Automatic production line for continuous electroplating of ultrafine metal wire

An automatic production line and thin metal wire technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. The line is smooth and beautiful, and the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

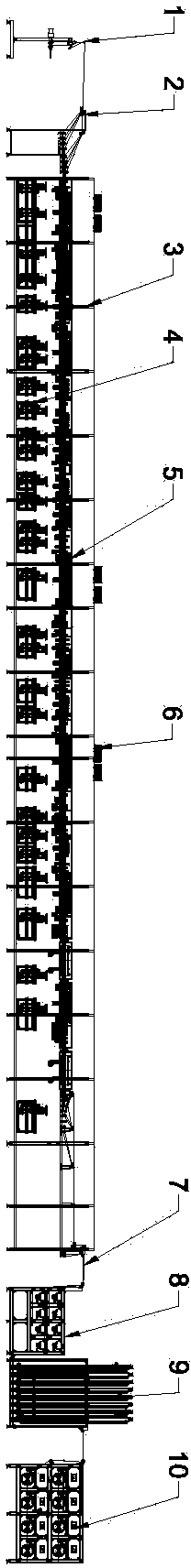

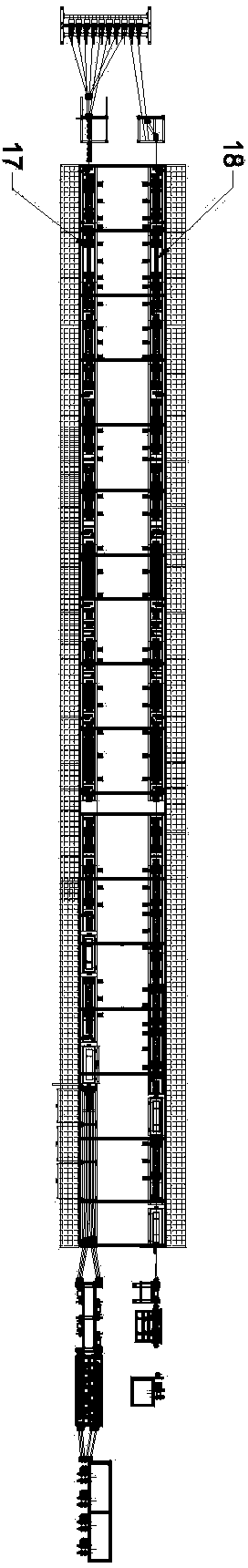

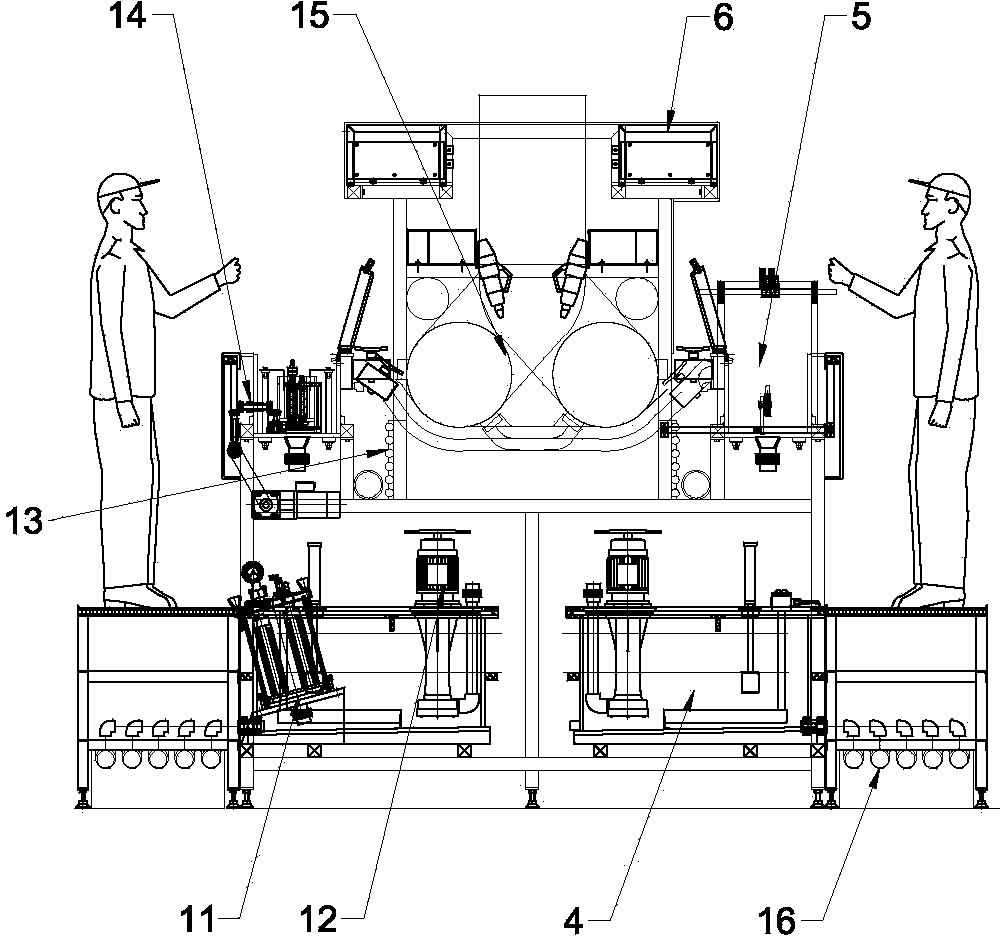

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027]As shown in Figures 1, 2, and 3, the ultra-fine metal wire continuous electroplating automatic production line consists of an unwinding mechanism 1, a guide wheel 2, a production line frame 3, a lower liquid storage tank 4, an upper working tank 5, an electroplating power supply 6, an ultra-fine Metal wire 7, driving mechanism 8, buffer mechanism 9, winding mechanism 10, filter 11, circulation pump 12, water supply pipe 13, conductive booster mechanism 14, exhaust pipe 15, drain pipe 16, working channel 17, working channel Composed of two 18s, it presents a straight double-channel structure. The operation pedestrian platform is arranged on both sides to facilitate the simultaneous production of two lanes. Each channel of the production line can be electroplated with multiple ultra-fine metal wires 7 at the same time, or can be electroplated with a single wire. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com