Wire puller for winding and winding device

A technology of a winding device and a wire puller, which is applied in the field of wire pullers, can solve problems such as potential safety hazards of operators, damage to the internal structure of the motor, and loose cables, etc., and achieves the goals of improving the quality of winding, strong practicability, and avoiding damage to the cables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order for those skilled in the art to better understand the technical solutions of the present invention, and to make the above-mentioned features, purposes and advantages of the present invention more clearly understood, the present invention will be further described below with reference to the embodiments. The examples are only used to illustrate the present invention and not to limit the scope of the present invention.

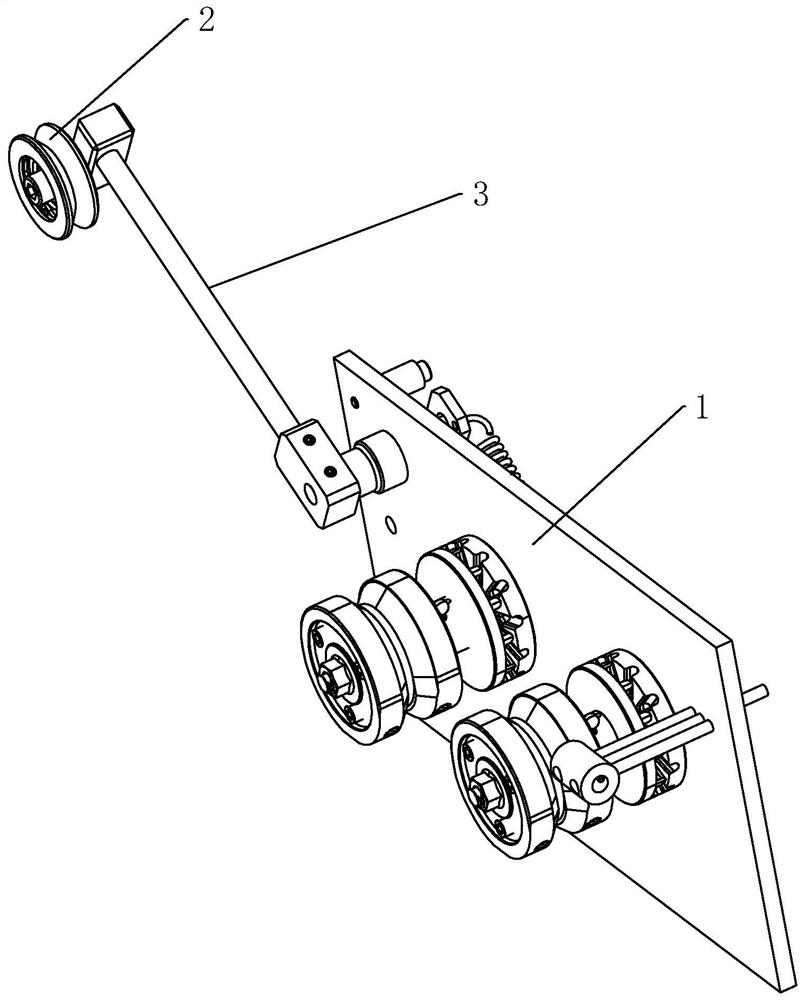

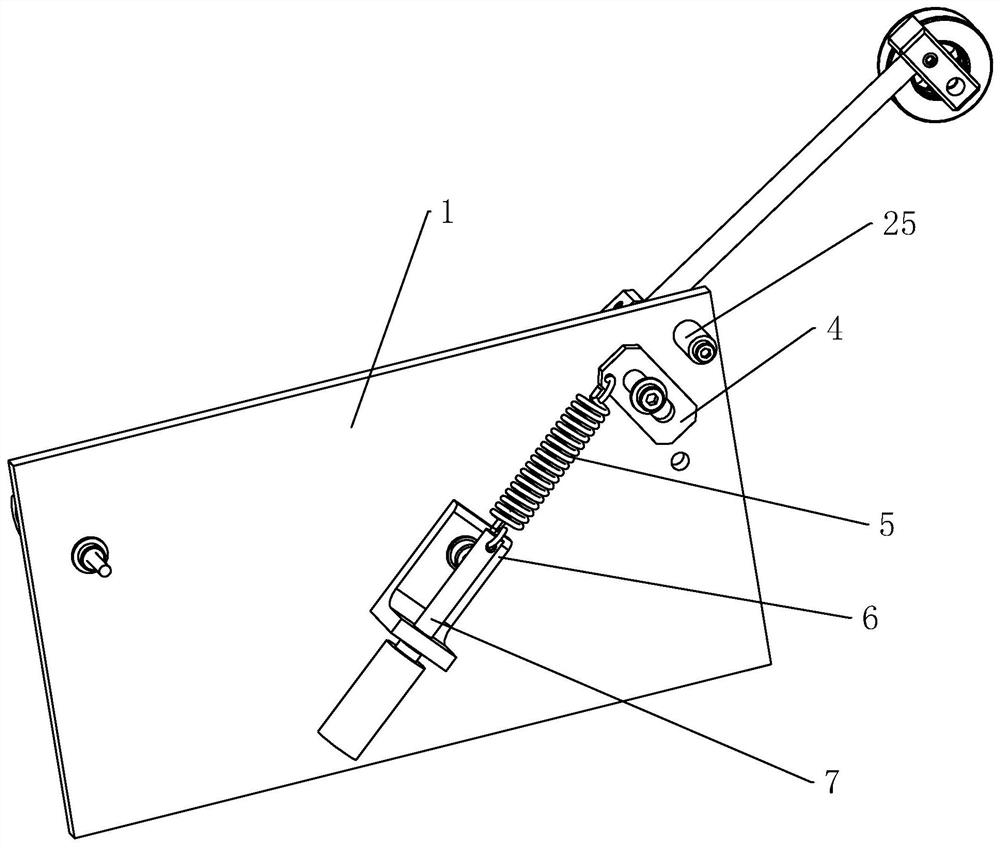

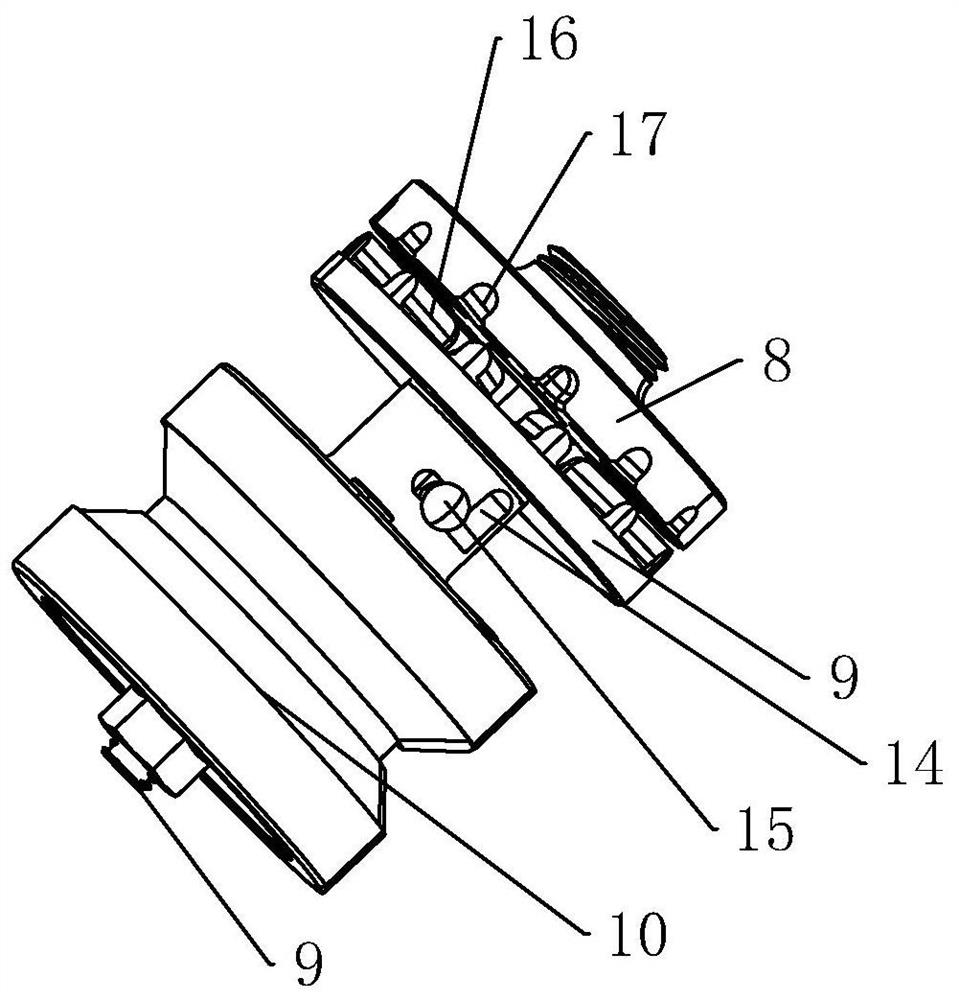

[0031] like Figure 1-7 As shown, the present invention includes a base 1 , an adjusting device arranged at one end of the base 1 , and a reverse buffering device arranged at the center of the base 1 .

[0032] The adjusting device includes a pulley 2, a bridge rod 3 with a Z-shaped structure, a baffle plate 4, a tension spring 5, a fixed seat 6 and an electric cylinder 7 for adjusting the torsion moment of the tension spring 5; the pulley 2 is sleeved through a bearing. At one end of the bridging rod 3, the other end of the bridging rod 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com