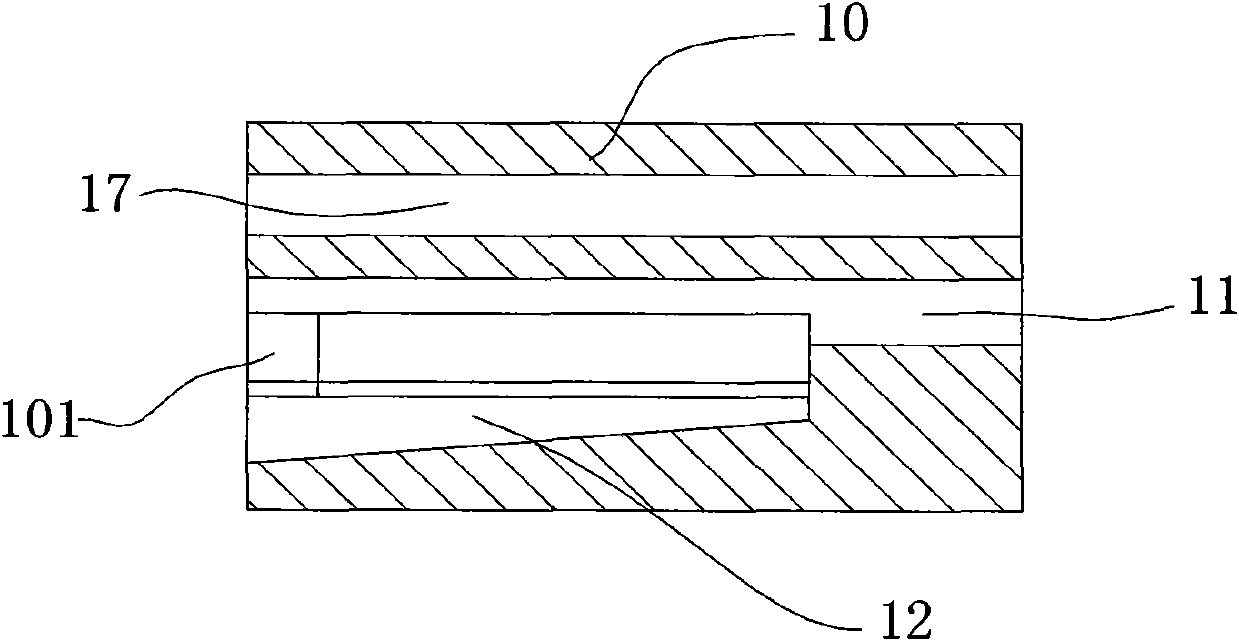

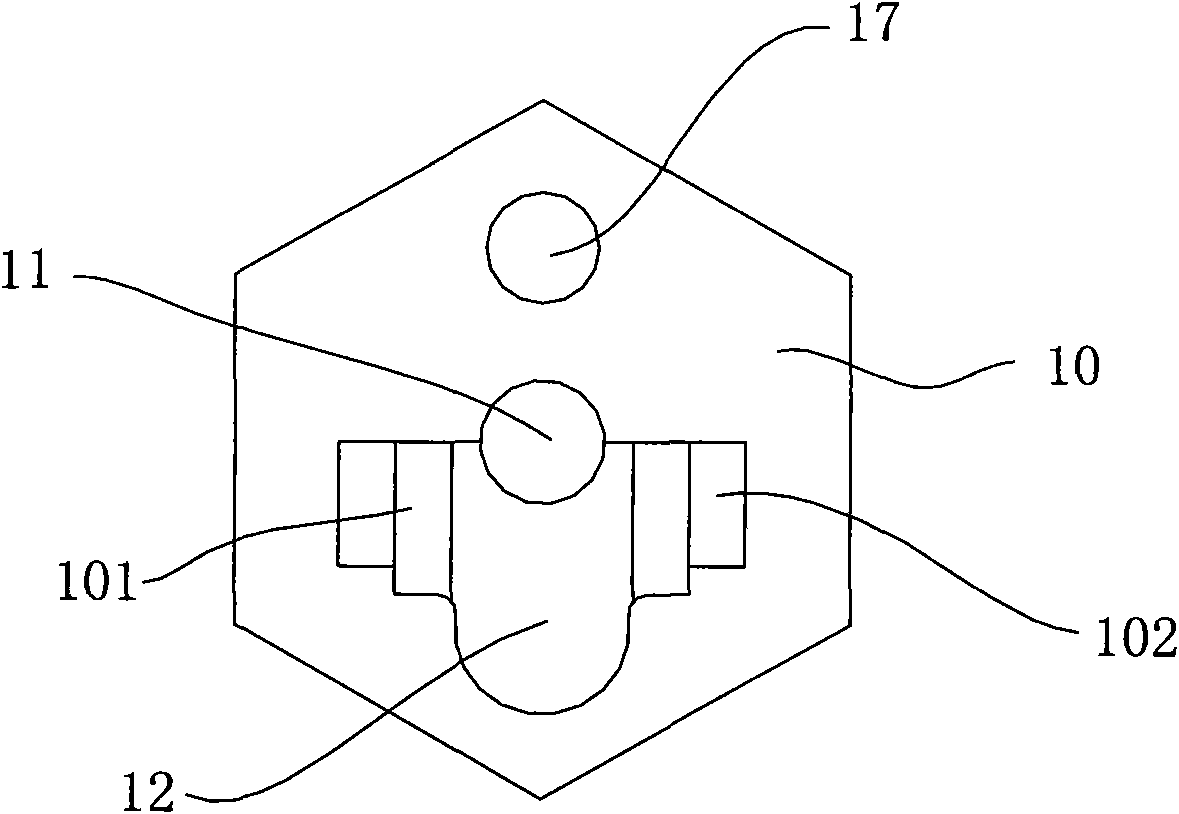

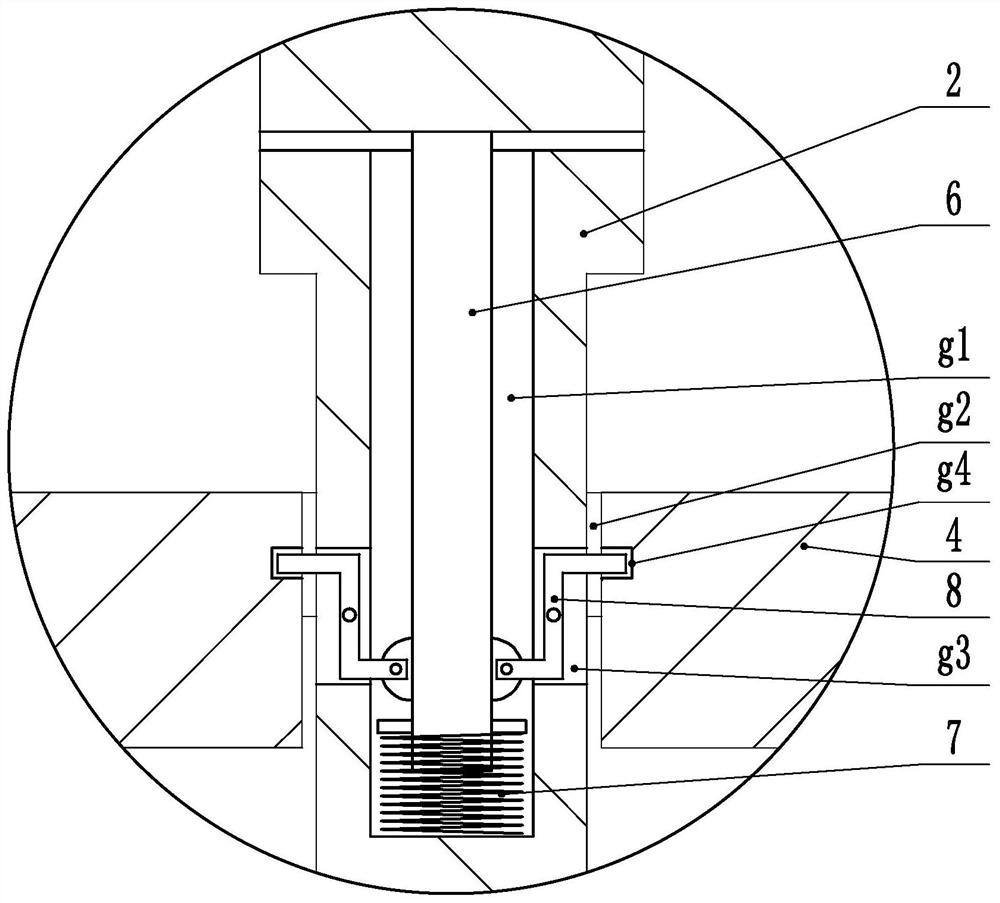

Tensioning steel wire seal and processing method thereof

The present invention provides a steel wire seal, comprising a lock head and a steel wire with one end connected on the lock head. The lock head is provided with a lock cylinder hole for inserting the steel wire and a marble hole for containing the marble and a spring; the hole diameter of the marble hole is matched with the diameter of the marble; the front part of the marble hole is obliquely penetrated through the middle part of the lock cylinder hole; the size of an area of which the marble hole and the lock cylinder hole penetrate is less than the diameter of the marble. The seal is characterized in that the lock cylinder hole and the marble hole are composed by enclosing a hole wall on the lock head and the surface of an internal core; the internal core is located at the tail end between two holes and is fixedly connected with the lock head; the part where the internal core located at the tail end of the marble hole and the spring form a stop structure; the processing method comprises the steps as follows: compression molding the lock head, the parison comprising a big hole cavity, then filling with the marble and the spring and inserting in the big hole cavity by the specific internal core, and then fixedly connecting the lock head and the steel wire, thereby avoiding the secondary drilling process of the marble hole; the seal has the advantages of accurate size of eachhole, good performance and convenient process.

Owner:黄山亿利工贸集团有限公司

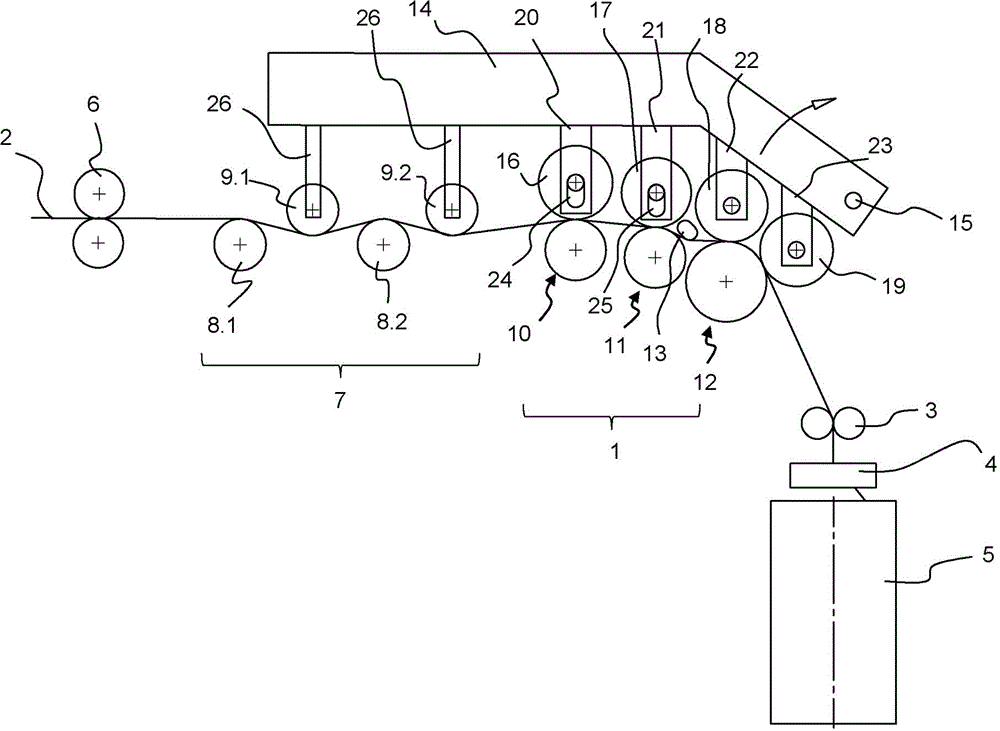

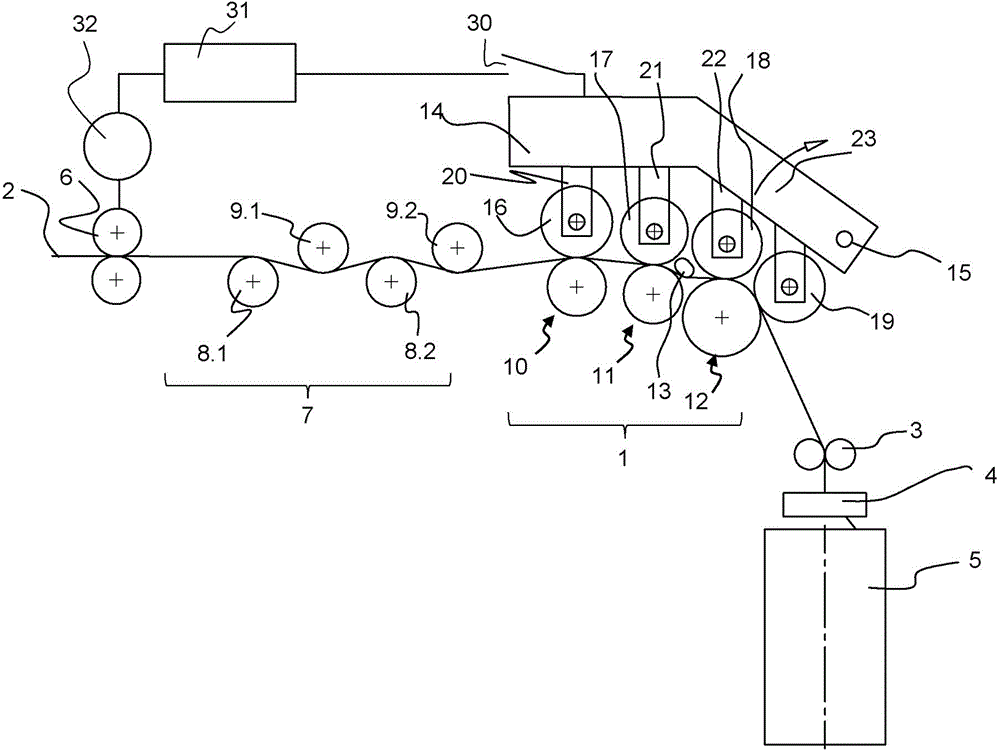

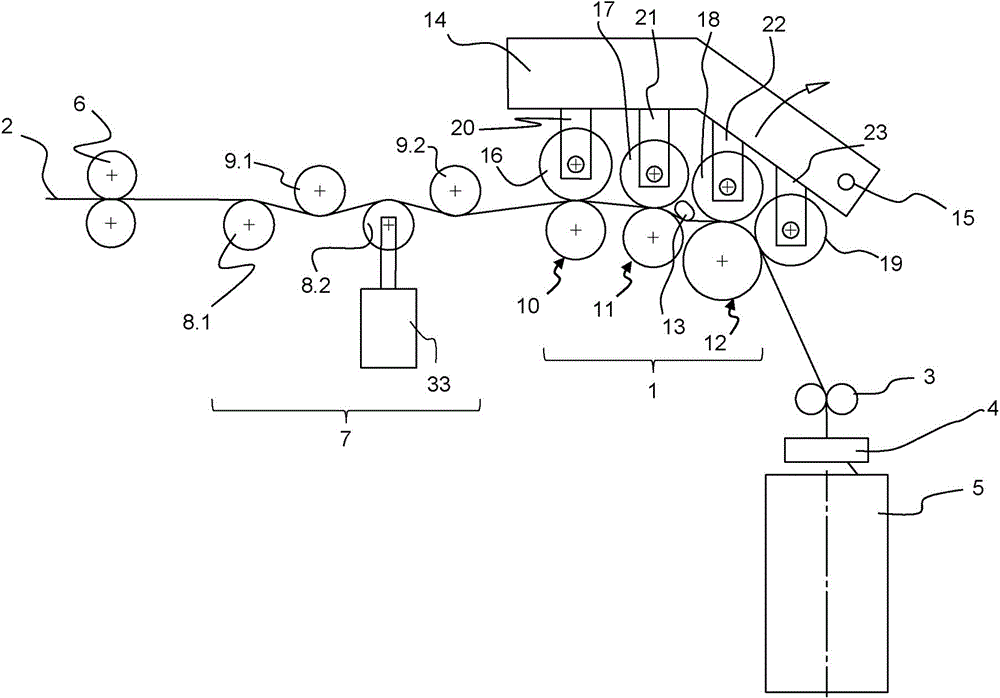

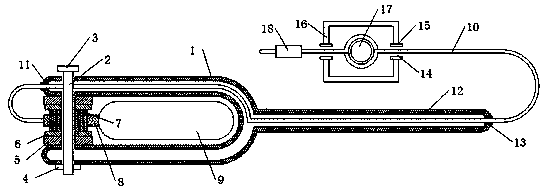

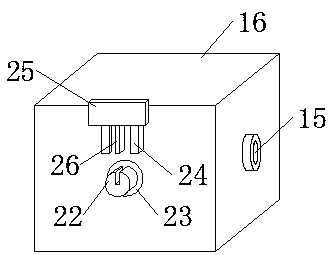

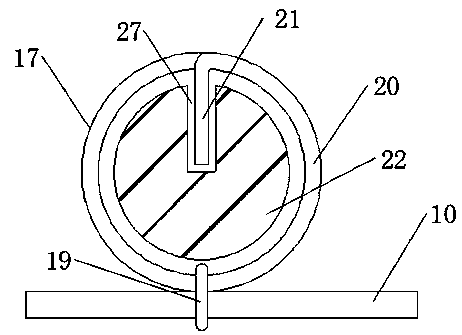

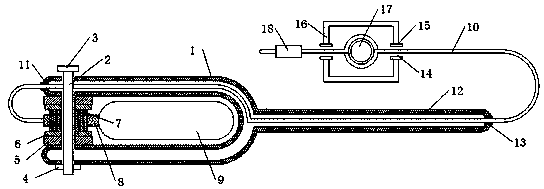

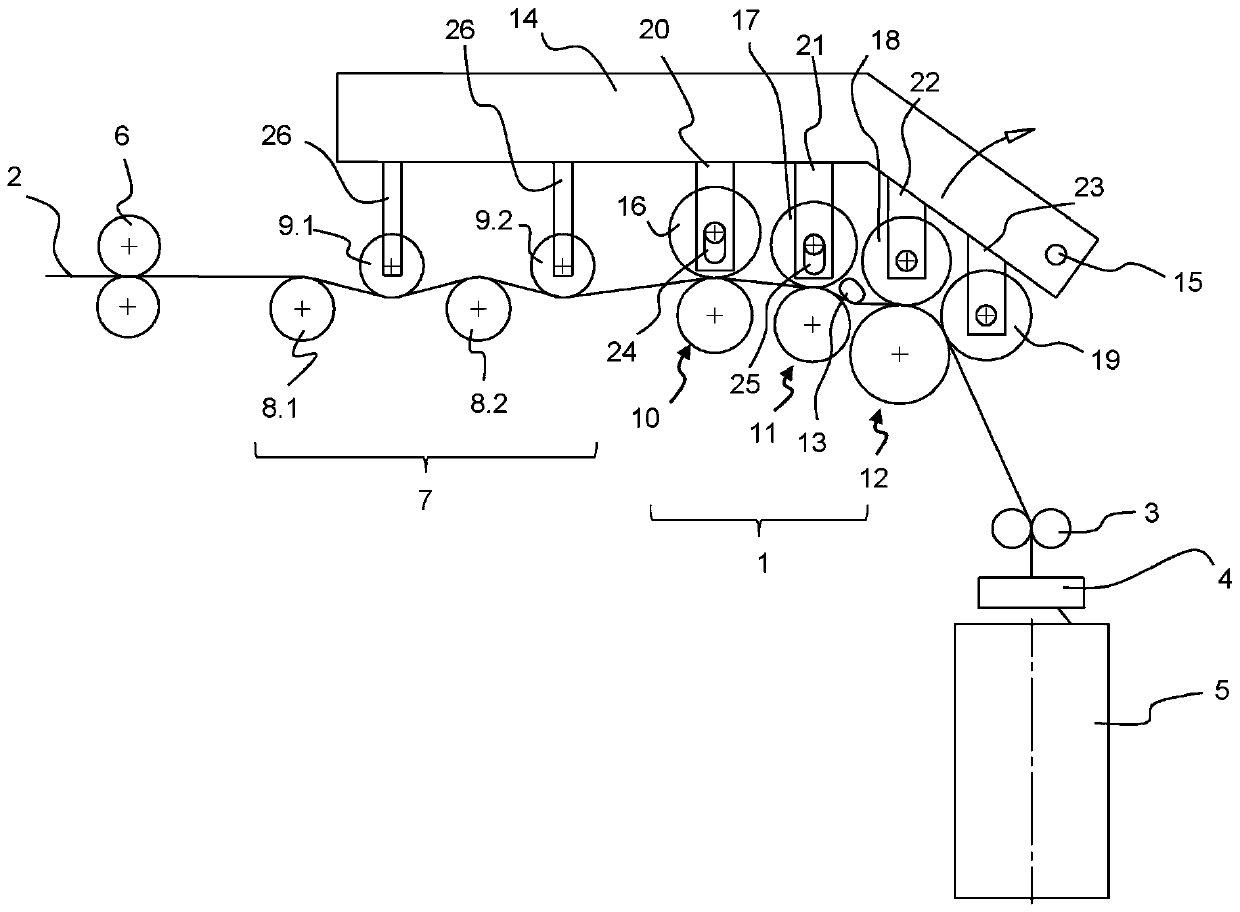

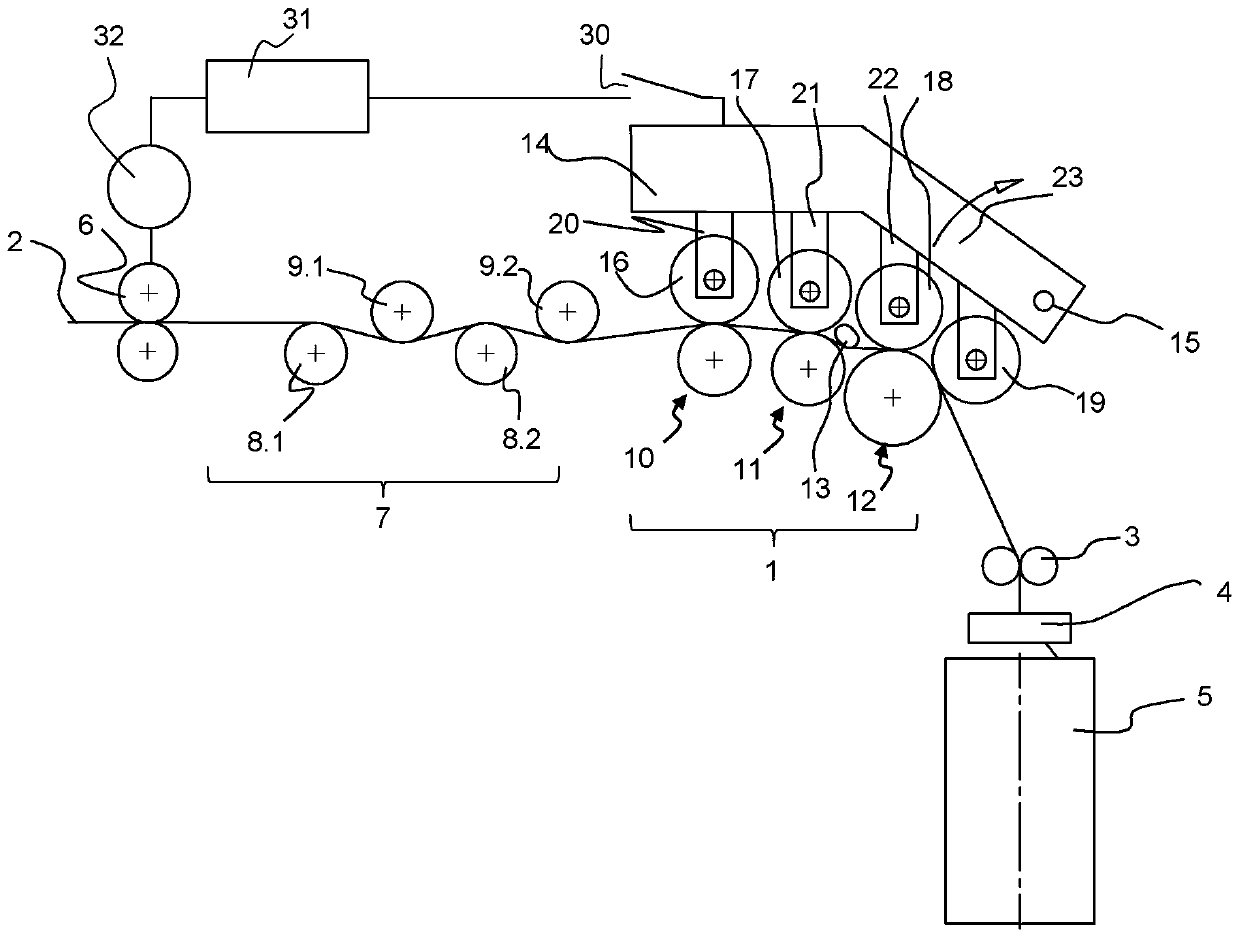

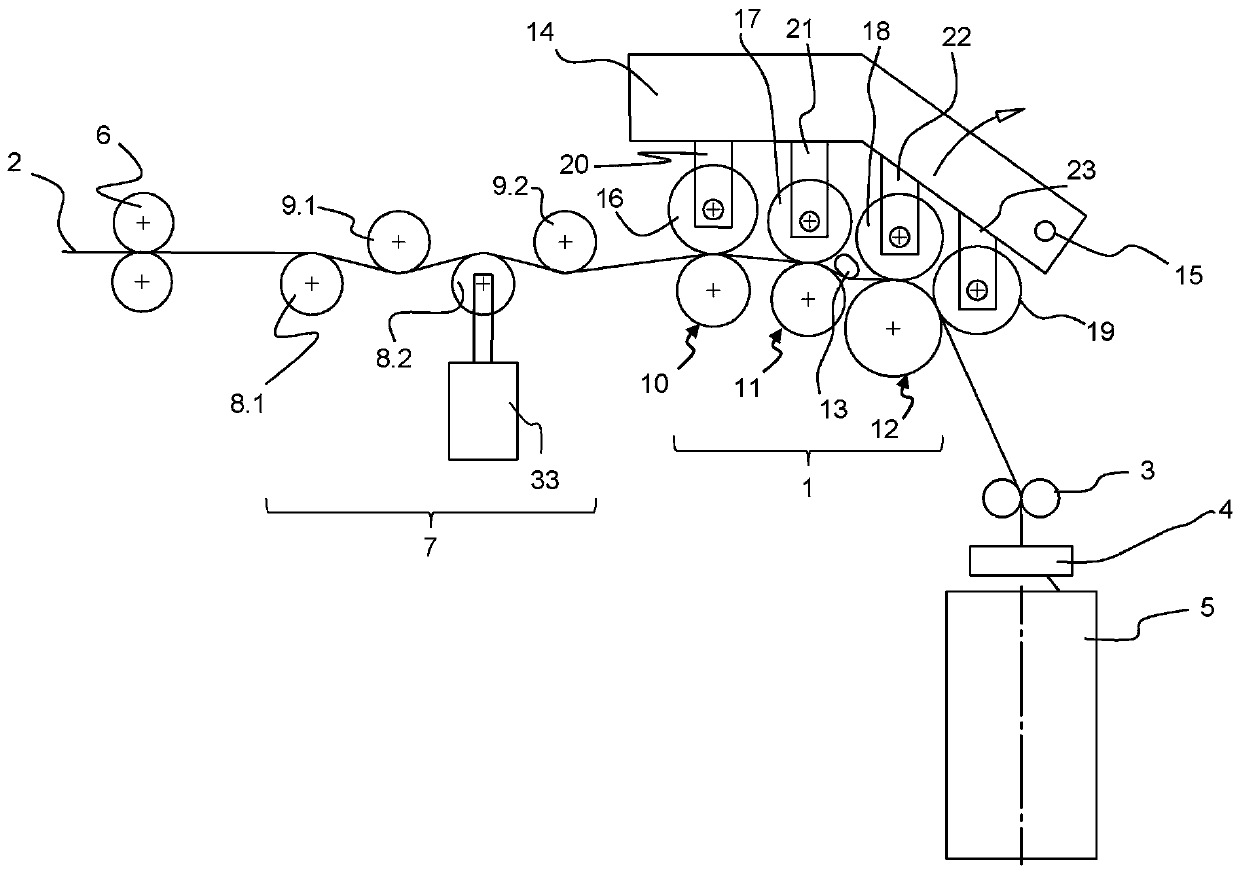

Method for opening a drafting system

In a method for opening a drafting arrangement (1) with a plurality of pairs of rollers for drawing a sliver (2), the fiber tape (2) between a pair of transport rollers (6) and an at least one input and a pair of output rollers (10, 12), a preferably input, at least one central and a pair of output rollers (10, 11, 12) comprising a drafting unit (1) taut, wherein each roller pair of the drafting unit (1) has at least one upper and one lower roll. Before opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released. In a corresponding drafting arrangement by means of a mechanical or electrical coupling or ; Control prior to the opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released.

Owner:RIETER INGOLSTADT GMBH

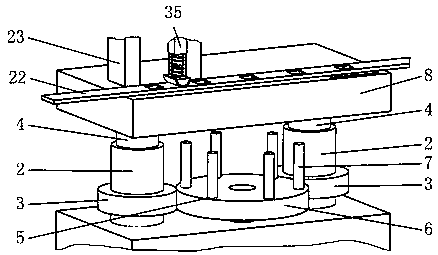

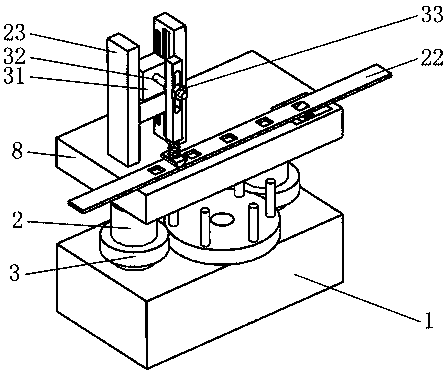

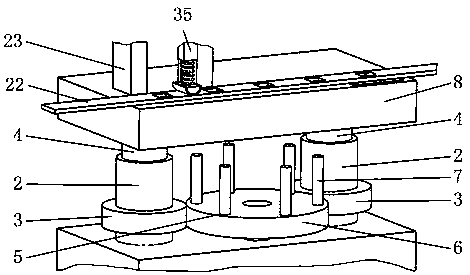

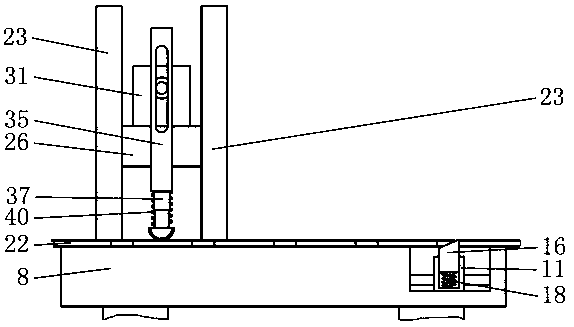

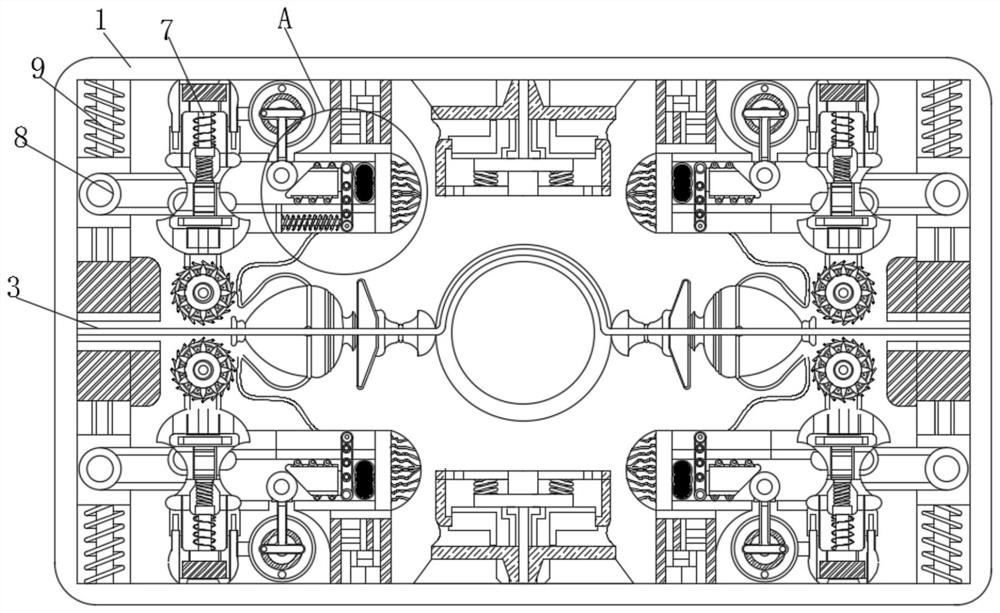

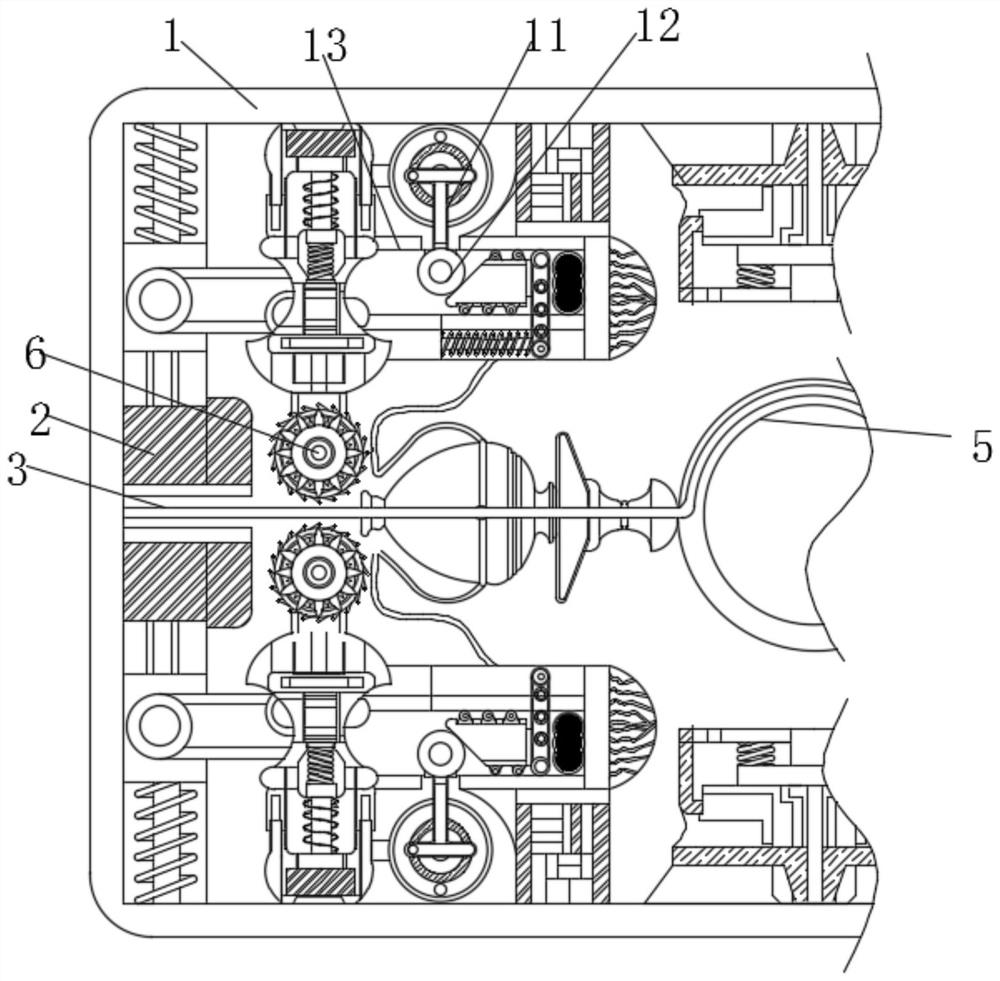

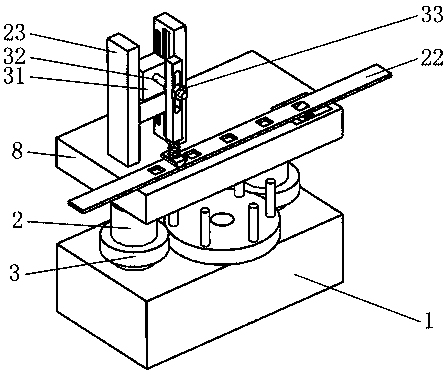

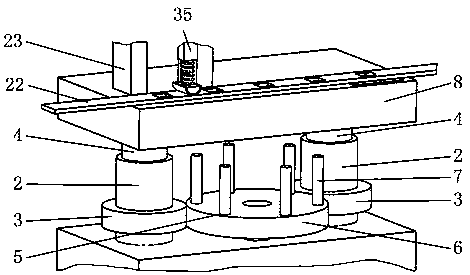

Equipment used by stamping mould

InactiveCN111570618AEffective toggle distancePass smoothlyPerforating toolsMetal-working feeding devicesStructural engineeringElectric drive

The invention belongs to the technical field of stamping moulds, and particularly relates to equipment used by a stamping mould. The equipment comprises a base, threaded sleeves, screws, a lifting plate, an electric drive module and the like, wherein the base is fixedly arranged at the discharge side of the stamping mould; and the two threaded sleeves which are matched with a bearing at the upperend of the base are separately connected to the lifting plate through the screws which are screwed up with the threaded sleeves. Height of the electric drive module can be regulated according to frequency of a stamping material strip of the stamping mould, so that an effective pulling distance, on the material strip, by a telescopic pole, a semicircular block and an arc-shaped friction cushion viaa swing plate under different stamping frequencies is guaranteed, and therefore, stamping frequency is guaranteed to be consistent with puling frequency, on the material strip, of the arc-shaped friction cushion. A limiting block which is matched with the material strip prevents the material strip from being returned under action of external force, so that effectiveness of forwards pulling the material strip through the telescopic pole, the semicircular block and the arc-shaped friction cushion via the swing plate is guaranteed.

Owner:林权豪

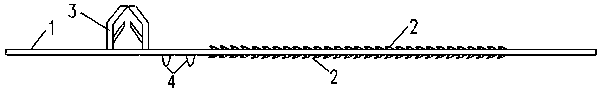

Packaging strip

A packaging strip comprises a plastic lock bar, each of the upper and lower faces of the plastic lock bar is provided with a plurality of rows of anti-pullback clamp teeth, each row includes two anti-pullback clamp teeth, one end of the plastic lock bar is provided with a lock cylinder, each of the front and rear ends of a lock hole of the lock cylinder is provided with a bolt, each bolt has a unidirectional-insertion reverse-fastening structure; a plastic lock bar receiving space is formed between the front and rows of the bolts. The plastic lock bar and the lock cylinder are formed by singleinjection molding; the production process is simplified; production capacity is improved. The lock bar and the lock cylinder are of double-side anti-pullback structure, top-bottom double safety is achieved by single locking via the lock hole, and pullback of the strip is effectively avoided; the efficient space is reserved between the two rows of the bolts in the lock cylinder, and slight packaging force can be ensured for application of the packaging strip. The packaging strip has the advantages of simple structure, good convenience of use and good durability.

Owner:山东腾鑫锁业有限公司

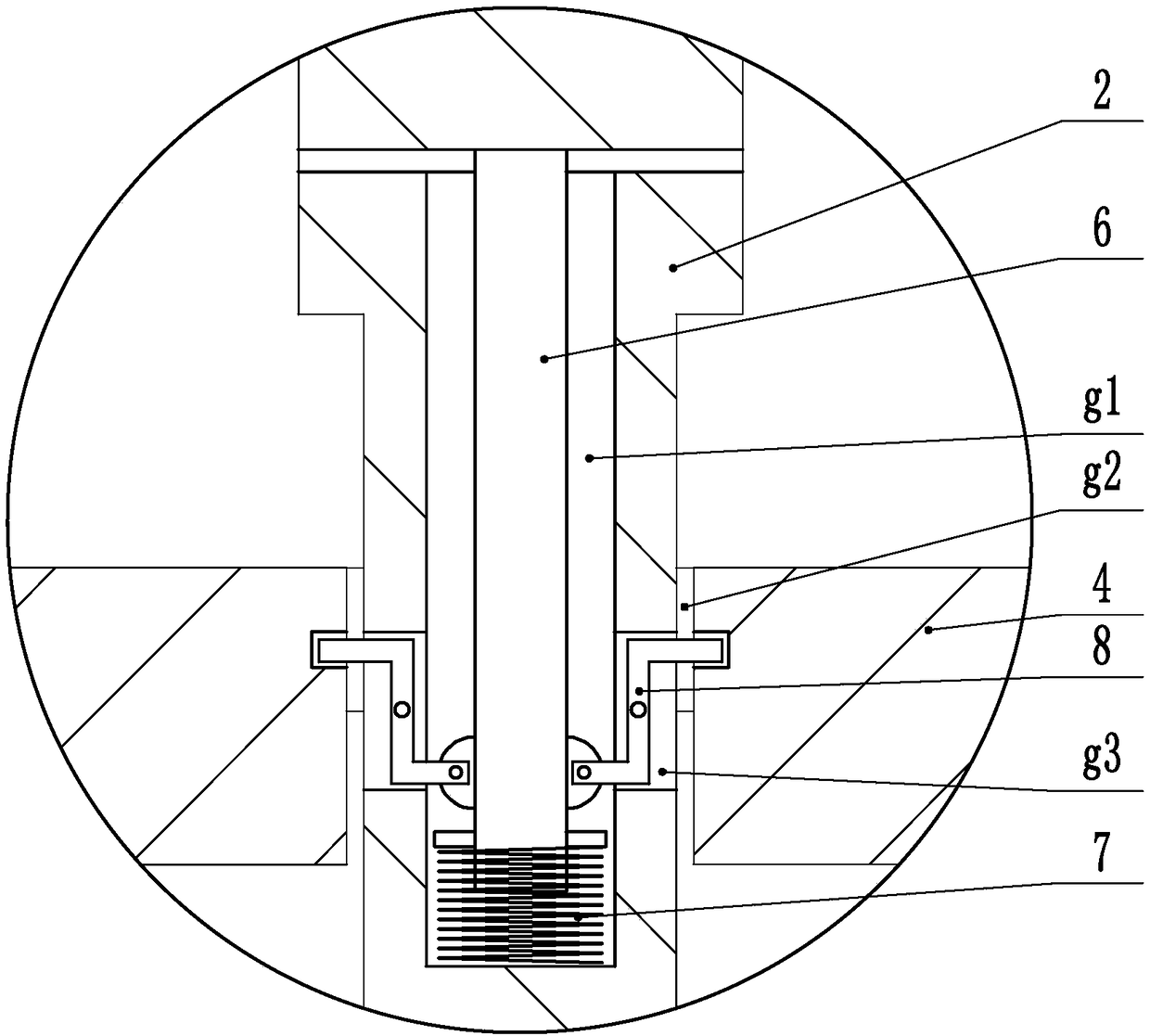

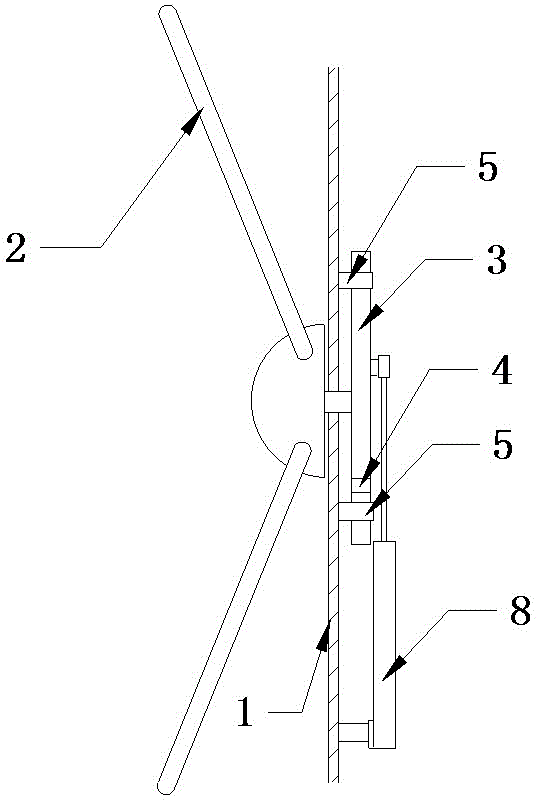

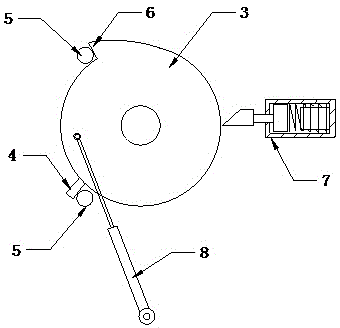

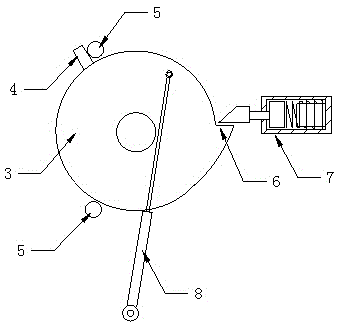

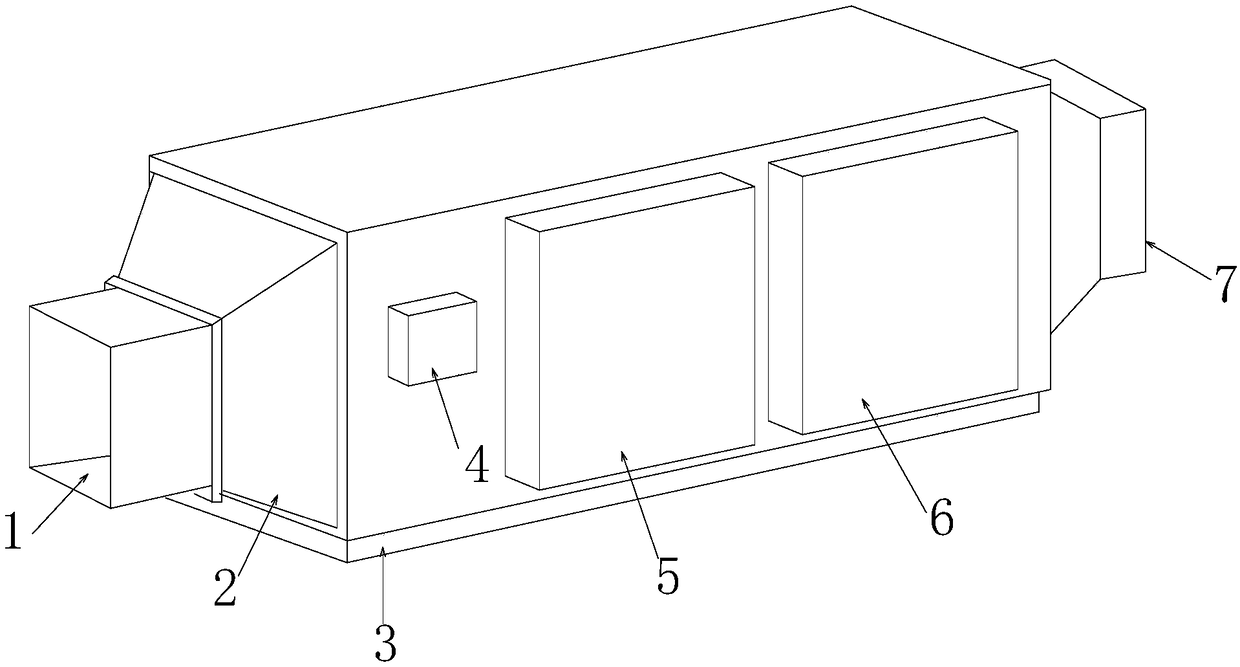

Three-rod gate machine for power supply service customer service hall

InactiveCN105678887ASolve the problem of being too close to the business personnelEliminate the risk of leaksIndividual entry/exit registersTraffic restrictionsService personnelElectromagnetic lock

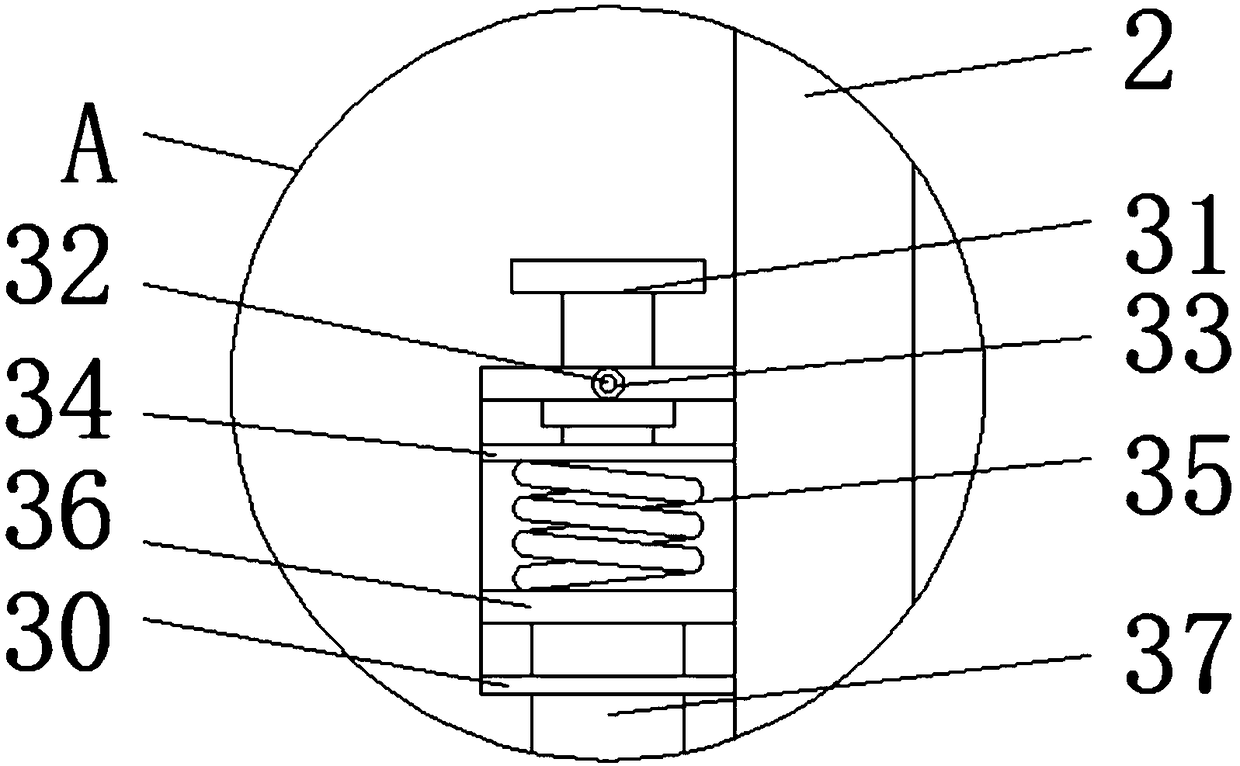

The invention discloses a three-rod gate machine for a power supply service customer service hall. The three-rod gate machine comprises a shell support (1), a three-rod rotating rod (2), a turntable (3), a limiting pin (4), limiting columns (5), an electromagnetic lock card (6), an electromagnetic lock (7), a damping spring (8) and a control circuit; the three-rod rotating rod (2) is connected with the turntable (3) inside the shell support (1), the periphery of the turntable (3) is provided with the limiting pin (4) and the electromagnetic lock card (6), the shell support (1) is provided with two limiting columns (5), the travel distance of the limiting pin (4) is limited by the two limiting columns (5), the electromagnetic lock (7) controlled by the control circuit is buckled with the electromagnetic lock card (6) so as to limit the rotation of the turntable (3), one end of the damping spring (8) is connected onto the turntable (3), and the other end of the damping spring (8) is hinged onto a fixed point. By adopting the three-rod gate machine, the problem that other persons are too close to the service personnel is solved, the confidence breach risk is eliminated, the legal rights and interests of customers are guaranteed, and the service order is regulated.

Owner:国网山东省电力公司聊城供电公司

Rotatable multi-interface charging pile for electric automobile

PendingCN110316010AAffect the service lifeFirmly connectedCharging stationsElectric vehicle charging technologyElectric wireElectric motor

The invention relates to a rotatable multi-interface charging pile for an electric automobile. The rotatable multi-interface charging pile comprises a pedestal and a connecting wire, wherein a first motor is arranged in the pedestal, and a first connecting shaft is arranged at the upper end of the first motor; a base is arranged at the upper end of the pedestal; a charging pile is fixed in the middle of the upper end of the base; supporting rods are inlaid on two sides of the upper end of the pedestal; and a solar panel is connected to the upper ends of the supporting rods. The rotatable multi-interface charging pile has the beneficial effects that the base can rotate on the pedestal by utilizing the first connecting shaft in order to drive the charging pile and a charging box to rotate, so that the orientation of a charging panel can be changed, the angle of the charging panel can be rotated by 360 degrees, a charging head can be conveniently connected to the electric automobile, a situation that the charging head cannot be directly connected to the electric automobile due to the parking position of the electric automobile is avoided, or a situation that a charging port part is bent when the charging head is charged in order to affect the service life of the charging head is avoided.

Owner:谢明仿

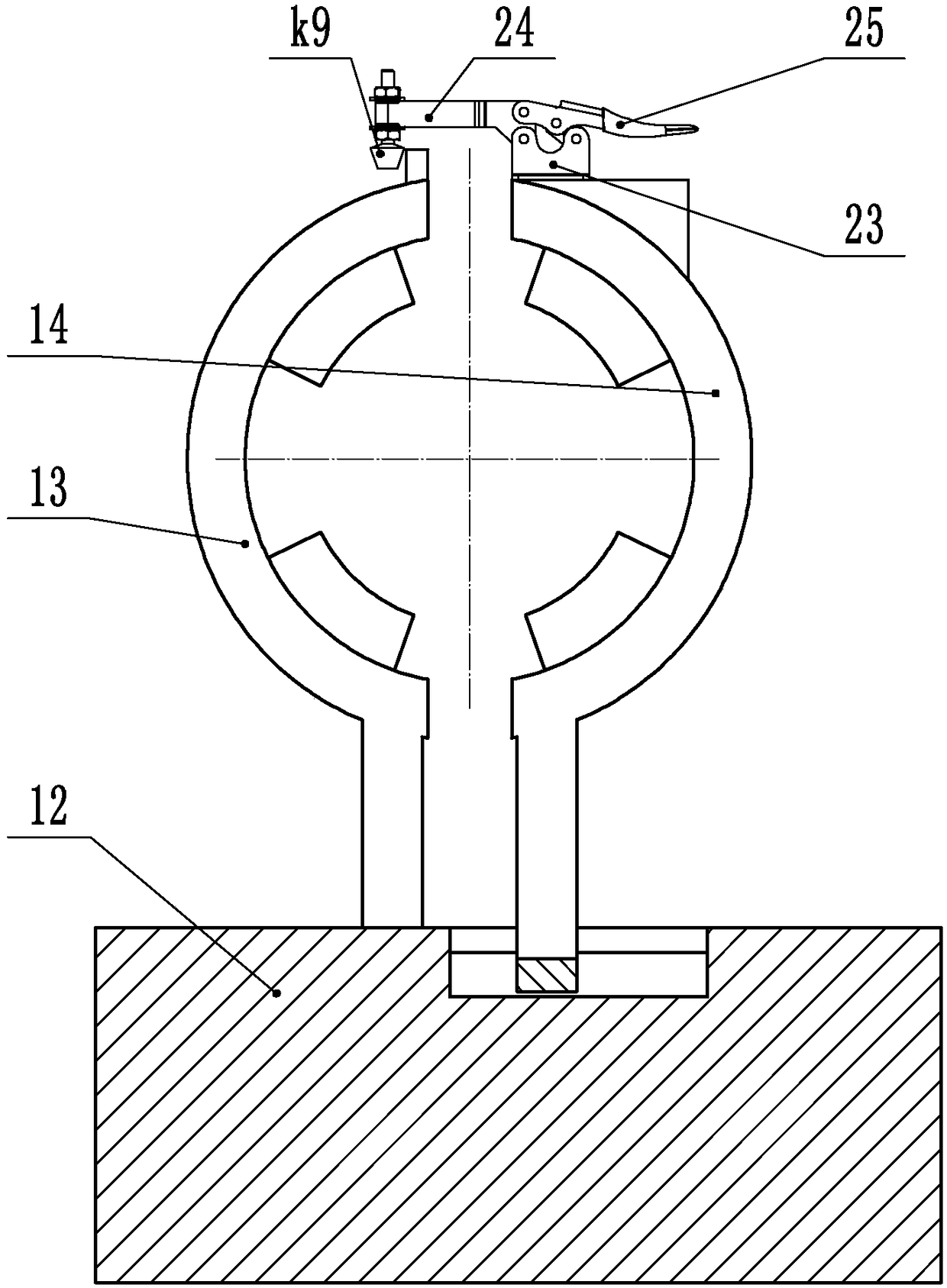

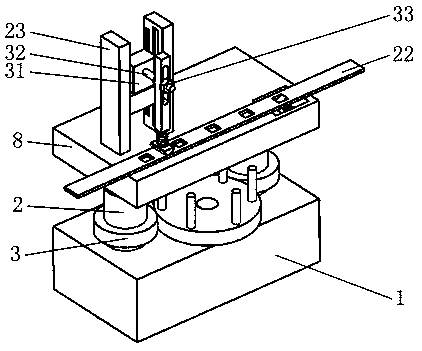

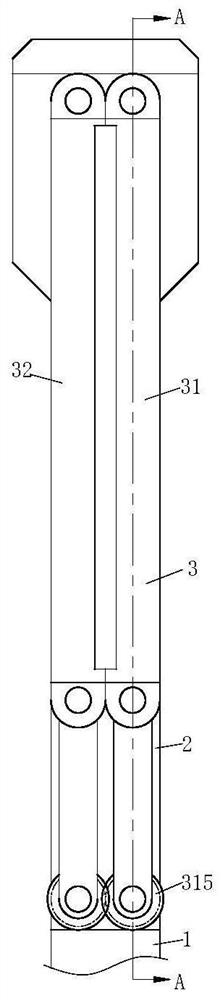

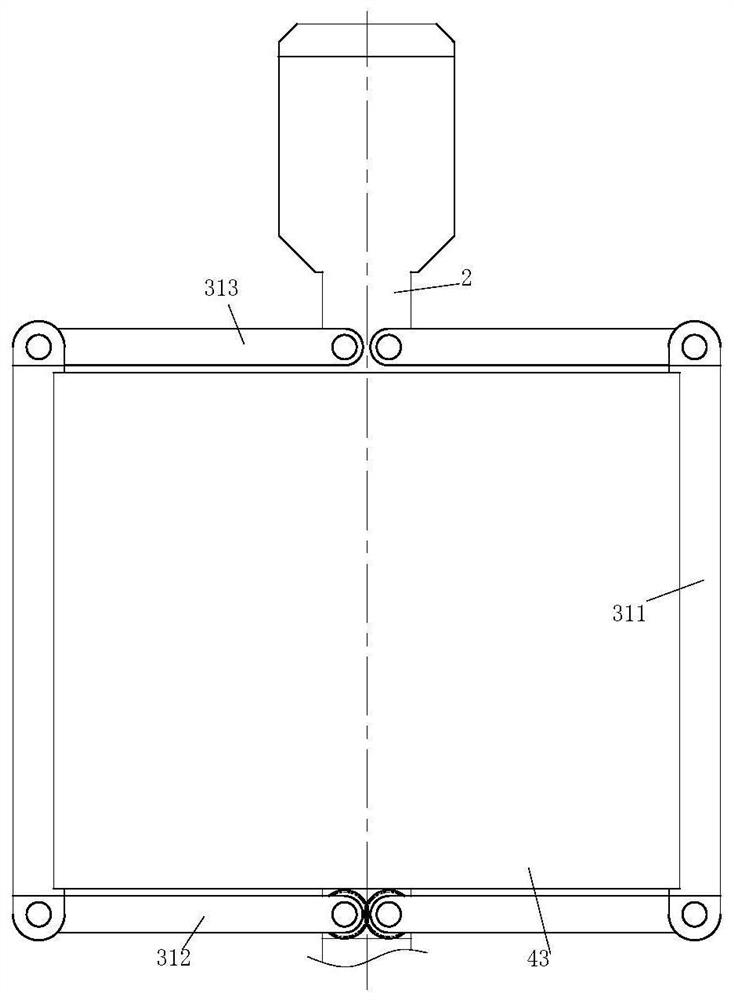

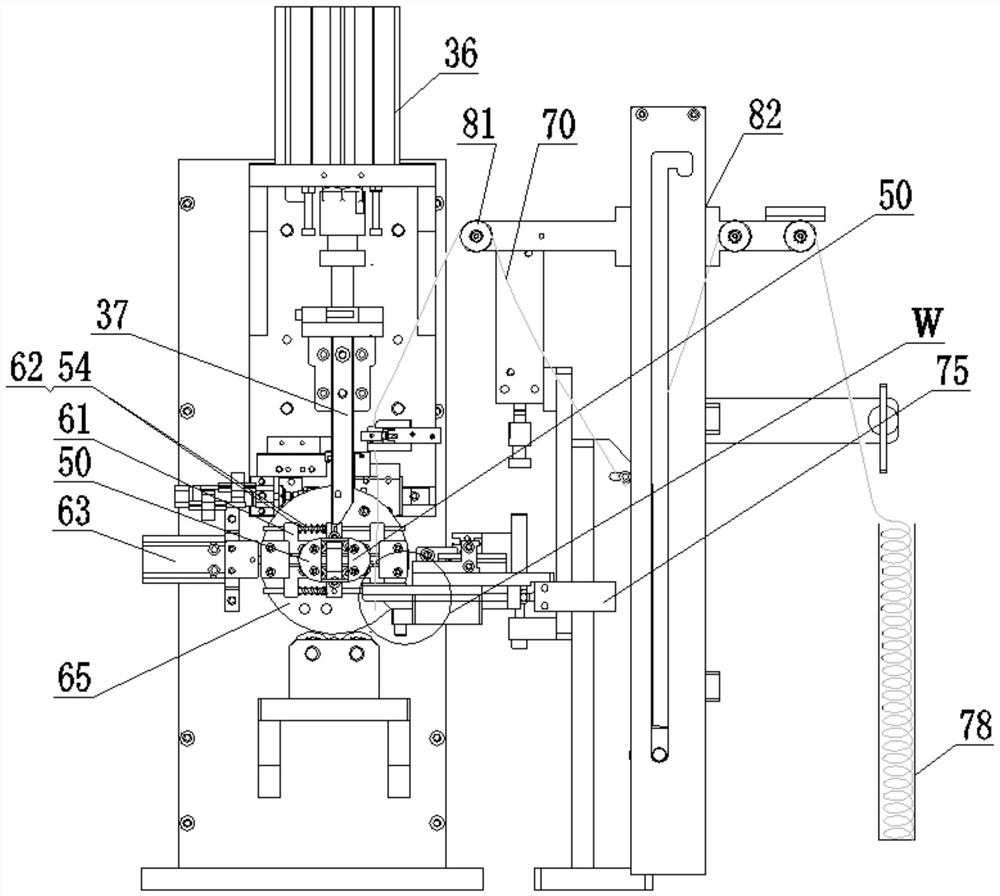

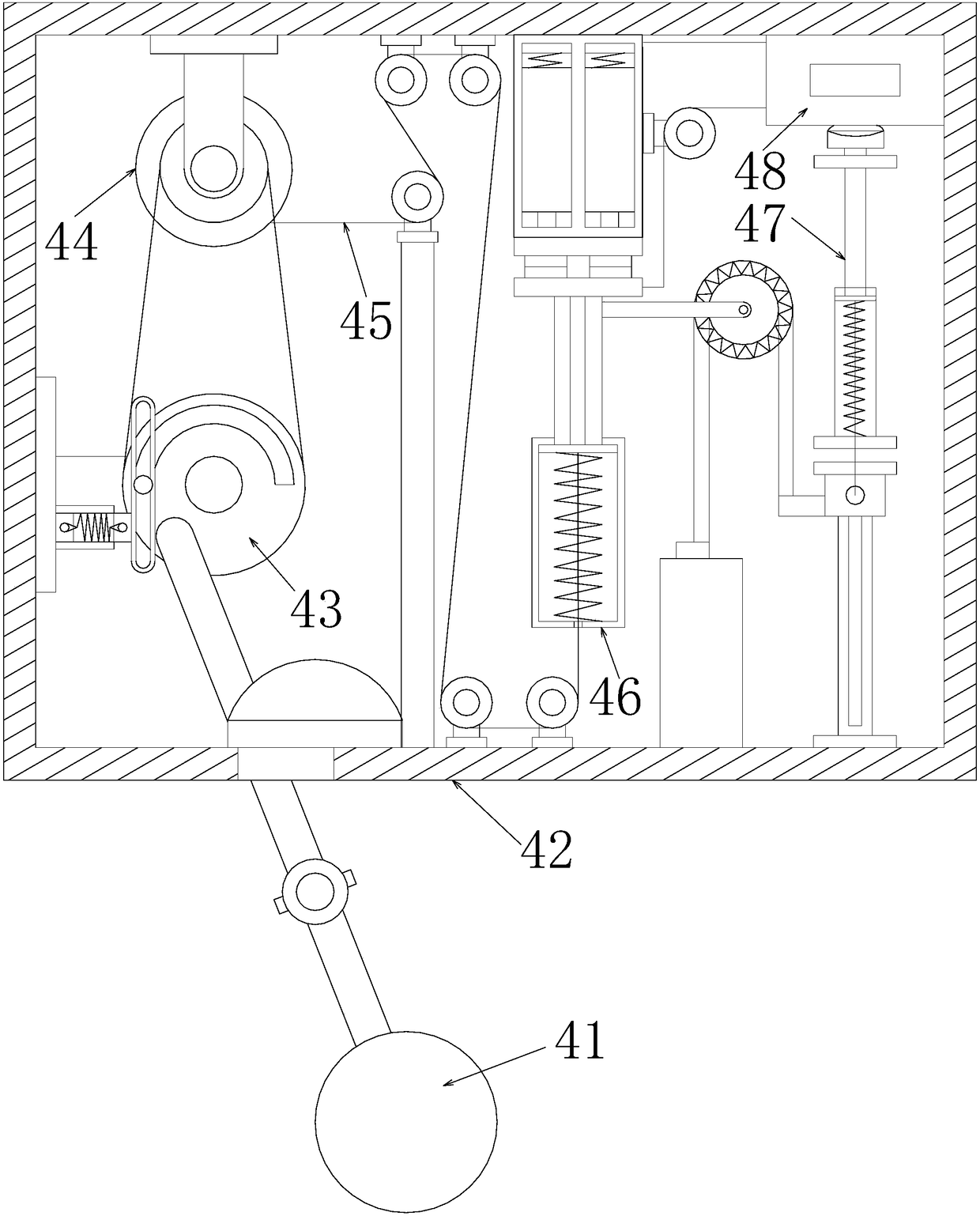

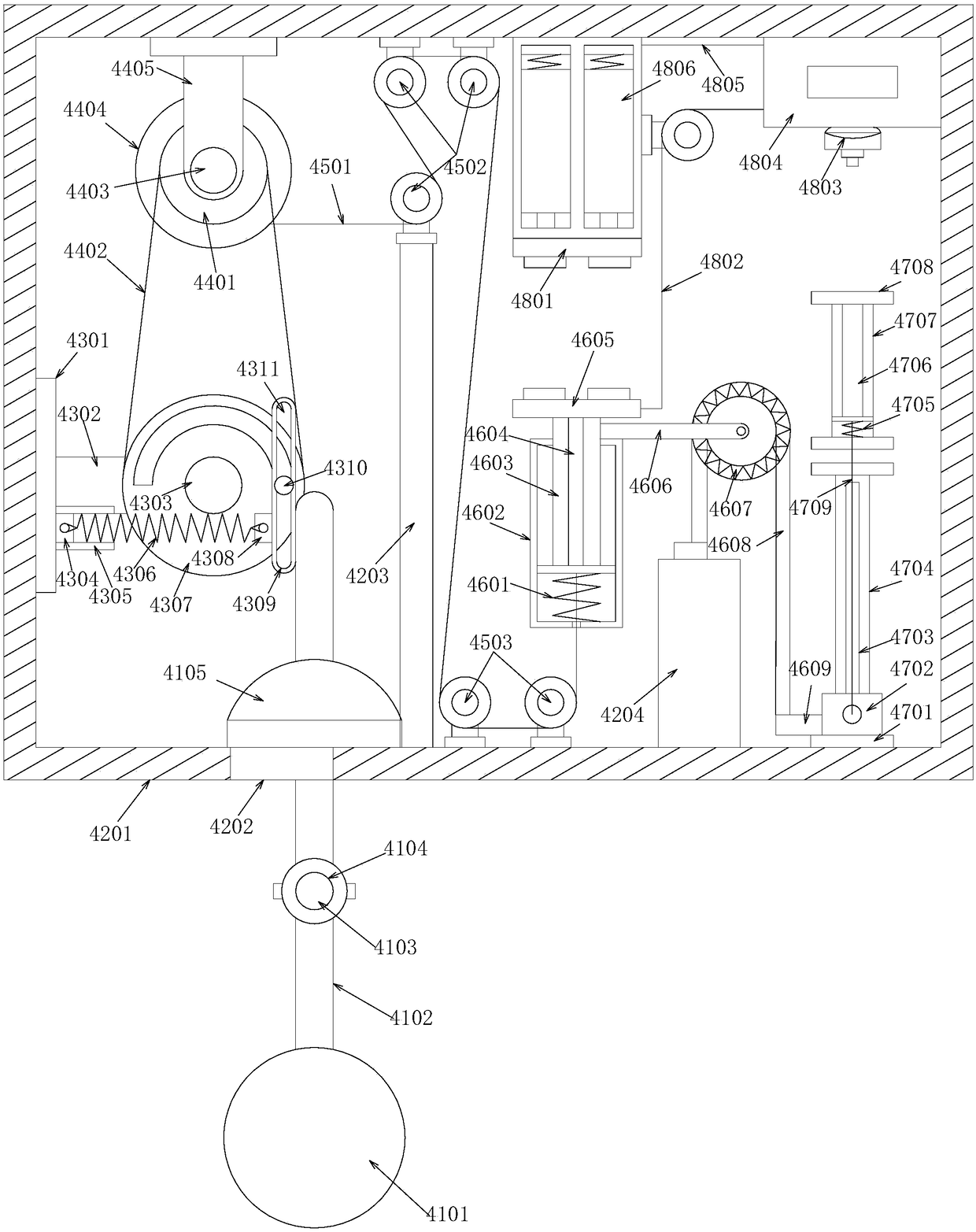

Device for stamping die

ActiveCN110026483AEffective toggle distancePass smoothlyShaping toolsPerforating toolsElectricityElectric drive

The invention belongs to the technical field of a stamping die, and in particular relates to a device for the stamping die. The device for the stamping die comprises a base, thread sleeves, threaded rods, a lifting plate, an electric driving module, etc., wherein the base is fixedly arranged on the discharging side of the stamping die, and the two thread sleeves matched with a bearing at the upperend of the base are connected with the lifting plate respectively through the threaded rods screwed with the two thread sleeves. According to the device for the stamping die, the height of the electric driving module can be adjusted according to the frequency of stamping a material strap of the stamping die, and the effective stirring distance of a swing plate to the material strap through a telescopic rod, a semicircular block and an arc-shaped friction pad under different stamping frequencies is ensured; and further, the fact that the stamping frequency is consistent with the stirring frequency of the arc-shaped friction pad to the material strap is ensured. A limiting block matched with the material strap prevents the material strap from being pulled back under external force, and theeffectiveness of stirring the material strap forward of the swing plate through the telescopic rod, the semicircular block and the arc-shaped friction pad is ensured.

Owner:杭州银湖机械弹簧有限公司

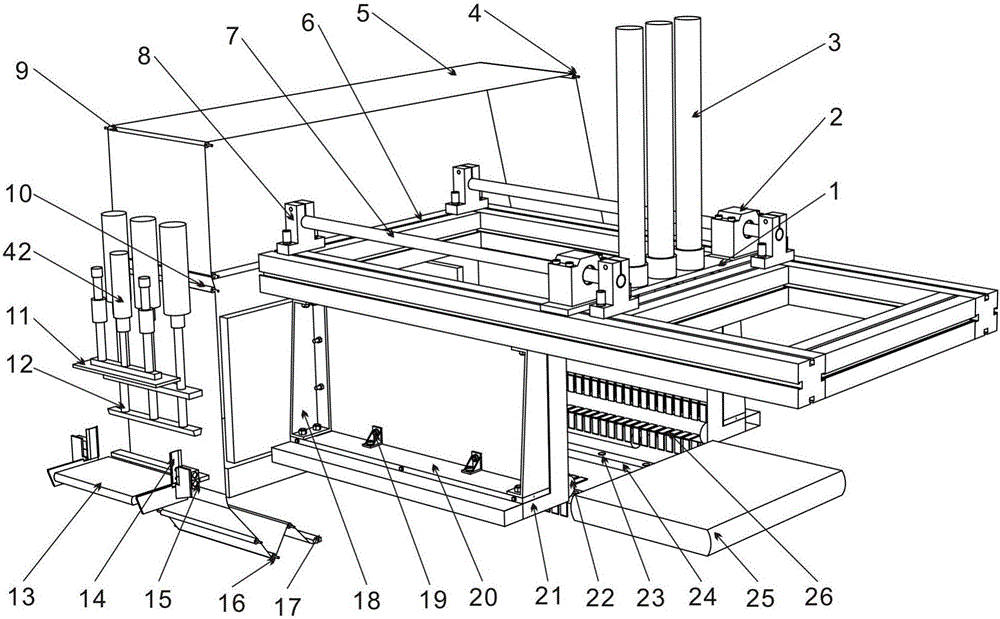

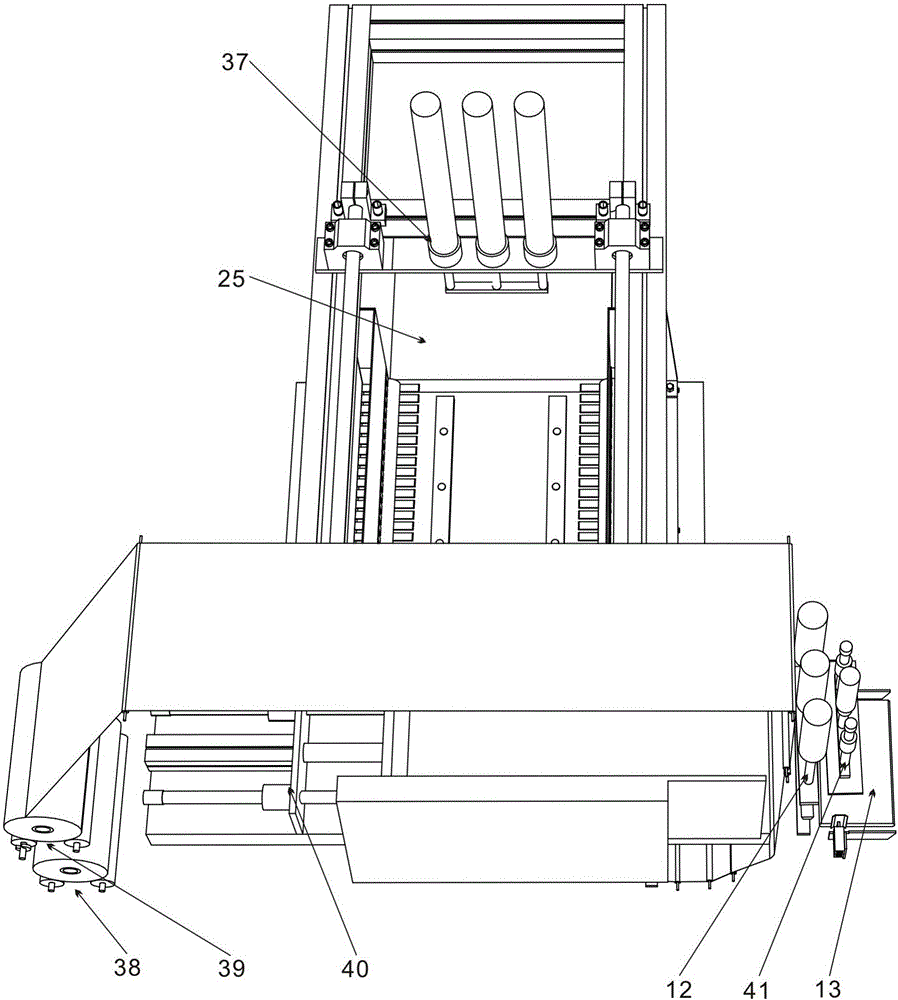

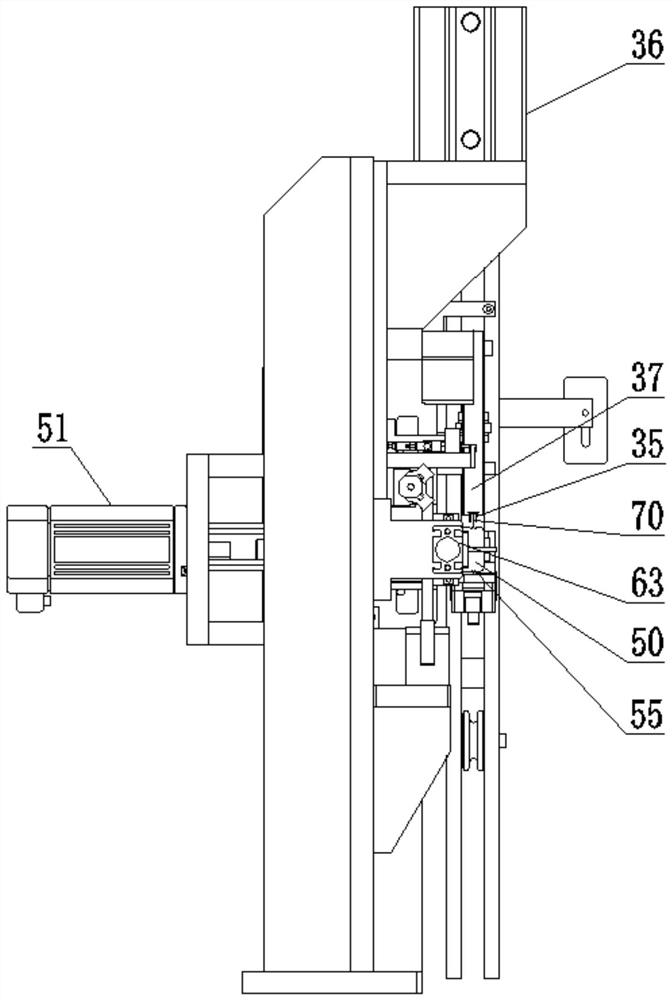

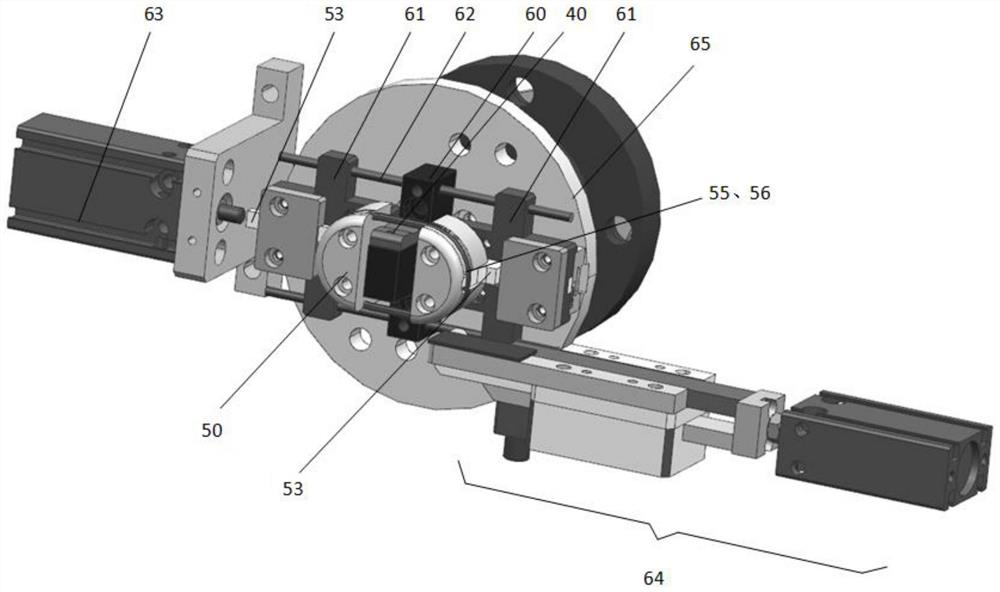

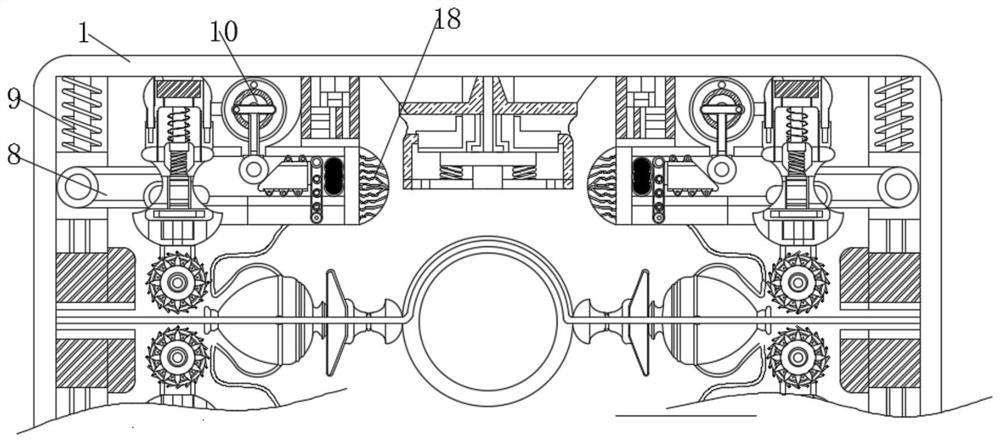

Cigarette sorting plastic packaging machine capable of increasing cigarette sorting first pass yield

ActiveCN106347757AAvoid mistakesPrevent pullbackWrapping material feeding apparatusPackaging automatic controlPlastic packagingFirst pass yield

The invention discloses a cigarette sorting plastic packaging machine capable of increasing the cigarette sorting first pass yield. The cigarette sorting plastic packaging machine comprises an input belt used for inputting scattered cigarettes, a sorting mechanism used for sorting the scattered cigarettes, a transfer mechanism used for receiving the sorted cigarettes and transferring the sorted cigarettes out, an output belt used for receiving the transferred cigarettes and output the cigarettes after plastic packaging is conducted, a clamping mechanism used for clamping cigarette which are not subjected to plastic packaging on the output belt, a plastic packaging mechanism used for conducting plastic packaging on the clamped cigarettes on the output belt and an active film supplying mechanism used for containing a film roll and actively outputting plastic packaging film when the clamped cigarette are subjected to plastic packaging. By means of the sorting mechanism, the situation that the cigarettes go wrong in the sorting process can be avoided, the active film supplying mechanism actively outputs the plastic packaging film to prevent the plastic packaging film from pulling back, and an upper pressing plate and two side pressing plates clamp the cigarettes to prevent the cigarettes from moving so as to avoid the condition that the plastic packaging mechanism crushes the cigarettes.

Owner:CHENGDU BRANCH OF SICHUAN TOBACCO CO

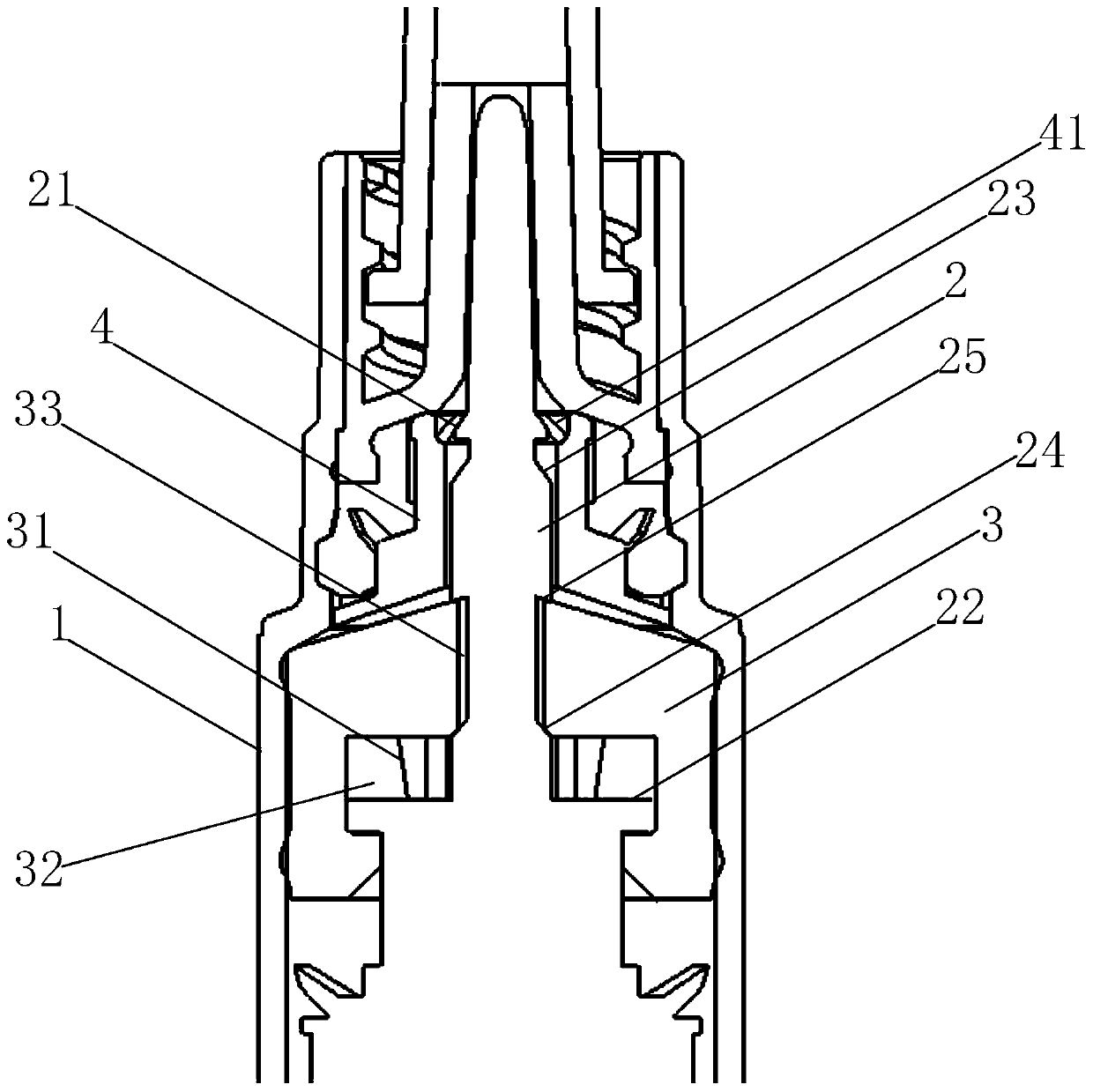

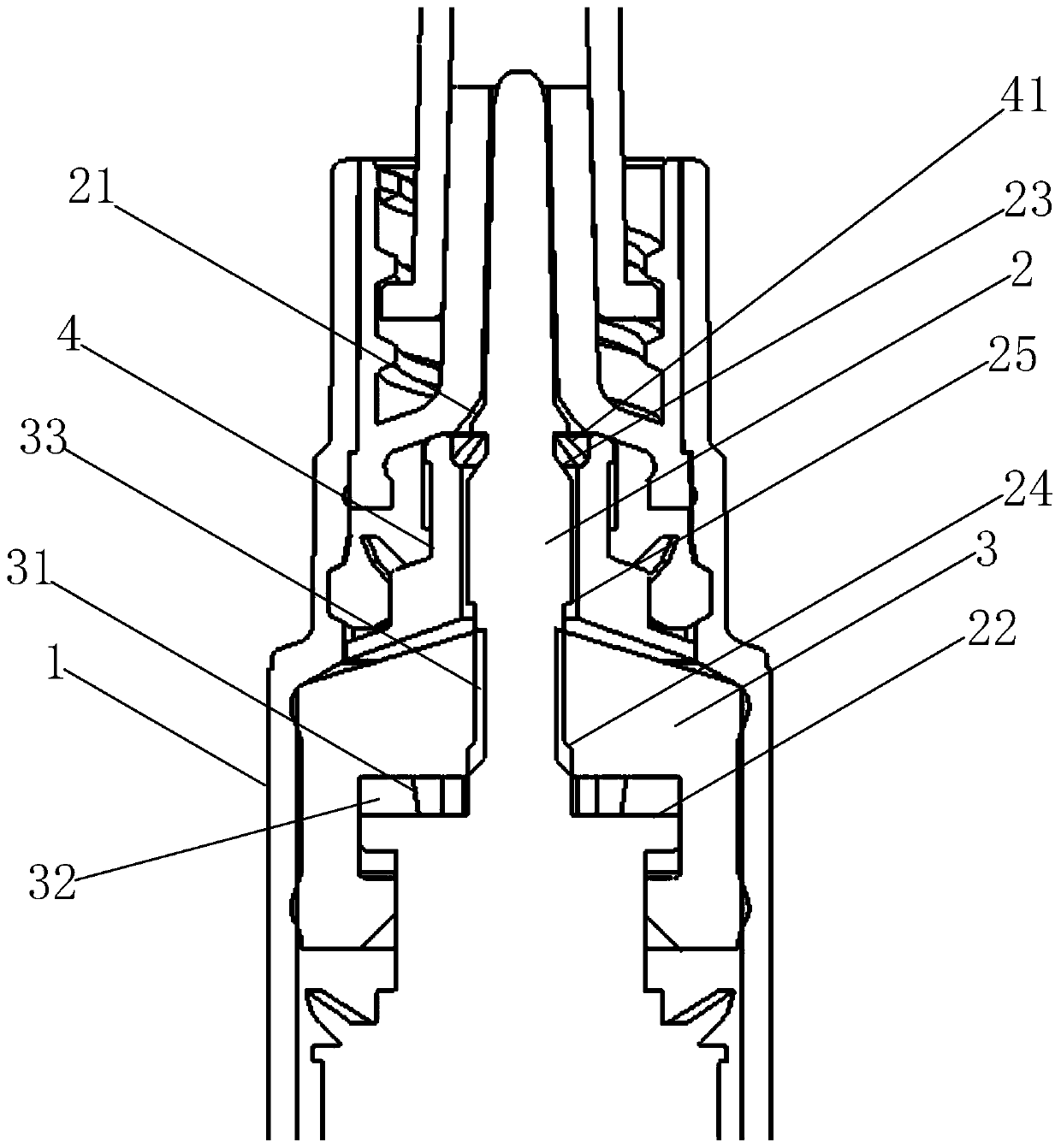

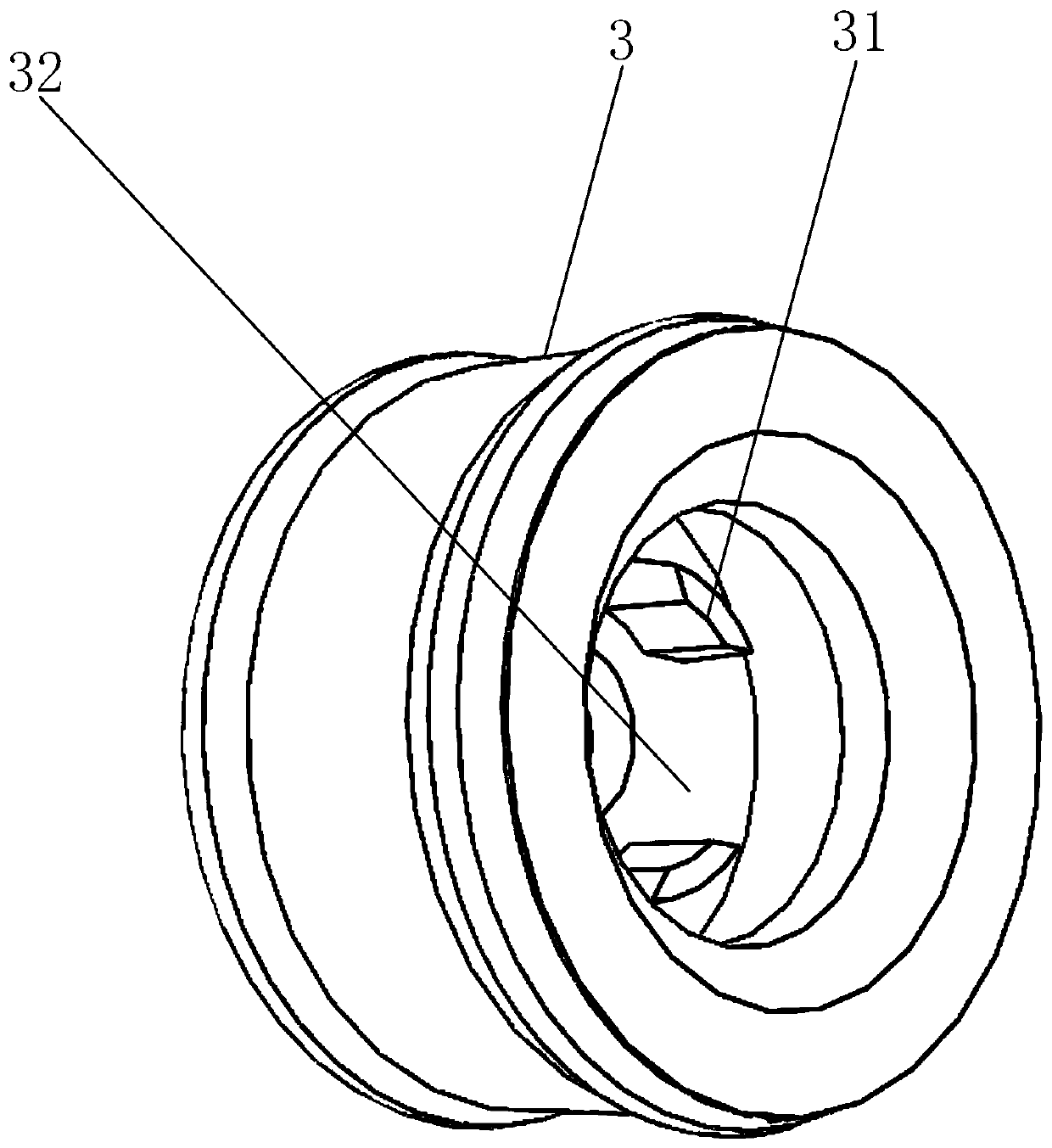

Pull-back self-locking syringe

The invention relates to the technical field of medical instruments, and in particular to a pull-back self-locking syringe. The syringe comprising a syringe body and a core rod movably disposed in thesyringe body. The syringe body is provided with a self-locking structure; the core rod is provided with a first frustum matched with the self-locking structure; the piston sleeves the core rod; the piston is internally provided with an elastic member; the core rod moves forward so that the first frustum crosses the self-locking structure, and the elastic member is compressed and drives the core rod to pull back; and the rear end surface of the first frustum abuts the self-locking structure. The pull-back self-locking syringe of the present invention comprises the self-locking structure disposed on the syringe body and the first frustum disposed on the core rod and matched with the self-locking structure. In the process of pushing the core rod forward, the first frustum passes over the self-locking structure, a first boss presses the elastic member on the piston, and the elastic member always pulls back the core rod, so that the rear end face of the first frustum always abuts the self-locking structure to achieve self-locking and prevent the syringe from being reused.

Owner:珠海德瑞医疗器械有限公司

A Multifunctional Outdoor News Gathering Device

ActiveCN108683964BReduce frictionEasy to storeMouthpiece/microphone attachmentsEngineeringMechanical engineering

The invention discloses a multifunctional outdoor news gathering apparatus, and the apparatus comprises a U-shaped frame, wherein the interior of the U-shaped frame is of a hollow structure, and two ends of the U-shaped frame are in plugging connection with an adjustment bolt. Moreover, one end of the adjustment bolt is connected with a rotating handle, and the opposite end of the adjustment boltis in spiral connection with a nut. According to the invention, the rotating handle is enabled to rotate by a certain length so as to reduce the frictional force between a first abrasive disk and a second abrasive disk, and then a microphone is enabled to rotate around the adjustment bolt which is taken as the center till the angle between the microphone and the U-shaped frame is suitable for a journalist to carry out the interviewing, and finally the rotating handle is enabled to rotate to adjust the adjustment bolt till the frictional force between the first abrasive disk and the second abrasive disk is sufficient for supporting the microphone. The above structure brings convenience to a user for storing the microphone, and the U-shaped frame is used for protecting the microphone to a certain degree. Moreover, the adjustment bolt can enlarge the movement range during interviewing while the microphone rotates.

Owner:浙江兴舟纸业有限公司

Multifunctional outdoor news gathering apparatus

ActiveCN108683964AReduce frictionEasy to storeMouthpiece/microphone attachmentsEngineeringMechanical engineering

The invention discloses a multifunctional outdoor news gathering apparatus, and the apparatus comprises a U-shaped frame, wherein the interior of the U-shaped frame is of a hollow structure, and two ends of the U-shaped frame are in plugging connection with an adjustment bolt. Moreover, one end of the adjustment bolt is connected with a rotating handle, and the opposite end of the adjustment boltis in spiral connection with a nut. According to the invention, the rotating handle is enabled to rotate by a certain length so as to reduce the frictional force between a first abrasive disk and a second abrasive disk, and then a microphone is enabled to rotate around the adjustment bolt which is taken as the center till the angle between the microphone and the U-shaped frame is suitable for a journalist to carry out the interviewing, and finally the rotating handle is enabled to rotate to adjust the adjustment bolt till the frictional force between the first abrasive disk and the second abrasive disk is sufficient for supporting the microphone. The above structure brings convenience to a user for storing the microphone, and the U-shaped frame is used for protecting the microphone to a certain degree. Moreover, the adjustment bolt can enlarge the movement range during interviewing while the microphone rotates.

Owner:浙江兴舟纸业有限公司

Energy-saving and environment-friendly road lamp

PendingCN114087565AAchieve cleanupEasy to installMechanical apparatusLighting support devicesEngineeringMechanical engineering

The invention relates to the technical field of road lighting, in particular to an energy-saving and environment-friendly road lamp, which comprises a vertical lamp pole and an arc-shaped lamp pole, wherein one end of the vertical lamp pole and one end of the arc-shaped lamp pole are welded together, the vertical lamp pole and the arc-shaped lamp pole form an inverted L shape, an opening mechanism is hinged to the back surface of the arc-shaped lamp pole, cleaning sponge is fixed to the back surface of the arc-shaped lamp pole, a handle is rotationally connected to the end, close to the vertical lamp pole, of the arc-shaped lamp pole, the opening mechanism can be opened or closed by rotating the handle, and a bulb is fixed to the other end of the arc-shaped lamp pole. According to the invention, when people play in a park and need to shelter from rain or sun, the opening mechanism is opened by rotating the handle, and the shielding area of the road lamp is increased through the opening mechanism, so that the effect of sheltering from rain or sun is achieved, and the practicability of the road lamp is improved.

Owner:叶亚华

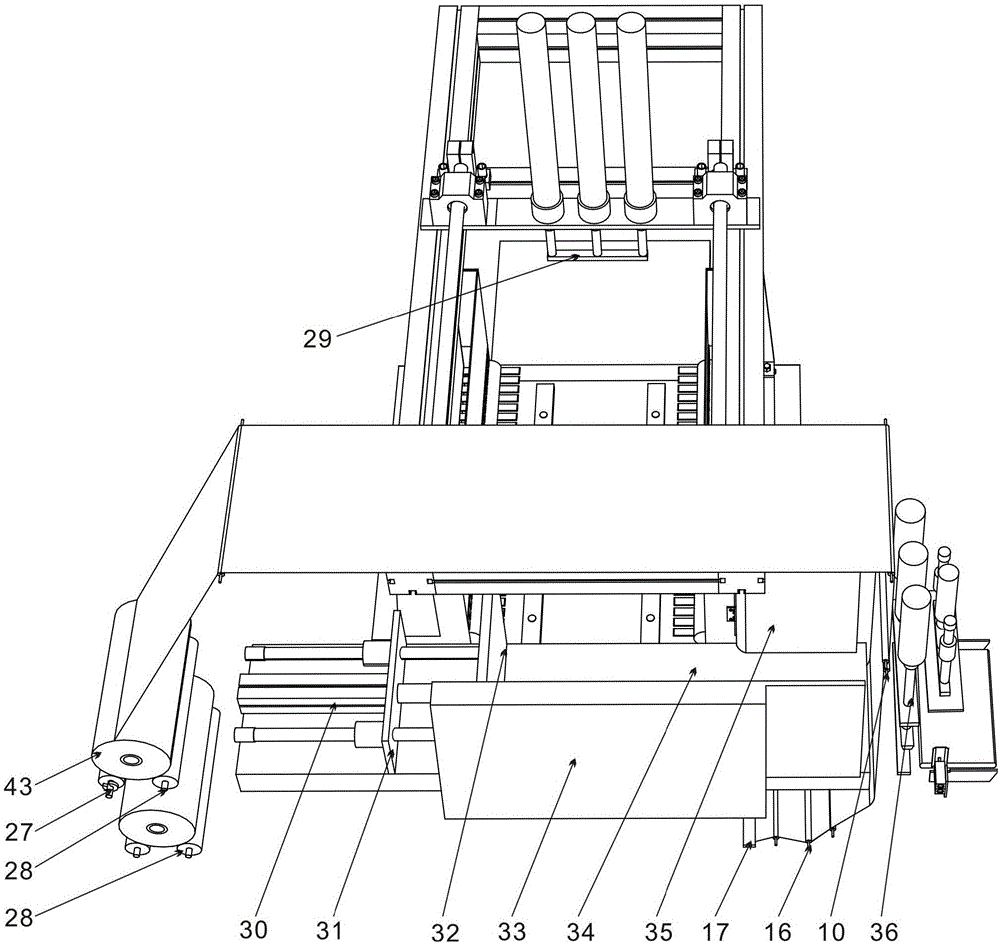

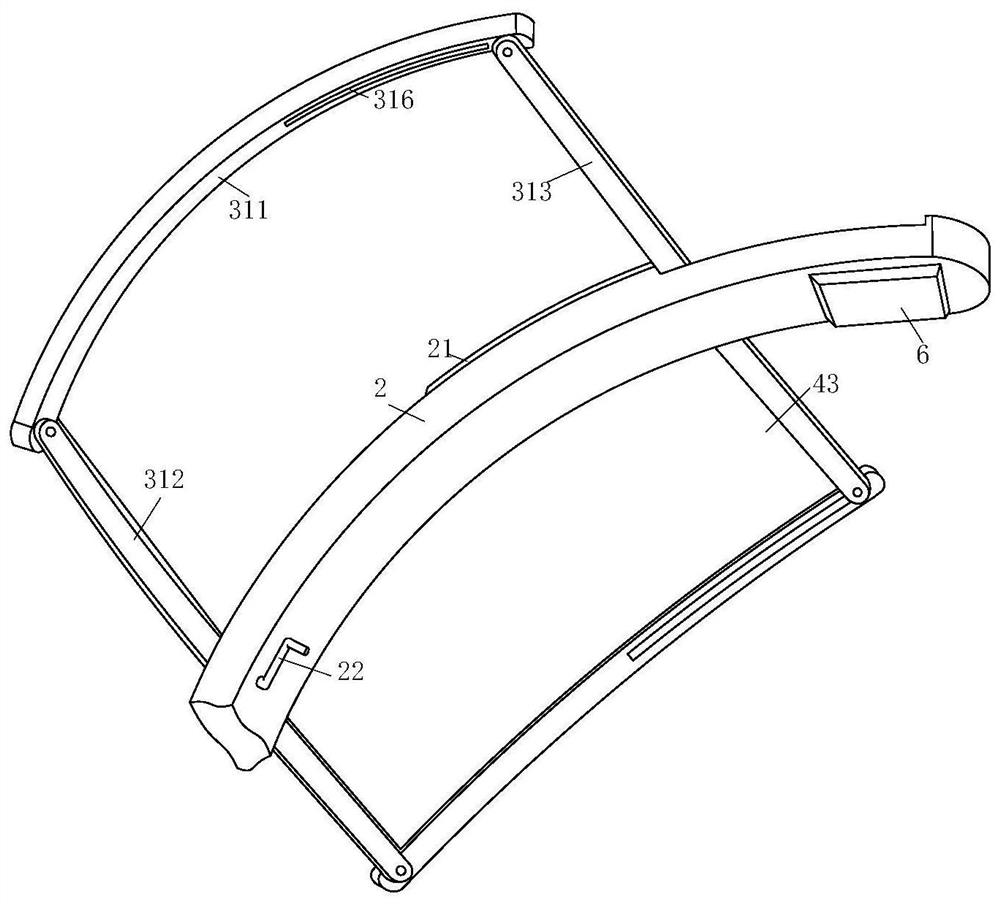

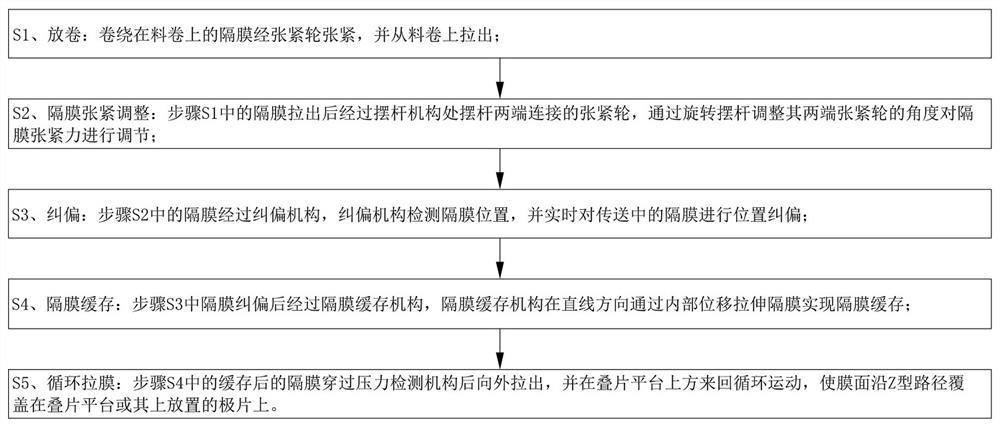

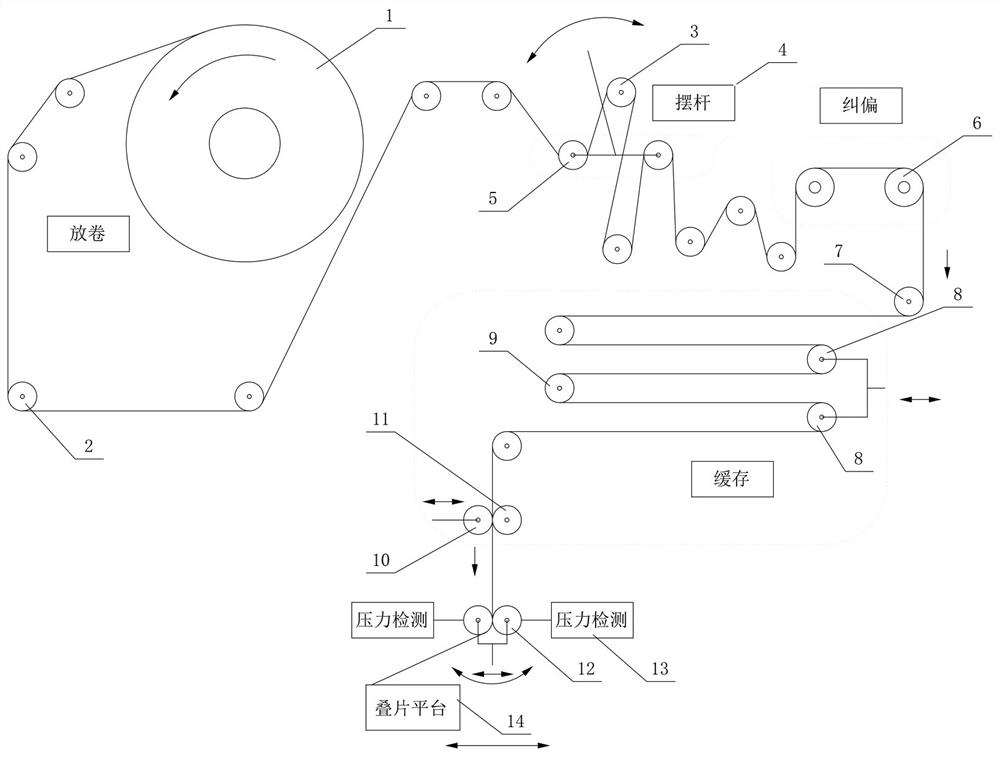

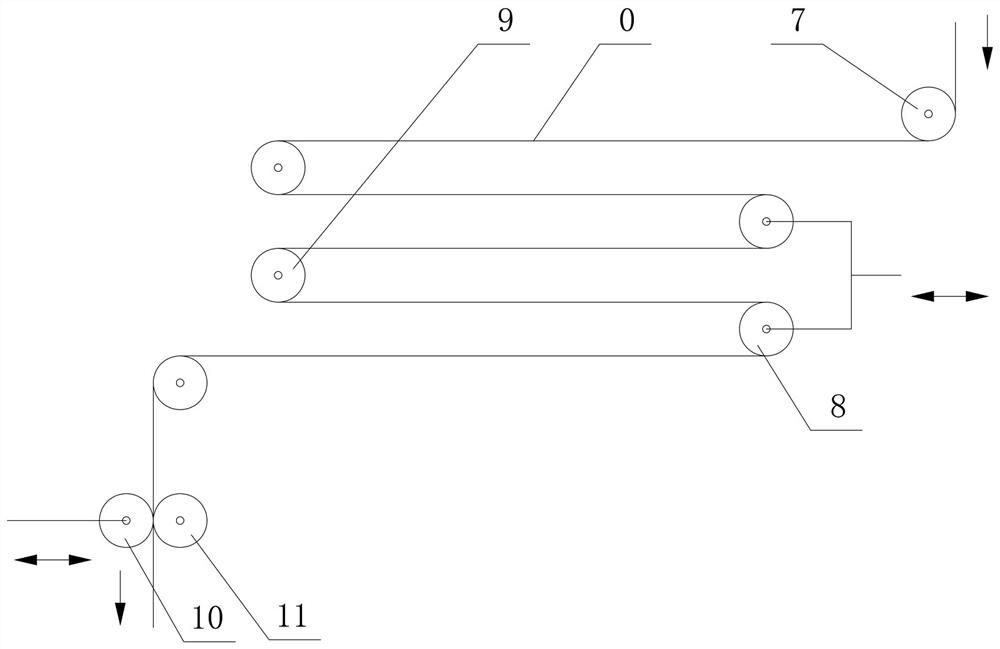

Battery cell diaphragm unwinding process and diaphragm unwinding device thereof

PendingCN114229564AGuaranteed constant tensionEnsure consistencyFinal product manufactureSecondary cellsStructural engineeringPole piece

The invention discloses a battery cell diaphragm unwinding process and a diaphragm unwinding device thereof, and the battery cell diaphragm unwinding process comprises the following process steps: S1, unwinding; s2, diaphragm tensioning adjustment; s3, deviation rectification; S4, diaphragm buffering; and S5, circularly drawing the film. The battery cell diaphragm unwinding device comprises a material roll, a swing rod mechanism, a deviation rectifying mechanism, a buffering mechanism, double rollers and a diaphragm drawing roller, and a belt-shaped diaphragm is wound on the material roll; the deviation rectifying mechanism is arranged at the rear section of the oscillating bar mechanism; the caching mechanism is arranged at the rear section of the deviation rectifying mechanism; the double rollers are arranged at the rear section of the caching mechanism; the membrane drawing roller is arranged at the rear section of the double rollers, and the membrane drawing roller drives the membrane to circularly move back and forth above the lamination platform after pressing the membrane, so that the membrane horizontally covers the lamination platform or the pole piece. The film laminating machine has the functions of diaphragm tension adjustment, position deviation correction, automatic buffer connection, tension detection and the like, continuous tensioning of the diaphragm and consistency of internal tensioning force are guaranteed, the surface quality of a laminated film is improved, and the laminating efficiency is effectively improved.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Tensioning steel wire seal and processing method thereof

The present invention provides a steel wire seal, comprising a lock head and a steel wire with one end connected on the lock head. The lock head is provided with a lock cylinder hole for inserting the steel wire and a marble hole for containing the marble and a spring; the hole diameter of the marble hole is matched with the diameter of the marble; the front part of the marble hole is obliquely penetrated through the middle part of the lock cylinder hole; the size of an area of which the marble hole and the lock cylinder hole penetrate is less than the diameter of the marble. The seal is characterized in that the lock cylinder hole and the marble hole are composed by enclosing a hole wall on the lock head and the surface of an internal core; the internal core is located at the tail end between two holes and is fixedly connected with the lock head; the part where the internal core located at the tail end of the marble hole and the spring form a stop structure; the processing method comprises the steps as follows: compression molding the lock head, the parison comprising a big hole cavity, then filling with the marble and the spring and inserting in the big hole cavity by the specific internal core, and then fixedly connecting the lock head and the steel wire, thereby avoiding the secondary drilling process of the marble hole; the seal has the advantages of accurate size of each hole, good performance and convenient process.

Owner:黄山亿利工贸集团有限公司

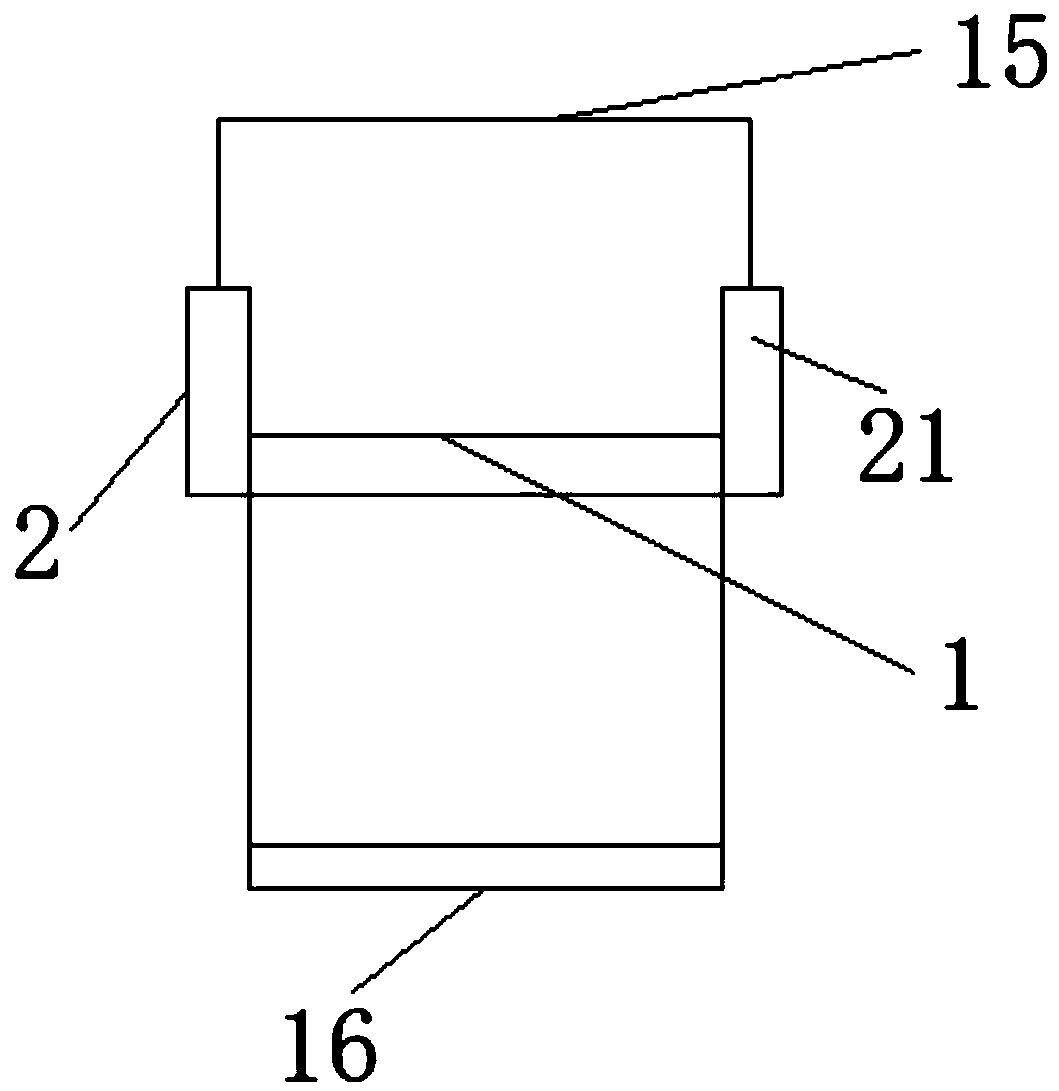

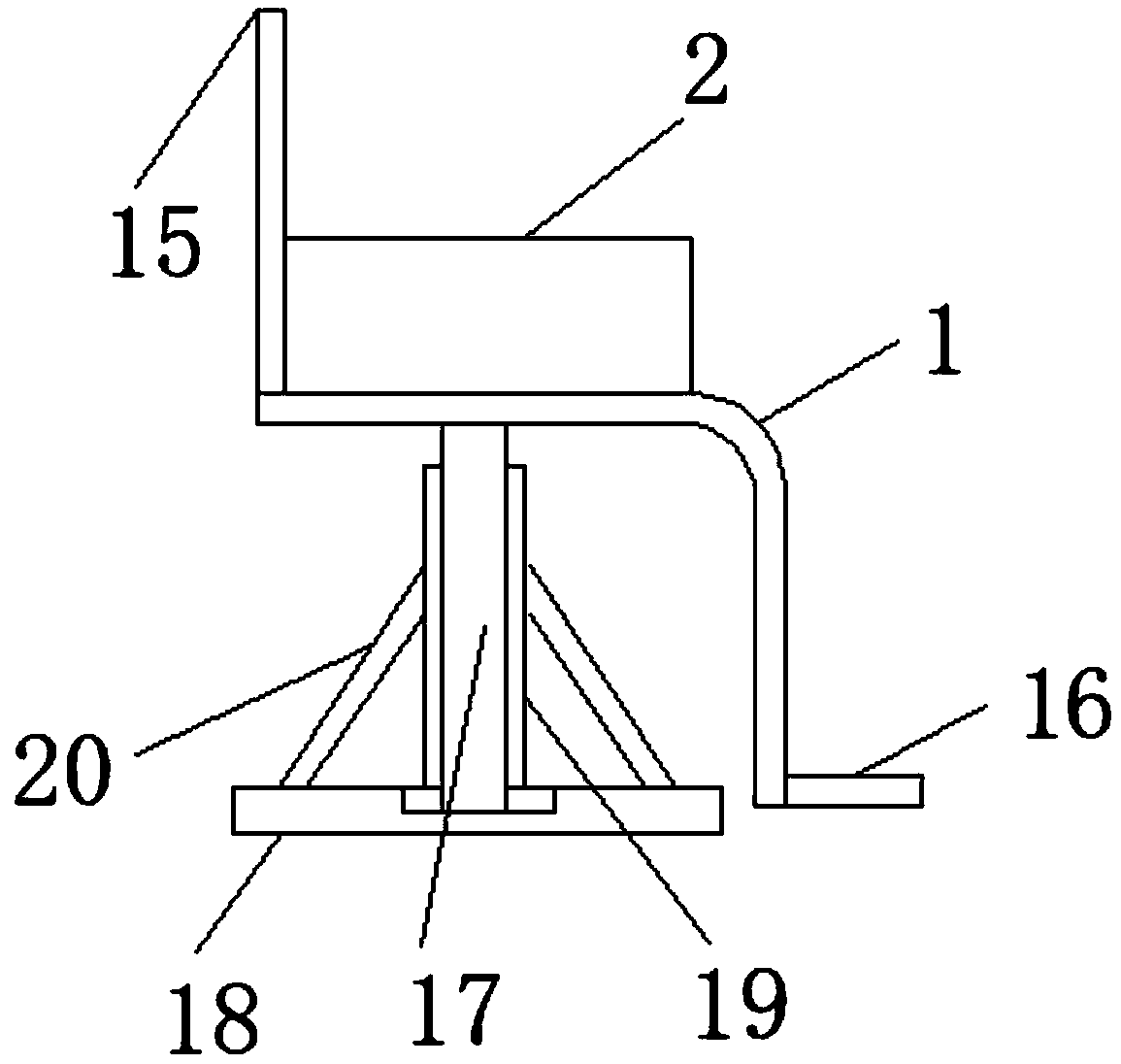

hair winding device

The invention provides a hair wrapping device, including a hair wrapping disc, which is connected with a drive system, and the drive system is used to drive the hair wrapping disc to rotate. The wire head pressing piece can rotate synchronously with the hair winding disk. When the external force drives the wire head pressing piece to deviate from the hair winding disk laterally, the gap between the wire head pressing piece and the hair winding disk is used as the place for placing the hair end. After the external force is removed, the hair end is pressed tightly on the hair winding plate through the wire head pressing member to press the hair end on the hair winding plate; when the hair end is pressed on the hair winding plate, the drive system The hair coil is driven to rotate so as to wind the hair strands on the hair coil to form a hair bundle. The invention is applicable to the preparation of hair ties of various specifications, and not only solves the problem of "the amount of hair has exceeded the required amount when the hair is coiled several times on the reel and fixed, resulting in the hair ties being wound not meeting the requirements and The technical problem of "material waste" has been greatly improved, and the production efficiency has been greatly improved.

Owner:KAILE TOYS CHONGQING

An office swivel chair with foldable armrests

Owner:安吉菲菲椅业有限公司

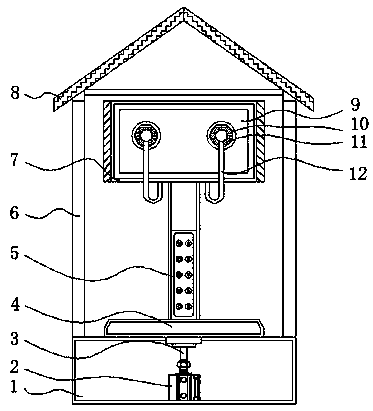

Visible light catalytic sewage treatment equipment

InactiveCN108373185AEnergy-savingPrevent pullbackWater/sewage treatment by irradiationWater treatment compoundsElectricityEnergy control

The invention discloses visible light catalytic sewage treatment equipment which structurally comprises a water inlet pipe, a treatment body, a base, an energy-saving control device, a left plank, a right plank and a water outlet pipe, wherein the bottom surface of the treatment body is fixedly connected to the top surface of the base; the water inlet pipe communicated to the treatment body is mounted at one end of the treatment body while the other end of the treatment body communicates to a water outlet pipe. Compared with the prior art, the visible light catalytic sewage treatment equipmentdisclosed by the invention has the beneficial effects that the visible light catalytic sewage treatment equipment provided with the energy control device has the functions of starting and stopping sewage treatment automatically without manual start and stop; the starter can be started automatically when sewage reaches a certain water level for light catalytic sewage treatment; and the starter canbe stopped automatically when the sewage is treated for stopping light catalytic sewage treatment, so that immediate start and stop are achieved, and the purpose of saving energy and electricity is achieved; the energy-saving environment-friendly performance of the visible light catalytic sewage treatment equipment is enhanced effectively, and the equipment conforms to a national sustainable development guideline.

Owner:曾清民

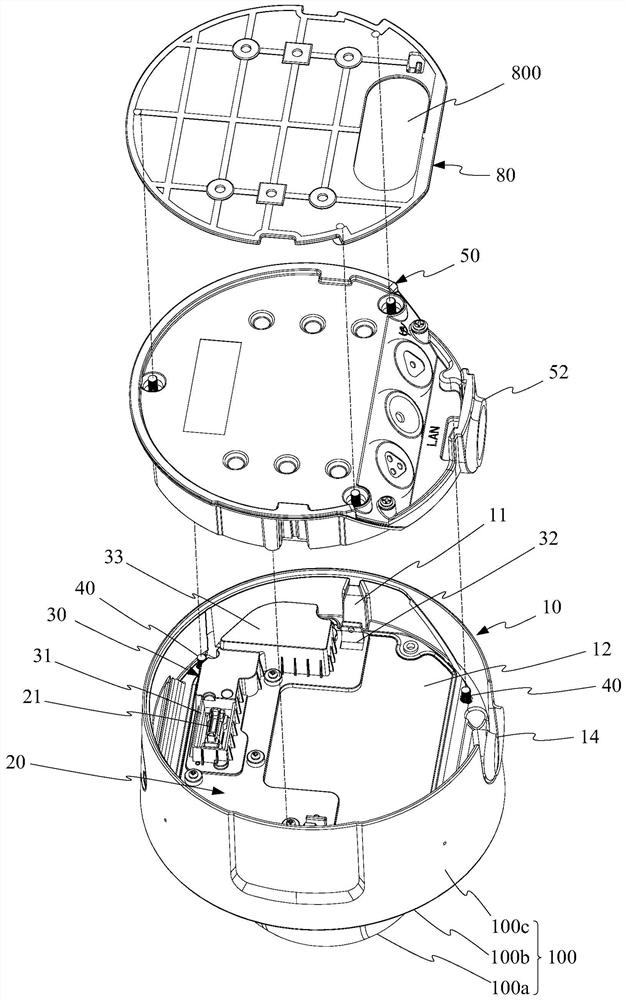

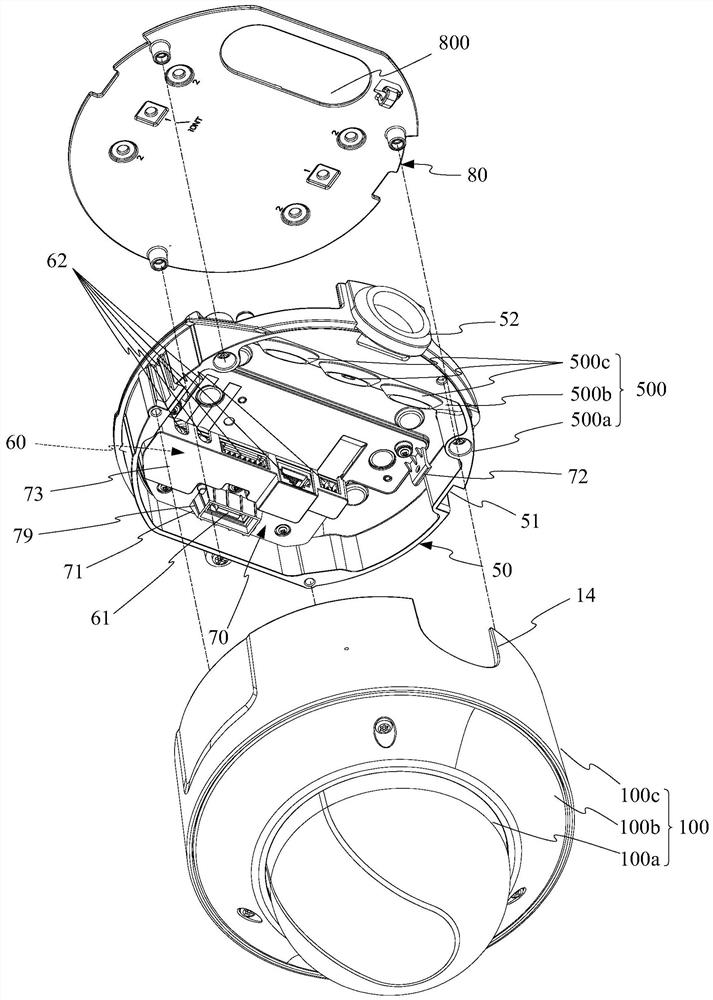

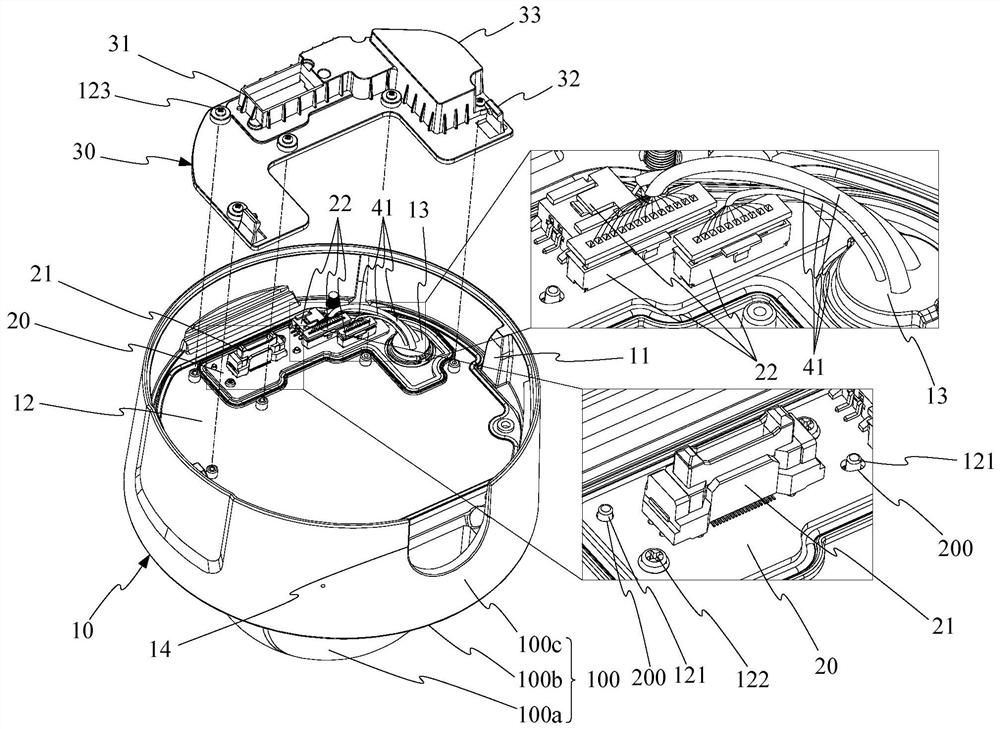

Camera

ActiveCN113676621AAvoid pullingPrevent pullbackTelevision system detailsCouplings bases/casesClassical mechanicsMechanical engineering

The invention discloses a camera. On the basis of the invention, an interface plate with a cable plugging interface and a waterproof threading plug are arranged on a lead machine base, so that an external cable can be plugged with the cable plugging interface without being dragged by a large margin after penetrating through the waterproof threading plug; moreover, a camera main body is provided with an adapter plate which is in signal connection with a machine core, and the adapter plate and the interface plate are respectively provided with a first inter-plate plugging interface and a second inter-plate plugging interface which are complementary, so that the first inter-plate plugging interface can be plugged into the second inter-plate plugging interface only through butt-joint assembly of the camera main body close to the lead machine base, and the signal connection between the external cable and the movement is realized. Therefore, pulling and pulling-back of the external cable can be reduced or even avoided in the installation process of the camera, the installation operation of the camera can be simplified, and the sealing fit between the external cable and the waterproof threading plug is prevented from being damaged.

Owner:HANGZHOU HIKVISION DIGITAL TECH

How to open the traction device

In a method for opening a drafting arrangement (1) with a plurality of pairs of rollers for drawing a sliver (2), the fiber tape (2) between a pair of transport rollers (6) and an at least one input and a pair of output rollers (10, 12), a preferably input, at least one central and a pair of output rollers (10, 11, 12) comprising a drafting unit (1) taut, wherein each roller pair of the drafting unit (1) has at least one upper and one lower roll. Before opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released. In a corresponding drafting arrangement by means of a mechanical or electrical coupling or ; Control prior to the opening of at least the input and / or middle roller pair (10, 11) of the drafting arrangement (1), the tension of the sliver (2) between the transport roller pair (6) and the drafting unit (1) is reduced, in particular released.

Owner:RIETER INGOLSTADT GMBH

Environment-friendly device for clamping thread ends of doubling thread breaking by overlarge tension

InactiveCN112695475AEnhanced internal tensile strengthPrevent static electricityFilament handlingTextile treatment carriersPhysicsEngineering

The invention relates to the technical field of textile, and discloses an environment-friendly device for clamping thread ends of doubling thread breaking by overlarge tension. The environment-friendly device comprises a shell, wherein a fixed block is fixedly connected to the left end of the inner wall of the shell, a channel is formed in the axis of the fixed block, a limiting block is movably connected to the right end of the channel, a disc is fixedly connected with the right end of the limiting block, rollers are movably connected with the right end of the fixed block, a guide column is movably connected with the upper end of the roller, a connecting rod is fixedly connected with the left end of the guide column, a compression spring is movably connected with the upper end of the connecting rod, a rotary disc is movably connected with the right end of the guide column, a T-shaped rod is movably connected with the front end of the rotary disc, and a running pulley is movably connected with the lower end of the T-shaped rod. Under the action of the compression spring, the guide column moves downwards, so that the two rollers press the doubling thread at the same time, so that the doubling thread is clamped between the rollers, and the thus effect of preventing the thread ends from being pulled back when the doubling thread breaks is achieved.

Owner:王婷婷

A full-thickness specimen sampler for gastric cancer

ActiveCN108433752BPrevent pullbackAvoid painSurgical needlesVaccination/ovulation diagnosticsAssayStructural engineering

The invention discloses a gastric cancer full-thickness specimen sampling apparatus, which comprises a needle tube and a core rod, wherein the core rod is arranged in the needle tube; a syringe needleis arranged on the needle tube; a cap is arranged at the end, back away from the syringe needle, of the needle tube; a rod hole, in which the core rod can slide, is formed in the cap; a rubber coveris arranged on the core rod; a fixing structure is arranged on the core rod; the fixing structure comprises a control rod, a spring and a Z-shaped locating piece; a sliding hole is formed in the corerod; a mounting hole is formed in the sidewall of the sliding hole; and a locating hole, in which the locating piece is embedded, is formed in the hole wall of the rod hole. The locating piece is justaligned with the locating hole when a suction amount nearly reaches a required value during sampling, and the control rod is pushed to slide under the power of the spring, so that the locating pieceis driven to get inserted into the locating hole and the core rod and the needle tube are locked; therefore precise control over the suction amount can be achieved, and pain in a patient due to excessive suction can be prevented; and in addition, less suction can be prevented, and the accuracy of test can be reduced.

Owner:WENZHOU PEOPLES HOSPITAL

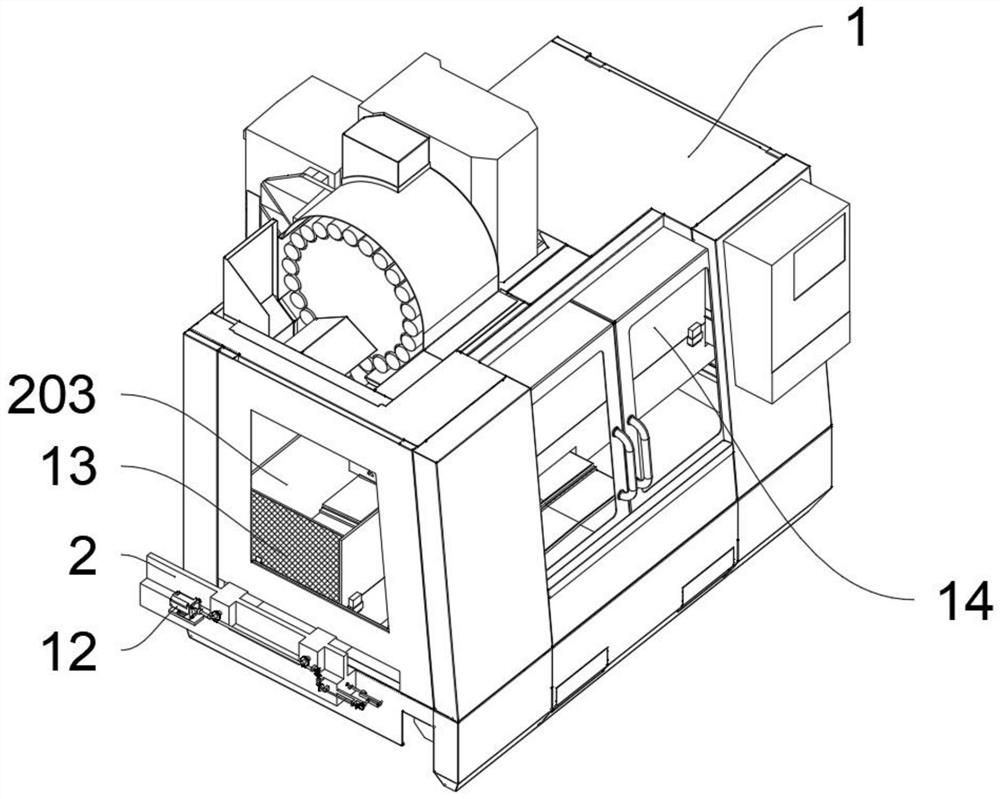

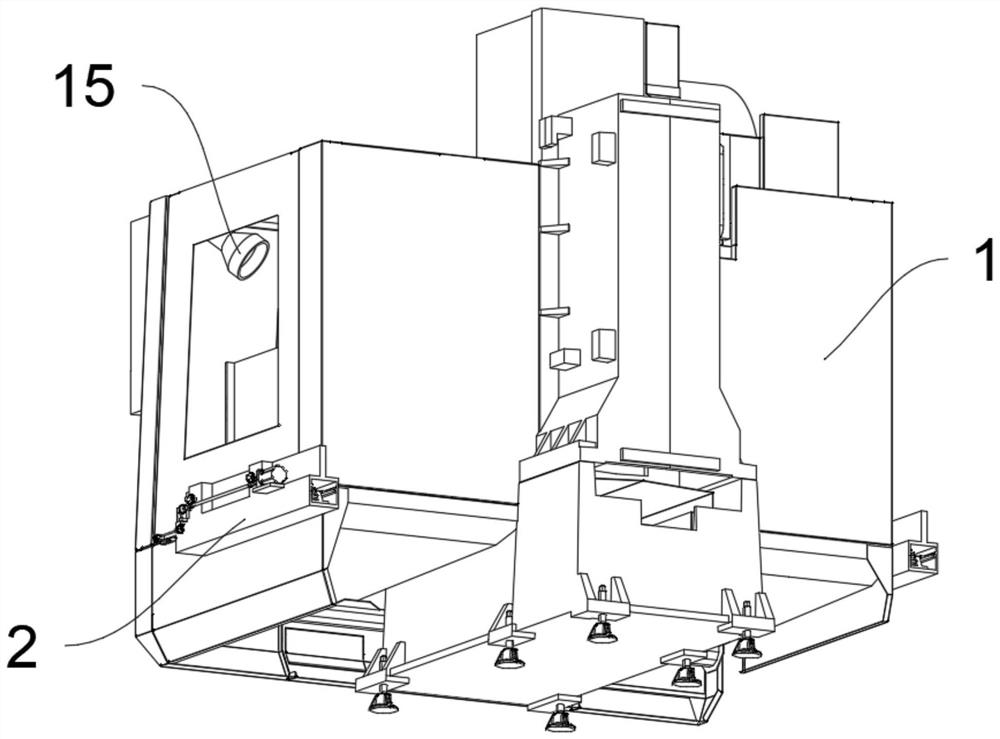

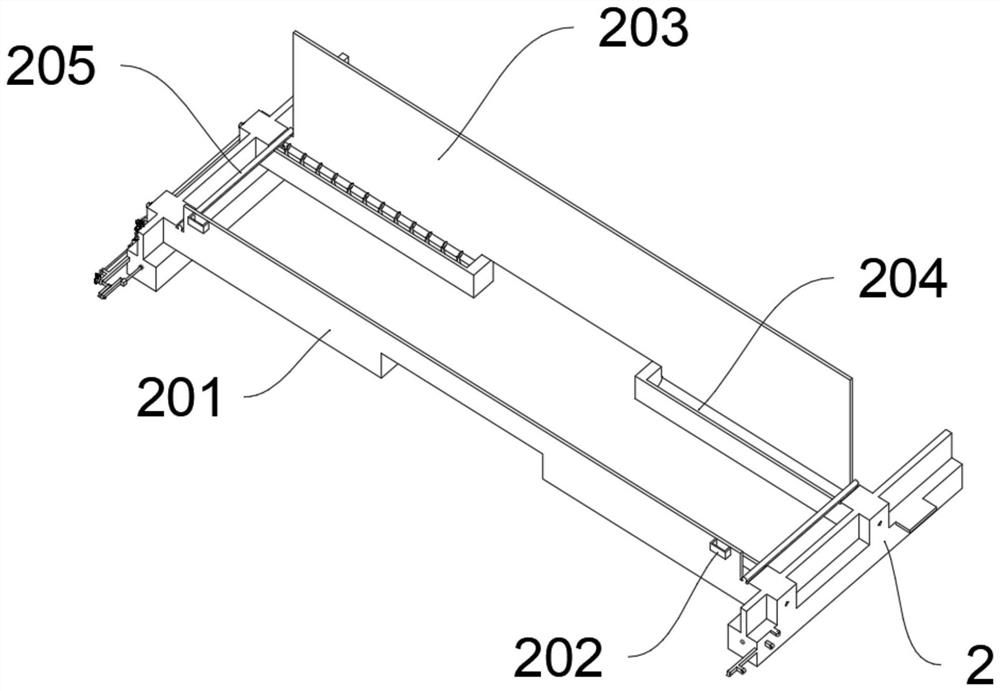

A kind of numerical control equipment equipped with double nozzle waste discharge mechanism

ActiveCN111546123BDischarge continuedAvoid accumulationMaintainance and safety accessoriesNumerical controlDischarge efficiency

The invention discloses a numerical control device equipped with a double-nozzle waste discharge mechanism, which relates to the technical field of numerical control machine tools and solves the problem that the previously used numerical control device is mainly discharged through accumulation, and after a large amount of iron filings are accumulated, a screw propeller is used to discharge them in one go In the equipment, the discharge efficiency is slow. A numerical control device equipped with a waste chip discharge mechanism with double nozzles, including a machine tool; the machine tool is a numerical control machine tool, square notches are opened on the bottom of both sides of the machine tool, and discharge channels are slidingly arranged in the square notches on both sides of the machine tool; Both sides of the discharge channel are provided with worms through the rotation of the shaft frame structure; through the arrangement of the discharge chute and the screw propeller, the waste chips in the numerical control equipment can be continuously discharged to avoid the accumulation of waste chips, and the discharge chute is tight. Attached to both sides of the X-axis of the machine tool, and the X-axis is bidirectionally assembled by the rear baffle and the detachable baffle, which can intercept a large amount of waste to ensure that it enters the discharge chute smoothly.

Owner:山东沅泰机械制造有限公司

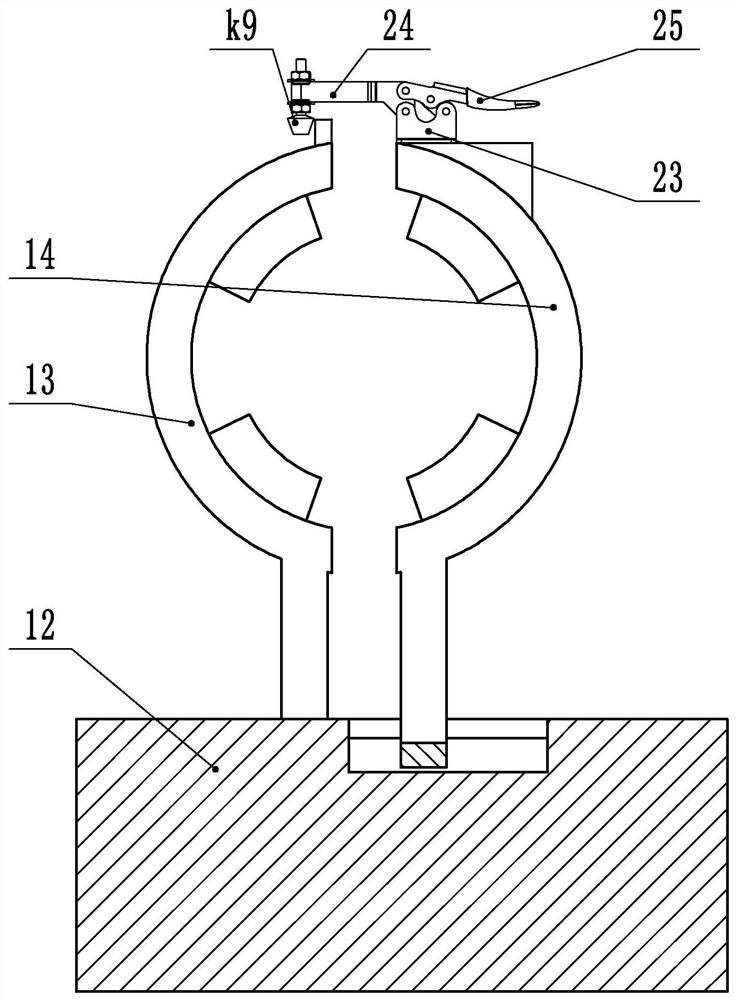

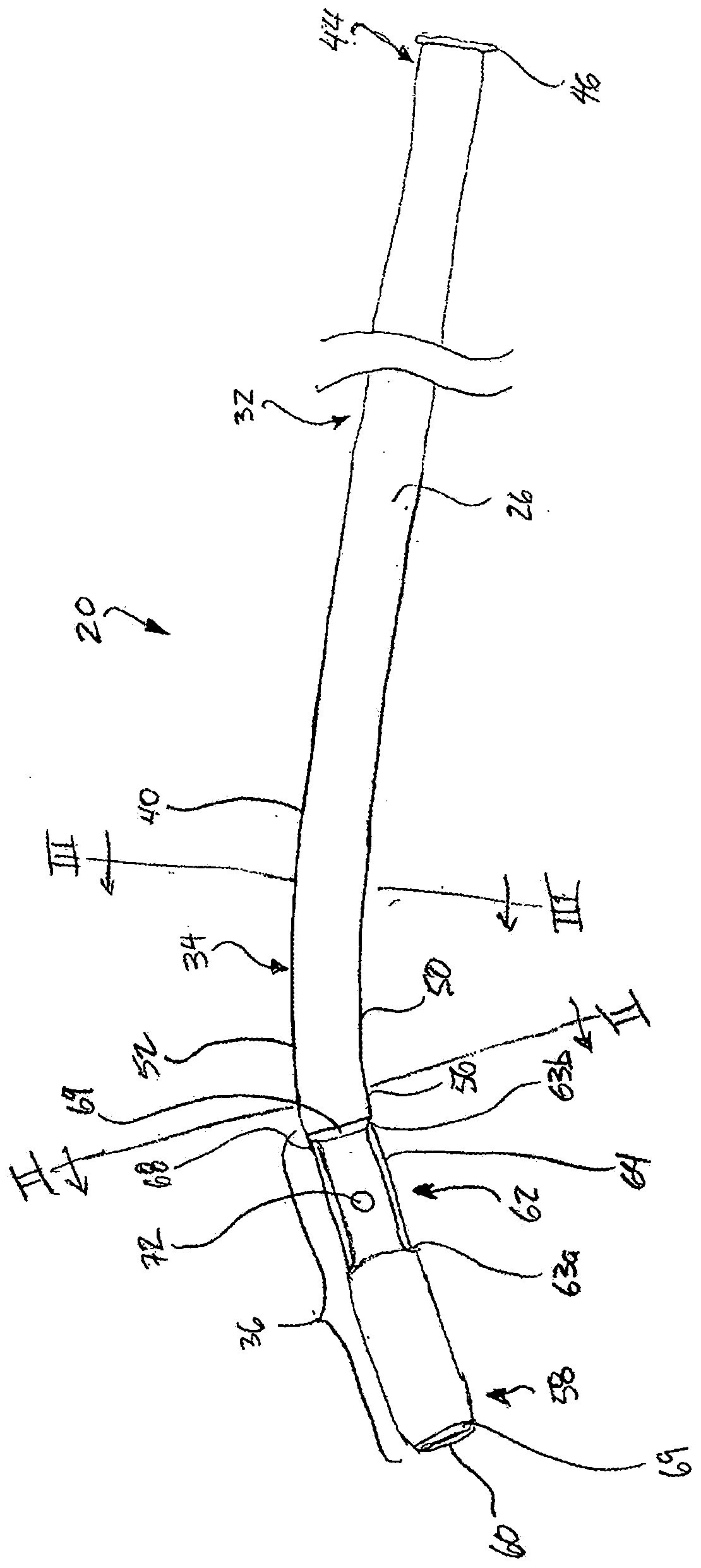

Vascular anchoring introducer sheath

PendingCN110799236APrevent pullbackSafe deliveryBalloon catheterSurgical needlesRight Atrial AppendagePericardial cavity

Provided are apparatus and methods for maintaining access to a location in the body while reducing or eliminating the potential for pulling an access device (e.g. a catheter) back through an opening.An introducer sheath (20) includes a distal indented portion (62) and a balloon (64), so that once placed in a desired location through tissue, the balloon can be inflated to anchor the sheath againstretraction. In particular examples, structure and methods for accessing the pericardial cavity via the right atrial appendage are shown.

Owner:MUFFIN +1

A device for stamping dies

ActiveCN110026483BEffective toggle distancePass smoothlyPerforating toolsMetal-working feeding devicesClassical mechanicsStructural engineering

The invention belongs to the technical field of a stamping die, and in particular relates to a device for the stamping die. The device for the stamping die comprises a base, thread sleeves, threaded rods, a lifting plate, an electric driving module, etc., wherein the base is fixedly arranged on the discharging side of the stamping die, and the two thread sleeves matched with a bearing at the upperend of the base are connected with the lifting plate respectively through the threaded rods screwed with the two thread sleeves. According to the device for the stamping die, the height of the electric driving module can be adjusted according to the frequency of stamping a material strap of the stamping die, and the effective stirring distance of a swing plate to the material strap through a telescopic rod, a semicircular block and an arc-shaped friction pad under different stamping frequencies is ensured; and further, the fact that the stamping frequency is consistent with the stirring frequency of the arc-shaped friction pad to the material strap is ensured. A limiting block matched with the material strap prevents the material strap from being pulled back under external force, and theeffectiveness of stirring the material strap forward of the swing plate through the telescopic rod, the semicircular block and the arc-shaped friction pad is ensured.

Owner:杭州银湖机械弹簧有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com