Traction device for vertical aluminum alloy pipe production line

A traction device and aluminum alloy technology, which is applied in the field of vertical aluminum alloy pipe extrusion traction device, can solve the problem that vertical aluminum alloy pipes cannot be applied, and achieve the effects of improving yield, reducing product length, and running smoothly and reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

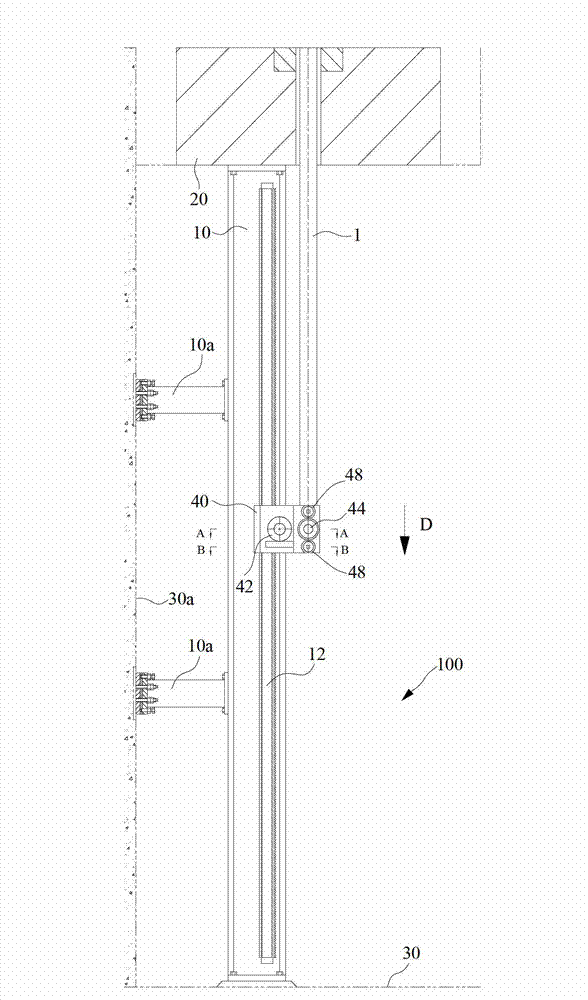

[0021] figure 1 Shown is a schematic front view of the pulling device used in the vertical aluminum alloy pipe production line of the present invention. Among them, the following "up" and "down" correspond to figure 1 shown above and below, "left" and "right" correspond to figure 1 The left and right sides, and hereinafter "front" correspond to figure 1 The side that can be displayed in the middle, and the "rear" corresponds to the figure 1 Opposite side shown in .

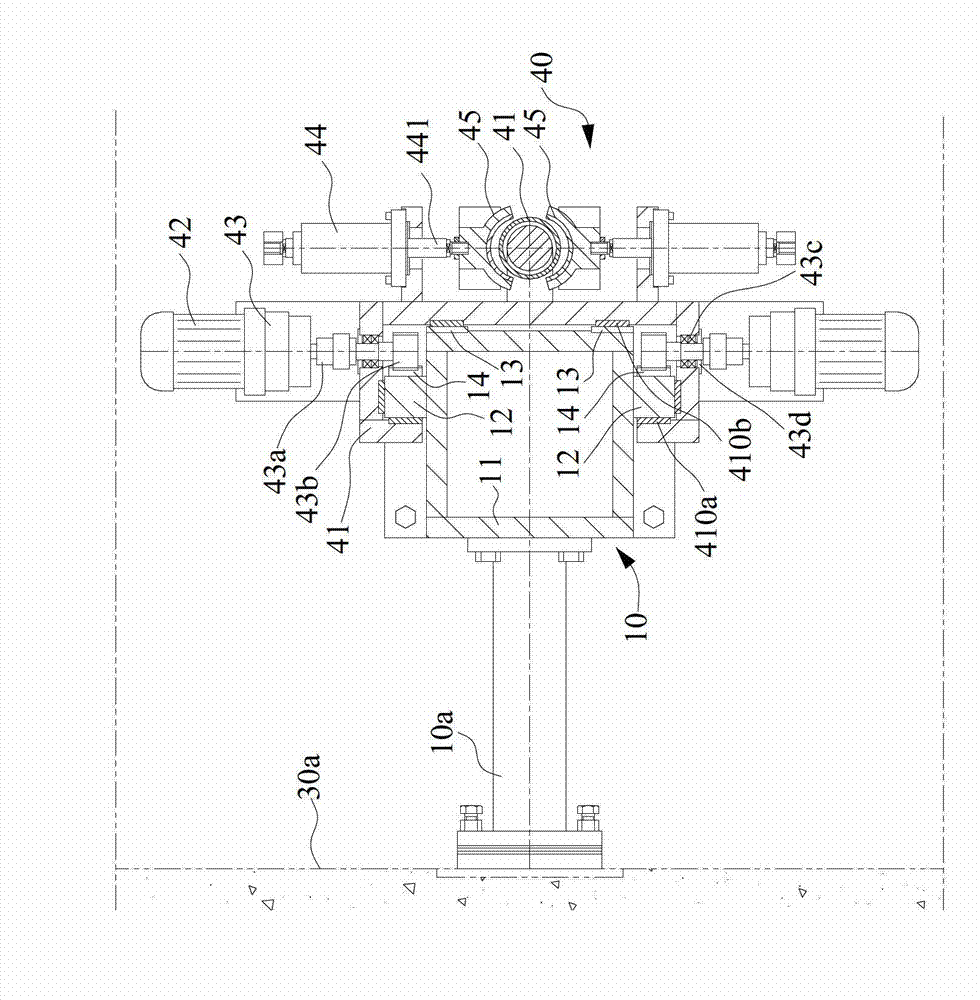

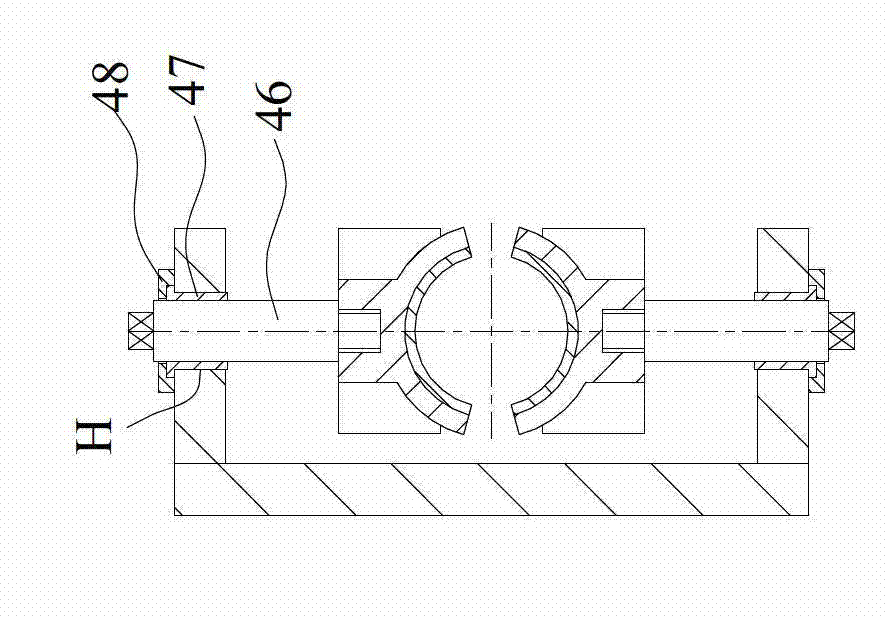

[0022] Such as figure 1 As shown, the traction device proposed by the present invention for the vertical aluminum alloy pipe production line includes a column 10 and a tractor 40 . The column 10 is arranged in the pit 100 below the extrusion equipment (not shown in the figure), the lower end of the column 10 is fixedly connected with the lower foundation 30 , and the upper end is fixedly connected with the base 20 . In order to ensure the rigidity of the column 10, at least one bracket 10a is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com