Self-adaption constant torque moment rope-storing system for rock roadway subsidiary transport system

An auxiliary transportation and self-adaptive technology, applied in the field of rope storage systems, can solve the problems of inconstant rotation speed and inconvenient control of rope storage drums.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

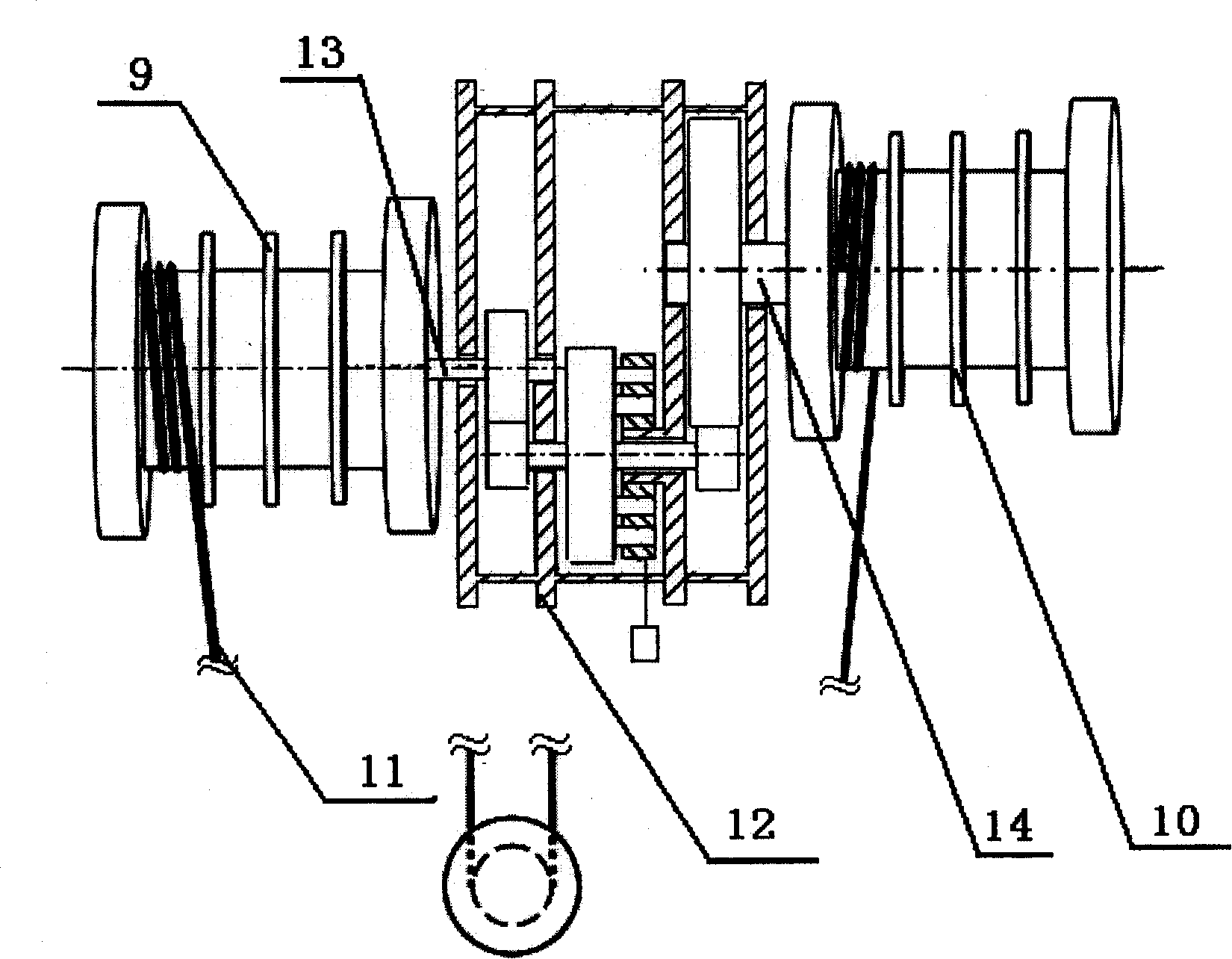

[0062] An adaptive constant torque rope storage device for auxiliary transportation system of rock roadway, comprising two rope storage drums 9, 10 with four-stage drum structure, and double planetary gears are arranged between the two rope storage drums 9, 10 The rotation adjustment device 12 is differentially controlled, and the axles of the two rope storage drums 9 and 10 are respectively connected to the rotating shafts at both ends of the rotation adjustment device 12 through the same input transmission pair 13 and output transmission pair 14 .

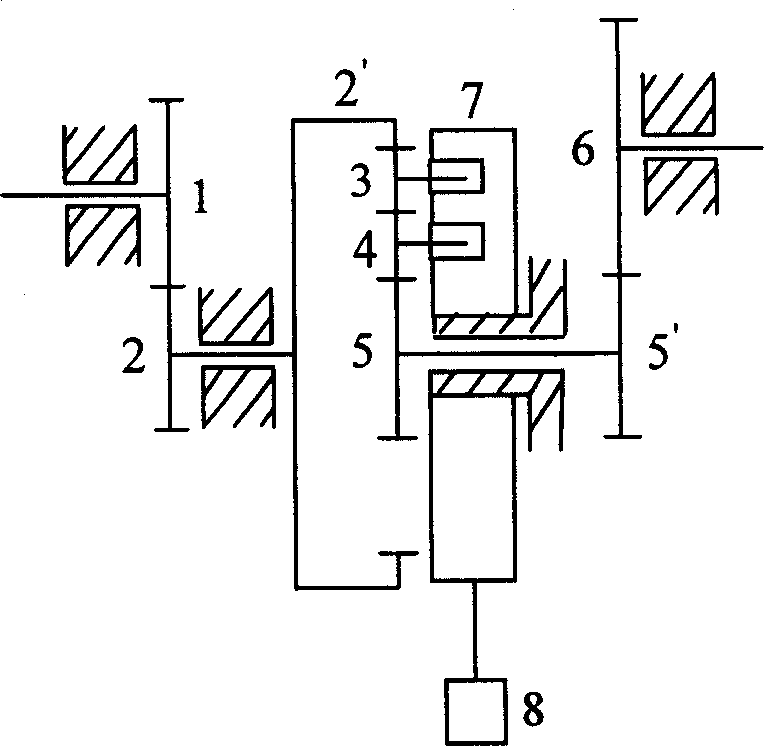

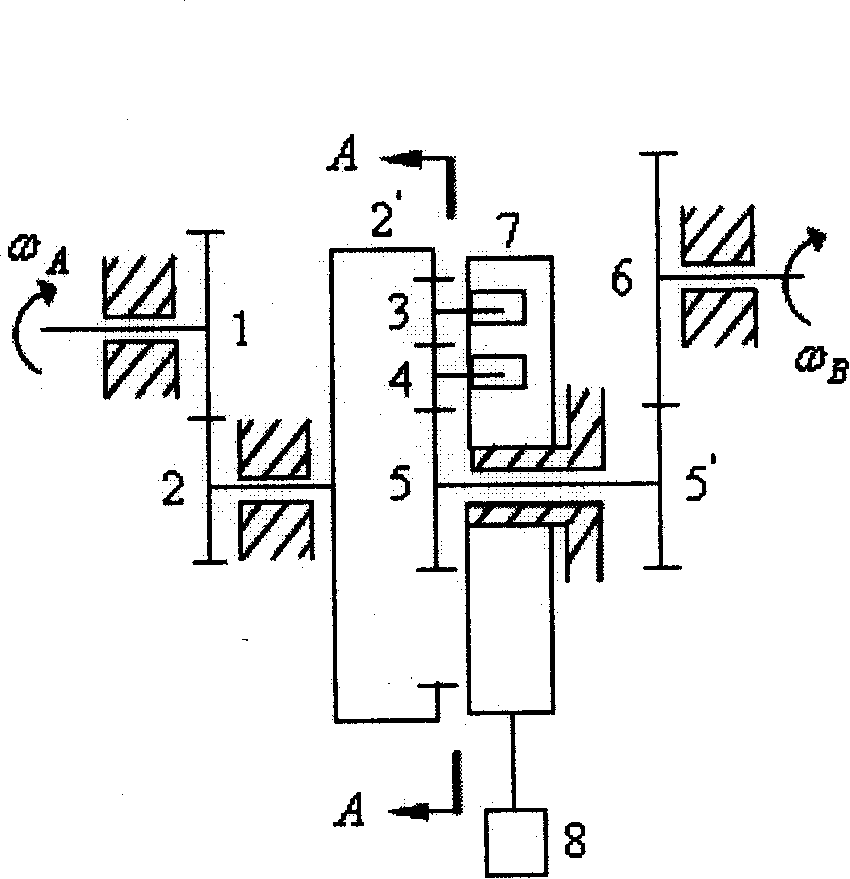

[0063] The structure of the double-planet wheel differential control rotation regulating device 12 is that it has an internal gear 2' and a differential control wheel 7 located on one side of the internal gear 2', and the outer planetary gear 7 meshed with the internal gear 2' The wheel 3 is also meshed with the inner planetary gear 4. The shafts of the outer planetary gear 3 and the inner planetary gear 4 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com