Patents

Literature

31results about How to "Guaranteed constant tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

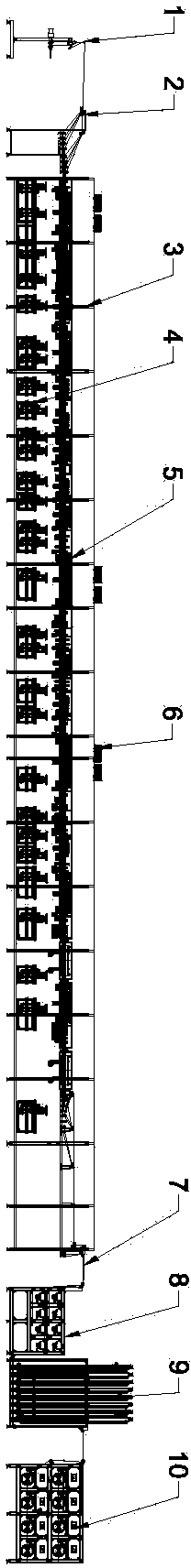

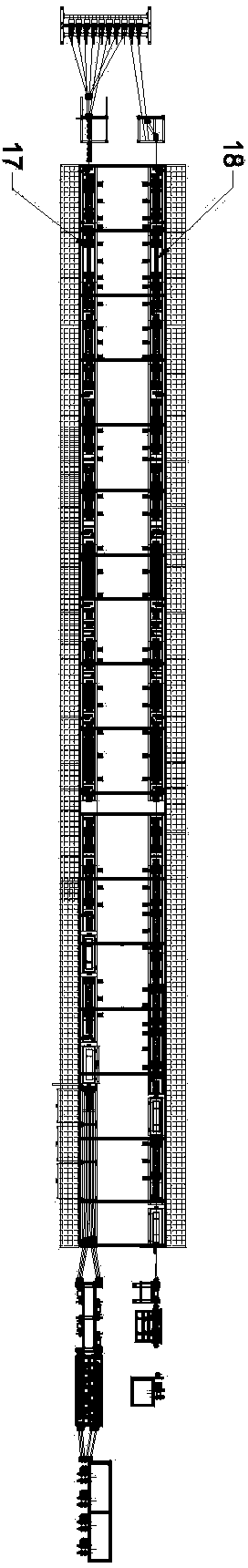

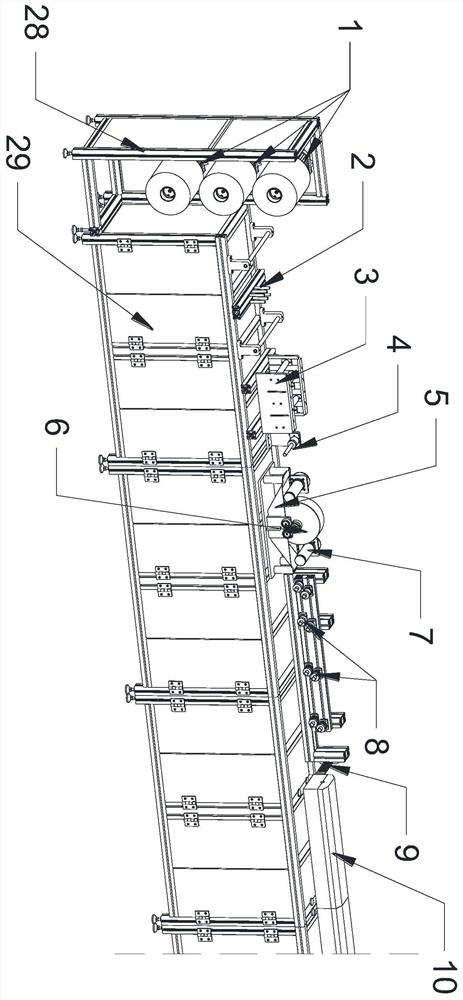

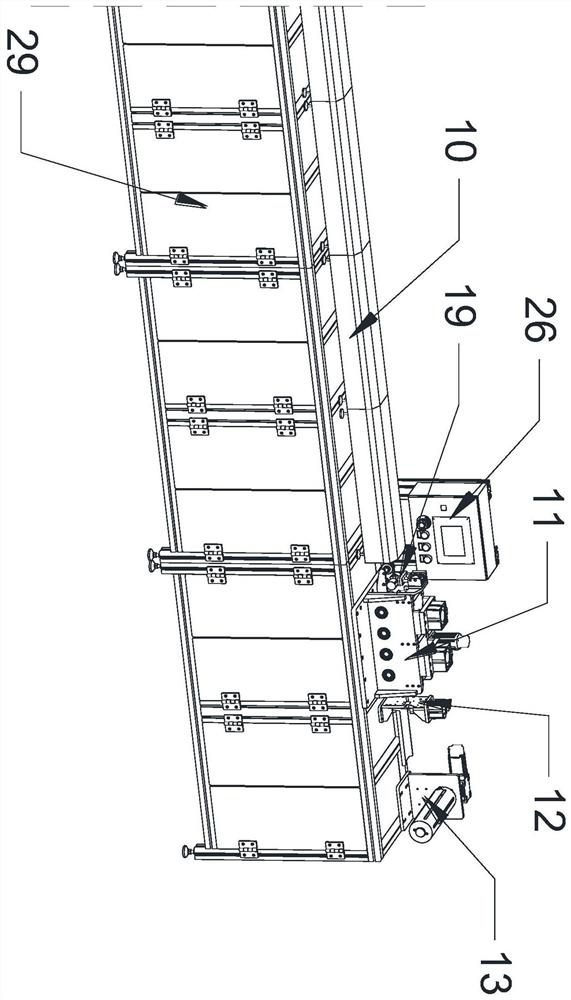

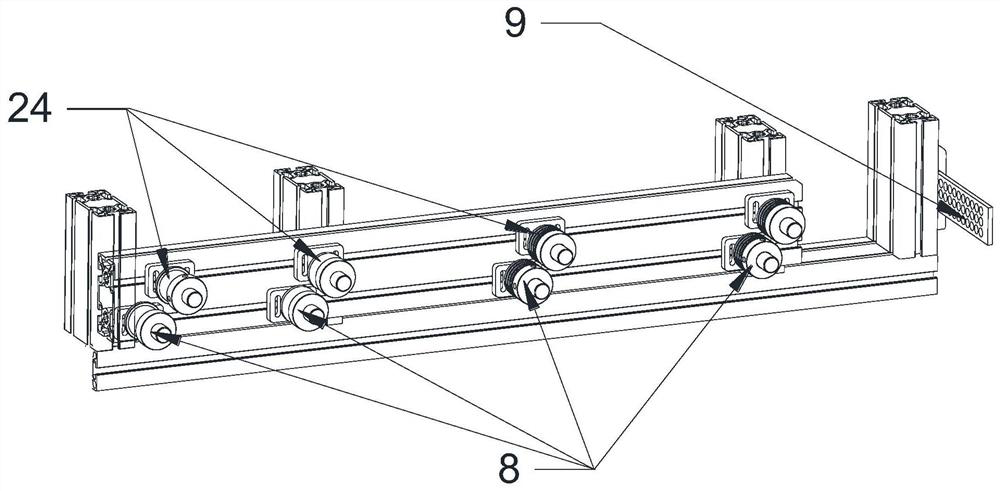

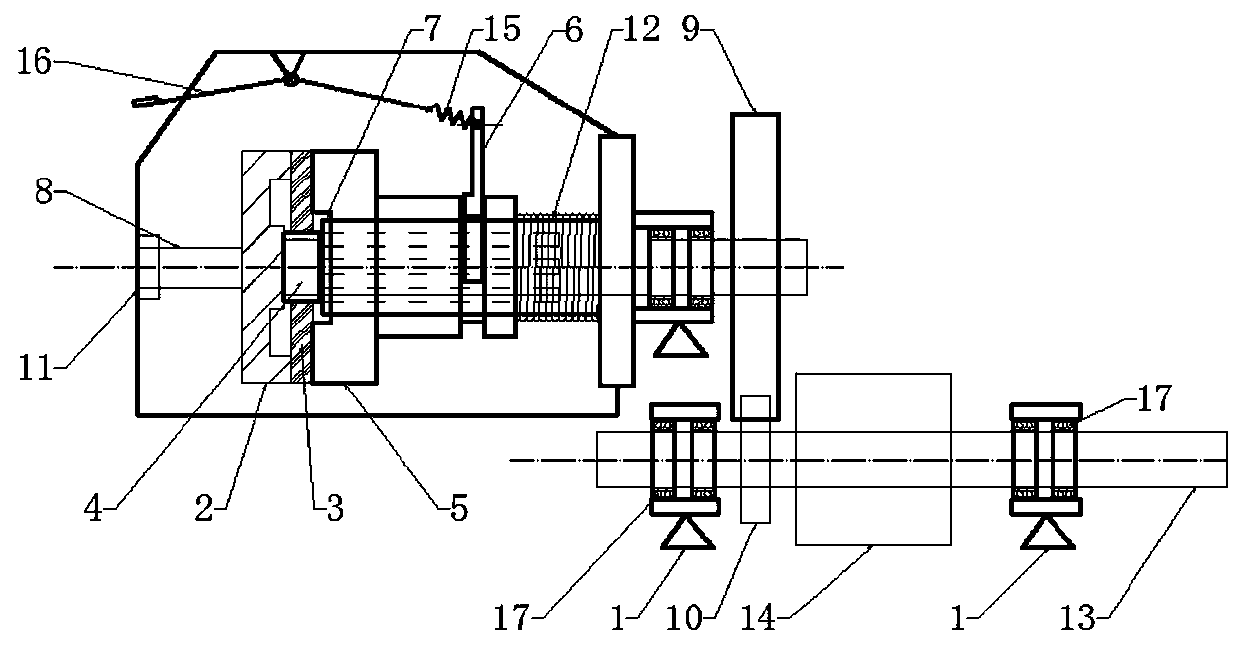

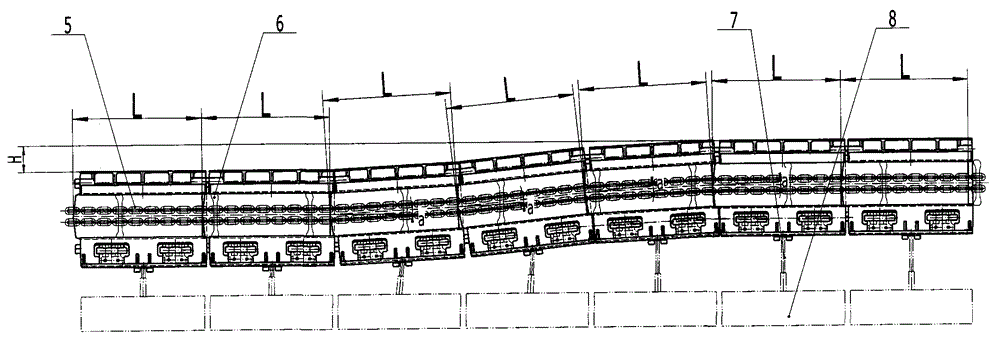

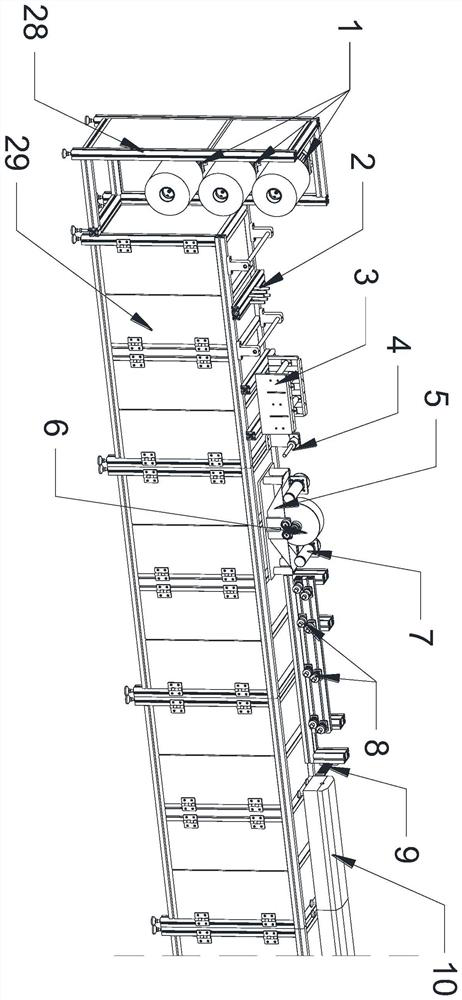

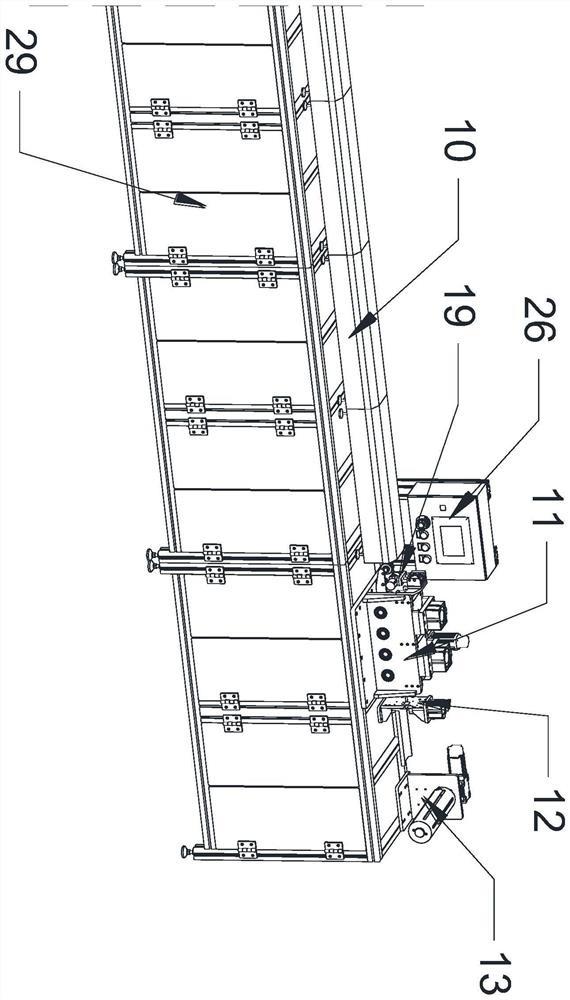

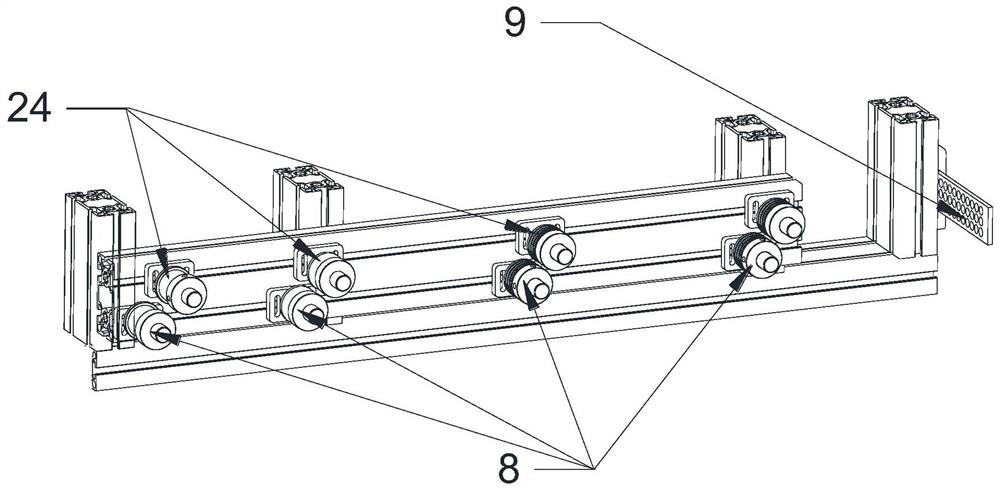

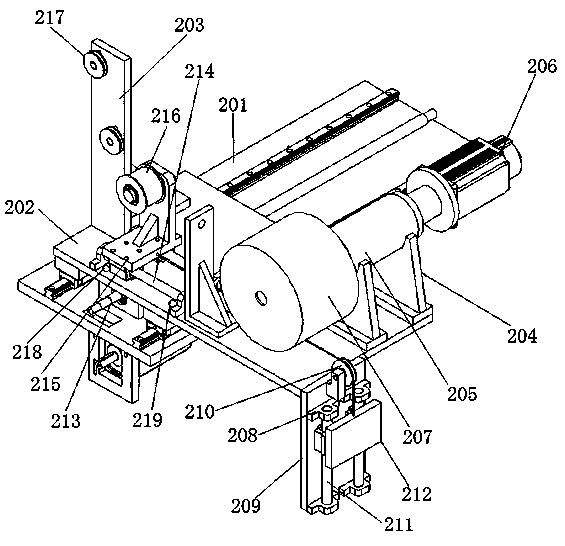

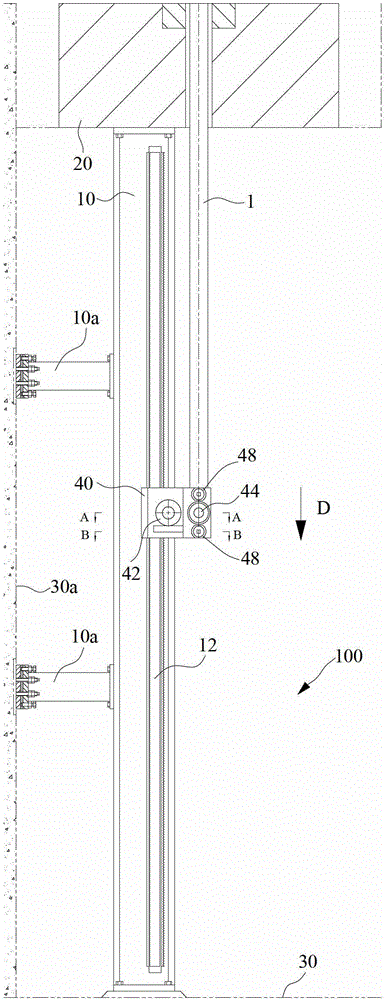

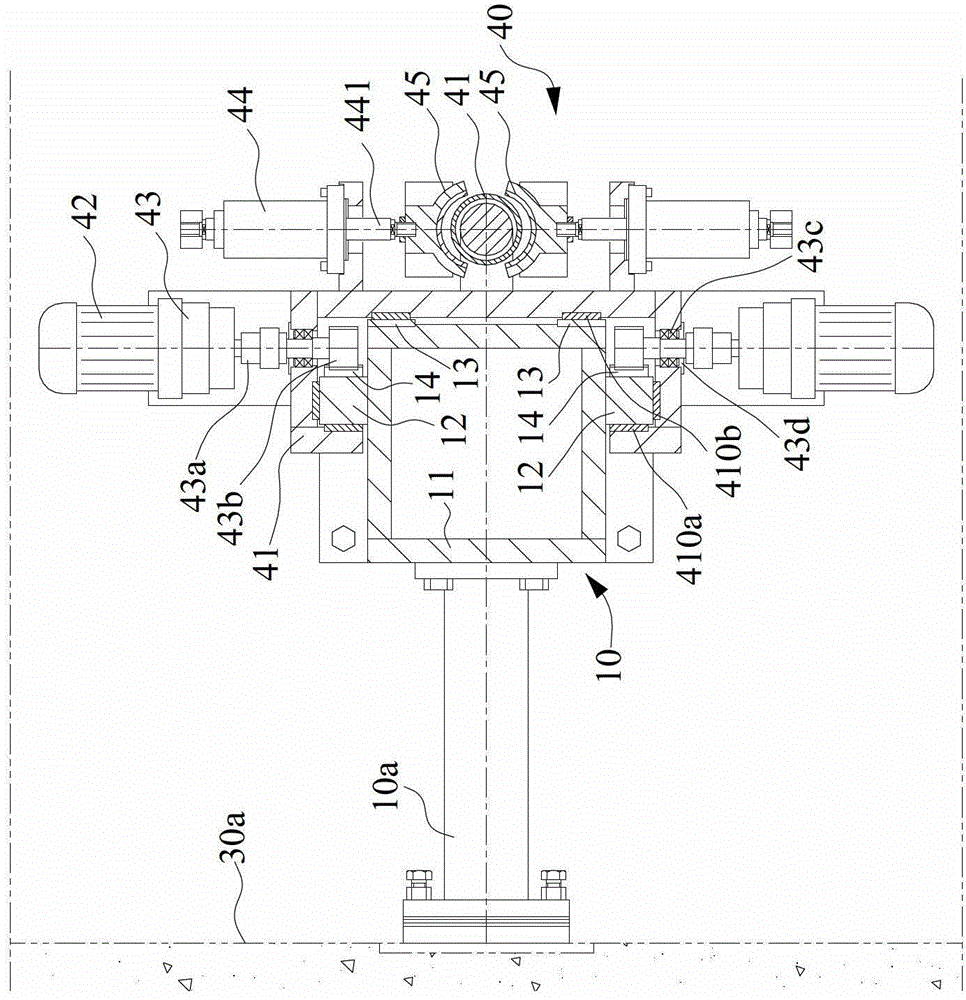

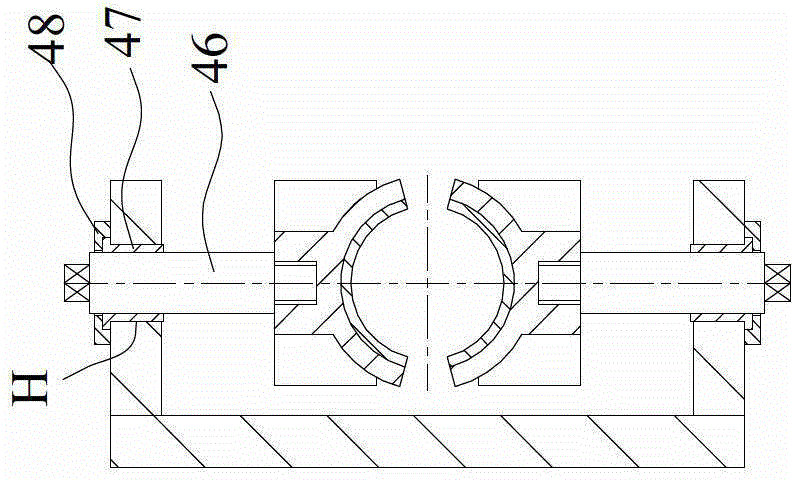

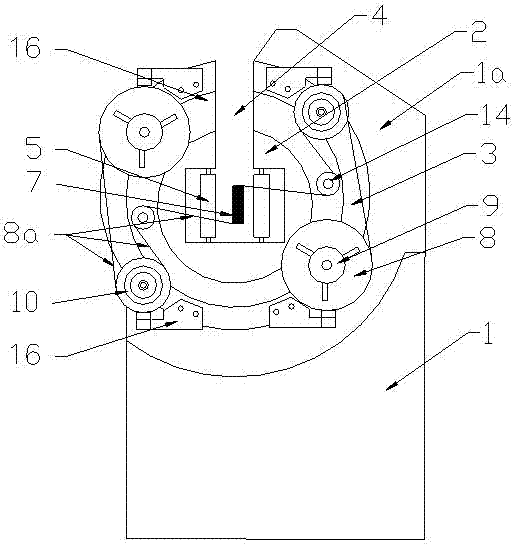

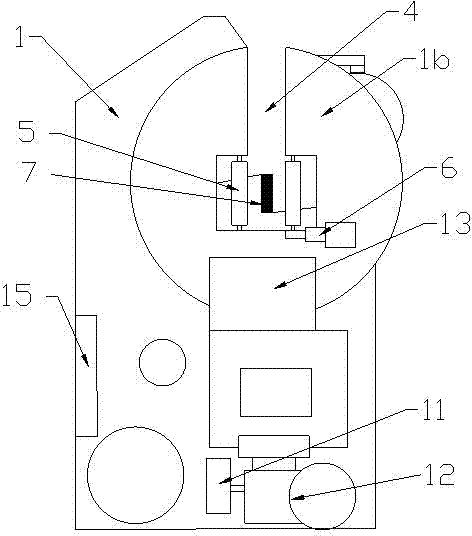

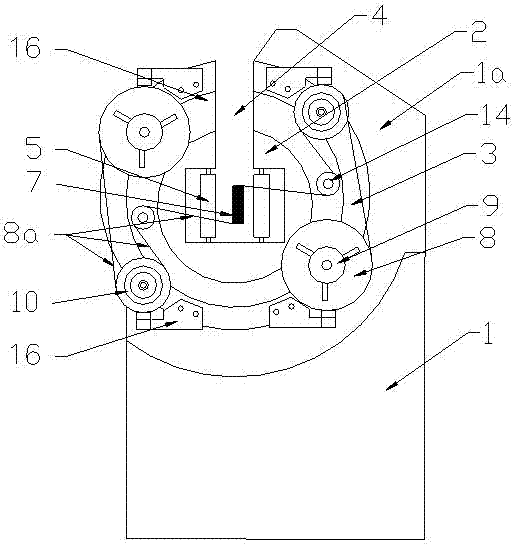

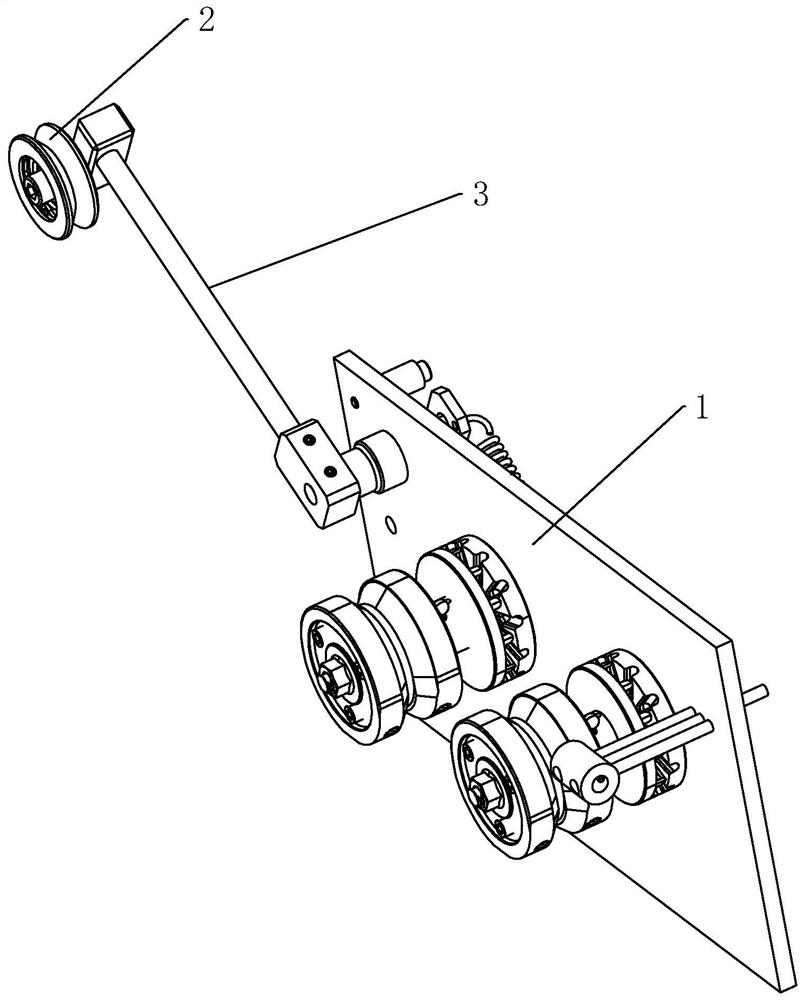

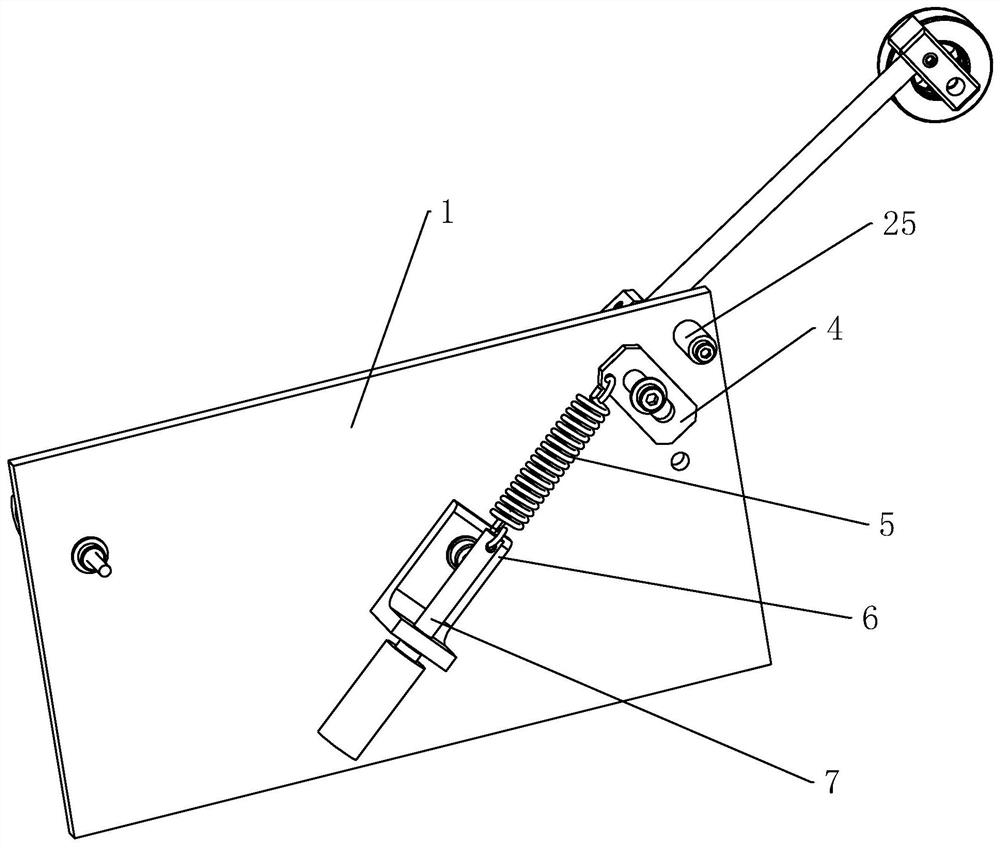

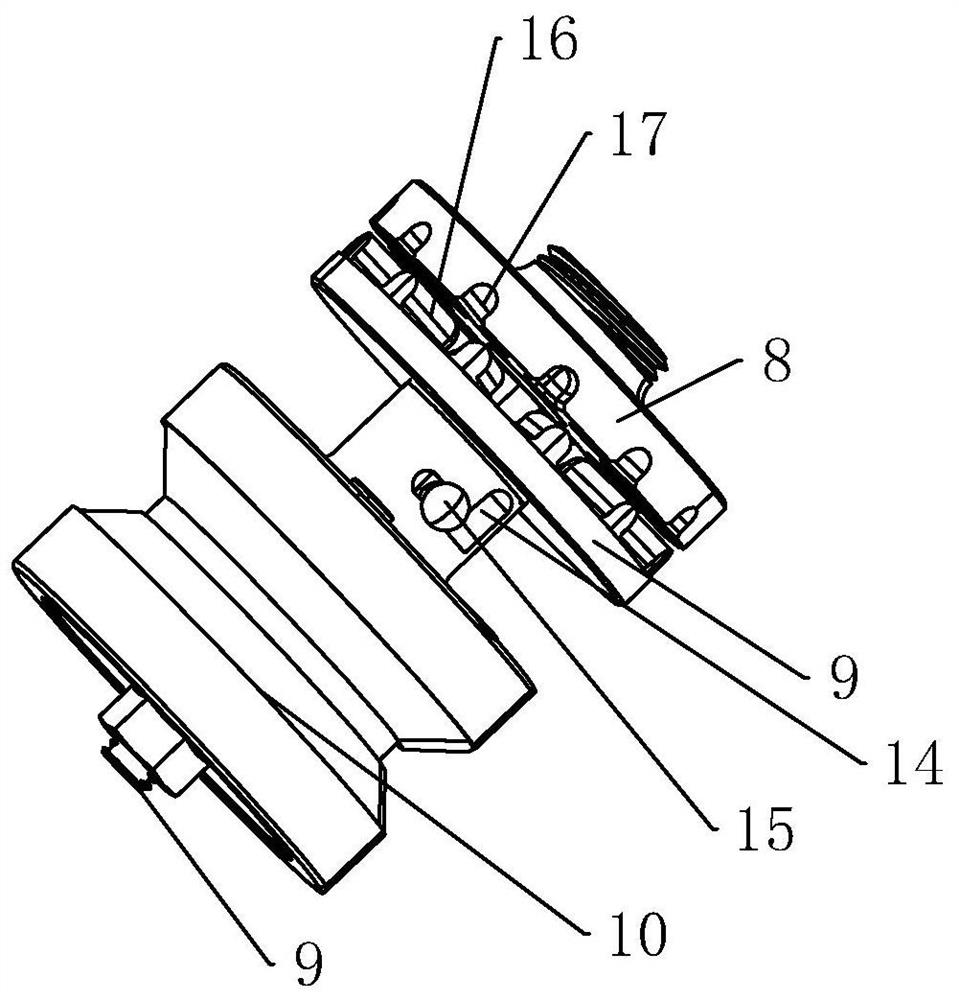

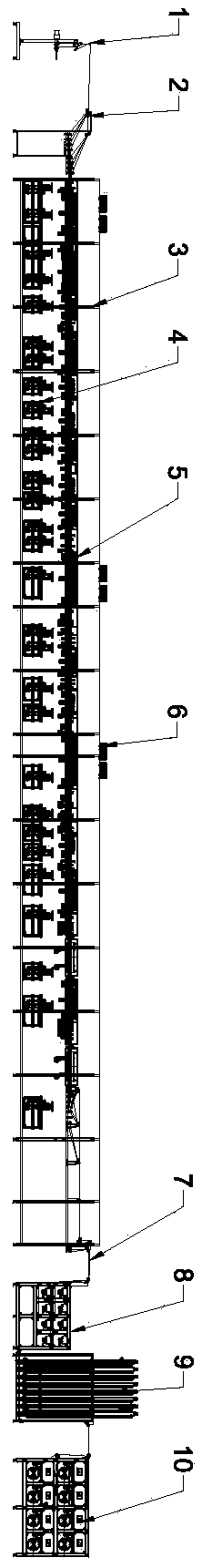

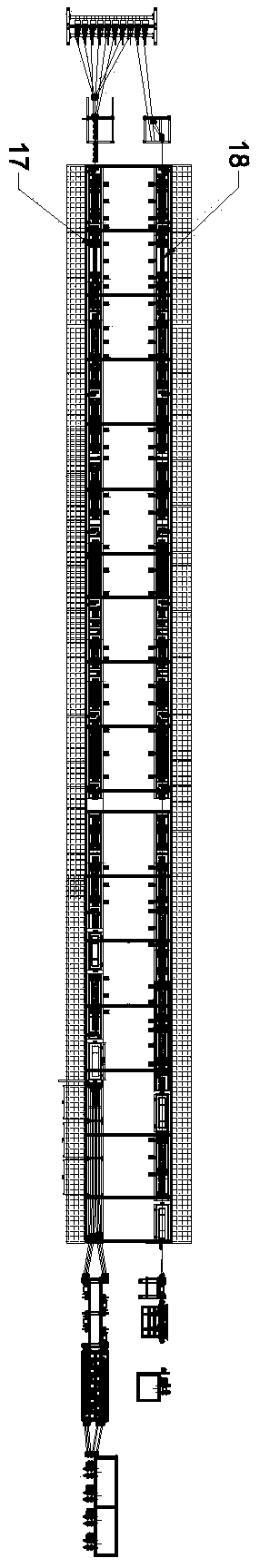

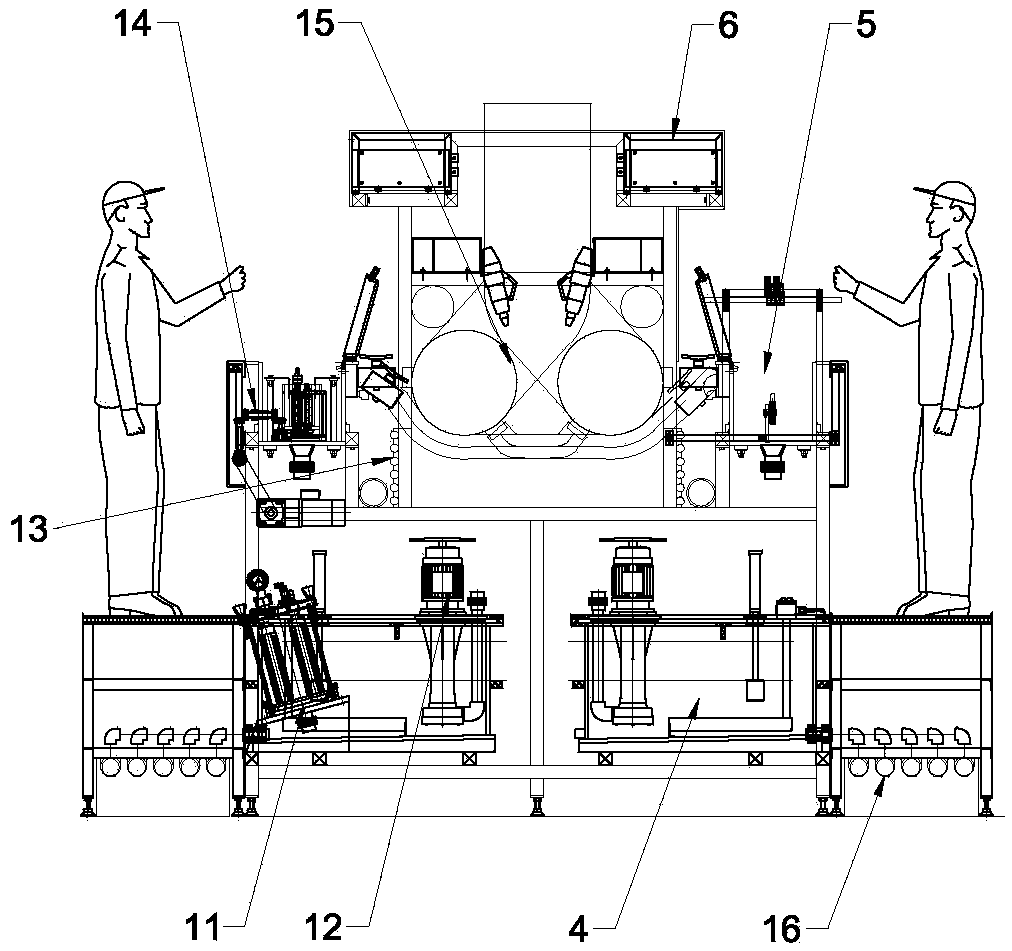

Automatic production line for continuous electroplating of ultrafine metal wire

InactiveCN103741186AGuaranteed constant tensionFlat and beautiful wiringFilament handlingProduction lineSurface layer

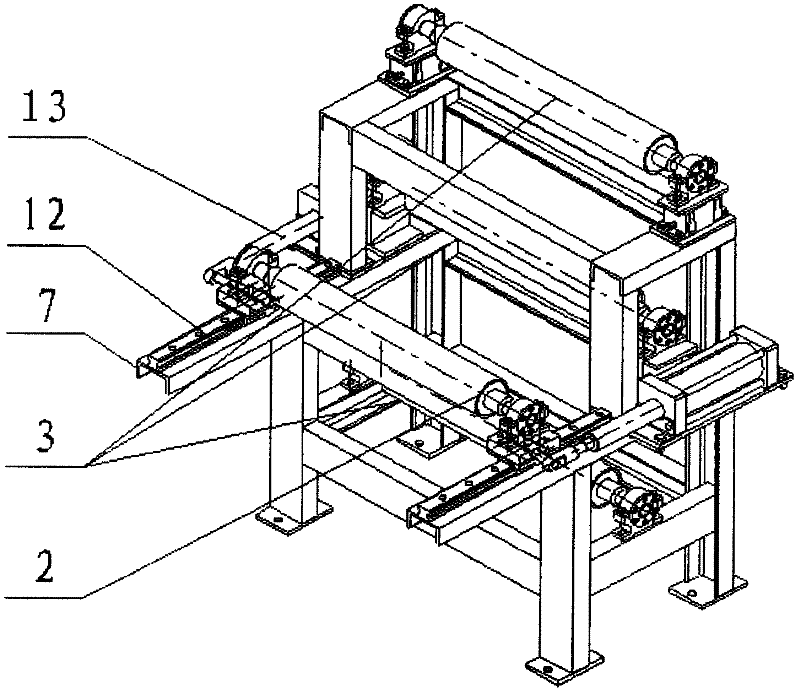

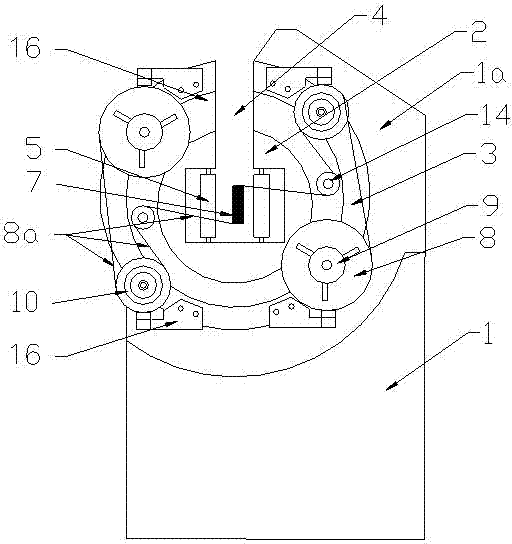

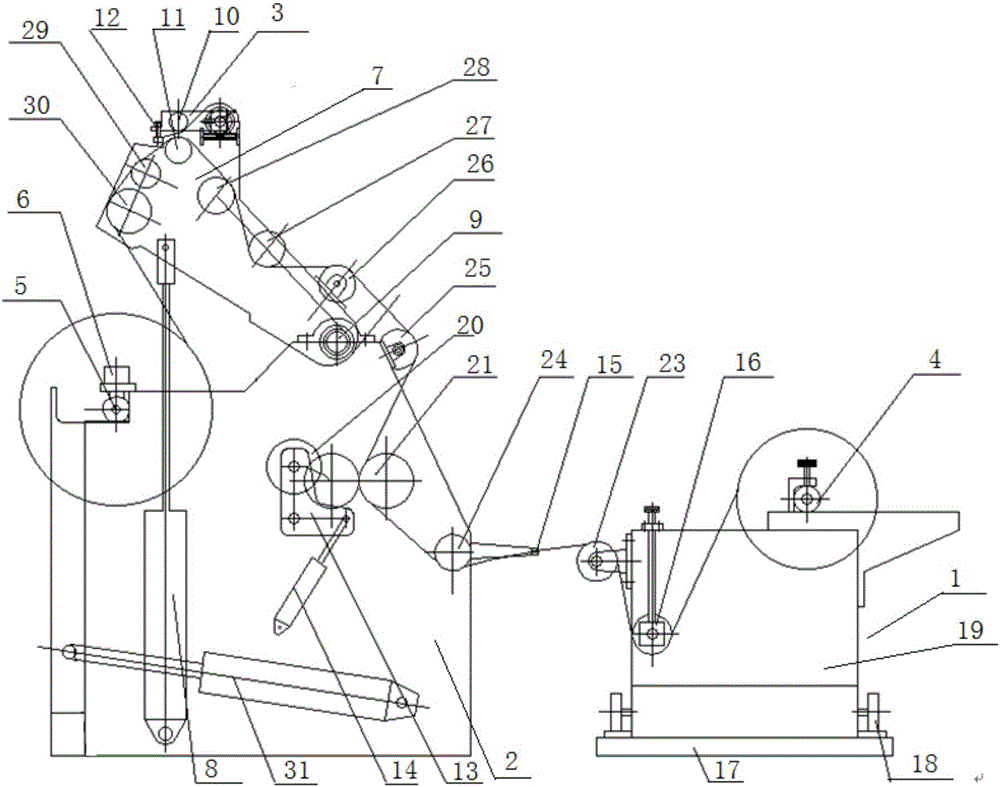

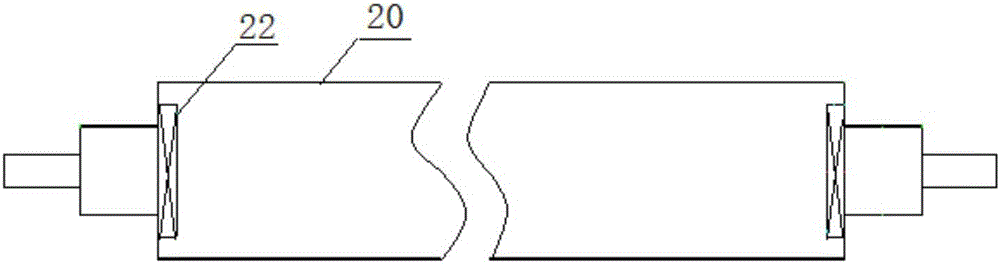

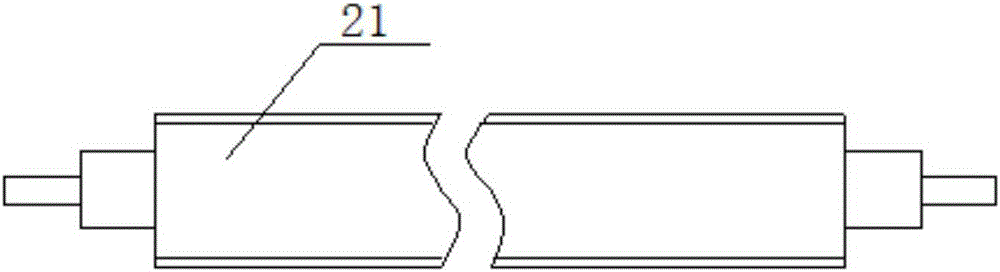

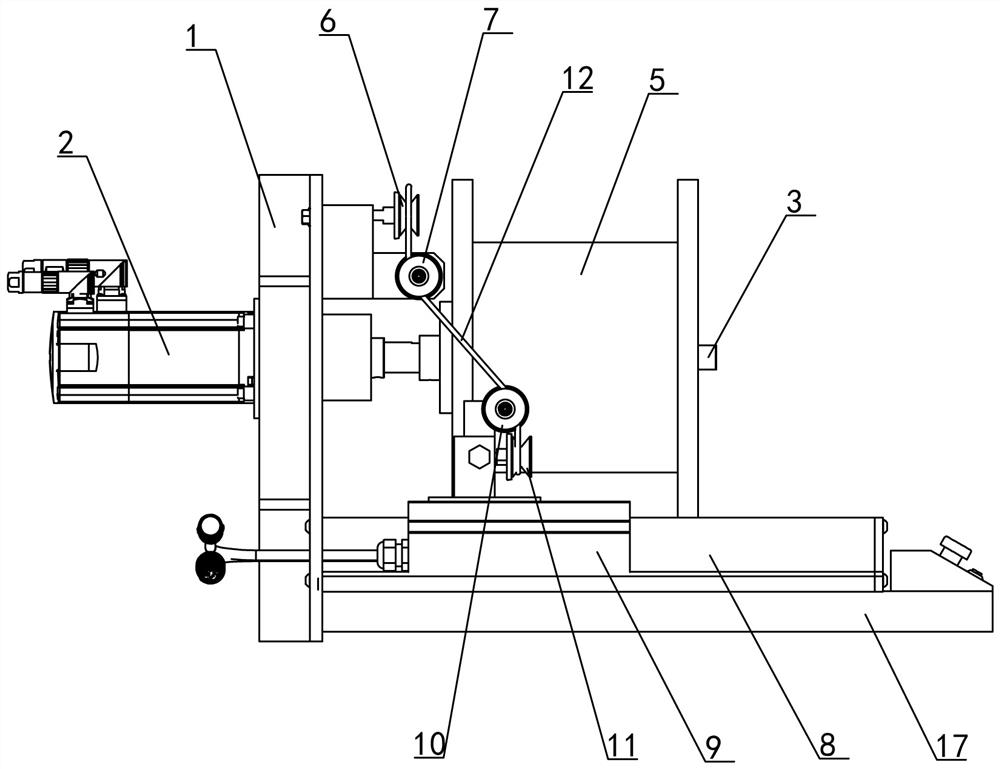

The invention relates to the technical field of electroplating equipment, and in particular relates to an automatic production line for continuous electroplating of an ultrafine metal wire, which is used for a solution of equipment for electroplating a surface layer of an ultrafine metal wire with other metal plating layers in the electroplating industry. A brand new unwinding mechanism is adopted for performing constant-tension unwinding, so that the tension of the metal wire during the unwinding keeps constant; by virtue of a brand new driving mechanism, the linear speed keeps constant when the metal wire moves in the production line and can be adjusted as required so as to meet requirements of an electroplating process; a winding mechanism can be used for performing constant-torque winding during winding, and the winding torque can be adjusted according to the thickness of the metal wire; by virtue of the brand new winding mechanism, the wire can be accurately arranged according to the winding speed, so that the metal wire can be smoothly and attractively arranged; a buffer mechanism is additionally arranged between the driving mechanism and the winding mechanism, and can be used for balancing the speed difference between the driving mechanism and the winding mechanism.

Owner:PLASTIC ENG

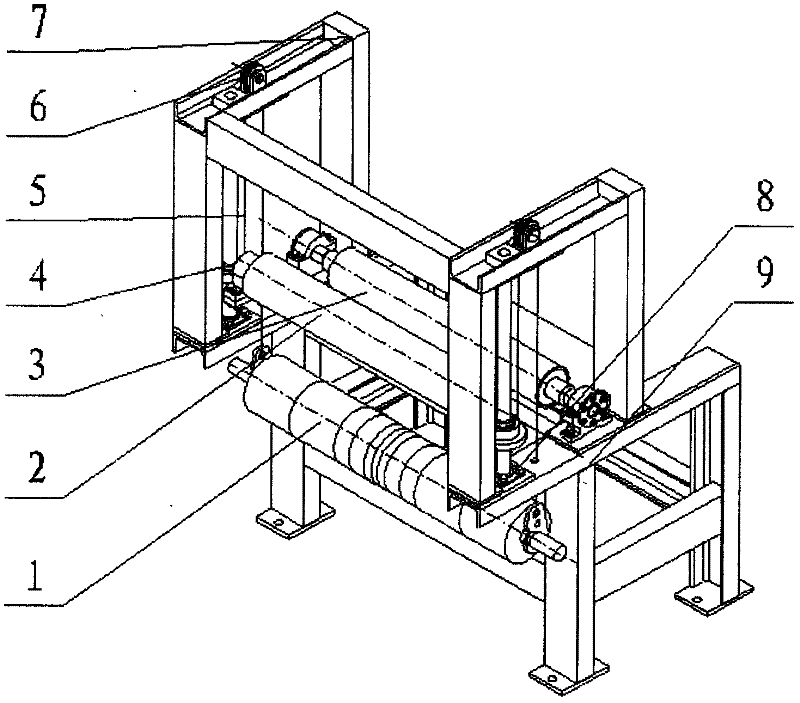

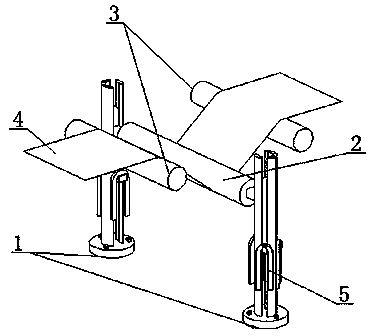

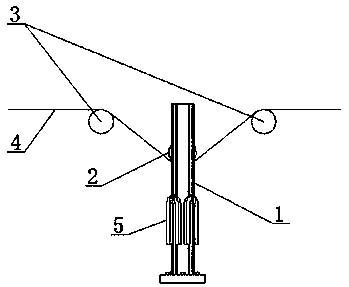

Tension adjusting mechanism for copper foil surface treating machine

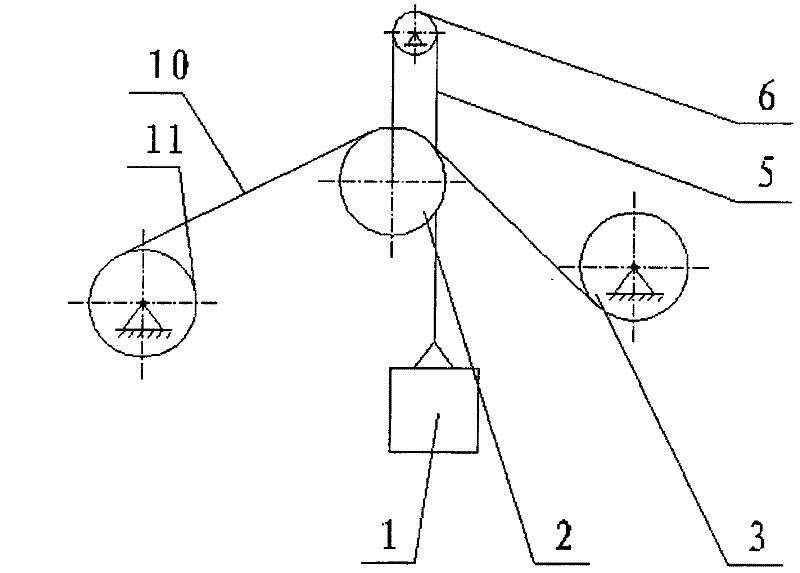

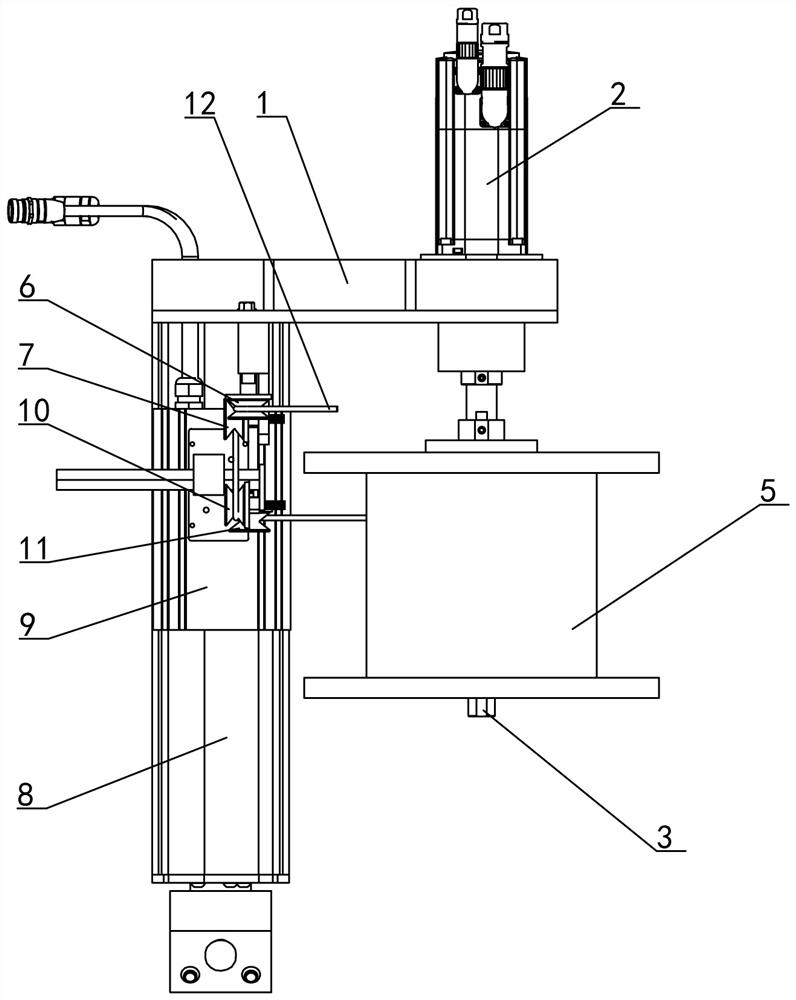

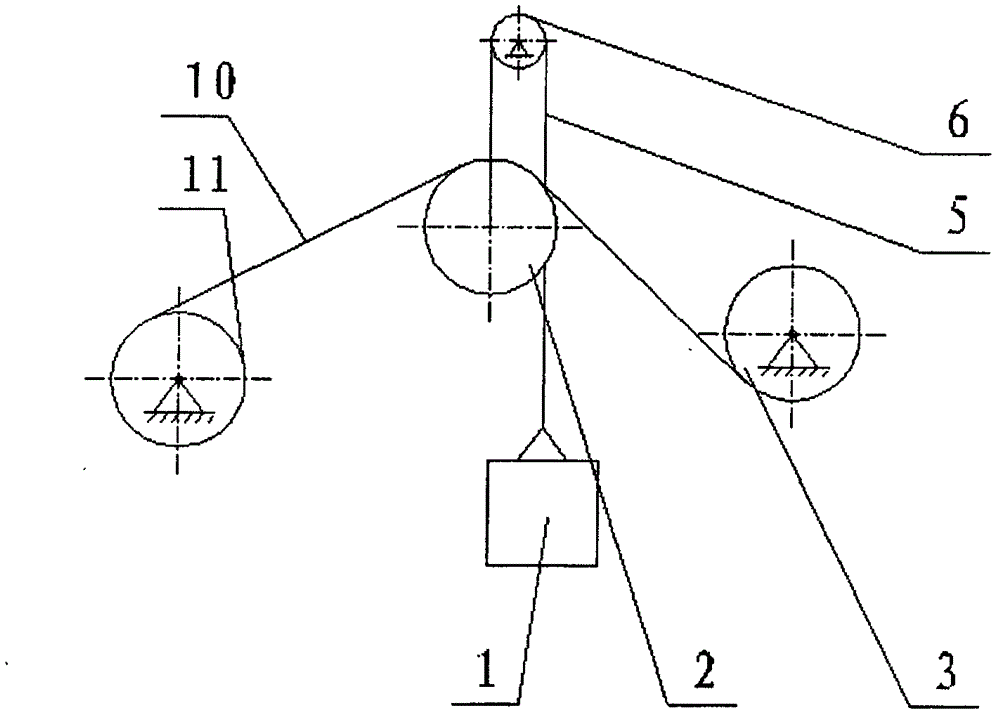

The invention relates to a tension adjusting mechanism for a copper foil surface treating machine; an upper bracket is fixed on the upper surface of a lower bracket; a guide roller is arranged in the middle of the upper surface of the lower bracket; a counterweight roller is positioned at one side of a tension adjusting roller and below the longitudinal beam of the lower bracket; the counterweight roller is hung at one end of a steel wire rope by virtue of fixed pulleys; the tension adjusting roller is positioned at the other side of the counterweight roller and above the longitudinal beam of the lower bracket; the tension adjusting roller is arranged on guide rod fixing seats positioned on the upper surface of the lower bracket; the pair of fixed pulleys are respectively arranged on the upper surface of a longitudinal beam of the upper bracket; the pair of guide rod fixing seats are respectively positioned on the upper surface of the lower bracket and the lower surface of the longitudinal beam of the upper bracket; and the positions of the two guide rod fixing seats correspond to each other. The tensile force generated by the gravity of a counterweight block is direct, and a copper foil is ensured to be tensioned since the change of the tensile force generated by the instant relaxation and tension of the copper foil can be made up by the movement of the tension adjusting roller at any time, so that the tensile force of the rolled copper foil is guaranteed to be constant. The tension adjusting mechanism has the characteristics of being simple in processing and installing as well as simple and convenient to operate, control and use.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

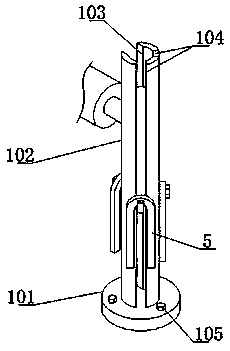

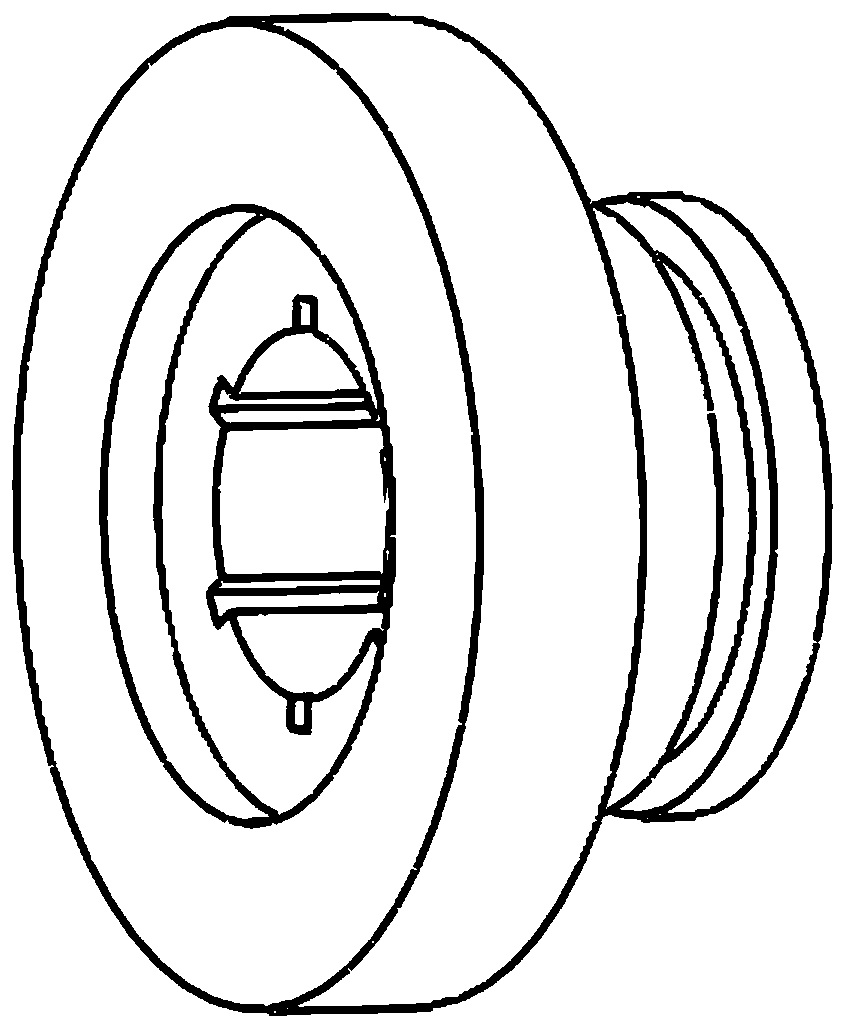

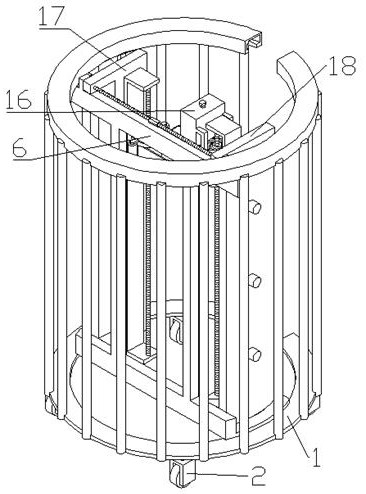

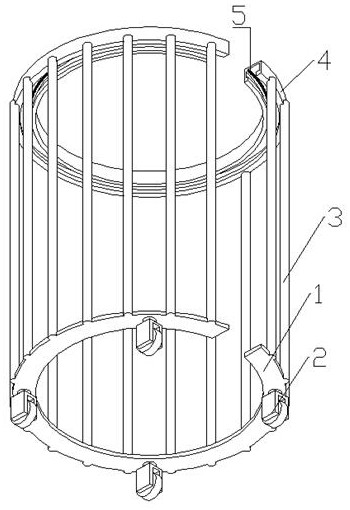

Wrapping head

ActiveCN102185435AUniform qualityGuaranteed constant tensionApplying solid insulationUniform - qualityEngineering

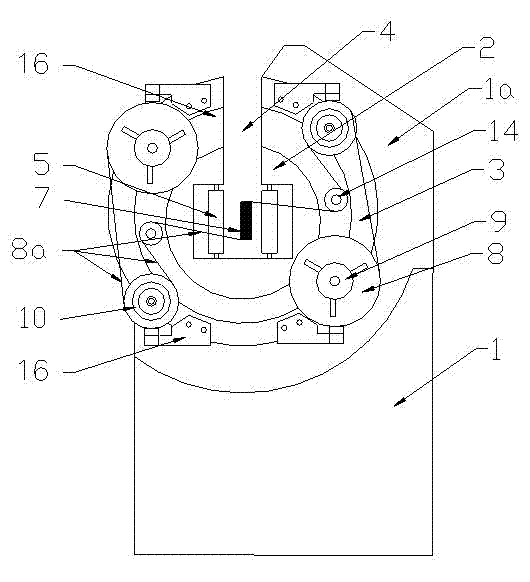

The invention discloses a wrapping head of a wrapping machine, particularly relating to a wrapping head of a generator bar wrapping machine. The wrapping head is characterized by comprising a fixing disc with an opening, and an internal ring arranged on the side surface at one end of the fixing disc, wherein the internal ring is internally provided with a roller that can clamp a bar in a rolling way; the internal ring is externally provided with a wrapping ring that can rotate around the internal ring; the rotating speed and the rotating direction of the wrapping ring can be adjusted; openings are arranged at the positions at the internal ring and the wrapping ring, corresponding to the fixing disc; one side surface of the wrapping ring is provided with a chuck and a tensioning wheel, wherein the wrapping disc can be assembled on the chuck; and the tensioning wheel can adjust the tensioning force of a wrapping belt. The wrapping head can ensure that the wrapping belt has constant tension and is not stretched or broken during the wrapping process; the tensioning force can be freely adjusted within 1kg to 15kg, thus meeting the requirements of different strip belt materials; the superposing degree can be controlled by the superposing positions of 1 / 2, 1 / 3 and the ends, thus ensuring the wrapping belt to have uniform quality.

Owner:GOODE EIS SUZHOU CORP LTD

Splitter provided with pneumatic clamping device

InactiveCN105883469AImprove thickness uniformityRelieve pressureMetal working apparatusArticle deliveryEngineeringConductor Coil

The invention discloses a single-shaft winding splitter provided with a pneumatic clamping device. The single-shaft winding splitter with the pneumatic clamping device comprises a frame, an unwinding device, a winding device, a guide roller set, a splitting device and the pneumatic clamping device, wherein the pneumatic clamping device comprises two cloth clipping rollers located below metal guide rollers (25), and two turnover frames (13) and two turnover pneumatic cylinders (14), which are fixedly arranged on two sides of the cloth clipping rollers; a to-be-split base material passes through between the two fabric clipping rollers. The splitter which is provided by the invention is convenient to operate and low in modification cost, can completely overcome phenomena that the thickness of the base material is uneven, a tail end is wound irregularly and reels are crossed in a splitting process, and greatly decreases the splitting consumption of the base material.

Owner:沈阳东铄电材有限公司

Device for preparing impregnated yarn by one-step method

ActiveCN113789623AGuaranteed constant tensionGuaranteed to evaporateLiquid/gas/vapor removalTextile treatment carriersPolymer scienceCarbon fibers

The invention relates to the technical field of carbon fiber impregnation, in particular to a device for preparing impregnated yarn by a one-step method. The device comprises a constant-tension unwinding mechanism, a no-twist positioning mechanism, a fiber spreading mechanism, a yarn tension sensor, an impregnation mechanism, an extrusion and setting mechanism, a drying oven, a traction mechanism and a cutting mechanism. Yarn is released from a yarn drum through the constant-tension unwinding mechanism; the released yarn is spread into flaky yarn through the fiber spreading mechanism; then, the yarn enters the impregnation mechanism to be impregnated with resin; excessive resin is extruded from impregnated yarn and the yarn is set through the extrusion and setting mechanism; the set yarn is thermally cured through the drying oven to form rod-shaped yarn; the rod-shaped yarn is pulled by adopting the traction mechanism; the cutting mechanism is adopted to cut the cured yarn into segments; and the whole carbon fiber impregnation process is completed. The impregnation process is completed in one step, the efficiency is high, no air hole exists in the interior after curing, and the product quality is high.

Owner:NEWTRY COMPOSITE

High speed constant tension yarn winding machine

PendingCN111620185AConstant tension achievedGuaranteed constant tensionFilament handlingYarnWinding machine

A high speed constant tension yarn winding machine comprises a yarn winding mechanism and a tension translation mechanism which are arranged on a vertical plate; the yarn winding mechanism comprises aservo motor; the servo motor is connected with a winding shaft; a winding drum is arranged on the winding shaft; a first yarn roller and a second yarn roller are arranged on the vertical plate; the first yarn roller and the second yarn roller are perpendicular to each other in the vertical direction; the tension translation mechanism comprises a linear guide way; a reciprocating translation slideblock is arranged on the linear guide way; the reciprocating translation slide block is driven by power to move on the linear guide way in a reciprocating manner; a third yarn roller and a fourth yarn roller are arranged on the reciprocating translation slide block; and the third yarn roller and the fourth yarn roller are perpendicular to each other in the vertical direction. During production, ayarn passes through the first yarn roller first, and then vertically changes direction to pass through the second yarn roller and the third yarn roller, and vertically changes direction to pass through the fourth yarn roller; and meanwhile, the third yarn roller and the fourth yarn roller moves in a reciprocating manner under the driving of the reciprocating translation slide block; and finally,the yarn is wound on the winding drum.

Owner:邱曦

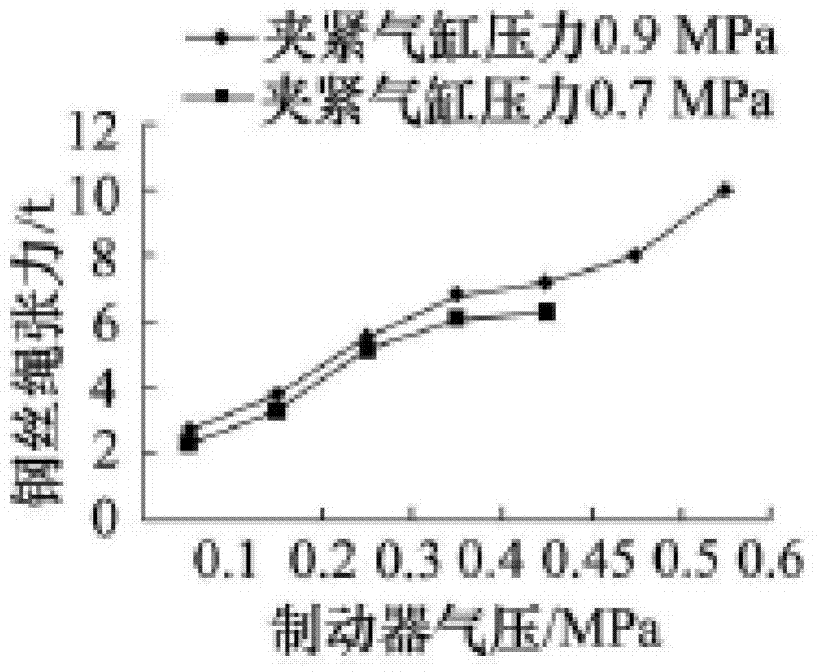

Steel wire rope clamping device based on air pressure transmission

InactiveCN103496646AGuaranteed constant tensionSmall amount of deformationWinding mechanismsPressure transmissionPressure system

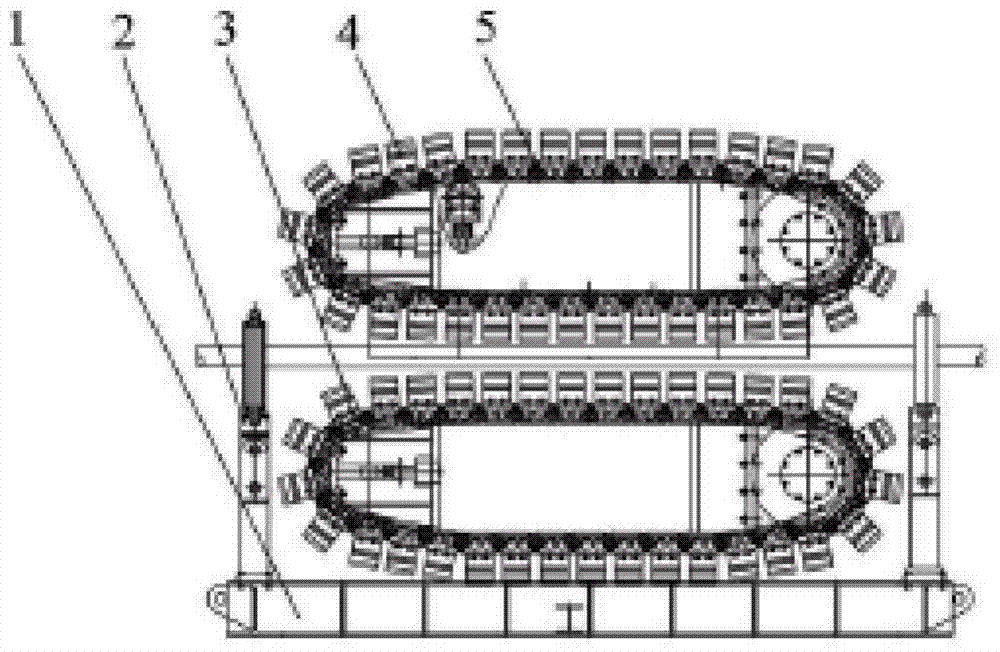

The invention discloses a steel wire rope clamping device based on air pressure transmission. The steel wire rope clamping device based on air pressure transmission comprises a steel wire rope clamping device, an air cylinder and a control cabinet. A cantilever double crawler and lower crawler ejecting and clamping structure is adopted in the steel wire rope clamping device and reasonable matching is achieved through an air pressure system, so that the clamping force of the crawlers on a steel wire rope is 25 times the tension value of the steel wire rope. Thus, self-adapting flexible control of the clamping force of an ejecting crawler and set tension is achieved. Under the condition that constant tension is exerted on the steel wire rope, the minimal deformation amount of the steel wire rope is automatically obtained and damage to the steel wire rope is avoided. In addition, constant damping force is exerted on the steel wire rope and rope disordering will not happen to the steel wire rope.

Owner:WUXI UNIVERSAL STEEL ROPE

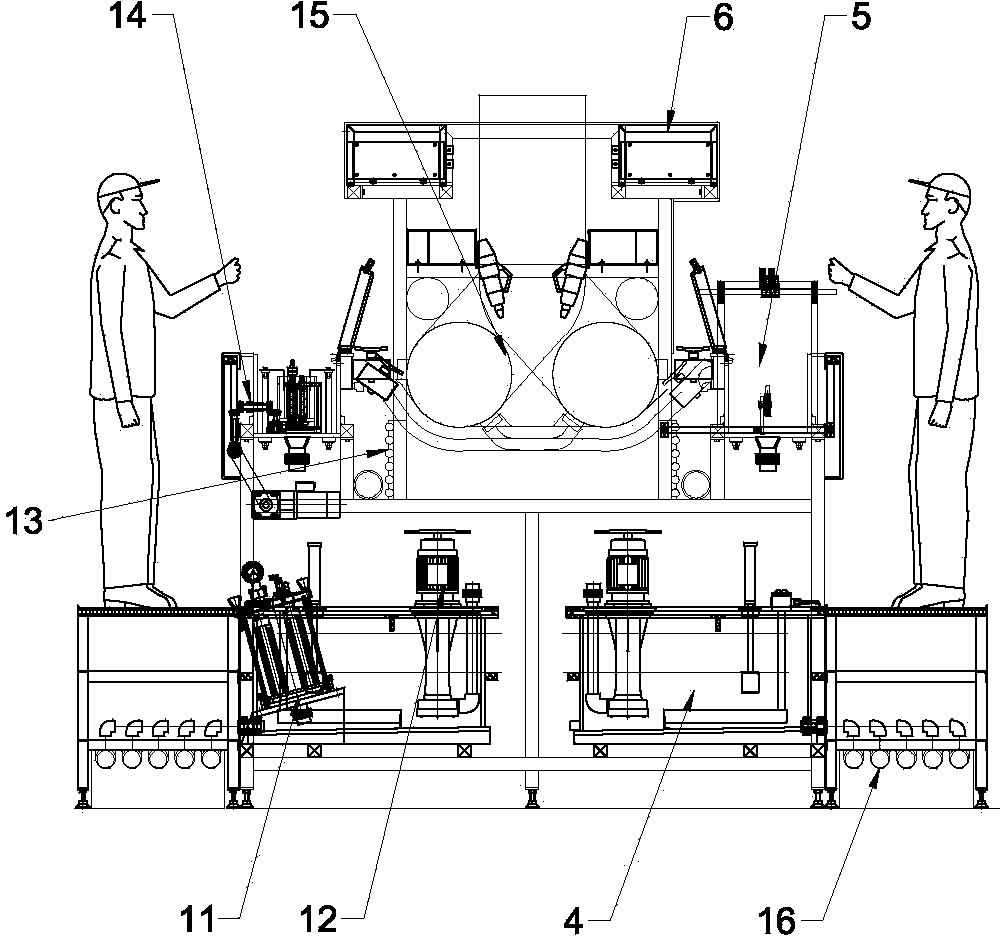

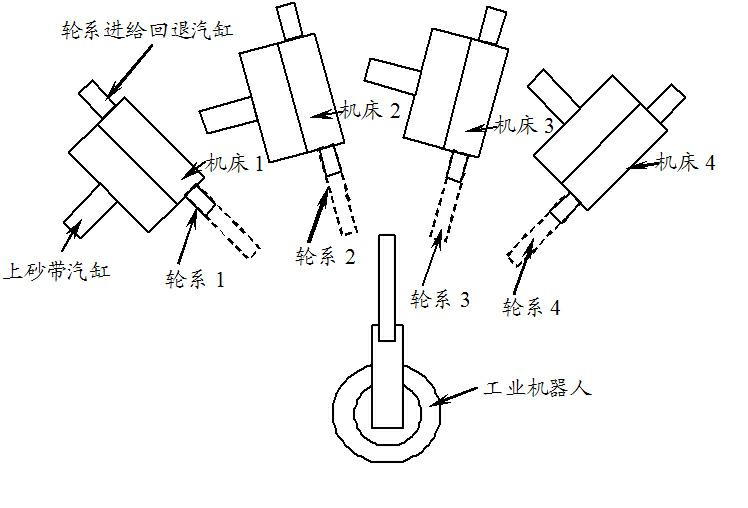

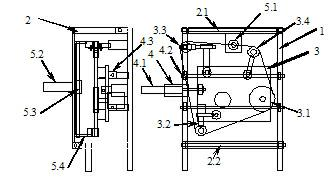

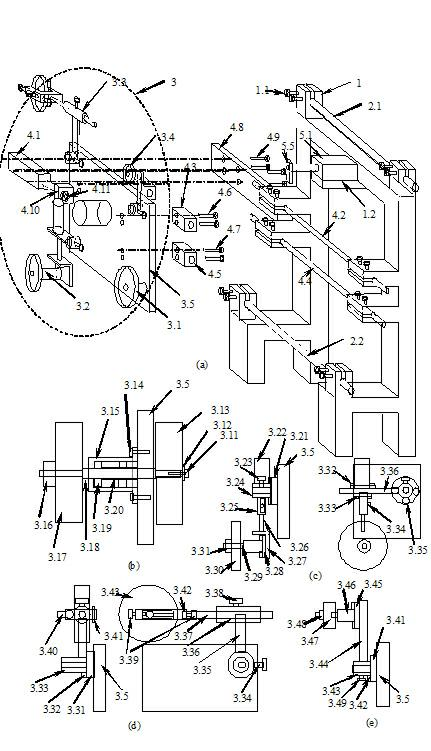

Automatic belt-switching vertical sanding machine tool for robot

InactiveCN102248468AAvoid singular positionsLarge working spaceBelt grinding machinesContinuous/uninterruptedEngineering

The invention discloses an automatic belt-switching vertical sanding machine tool for a robot. The sanding of parts is finished on four machine tools in the cooperation of four groups of machine tools and an industrial robot; a sanding wheel system (3) is composed of a sanding driving wheel (3.1), a fixed wheel (3.4), a pneumatic tension wheel (3.2) and a deviation-adjusting wheel (3.3), and a sand belt is tensioned on four wheels; a wheel system forward-backward device (4) is composed of a guide rail and a telescopic cylinder, a sliding table (4.3) of the guide rail is connected with a wheel system supporting board, a guide rod (4.2) of the guide rail is connected with a frame (1) of the machine tool, the telescopic cylinder (4.1) is fixed on the frame (1); a belt-unloading cylinder (5.1) is mounted on the frame (1), a belt-loading cylinder (5.2) is mounted on a machine shell (2), a sand belt prepositioning mechanism (5.3) and a sand belt pre-tensioning mechanism (5.4) are mounted on the machine shell (2) of the machine tool. The industrial robot provided by the invention can carry out continuously sanding on mass parts, the parts processing efficiency is high, and the automatic sanding of the parts is actually realized.

Owner:煜雄机器人有限公司

Tension adjustment device for high-strength fiber laid fabric

PendingCN110654915AGuaranteed constant tensionGuarantee product qualityWebs handlingFiberProduction line

The invention discloses a tension adjustment device for a high-strength fiber laid fabric. The tension adjustment device comprises a support and a press roller movably arranged on the support, and thewhole tension adjustment device is arranged between two rollers in a production line. The support is fixed on the ground. Laid fabric fibers pass the press roller from below. The tension adjustment device can be arranged between the two rollers in the production line when in use. During the use, the press roller moves downwards under the action of a balancing weight and the gravity and continuously apply downward pressure onto polyethylene fibers on the production line. Even if the fibers are used for a long time and stretched, the press roller still moves downwards and continuously apply pressure onto the fibers. Thus, the tension of the fibers cannot be reduced suddenly. The fibers are continuously tightened. Further, the production quality is guaranteed.

Owner:JINLING INST OF TECH

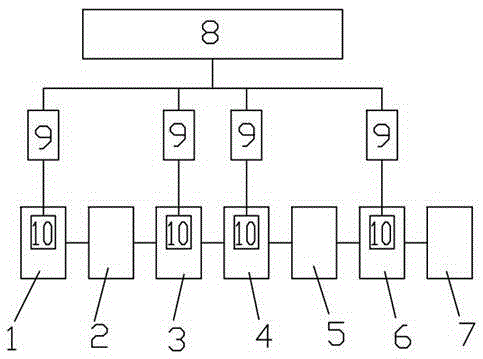

Constant tension control system of composite production line

InactiveCN106044332APrevent looseningIncreased level of controlWebs handlingProduction lineEngineering

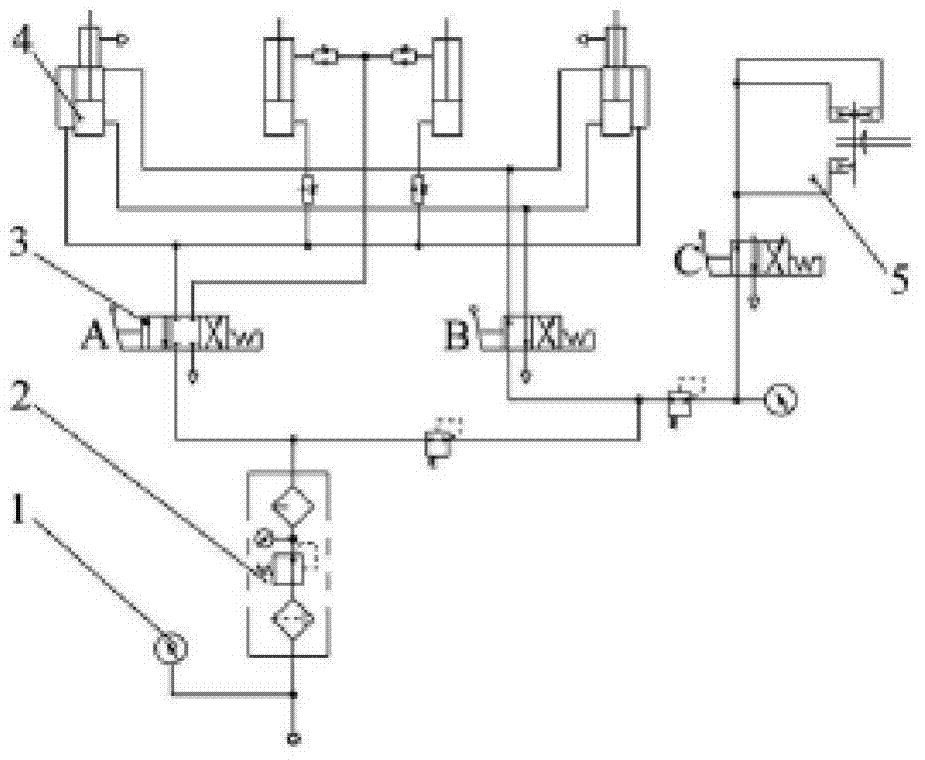

The invention discloses a constant tension control system of a composite production line. The constant tension control system comprises a PLC, a variable frequency driver, a variable frequency motor and a sensing encoder. The PLC is connected with the variable frequency driver through a communication line. The variable frequency driver is connected with the variable frequency motor through a communication line. The PLC transmits a motion instruction to the variable frequency driver to control the variable frequency driver to drive the variable frequency motor so as to realize the unwinding, compounding and winding process of the composite production line. The sensing encoder is arranged on the variable frequency motor and is connected with the PLC through a communication line to transmit feedback signals of motion of the variable frequency motor to the PLC so as to adjust the instruction transmitted to the variable frequency driver by the PLC. The constant tension control system is used for guaranteeing constant tension of all devices on the composite production line, so that the control level of material quality is improved, and the production cost is lowered.

Owner:徐仕坚

Discharge damping device of bag making machine

InactiveCN107781354AUnloading is stableImprove product qualityVibration suppression adjustmentsDisk bufferDamping function

The invention discloses a material discharging damping device for a bag making machine, which mainly includes a fixed end, a friction damping mechanism, a pressure regulating mechanism and a transmission mechanism thereof; A pressure plate, a spline, a preload spring, a pressure adjustment mechanism including a shift fork, a shift fork spring, and an adjustment handle, and a transmission mechanism including a friction disc, a driven gear, and a driven shaft. In the present invention, the pressure plate squeezes the buffer plate, and the buffer plate further squeezes the friction plate to transfer the frictional resistance to the friction plate, and finally realizes the function of damping and discharging through the transmission mechanism, wherein the buffer plate plays a role of buffering when the pressure plate pressure changes suddenly. The function makes the unwinding more stable, ensures the constant tension during unwinding, and improves the product quality to a certain extent.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

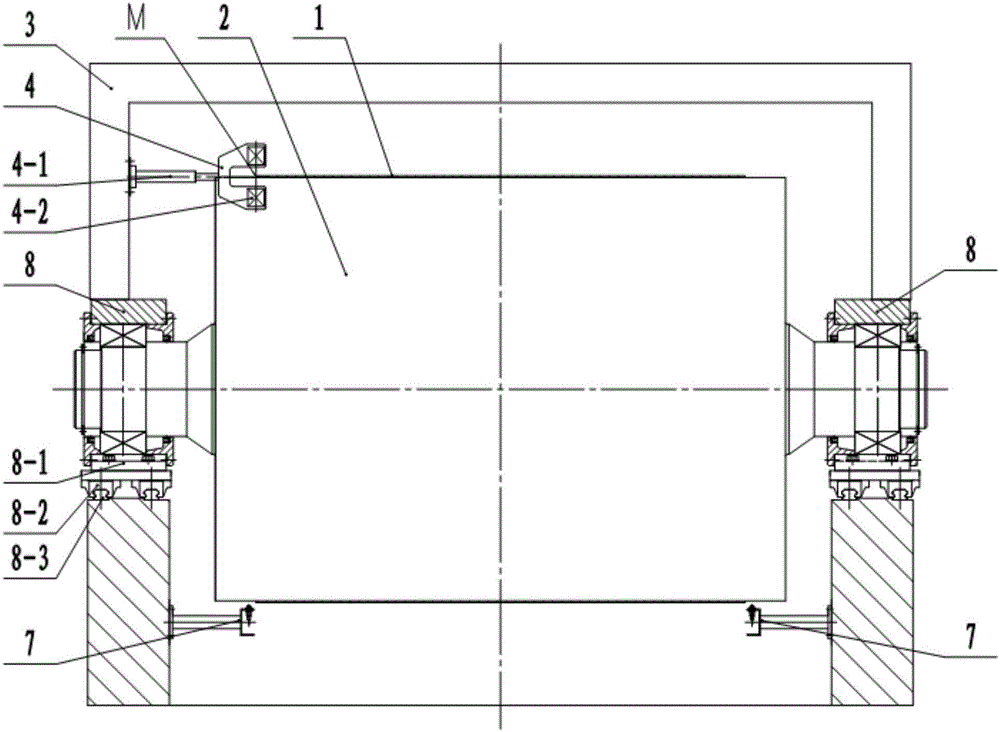

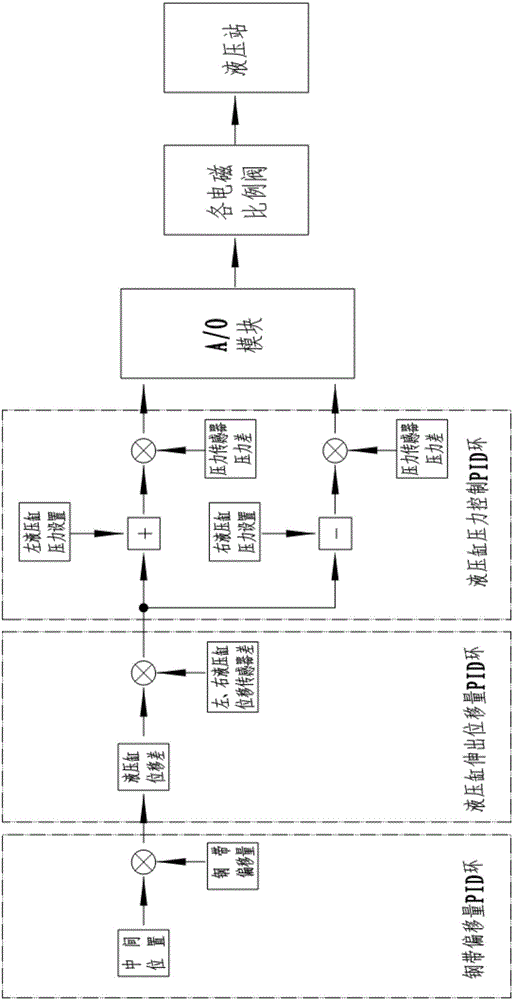

Tensioning and rectifying system of steel belt of plastic film casting machine set

ActiveCN106514919AGet offset in real timeOffset guaranteeFlat articlesCoatingsHydraulic cylinderEngineering

The invention provides a tensioning and rectifying system of a steel belt of a plastic film casting machine set. The system comprises the steel belt, a driving roller, a tensioning cold roller, a base, a hydraulic system and a PLC system, wherein the hydraulic system comprises a left hydraulic cylinder, a right hydraulic cylinder, pressure sensors, displacement sensors and hydraulic stations; the PLC system comprises a plurality of PID rings and AO modules; pistons of the left hydraulic cylinder and the right hydraulic cylinder are controlled to move through PID operation, and two shaft ends of the tensioning cold rollers are accordingly driven to move, so as to achieve the rectifying and tensioning of the steel belt; a side edge detecting sensor is arranged at the edge of one side of the steel belt and used for detecting the offset of the steel belt in real time; extreme position proximity switches are arranged at two sides of the steel belt and used for protecting the steel belt. The system is provided with a manual control mode for directly setting output pressure value for the left hydraulic cylinder and the right hydraulic cylinder. With the adoption of the system, the offset of the steel belt in running can be effectively kept within a fixed range, and meanwhile, the tensioning force of the steel belt is constant, and as a result, the consistency of the steel belt in running and the quality of thick cast sheets can be obviously improved.

Owner:桂林格莱斯科技有限公司

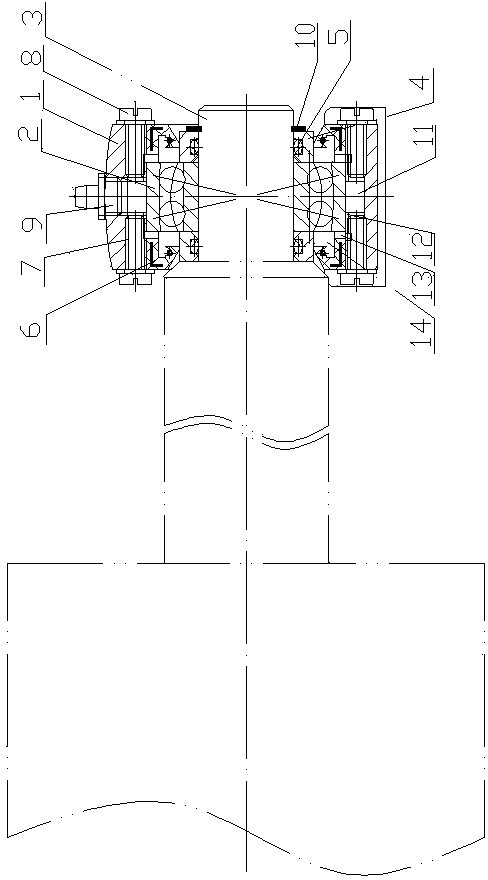

Oil storing bearing mechanism

InactiveCN103807305AGood long-lasting lubrication protectionEliminate stagnationBearing unit rigid supportPapermakingDouble row

The invention discloses an oil storing bearing mechanism relating to the technical field of spinning, plastic, papermaking and tanning. The oil storing bearing mechanism comprises a bearing base, double rows of self-aligning bearings and guiding roller shaft necks, wherein the guiding roller shaft necks arranged on the two sides of the double rows of self-aligning bearings are respectively sleeved with shaft neck abrasive discs; the two sides of the double rows of self-aligning bearings are respectively provided with a fluororubber groove oil seal, the two end surfaces of the bearing base are respectively provided with screw holes, and each screw hole is internally in threaded connection with a magnetism screw; the top of the bearing base is provided with an oil filling cup screw hole, and the front ends of the guiding roller shaft necks are respectively provided with clamp spring check ring locks for a shaft; a first oil storing groove is formed in the periphery of the inner hole wall of the bearing base, and second oil storing grooves are symmetrically formed in the inner hole walls of the bearing base on the two sides of the first oil storing groove; four oil grooves are uniformly formed in the end surface of one side, which are close to one side of the double rows of self-aligning bearing, of the fluororubber groove oil seals, a cavity is arranged on one side of the combining surface of the fluororubber groove oil seals and the double rows of aligning bearings. The oil storing bearing mechanism provided by the invention has the advantages that of being durable and reliable in performance, saving cost, reducing consumption, and being suitable for multiple heat sources.

Owner:扬州市江都印染机械有限公司

Tension adjusting mechanism for copper foil surface treating machine

The invention relates to a tension adjusting mechanism for a copper foil surface treating machine; an upper bracket is fixed on the upper surface of a lower bracket; a guide roller is arranged in the middle of the upper surface of the lower bracket; a counterweight roller is positioned at one side of a tension adjusting roller and below the longitudinal beam of the lower bracket; the counterweight roller is hung at one end of a steel wire rope by virtue of fixed pulleys; the tension adjusting roller is positioned at the other side of the counterweight roller and above the longitudinal beam of the lower bracket; the tension adjusting roller is arranged on guide rod fixing seats positioned on the upper surface of the lower bracket; the pair of fixed pulleys are respectively arranged on the upper surface of a longitudinal beam of the upper bracket; the pair of guide rod fixing seats are respectively positioned on the upper surface of the lower bracket and the lower surface of the longitudinal beam of the upper bracket; and the positions of the two guide rod fixing seats correspond to each other. The tensile force generated by the gravity of a counterweight block is direct, and a copper foil is ensured to be tensioned since the change of the tensile force generated by the instant relaxation and tension of the copper foil can be made up by the movement of the tension adjusting roller at any time, so that the tensile force of the rolled copper foil is guaranteed to be constant. The tension adjusting mechanism has the characteristics of being simple in processing and installing as well as simple and convenient to operate, control and use.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

V-shaped geometric form of middle plate structure of middle groove

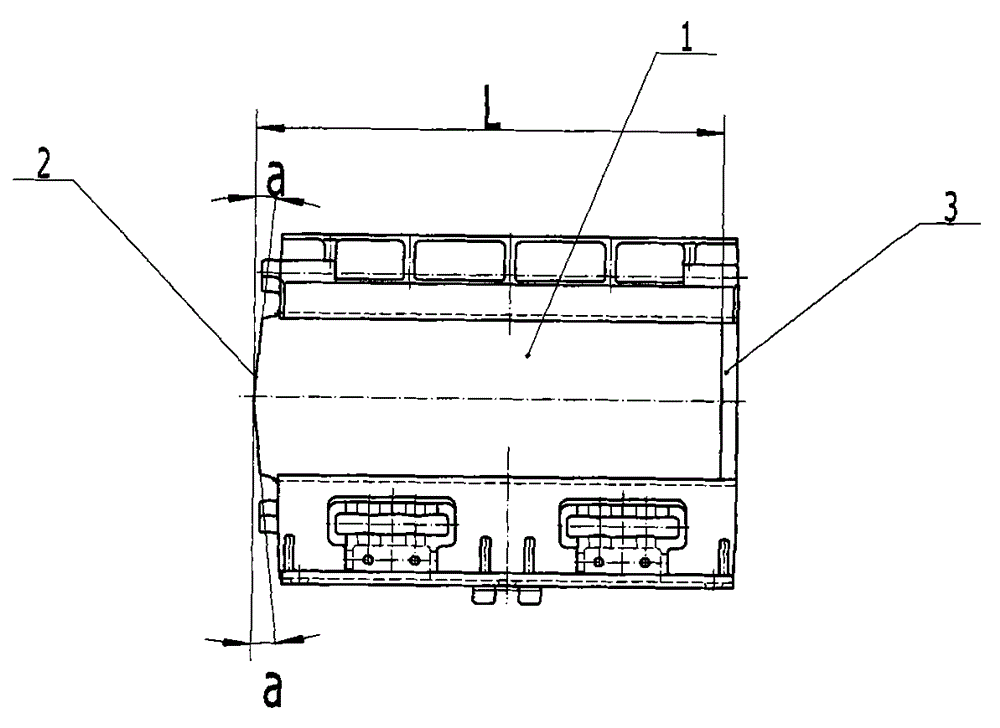

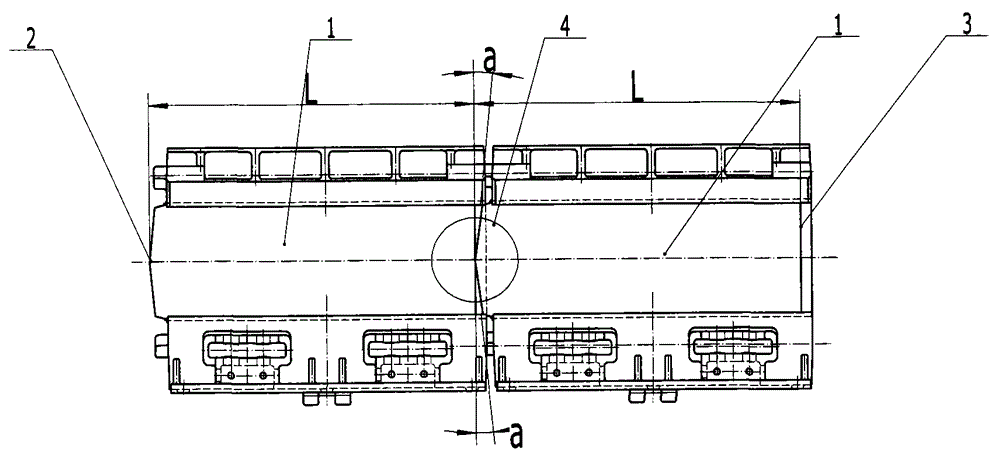

InactiveCN105292940AMeet corner needsTo achieve the purpose of constant tensionConveyorsGeometric formLateral displacement

The invention discloses a V-shaped geometric form of a middle plate structure of a middle groove. A head end (2) of a middle plate (1) of a middle groove part of a traditional scraper conveyer is designed as a V-shaped edge port with an outward obtuse angle; the V-shaped port is corresponding to a vertical surface of a center line of the middle plate to form an included angle a; a traditional straight port is remained at a tail end (3); meanwhile, the length from a sharp angle at a V end (2) of the head end of the middle plate to a flat port (3) at the tail end is a standard section length L; the shape and size consistency of the middle groove part is kept in operation; in installation and linkage, a K-shaped connecting form is formed in the head-tail connecting place of the middle plate in the middle of each section of the middle groove, so that a gap included angle is formed; and no-gap linkage is realized through head-tail leaning of the middle plate. The no-gap linkage can guarantee constant tension of a ring chain, so that the displacement and the impact of the middle groove in a working state are effectively controlled, and the turning demands needed by the formation of an S-shaped curved line in lateral displacement of the middle groove are guaranteed.

Owner:史庆丰

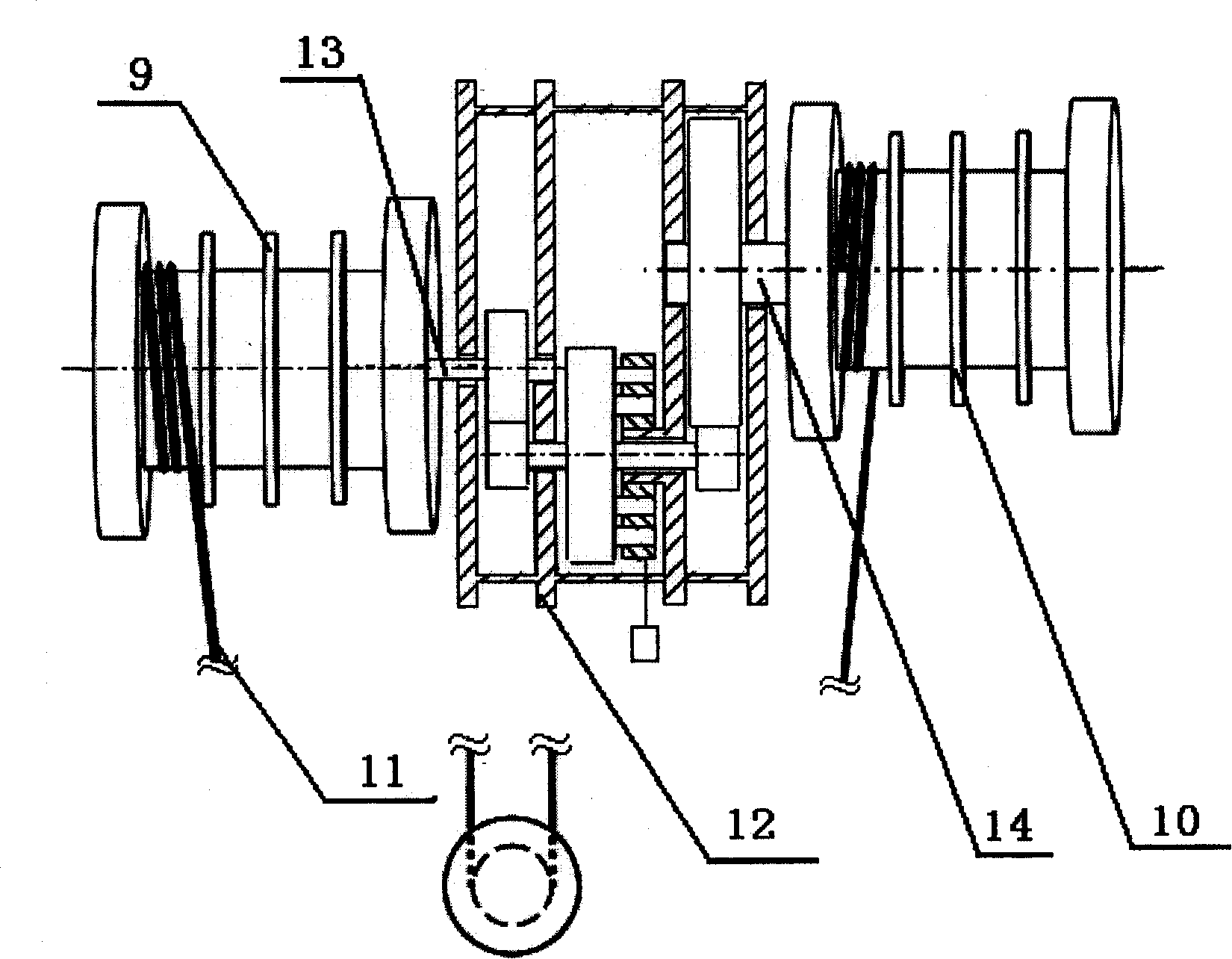

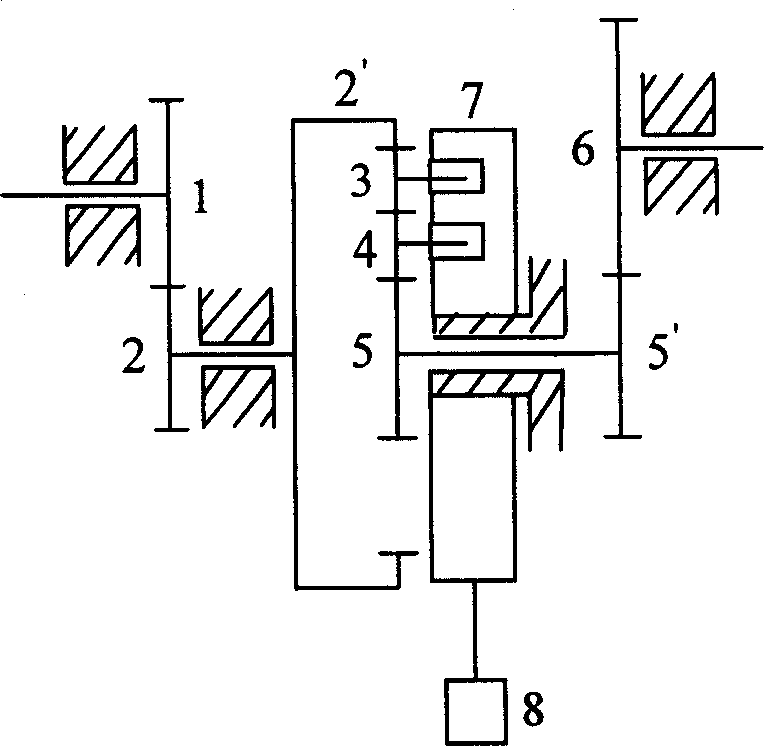

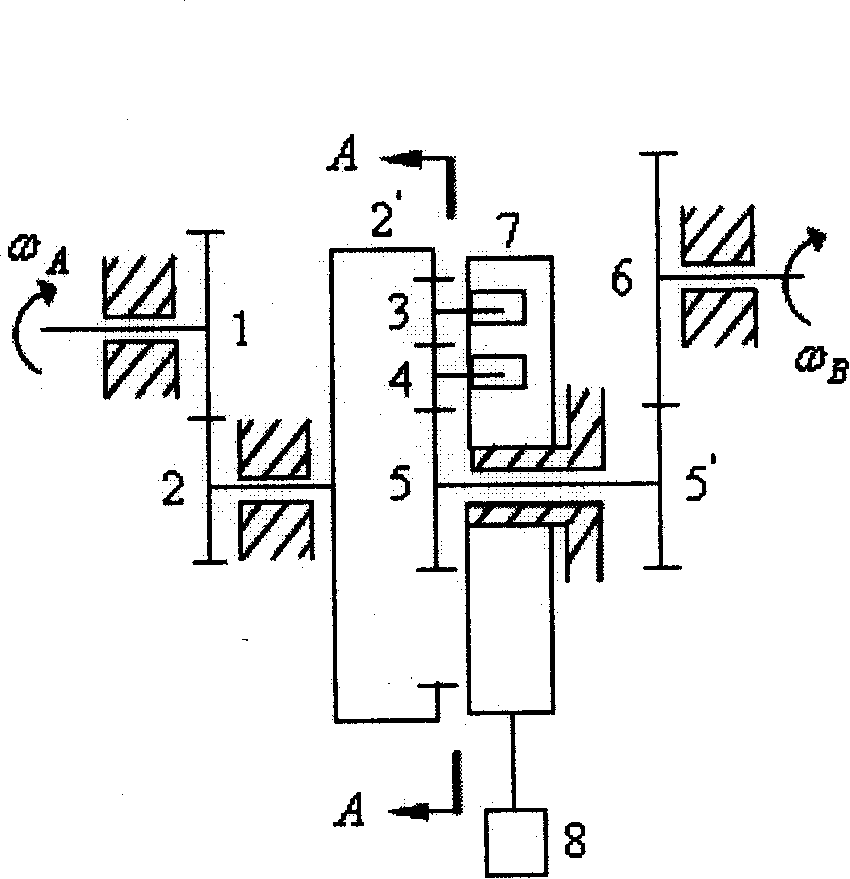

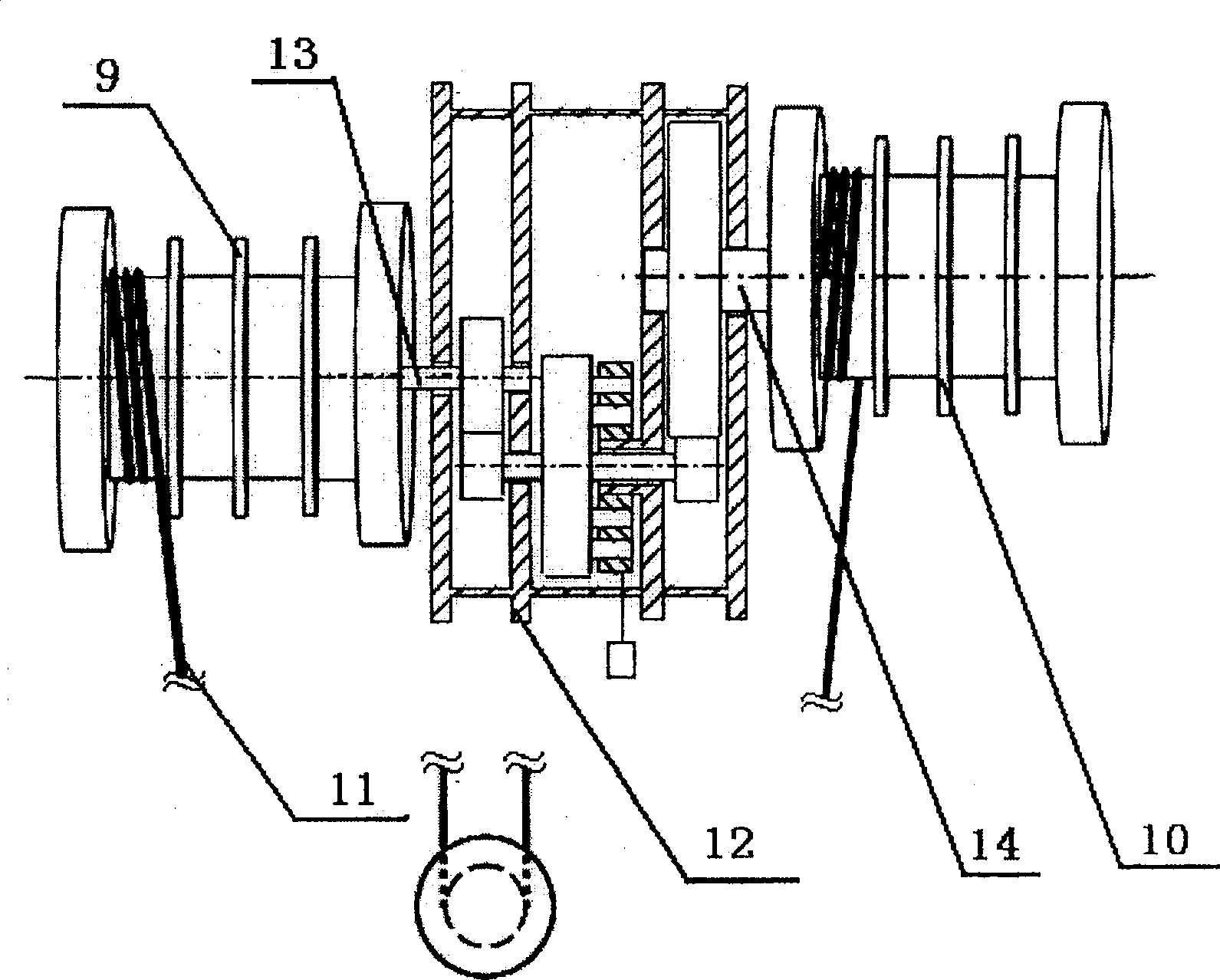

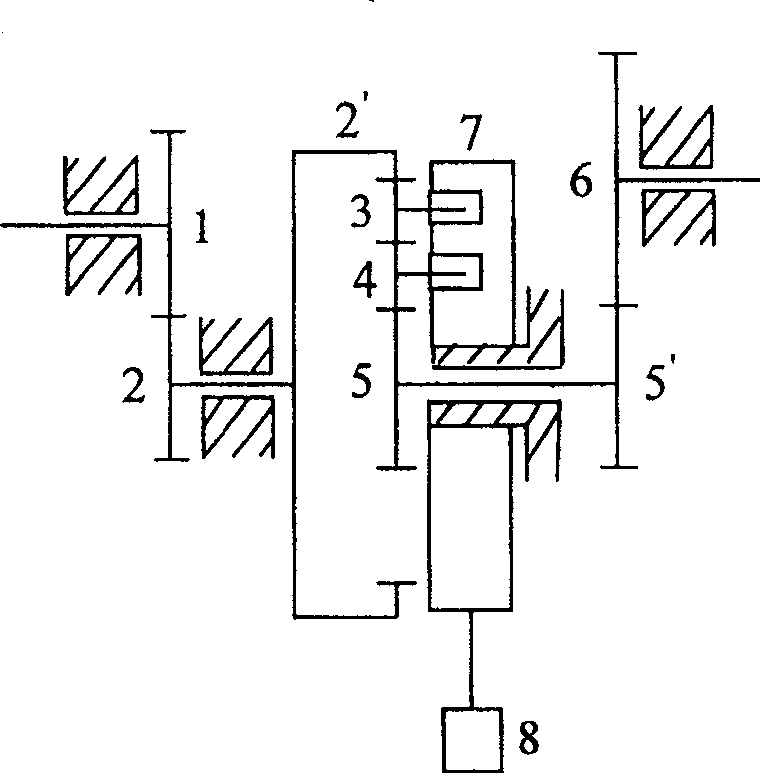

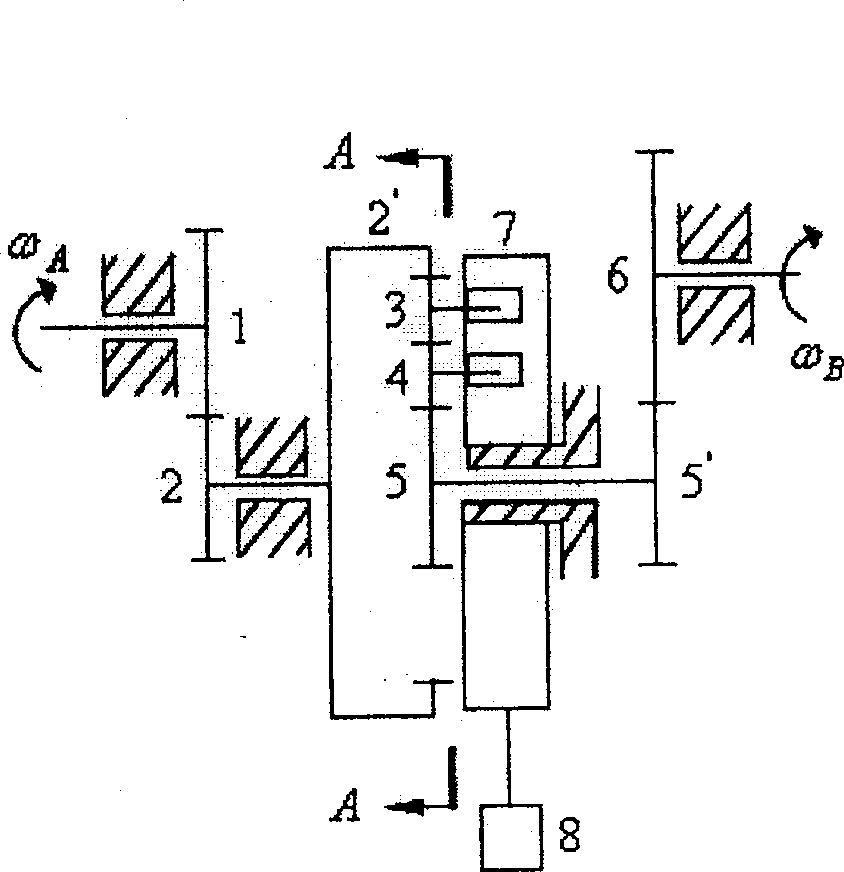

Self-adaption constant torque moment rope-storing system for rock roadway subsidiary transport system

InactiveCN101190772AGuaranteed constant tensionReduce the maximum rotational differenceWinding mechanismsAuto regulationTransport system

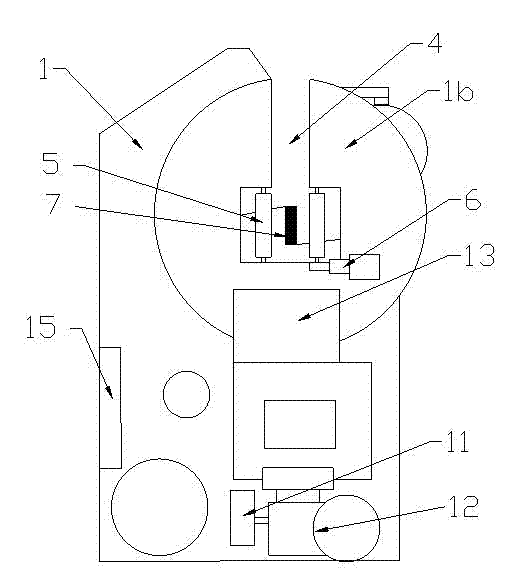

The invention discloses an adaptive constant-torque stored rope device used in the rock drift aided transportation system, which consists of two stored rope rollers (9, 10), and a double planet wheel differential control rotation adjusting device(12) is arranged between the two stored rope rollers (9, 10), furthermore, the axles of the two stored rope rollers (9, 10) are correspondingly and respectively connected with the two axles of the rotation adjusting device (12) through relevant drive pair (13, 14). The adaptive constant-torque stored rope system provided by the invention has the advantages of ensuring the stored rope system automatically balance the steel rope static tension torque in practical applications, automatically adjusting the rotation angle difference between the stored rope cylinders in two sides, effectively decreasing the maximal rotation difference between the stored rope cylinders in the two sides of the stored rope cylinder system, and optimalizing the stored rope system.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

One-step dipping yarn device

ActiveCN113789623BGuaranteed constant tensionGuaranteed to evaporateLiquid/gas/vapor removalTextile treatment carriersFiberPolymer science

The invention relates to the technical field of carbon fiber dipping, in particular to a one-step dipping yarn device, comprising: a constant tension unwinding mechanism, a twist-free positioning mechanism, a fiber spreading mechanism, a yarn tension sensor, a dipping mechanism, a glue extrusion setting mechanism, and an oven , traction mechanism and cutting mechanism, the yarn is released from the bobbin through the constant tension unwinding mechanism, and the unwinding mechanism is used to spread the released yarn into sheet-like yarn, and then the yarn enters the dipping mechanism. Impregnated with resin, the impregnated yarn is squeezed out of excess resin and shaped by the extrusion setting mechanism. The shaped yarn is thermally cured into a rod-shaped yarn through an oven, and the rod-shaped yarn is pulled by a pulling mechanism. A cutting mechanism is used to cut the cured yarn into segments to complete the entire carbon fiber dipping process. The dipping process of the present invention is completed in one step, with high efficiency, no pores inside after curing, and high product quality.

Owner:NEWTRY COMPOSITE

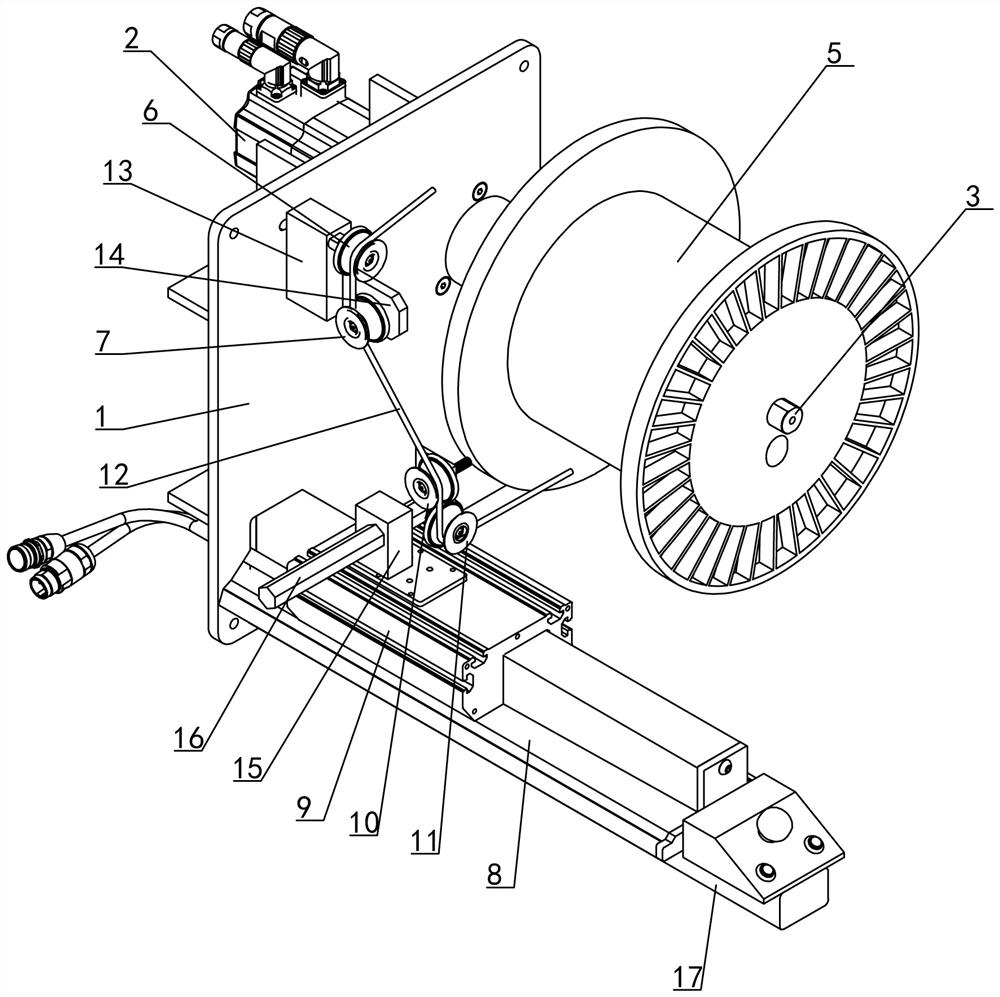

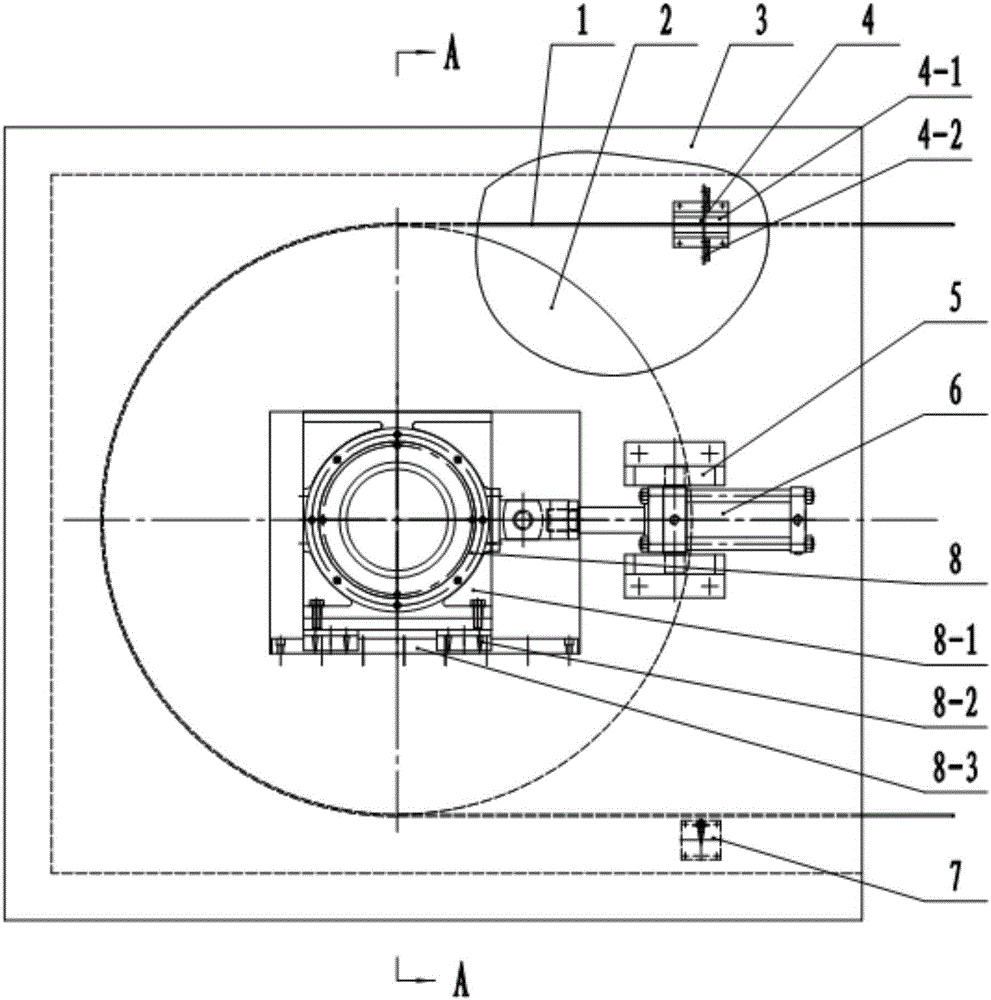

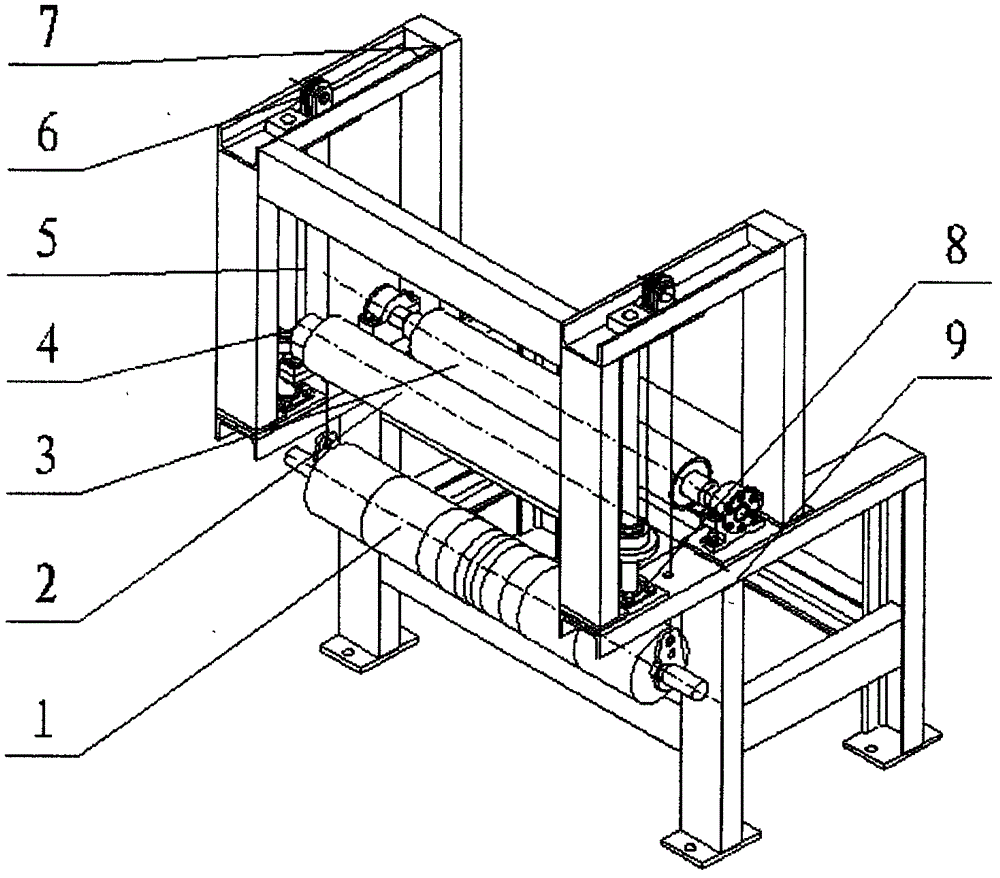

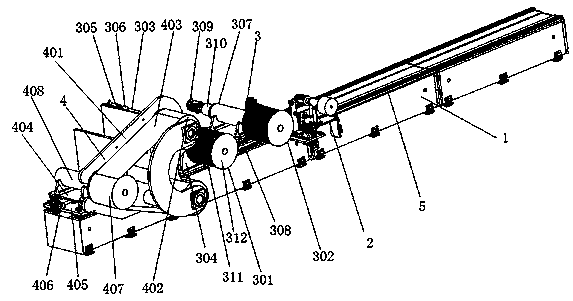

Synchronous belt forming device

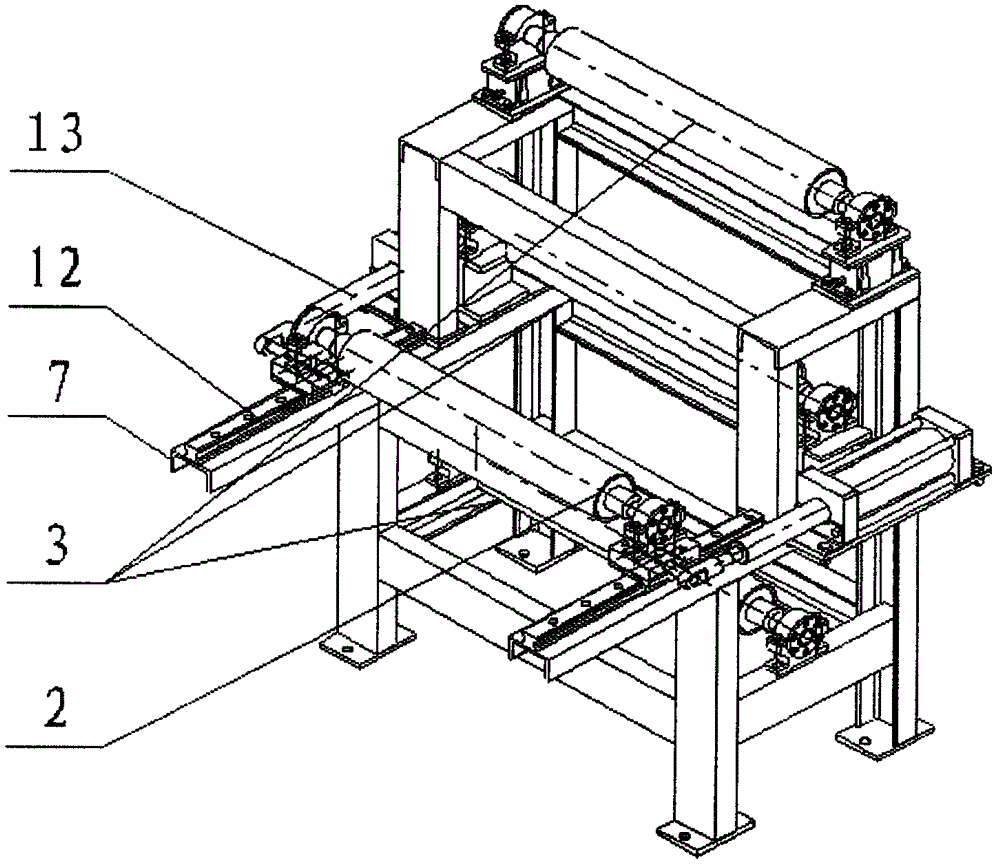

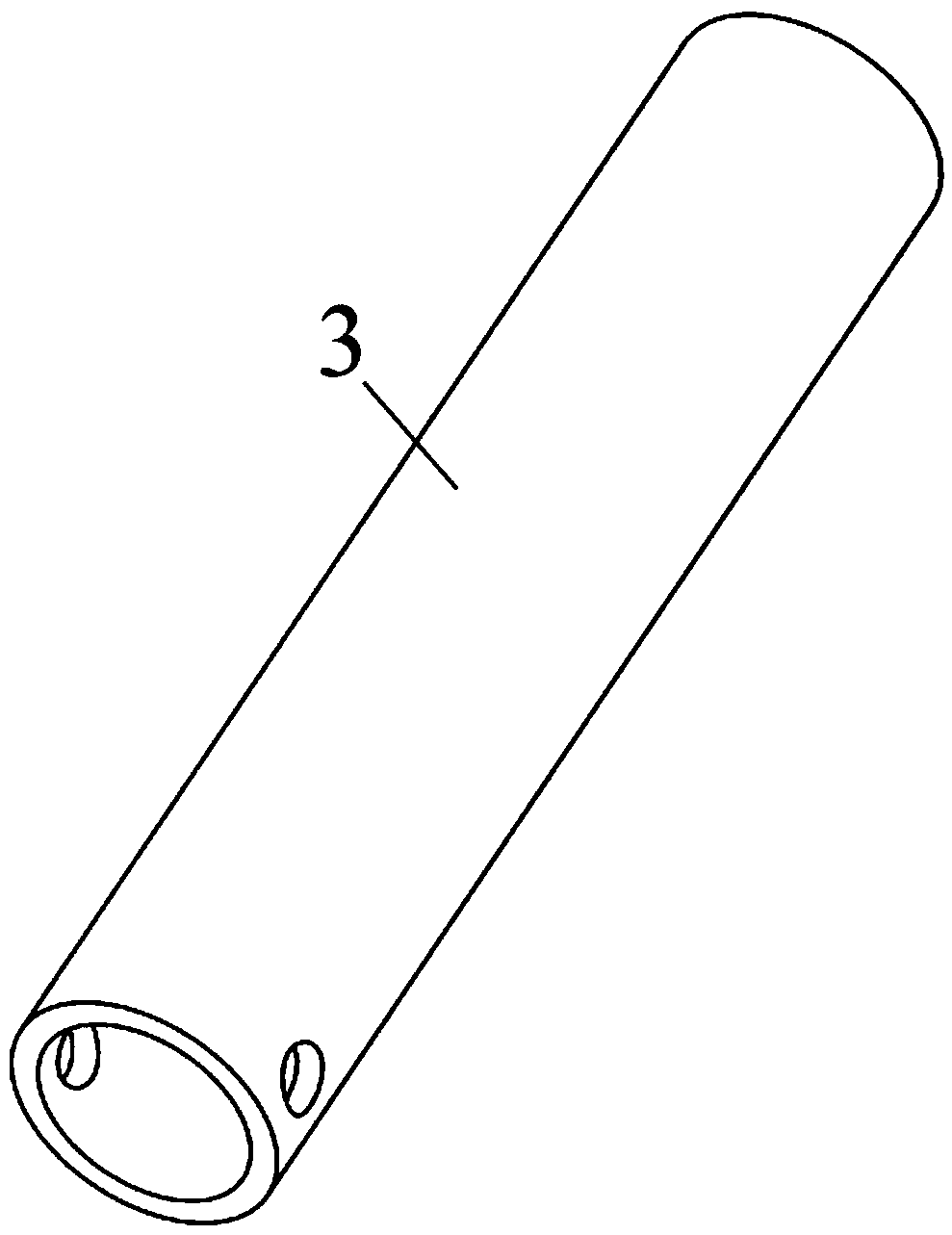

PendingCN111186064AGuaranteed constant tensionReasonable structural designWinding machineClassical mechanics

The invention discloses a synchronous belt forming device. The synchronous belt forming device comprises a rack (1), a steel wire winding mechanism (2), a steel wire output mechanism (3) and a steel belt extrusion forming mechanism (4), wherein the rack (1) is provided with a linear guide rail (5), and the steel wire winding mechanism (2), the steel wire output mechanism (3) and the steel belt extrusion forming mechanism (4) are arranged on the linear guide rail (5) in sequence; and the steel wire winding mechanism (2) comprises a first bottom plate (201), a second bottom plate (202), a reverse wheel installation plate (203), a first spindle box base (204), a first spindle box (205), a first servo motor (206), a steel wire cylinder (207) and a balance weight mechanism (208) which is used for tightening a steel wire up. The synchronous belt forming device is high in production efficiency, high in running stability and high in yield.

Owner:TAIZHOU CHIJUN INTELLIGENT EQUIP CO LTD +1

Self-adaption constant torque moment rope-storing system for rock roadway subsidiary transport system

InactiveCN100542940CGuaranteed constant tensionReduce the maximum rotational differenceWinding mechanismsAuto regulationTransport system

The invention discloses an adaptive constant-torque stored rope device used in the rock drift aided transportation system, which consists of two stored rope rollers (9, 10), and a double planet wheel differential control rotation adjusting device(12) is arranged between the two stored rope rollers (9, 10), furthermore, the axles of the two stored rope rollers (9, 10) are correspondingly and respectively connected with the two axles of the rotation adjusting device (12) through relevant drive pair (13, 14). The adaptive constant-torque stored rope system provided by the invention has the advantages of ensuring the stored rope system automatically balance the steel rope static tension torque in practical applications, automatically adjusting the rotation angle difference between the stored rope cylinders in two sides, effectively decreasing the maximal rotation difference between the stored rope cylinders in the two sides of the stored rope cylinder system, and optimalizing the stored rope system.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

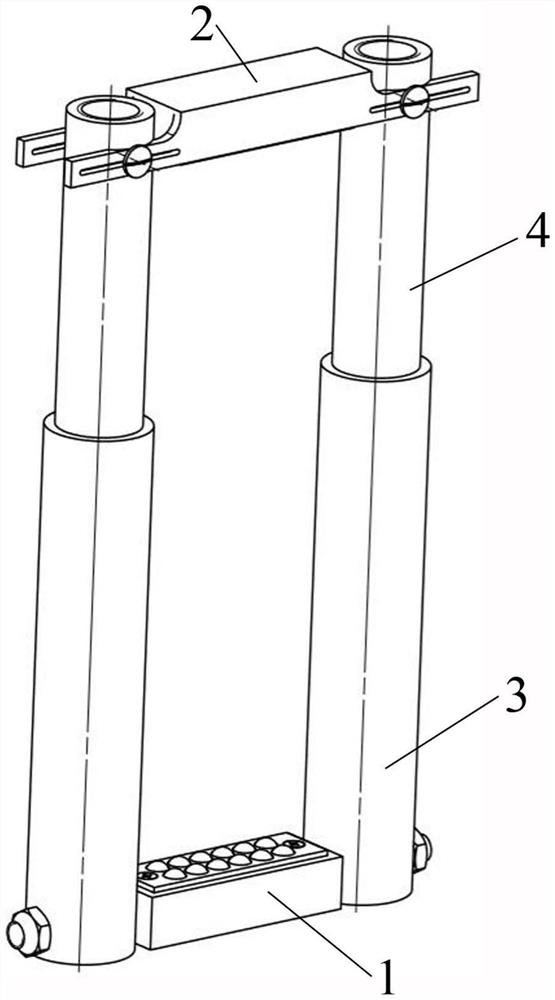

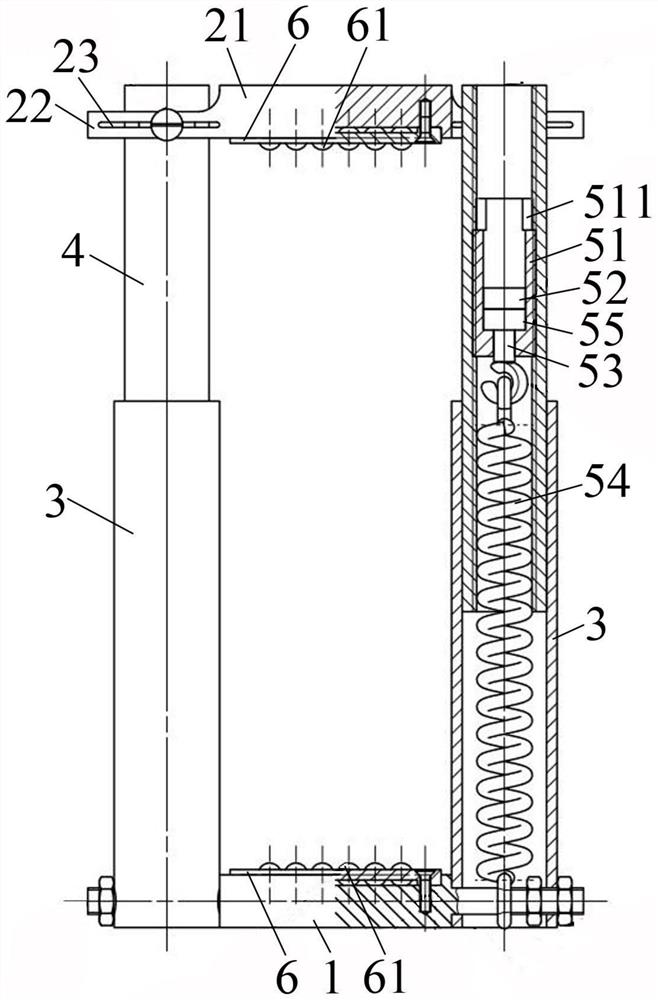

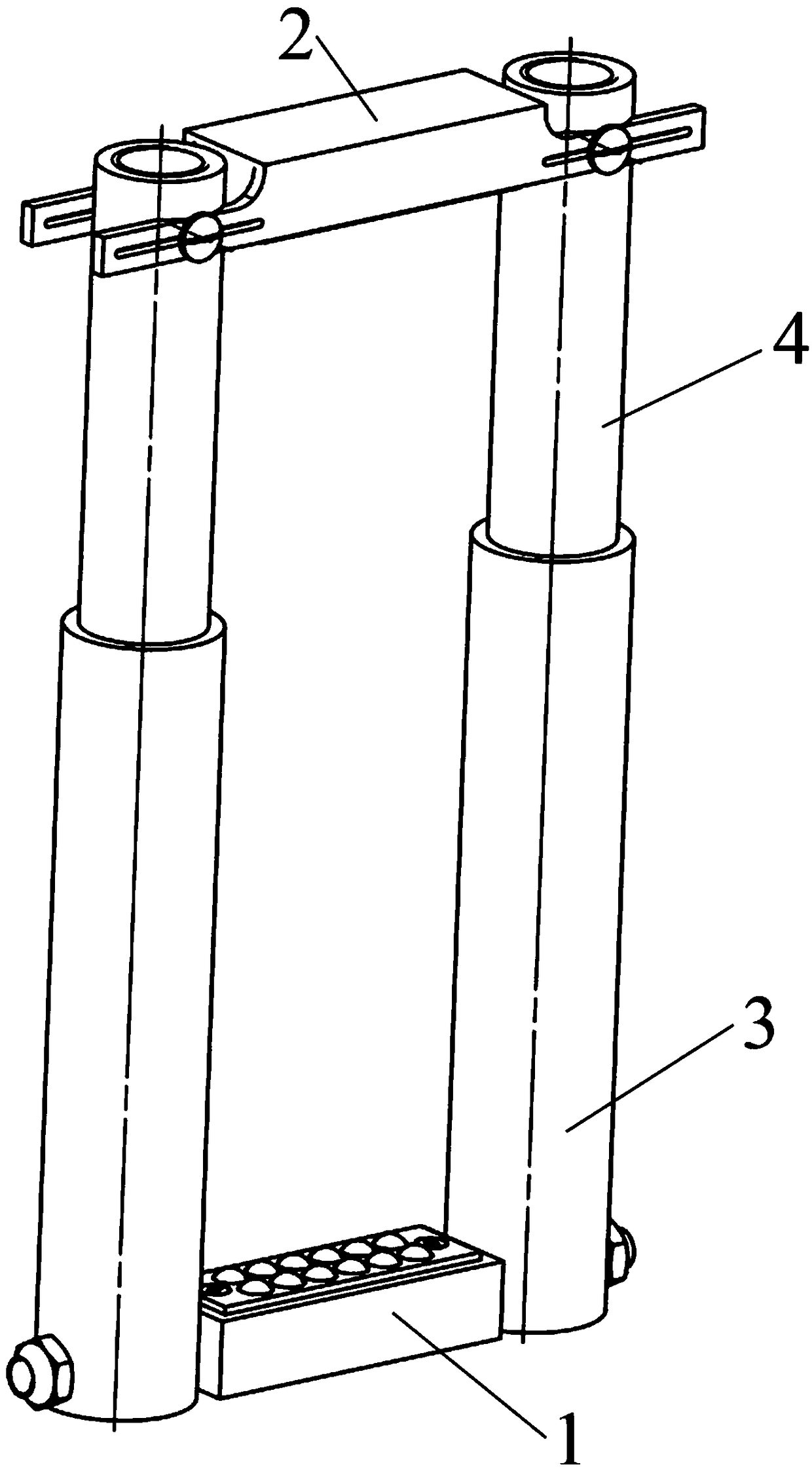

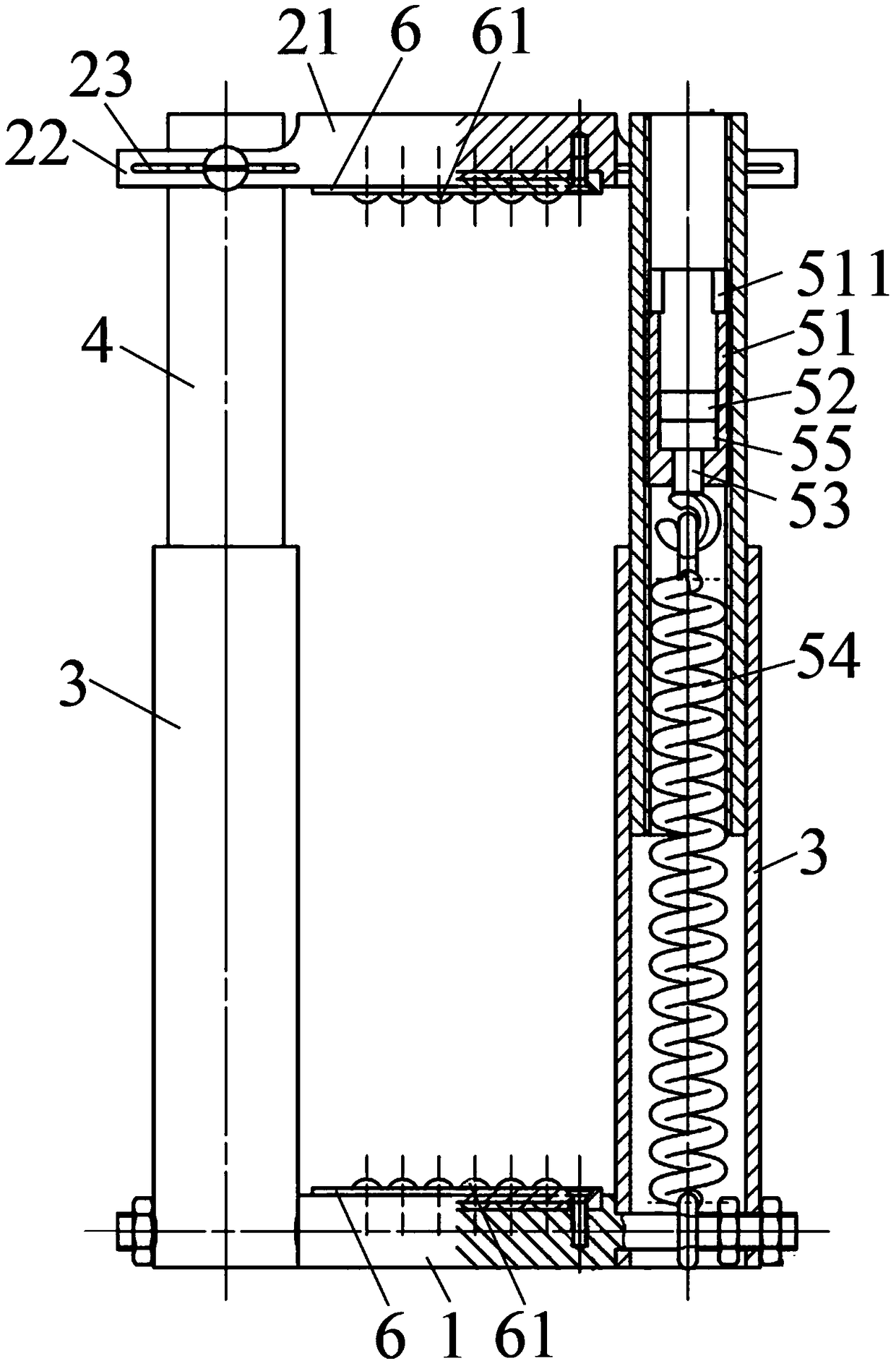

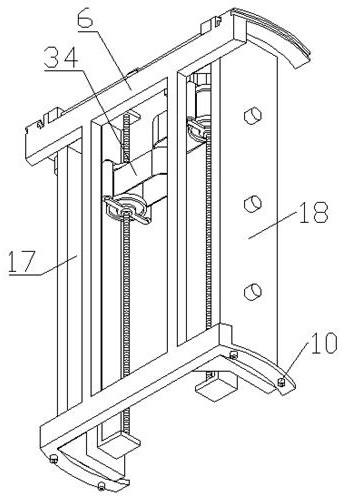

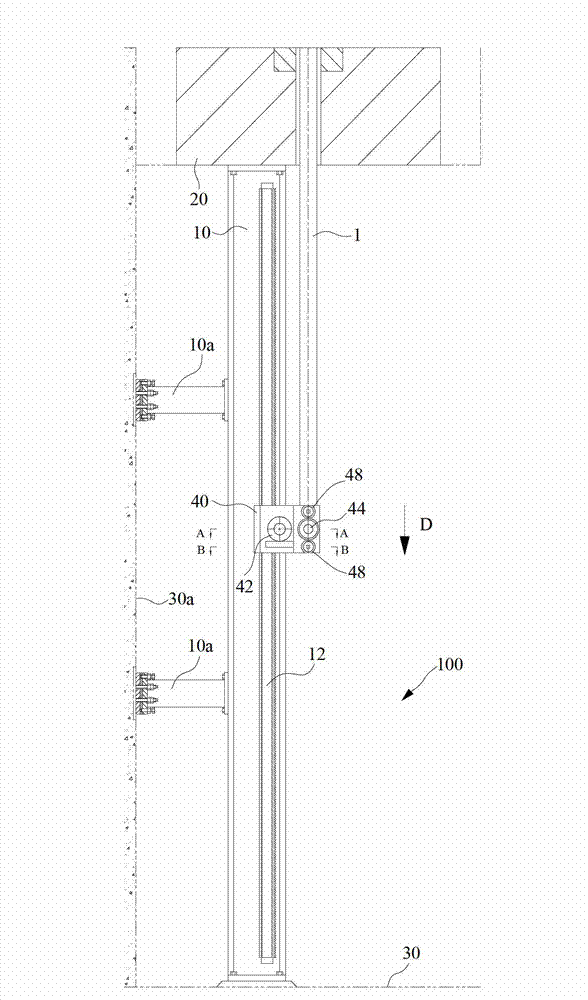

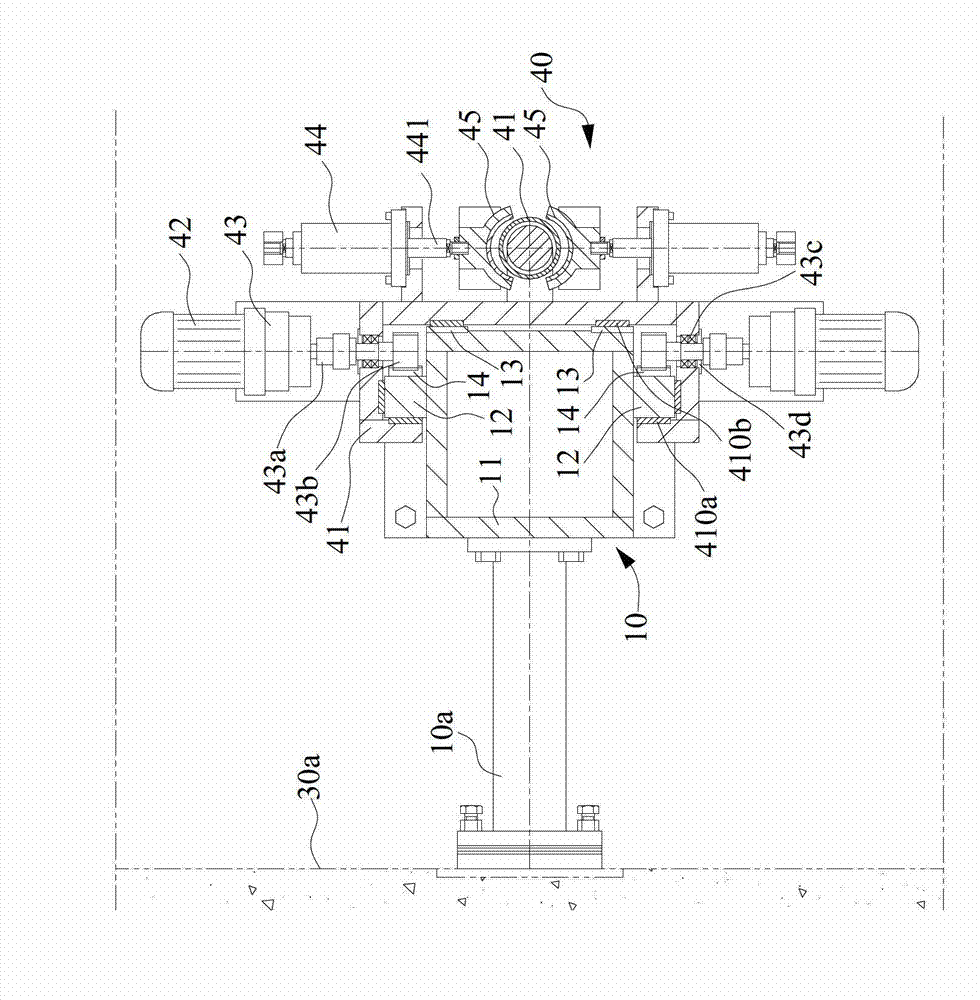

Traction device for vertical aluminum alloy pipe production line

The invention provides a traction device for a vertical aluminum alloy pipe production line. The traction device is used for drawing and extruding produced aluminum alloy pipes and comprises upright columns and a traction trolley capable of walking on the upright columns; the upper ends and / or the lower ends of the upright columns are respectively connected to a base and a lower foundation of the vertical aluminum alloy pipe production line; the aluminum alloy pipes are extruded to extend from a position below the base; the traction trolley comprises clamping pieces; and the clamping pieces are clamped at one ends of the aluminum alloy pipes, so that the traction trolley can draw the aluminum alloy pipes to move downwards.

Owner:TAIYUAN HEAVY IND

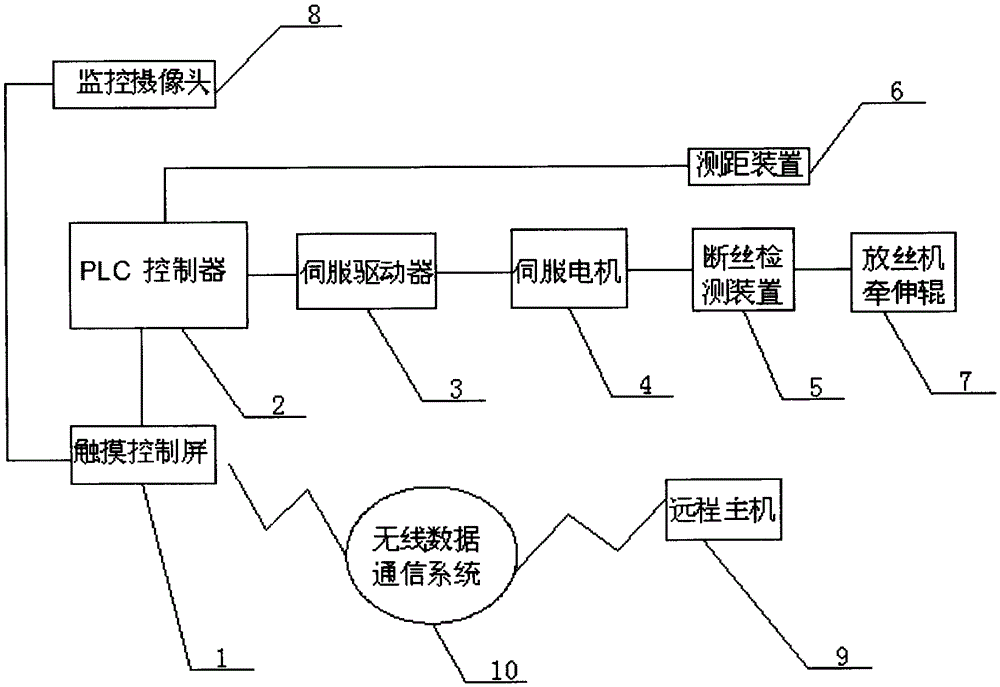

Fiber feeding machine control system

InactiveCN105527917AGuaranteed constant tensionControl healthProgramme control in sequence/logic controllersFiberCarbon fibers

The invention provides a fiber feeding machine control system, relating to the technical field of carbon fiber manufacturing equipment. A touch control screen is arranged on a PLC which is connected to a servo driver through a communication line. The servo driver is connected to a servo motor through a communication line. The servo motor is connected to a fiber breaking detection device which is connected to a fiber laying machine drawing roller. A distance measuring device is connected to the PLC. A monitoring camera is arranged above a fiber feeding machine and is connected to the touch control screen. A remote host machine is connected to the touch control screen through a wireless data communication system. The constant tension of a fiber feeding system can be ensured, and the current fiber length can be detected and displayed in real time. A good man-machine communication interface also is provided, and the machine running condition can be remotely displayed and controlled in real time.

Owner:镇江奥立特机械制造有限公司

A belt drive tensioner with adjustable size and tension

A belt drive tensioning clamp with adjustable size and tension force, comprising a fixed plate, including a fixed part and connecting parts arranged on both sides of the fixed part; A set of sliding bars, the sliding bars are also provided with fixing grooves; sleeves, one end of the sleeves is provided with a group of openings pierced through the connecting part, and the sleeves pass through a set of sleeves arranged on the inside of the sleeve and The outer nut is fixed on the connection part; the inner tube is arranged inside the casing, and the upper end of the inner tube is provided with a card slot, and an opening is provided in the card slot, and the slide bar is fixed by a slotted spherical head screw fixed in the card slot; the tension adjustment mechanism is arranged in the casing and the inner tube, one end of the tension adjustment mechanism is fixed on the connecting part, and the other end is fixed in the inner tube, which can adapt to Belt transmission requirements of different sizes can be installed quickly, ensuring constant tension, realizing general transformation, reusable, improving utilization rate and saving cost.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

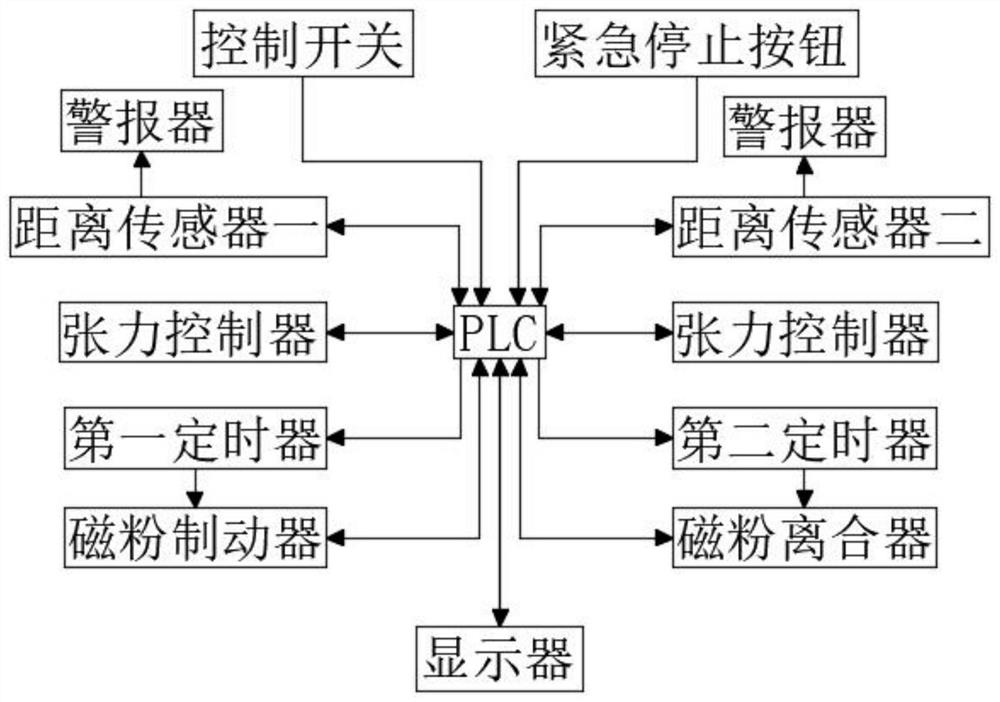

Constant-tension winding and unwinding hardware control system with synchronous winding and unwinding function

PendingCN114084724AEliminate errorsRealize the function of synchronous winding and unwindingWebs handlingBrakeControl system

The invention discloses a constant-tension winding and unwinding hardware control system with a synchronous winding and unwinding function, wherein the system comprises a PLC, the PLC is electrically connected with a first timer and a second timer respectively, and the PLC is bidirectionally and electrically connected with a first distance sensor, a second distance sensor, a magnetic powder brake, a magnetic powder clutch, a displayer and two tension controllers respectively; and the first timer and the second timer are electrically connected with the magnetic powder brake and the magnetic powder clutch respectively. The distance sensors are arranged to assist the tension controllers in use, the distance sensors are used for measuring the specific fixed distance between the distance sensors and a material in advance, the drooping condition of the material can be measured in time at the moment that the tension drops, the tension controllers adjust the tension in time, the drooping condition of the material is avoided, long-time operation of constant tension of the system is guaranteed, the winding mechanism is prevented from winding the material which does not meet requirements when the material droops, and the quality of the material is improved.

Owner:ZHEJIANG GONGPING SMART EQUIP CO LTD

Size and tensioning force adjusting belt drive tensioning clamp

A size and tensioning force adjusting belt drive tensioning clamp comprises a fixed board, a movable board, a casing pipe, an inner pipe and a tensioning force adjusting mechanism, wherein the fixed board comprises a fixed portion and connection portions arranged on two sides of the fixed portion; the movable board comprises a movable board body and a set of slide strips on two sides of the movable board body; the slide strips are provided with fixing grooves; one end of the casing pipe is provided with a set of open holes penetrating into the connection portions; the casing pipe is fixed to the connection portions through a set of nuts arranged on the inner side and the outer side of the casing pipe; the inner pipe is arranged inside the casing pipe; a clamping groove is formed in one endof the inner pipe; an open hole is formed in the clamping groove; the slide strips are fixed into the clamping groove through grooved sphere face cylindrical head screws; the tensioning force adjusting mechanism is arranged inside the casing pipe and the inner pipe; one end of the tensioning force adjusting mechanism is fixed to the connection portions; and the other end of the tensioning force adjusting mechanism is fixed in the inner pipe. The size and tensioning force adjusting belt drive tensioning clamp can adapt to belt drive requirements for different sizes, can be rapidly mounted, ensures the constant tensioning force, achieves general modification, can be recycled, improves the utilization rate and saves the cost.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

Wrapping head

ActiveCN102185435BUniform qualityGuaranteed constant tensionApplying solid insulationUniform - qualityMechanical engineering

The invention discloses a wrapping head of a wrapping machine, particularly relating to a wrapping head of a generator bar wrapping machine. The wrapping head is characterized by comprising a fixing disc with an opening, and an internal ring arranged on the side surface at one end of the fixing disc, wherein the internal ring is internally provided with a roller that can clamp a bar in a rolling way; the internal ring is externally provided with a wrapping ring that can rotate around the internal ring; the rotating speed and the rotating direction of the wrapping ring can be adjusted; openings are arranged at the positions at the internal ring and the wrapping ring, corresponding to the fixing disc; one side surface of the wrapping ring is provided with a chuck and a tensioning wheel, wherein the wrapping disc can be assembled on the chuck; and the tensioning wheel can adjust the tensioning force of a wrapping belt. The wrapping head can ensure that the wrapping belt has constant tension and is not stretched or broken during the wrapping process; the tensioning force can be freely adjusted within 1kg to 15kg, thus meeting the requirements of different strip belt materials; the superposing degree can be controlled by the superposing positions of 1 / 2, 1 / 3 and the ends, thus ensuring the wrapping belt to have uniform quality.

Owner:GOODE EIS SUZHOU CORP LTD

Wire puller for winding and winding device

PendingCN114735533ASolve loose phenomenaGuaranteed constant tensionFilament handlingClassical mechanicsPulley

The wire puller comprises a base, an adjusting device arranged at one end of the base and a reverse buffering device arranged in the center of the base, the adjusting device comprises a pulley, a bridging rod of a Z-shaped structure, a baffle, an extension spring, a fixing base and an electric air cylinder, the pulley is arranged at one end of the bridging rod through a bearing in a sleeving mode, and the baffle is arranged on the base. The electric air cylinder is arranged on the side, close to the baffle, of the base through a fixing base, and an air rod of the electric air cylinder is connected with the baffle through an extension spring. The reverse buffering device comprises a mounting base, a positioning shaft and a tensioning wheel, the positioning shaft is located on the side, close to the pulley, of the base, the tensioning wheel is arranged on the positioning shaft in a sleeving mode and connected with the mounting base through the positioning shaft, and the mounting base is located between the tensioning wheel and the base and inserted into the base; according to the rope winding device, when a rope is wound, the rope can be in a constant stress and tightening state all the time, and when encountering special situations, reverse buffering can be conducted immediately, so that the rope stops moving gradually.

Owner:JIANGSU HAIFENG ROPE TECH CO LTD

Tree painting device for landscaping

InactiveCN113424736AGuaranteed constant tensionEffective squeezePlant protectionRolling-element bearingGear wheel

The invention discloses a tree painting device for landscaping, which comprises a base, universal wheels, supporting columns, an arc-shaped rail, an arc-shaped gear ring, a supporting frame, a bearing seat, a two-way screw rod, a hexagonal column, a rolling bearing, a dovetail seat, a supporting shaft, a transmission gear, a reduction gearbox, a transmission motor and a smearing part, wherein the plurality of universal wheels are fixed to the bottom end of the base, and the plurality of supporting columns are fixed to the top end of the base. According to the tree painting device, the transmission motor is controlled to rotate forwards and backwards, rolling contact between a smearing belt and trees and a lime water mixture flowing out of a bamboo joint pipe are matched, the surfaces of the trees can be evenly smeared with the lime water mixture, and an adjustable left transmission frame and an adjustable right transmission frame can ensure continuous tightening of the smearing belt, so that effective extrusion on the surface of the trees is realized, lime water can be ensured to fully permeate into gullies and lines on the surfaces of the trees with different thicknesses, and a good protection effect is ensured.

Owner:西安精诚企服信息科技有限公司

Traction device for vertical aluminum alloy pipe production line

The invention provides a traction device for a vertical aluminum alloy pipe production line. The traction device is used for drawing and extruding produced aluminum alloy pipes and comprises upright columns and a traction trolley capable of walking on the upright columns; the upper ends and / or the lower ends of the upright columns are respectively connected to a base and a lower foundation of the vertical aluminum alloy pipe production line; the aluminum alloy pipes are extruded to extend from a position below the base; the traction trolley comprises clamping pieces; and the clamping pieces are clamped at one ends of the aluminum alloy pipes, so that the traction trolley can draw the aluminum alloy pipes to move downwards.

Owner:TAIYUAN HEAVY IND

1:2 type triangular tooth ratchet compensating device for catenary and additional wire compensating anchor

InactiveCN106494262AGuaranteed constant tensionWith break brake functionTrolley linesEngineeringLine Break

The invention relates to a 1:2 type triangular tooth ratchet compensating device for a catenary and an additional wire compensating anchor. A compensation rope of an ordinary ratchet compensation device is fixed on a ratchet body as a single rope and a single or double-lug wedge clip, and is easy to fall off or not fixed into a groove. The long-term use of the ordinary ratchet compensation device results in security risks. A double-sided plate ratchet support of the 1:2 type triangular tooth ratchet compensating device comprises two opposite and parallel side plates. Each side plate is connected with a triangular integral connecting arm. A vertex of the triangular integral connecting arm is connected to the side plate through a twin shaft; the second vertex is connected to the side plate through a limiting shaft, a fixing hole of a limiting shaft is an arc-shaped slotted hole; the third vertex is connected with a ratchet assembly through a ratchet shaft. The bottom of the side plate is welded with a brake block. The 1:2 type triangular tooth ratchet compensating device can adjust itself according to the force direction of the wire and the length of linear expansion, has the function of free compensation along with the temperature change, ensures the constant tension of the catenary or the additional wire, and has the braking function under line breaking conditions so as to improve the reliability.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

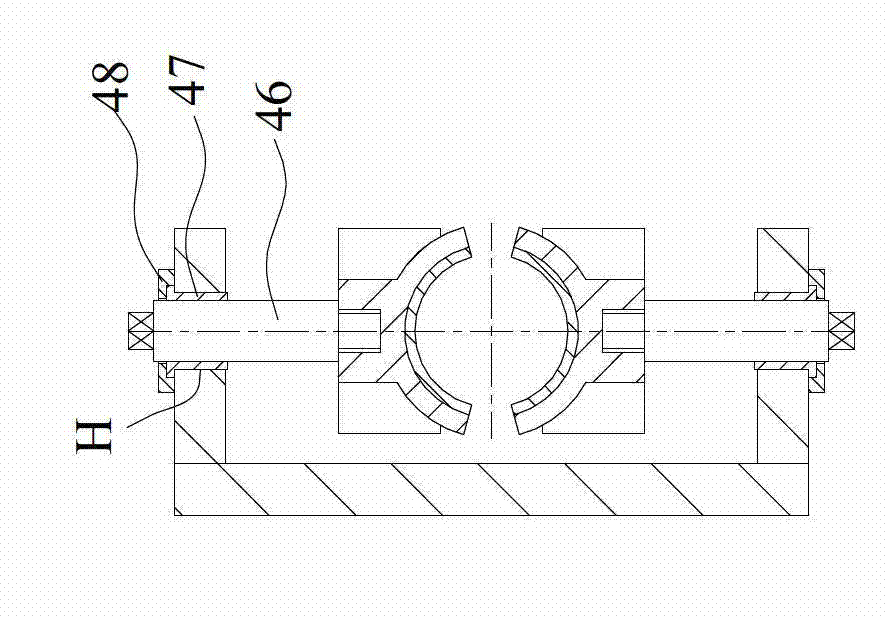

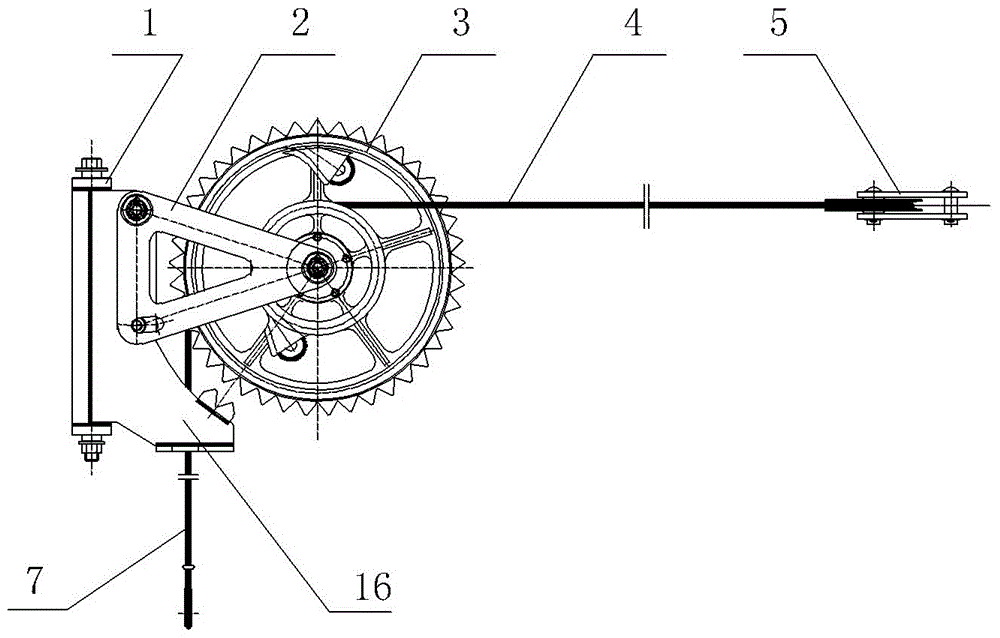

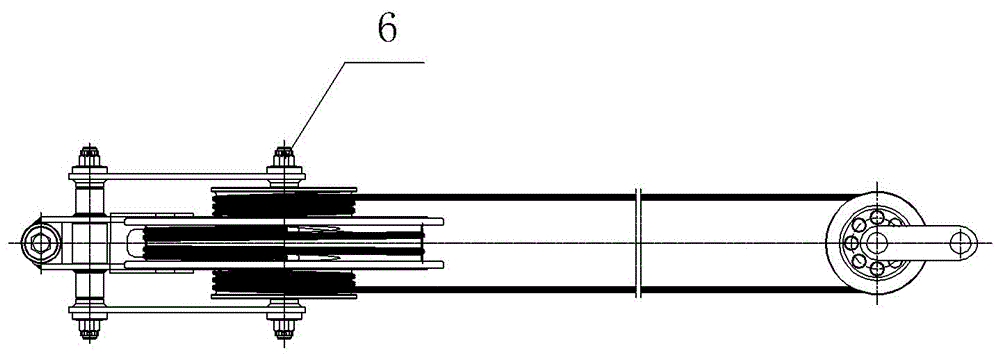

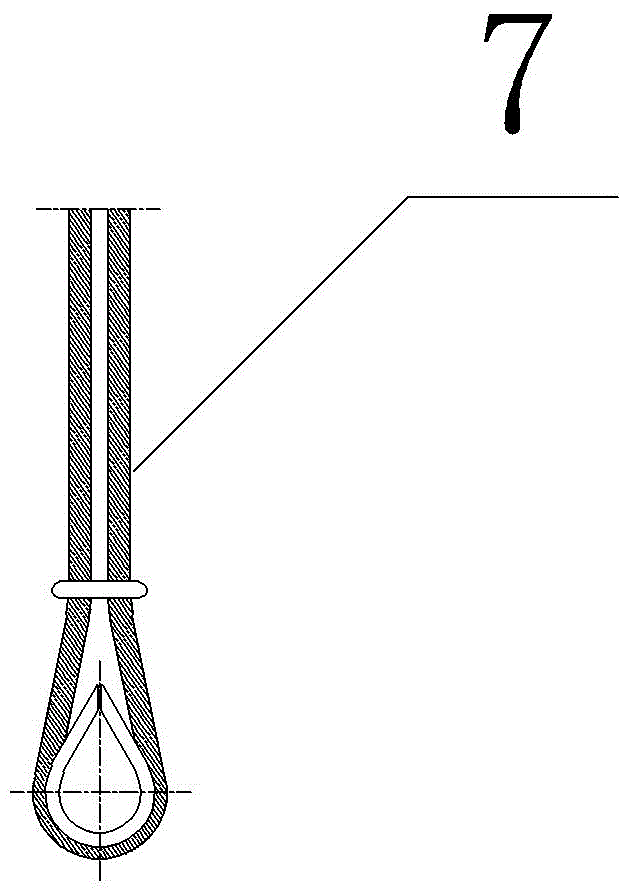

Ultra-fine wire continuous electroplating automatic production line

InactiveCN103741186BGuaranteed constant tensionFlat and beautiful wiringFilament handlingProduction lineSurface layer

The invention relates to the technical field of electroplating equipment, and in particular relates to an automatic production line for continuous electroplating of an ultrafine metal wire, which is used for a solution of equipment for electroplating a surface layer of an ultrafine metal wire with other metal plating layers in the electroplating industry. A brand new unwinding mechanism is adopted for performing constant-tension unwinding, so that the tension of the metal wire during the unwinding keeps constant; by virtue of a brand new driving mechanism, the linear speed keeps constant when the metal wire moves in the production line and can be adjusted as required so as to meet requirements of an electroplating process; a winding mechanism can be used for performing constant-torque winding during winding, and the winding torque can be adjusted according to the thickness of the metal wire; by virtue of the brand new winding mechanism, the wire can be accurately arranged according to the winding speed, so that the metal wire can be smoothly and attractively arranged; a buffer mechanism is additionally arranged between the driving mechanism and the winding mechanism, and can be used for balancing the speed difference between the driving mechanism and the winding mechanism.

Owner:PLASTIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com