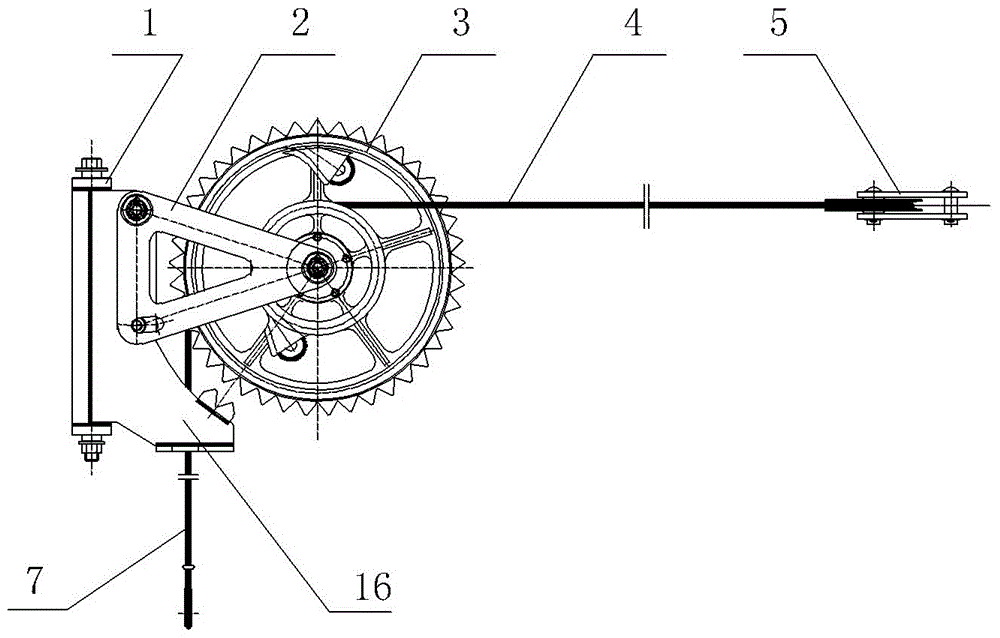

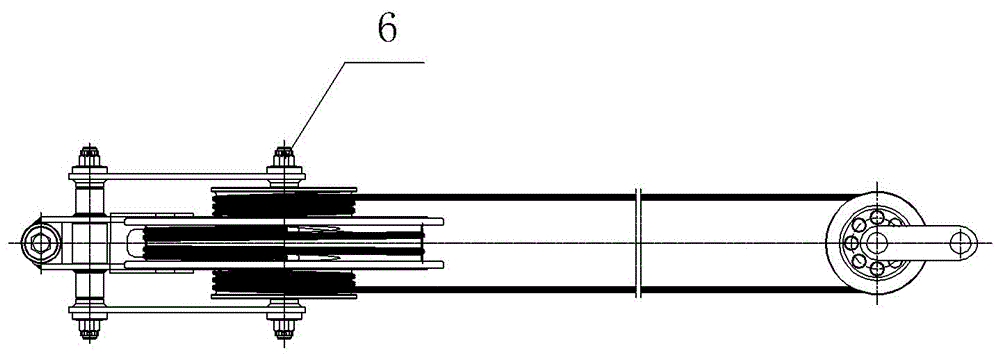

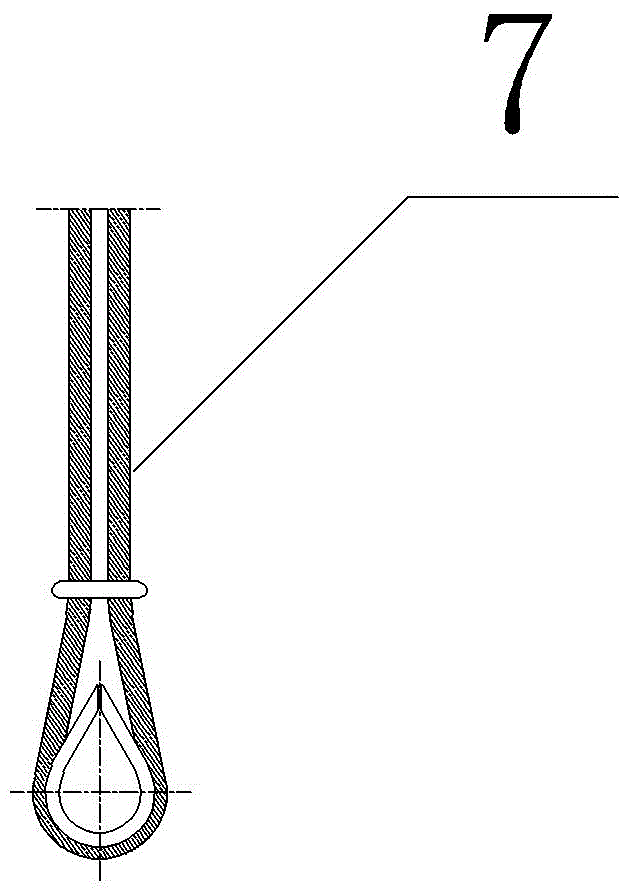

1:2 type triangular tooth ratchet compensating device for catenary and additional wire compensating anchor

A compensating device and catenary technology, applied in the direction of overhead lines, etc., can solve the problem of insufficient stroke of falling weight, and achieve the effect of improving reliability and avoiding mutual friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in combination with specific embodiments.

[0045] The catenary of electrified railways generally adopts full compensation design, and gravity compensation is mostly used for anchoring. Because the ratchet compensation device has compact structure, high strength, high compensation efficiency, high reliability and braking function, it is mostly used on electrified railways and high-speed rails. use.

[0046] The additional wires in the catenary system generally adopt non-constant tension design (no compensation), but in the windy area, especially in the windshield section, the large swing of the additional wire seriously affects the safety of driving operation, so the full (half) compensation design is also adopted , The terminal adopts a ratchet compensation device. The transmission ratio of the ordinary ratchet compensation device is 1:3, but the additional wire has a large expansion, and the travel space of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com