A belt drive tensioner with adjustable size and tension

A tensioning force, belt drive technology, applied to belt drive tensioning clips, tensioning of mechanical belt drives. field, it can solve the problems of lack of versatility and rapid use many times, and achieve the effect of ingenious design, constant tension and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

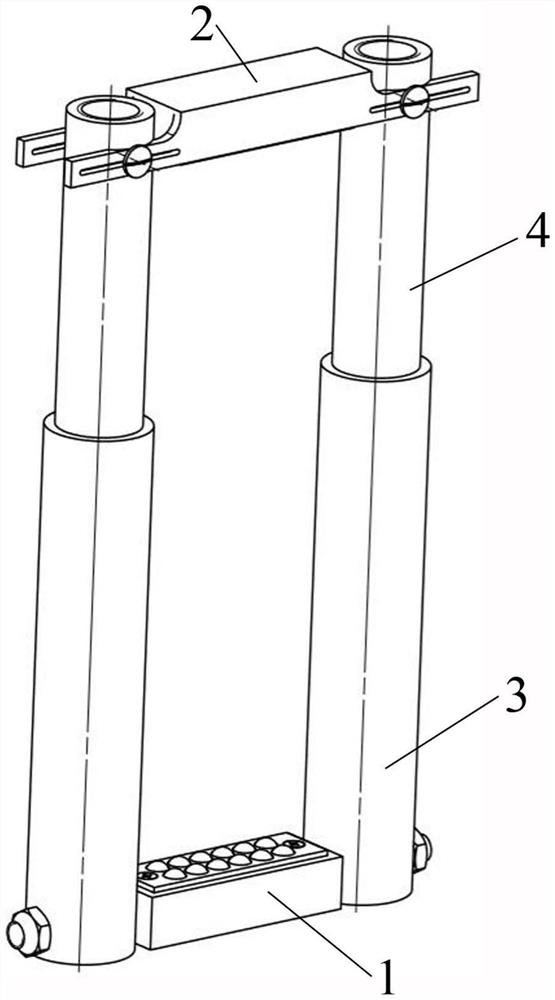

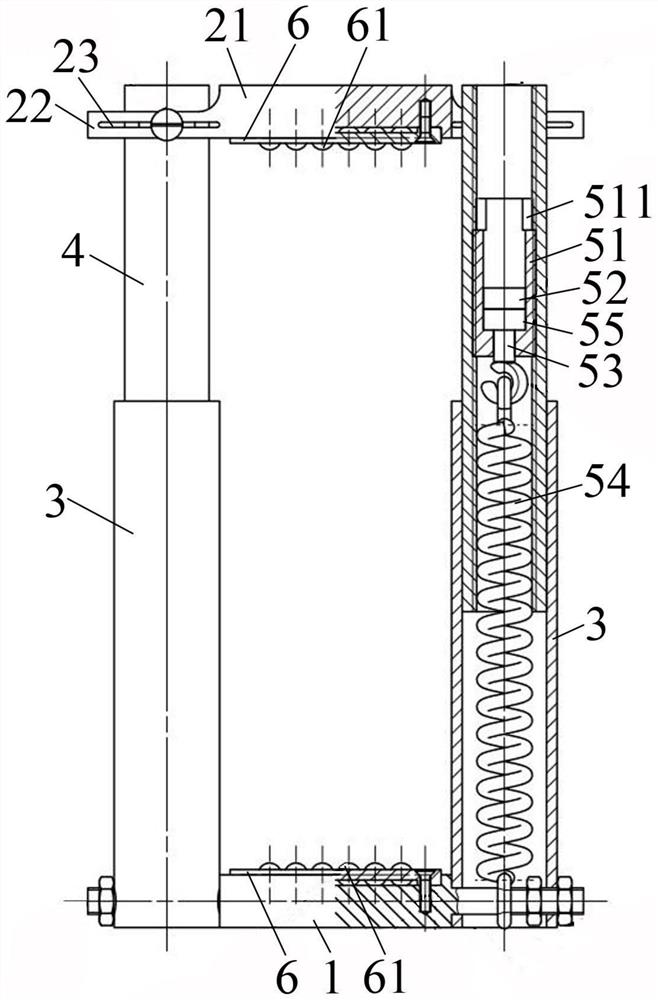

[0046] like Figure 1-2 The shown adjustable size and tension belt drive tension clamp includes a fixed plate 1 , a movable plate 2 , a set of sleeve pipes 3 , a set of inner tubes 4 and a set of tension adjustment mechanisms 5 . Wherein, the fixing plate 1 includes a fixing part 11 and connecting parts 12 arranged on two sides of the fixing part 11 . In addition, if Figure 13 As shown, the movable panel 2 includes a movable panel body 21 and a set of sliding bars 22 arranged on both sides of the movable panel body 21 , and the sliding bars 22 are also provided with oblong fixing grooves 23 . Again, if image 3 As shown, one end of the sleeve 3 is provided with a group of openings pierced through the connecting portion 12, as Figure 6-7 As shown, the sleeve 3 is fixed to the connecting portion 12 by a set of nuts arranged inside and outside of the sleeve 3 . In addition, the inner tube 4 is located inside the casing 3, such as Figure 4 As shown, the upper end of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com