Fiber feeding machine control system

A technology of control system and wire feeder, applied in general control system, control/regulation system, program control, etc., can solve the problems of high professional requirements of staff, insufficient response speed, waste of human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

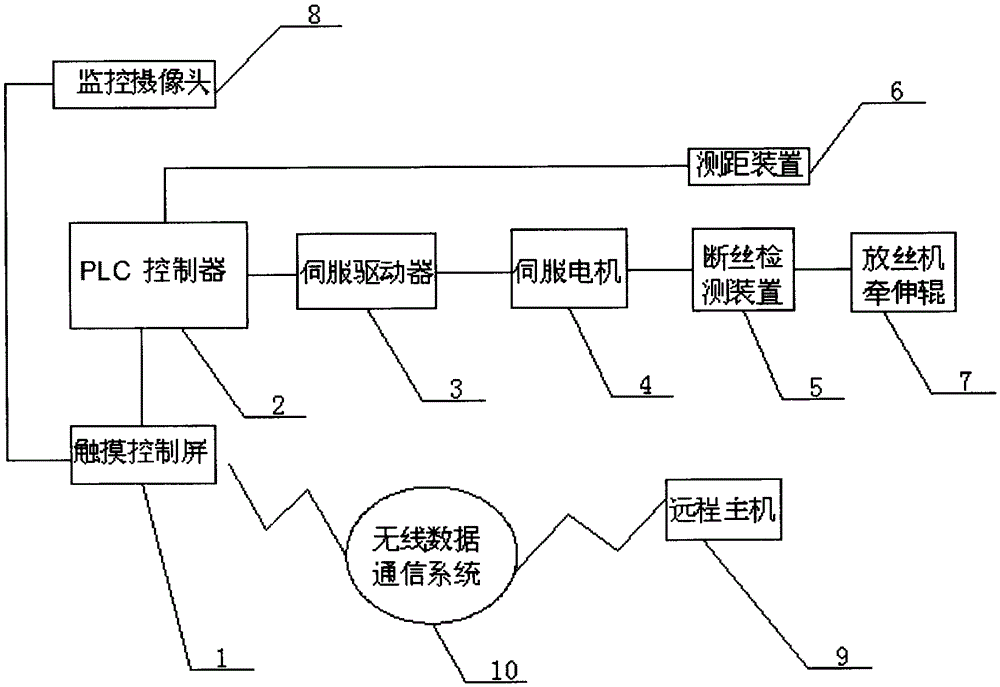

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

[0012] see as figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes a touch control screen 1, a PLC controller 2, a servo driver 3, a servo motor 4, a broken wire detection device 5, a distance measuring device 6, and a drawing roller of a wire unwinding machine 7. Surveillance camera 8, remote host 9, wireless data communication system 10; the touch control panel 1 is set on the PLC controller 2, the PLC controller 2 is connected with the servo driver 3 through the communication line, and the servo driver 3 is connected with the servo motor through the communication line 4 connection, the servo motor 4 is connected with the broken wire detection device 5; the broken wire detection device 5 is connected with the drawing roller 7 of the wire unwinding machine; the distance measuring device 6 is connected with the PLC controller 2; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com