Patents

Literature

51results about How to "Accurate wiring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

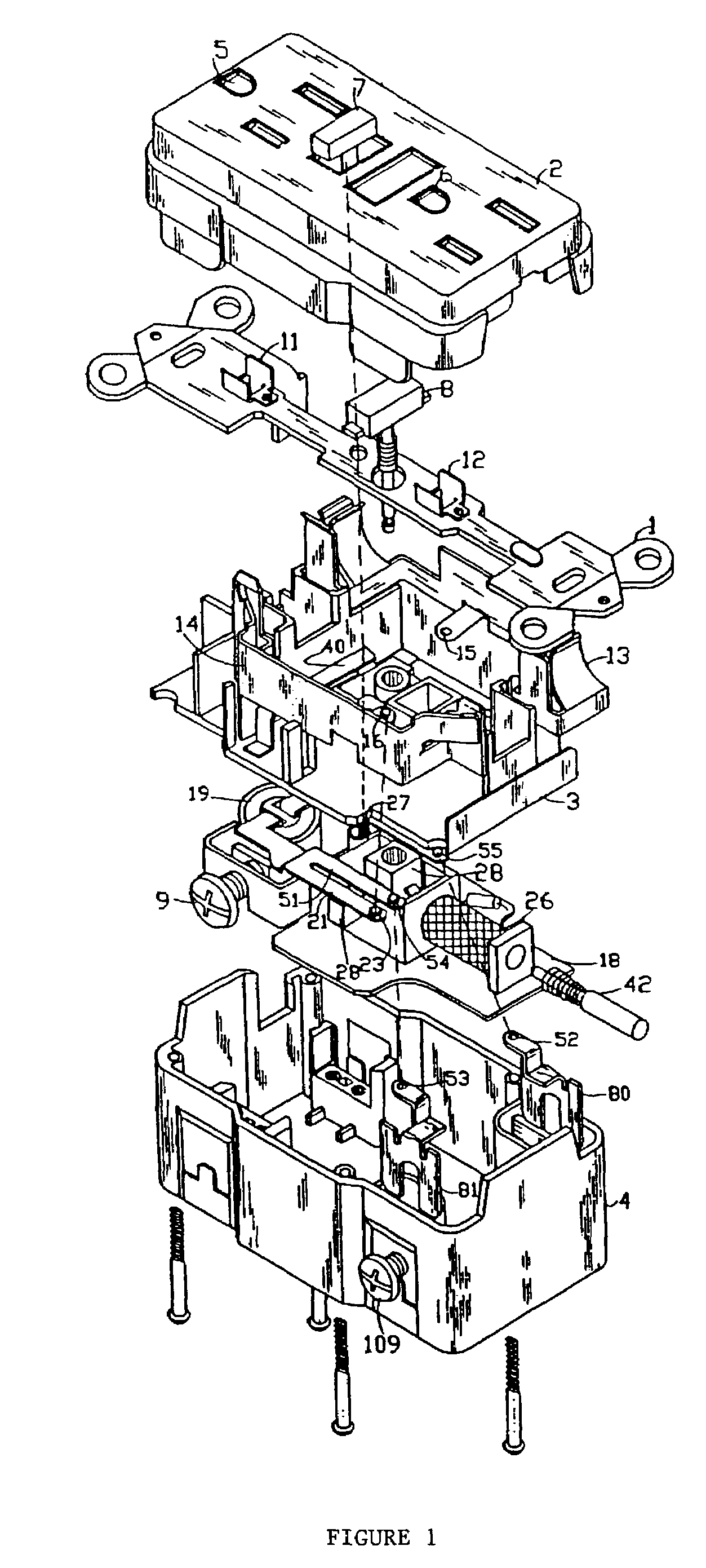

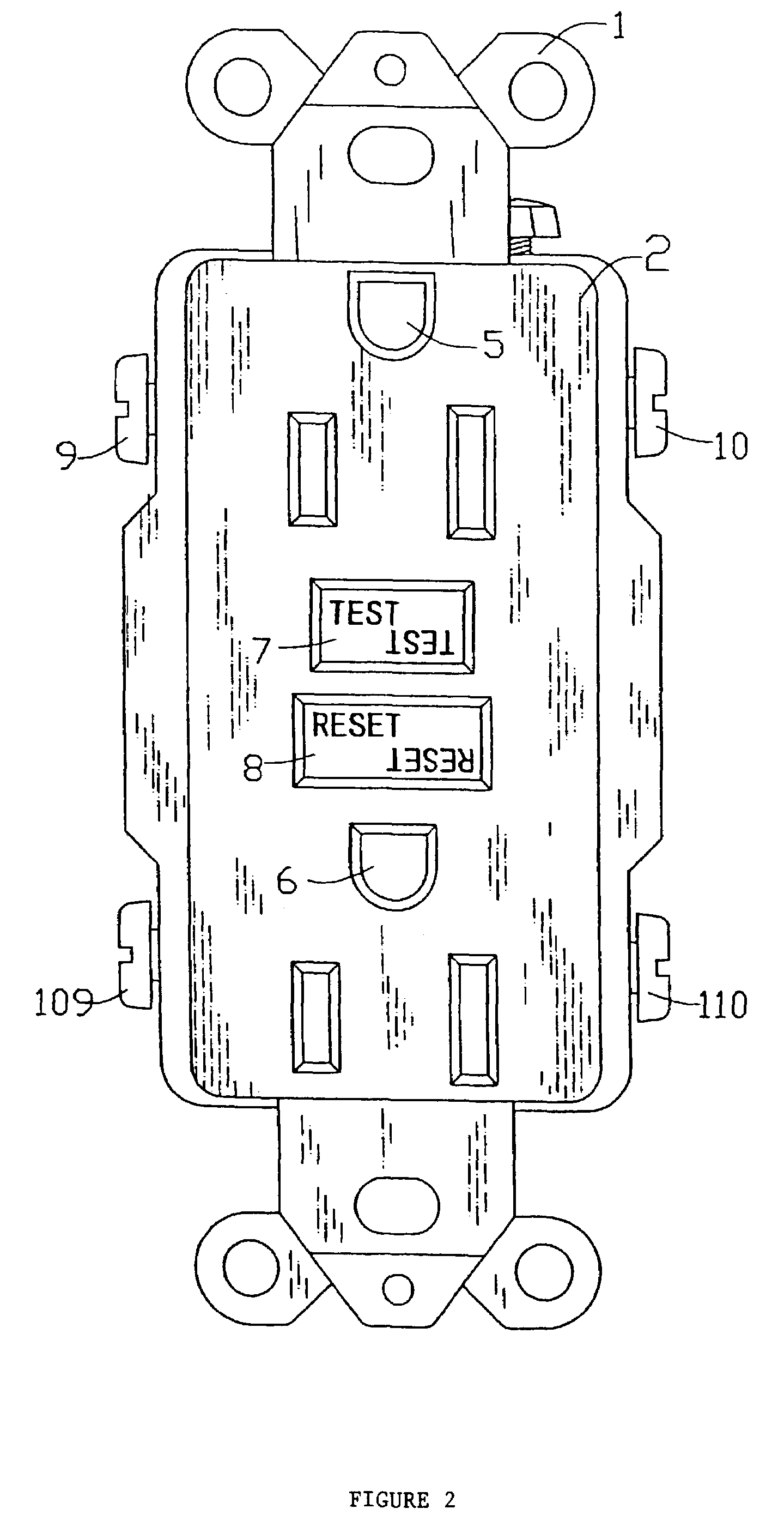

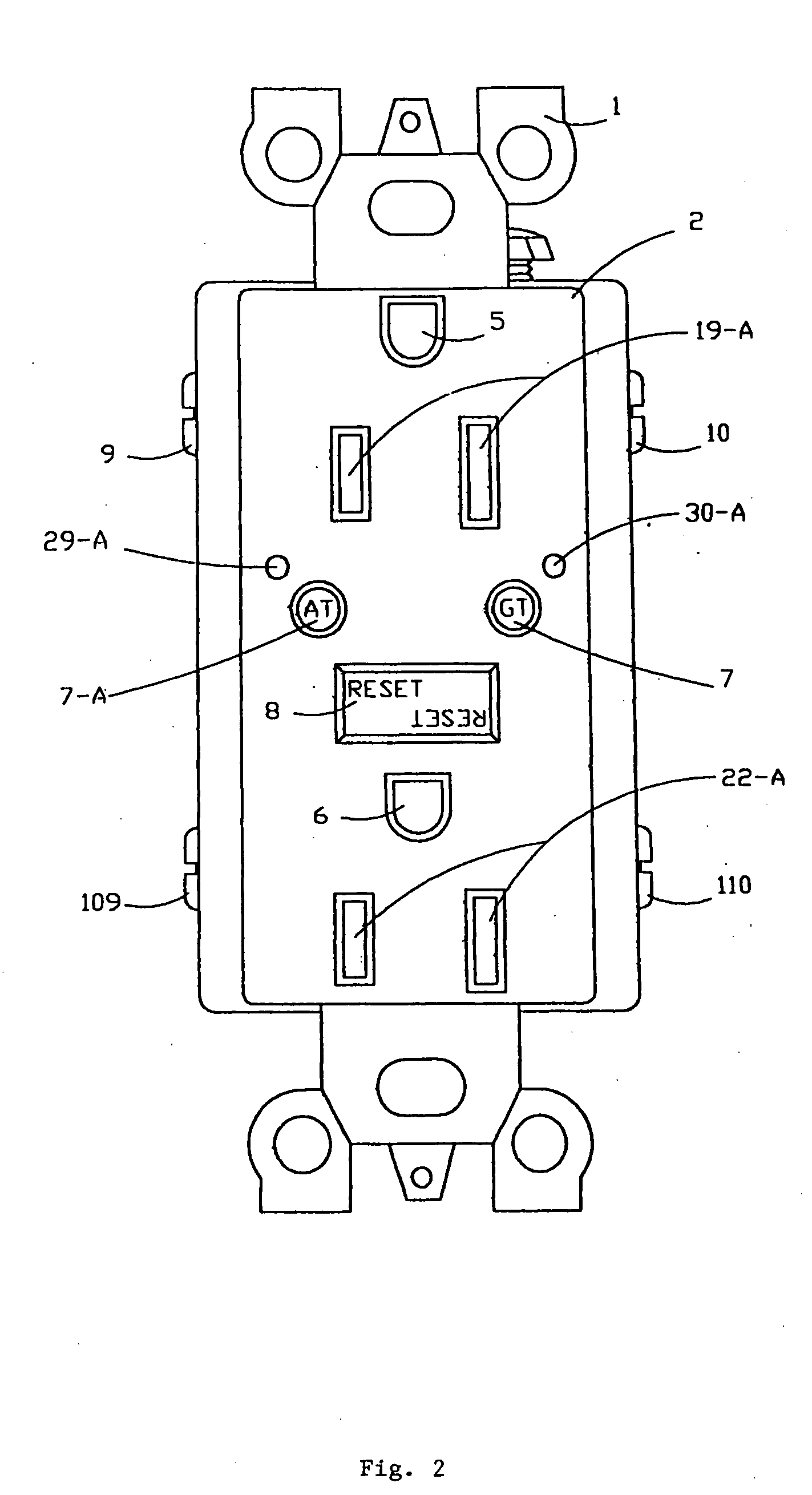

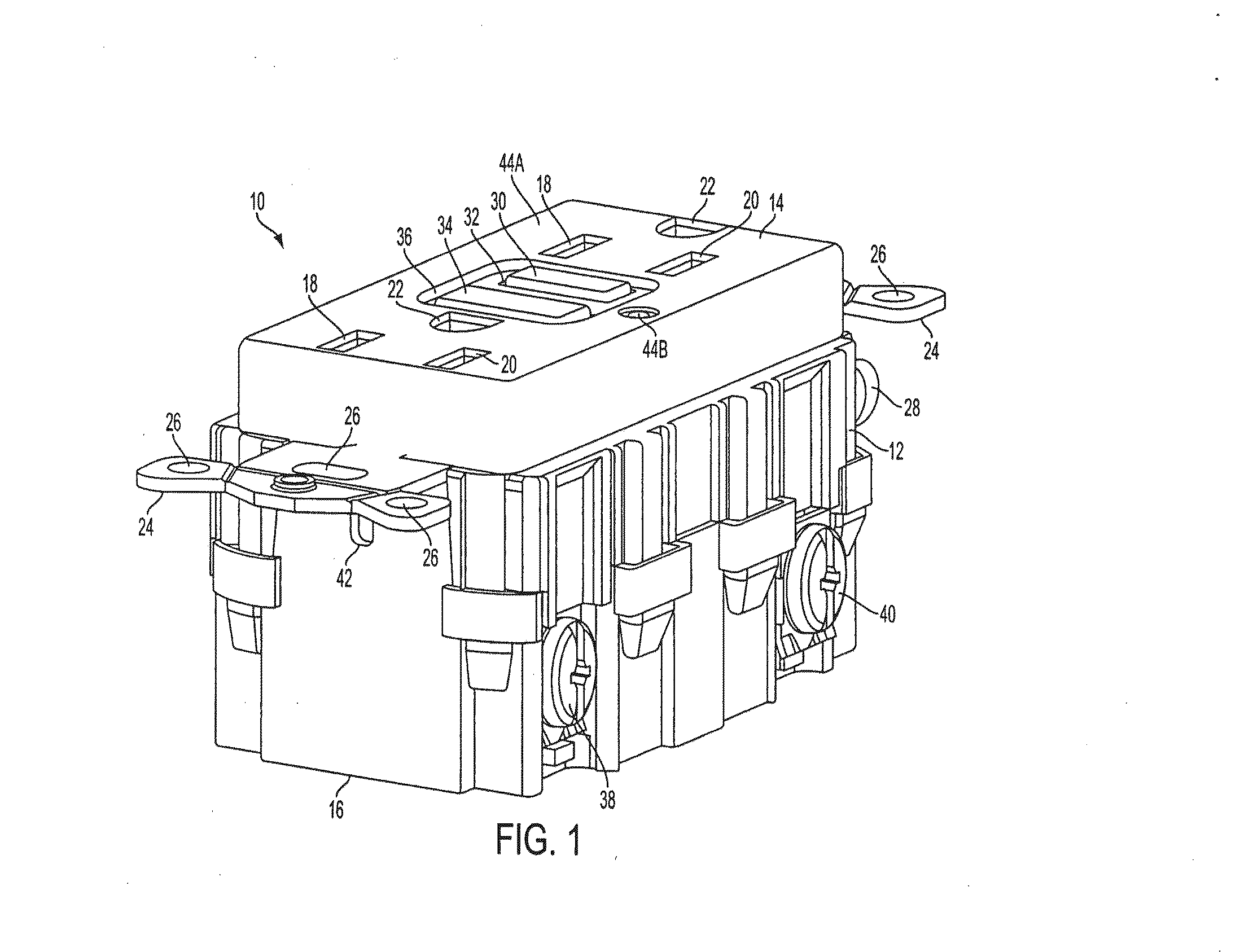

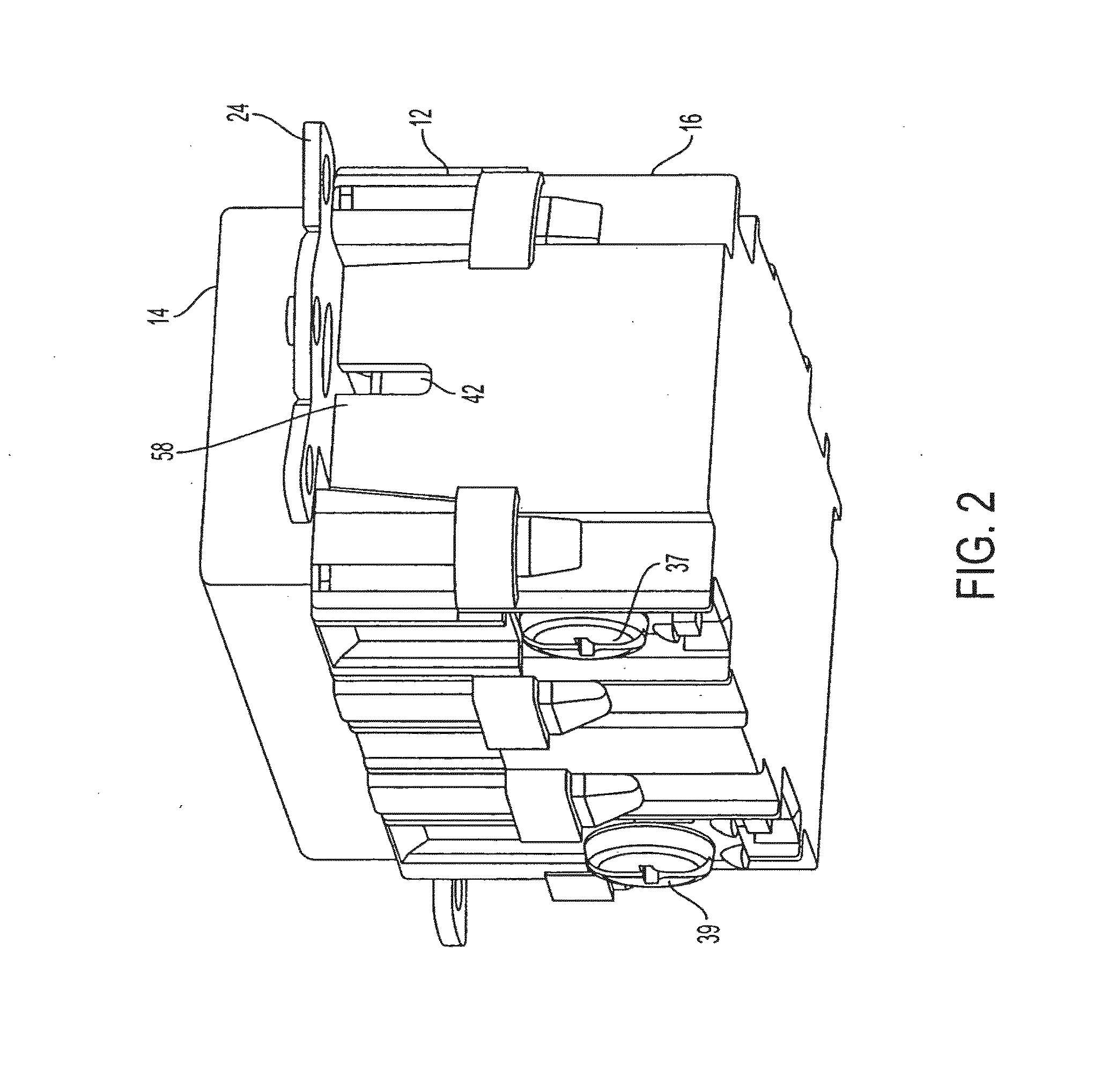

Receptacle device having circuit interrupting and reverse wiring protection

InactiveUS7019952B2Avoid flowAccurate wiringCoupling device detailsEmergency protective arrangement detailsElectricityElectronics

A circuit interrupting system has an upper cover, an intermediate support, and a base. A mounting strap is installed between the upper cover and the intermediate support, and a electric circuit board installed between the intermediate support and the base. The upper cover includes an electric output plug, a test button, and a reset button. The mounting strap includes a ground point that is connected to a ground receptacle of the electric output plug; the intermediate support on both sides a pair of output conductors. The electric circuit board comprises a differential transformer, a solenoid coil having a plunger inside, a reset button bias member, and a flexible switch; both sides of the base respectively comprise in parallel a pair of electric input connection screws and a pair of electric output point. The ground fault circuit interrupting system is installed within an output box on the wall of an ordinary household which prevents hazard caused to human and household electronics by errors in the installation of the connection lines.

Owner:SHANGHAI MEIHAO ELECTRIC APPLIANCES

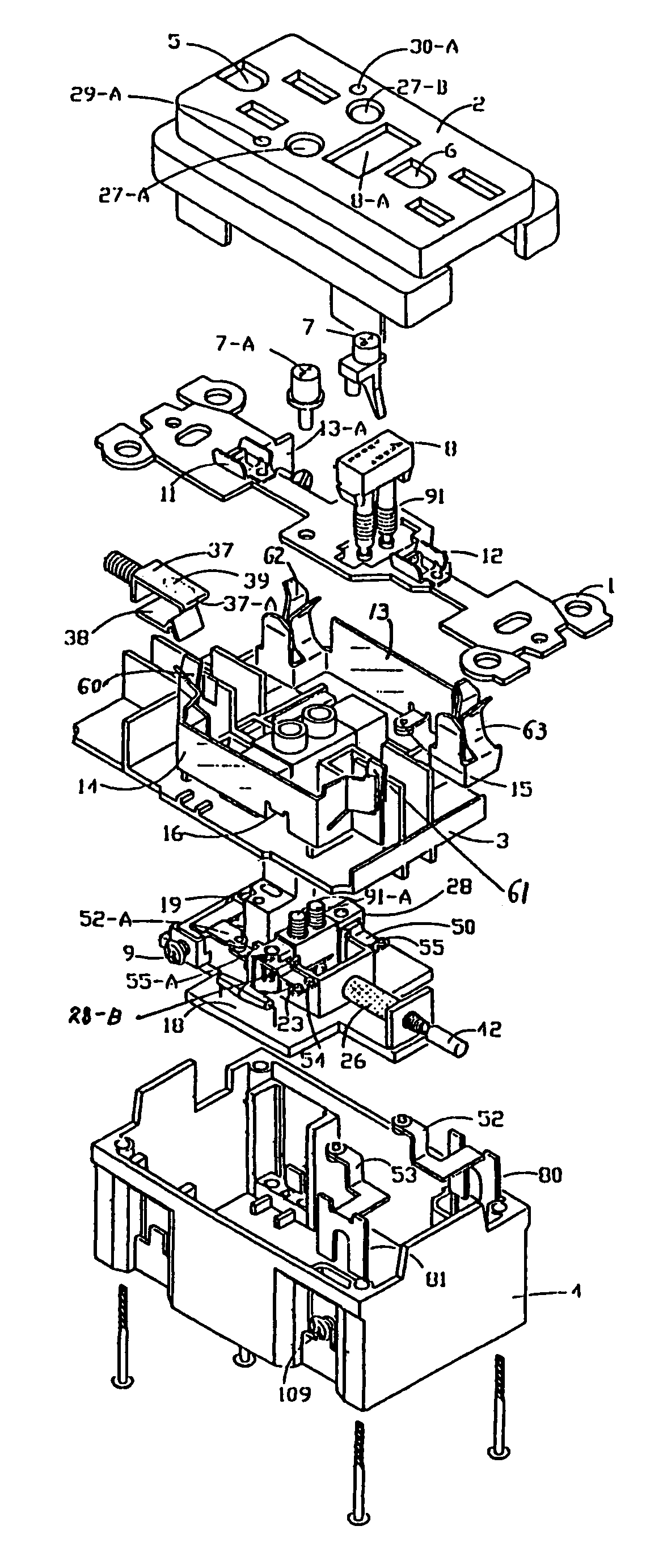

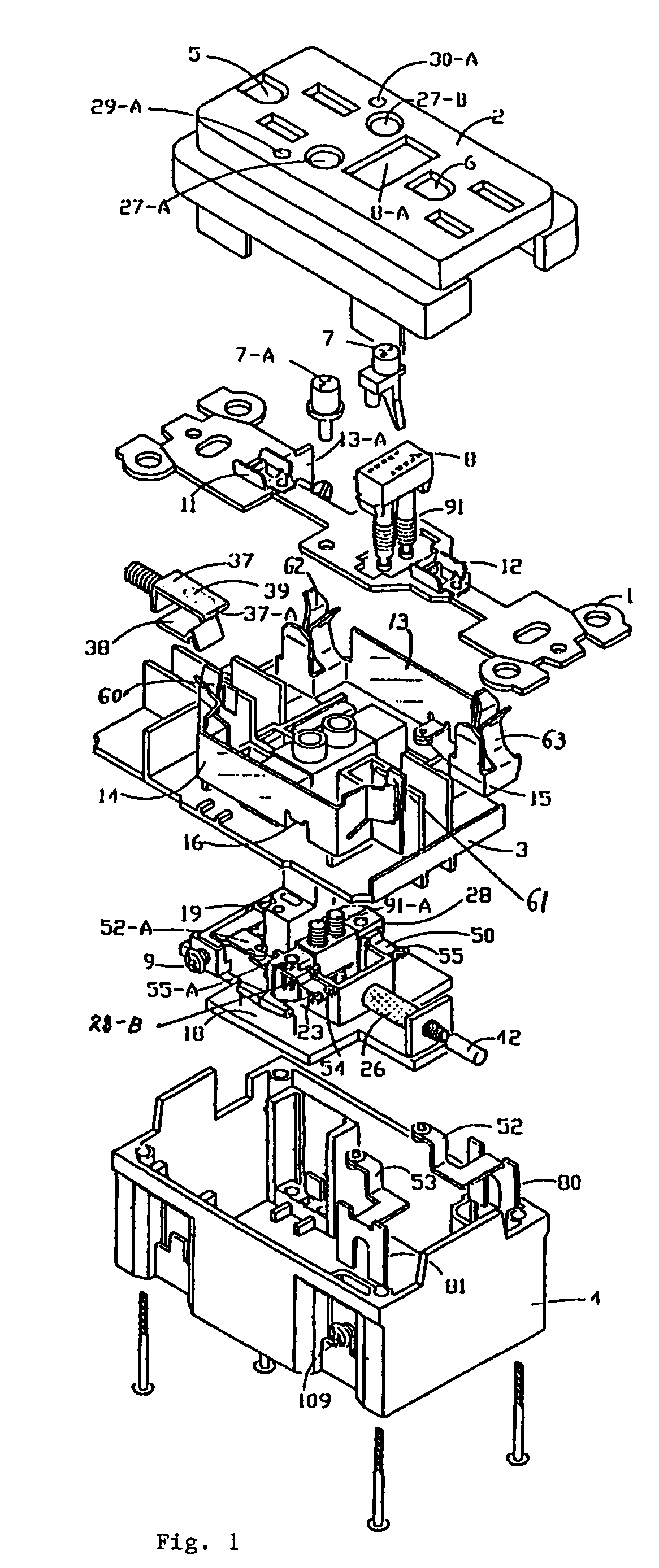

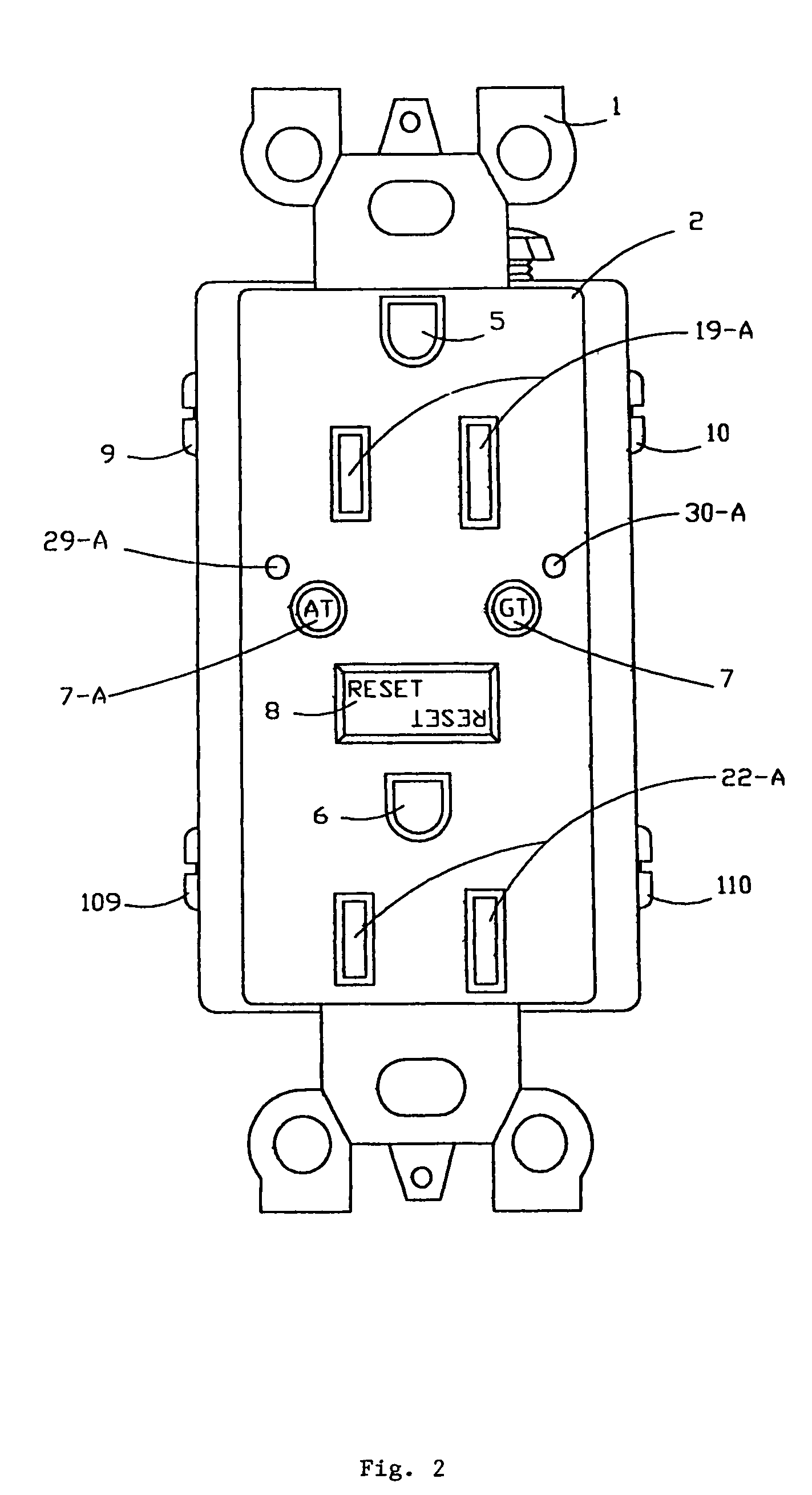

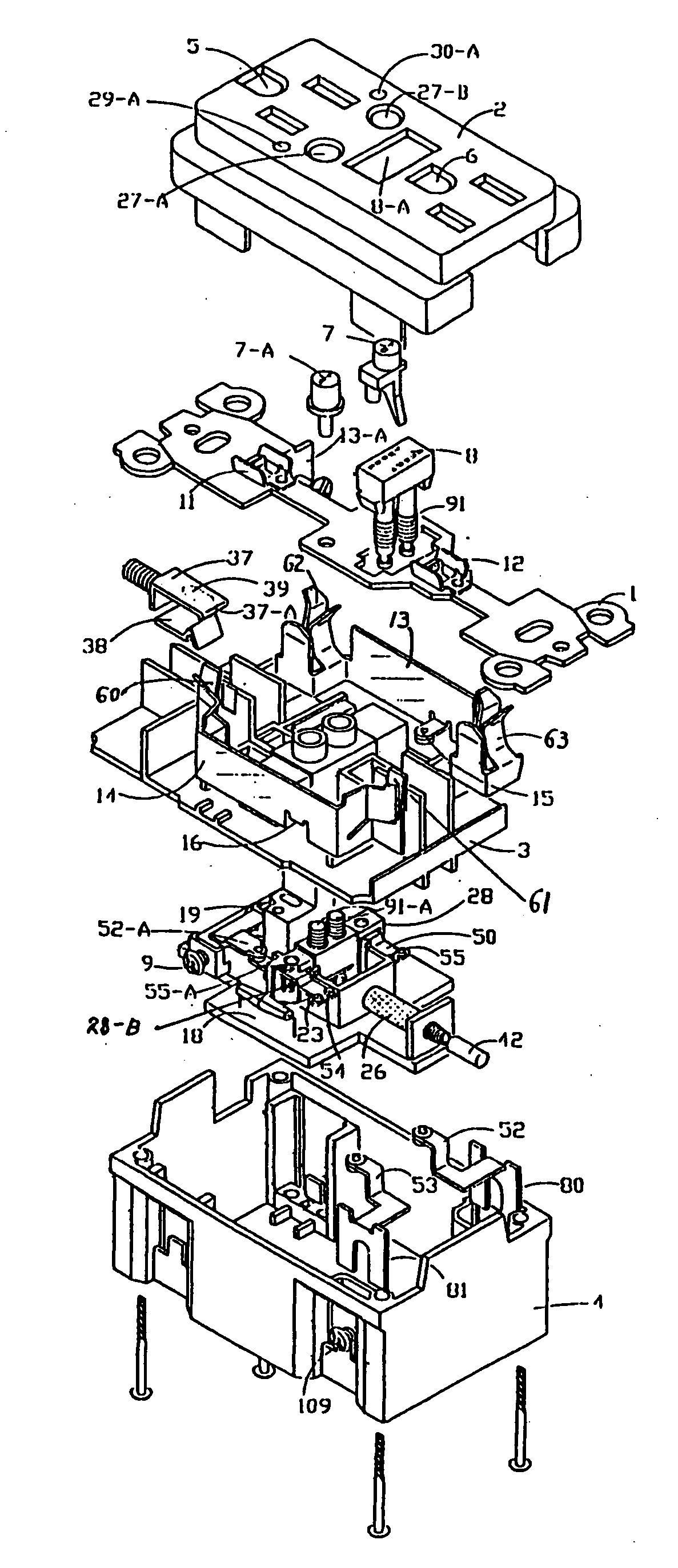

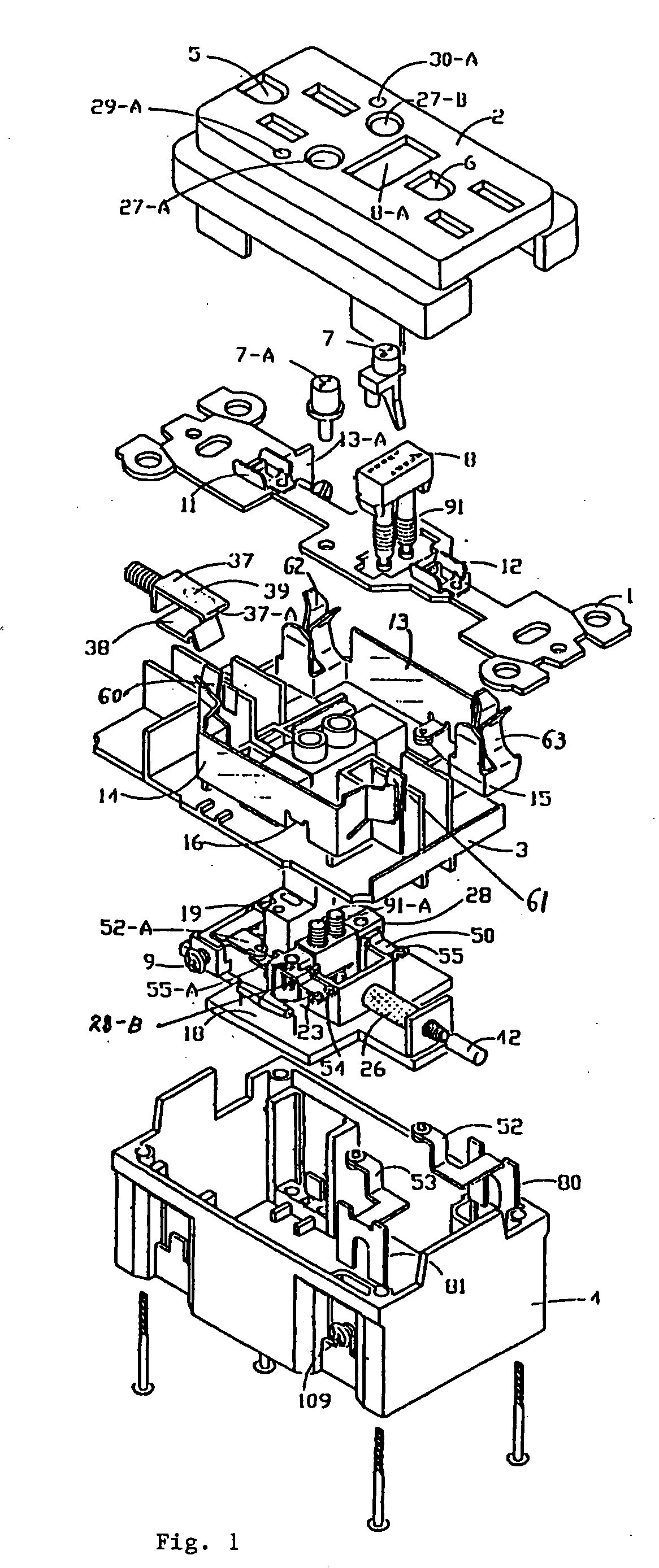

Receptacle device having protection against arc faults and leakage currents

InactiveUS6998945B2Avoid disadvantagesEasy to useSwitch operated by falling currentEmergency protective arrangement detailsElectrical conductorTransformer

A receptacle device for protection against arc faults and leakage currents, including an arc fault test button, a leakage test button, and a reset button. Test resistors are arranged below the arc fault test button and the leakage test button wherein the test resistors are coupled to an electrical circuit board. The electrical circuit board includes an arc sampling resistor to detect arc faults and a leakage detection differential transformer to detect leakage currents. In order to provide good contacts between mobile and stationary electrical contacts of the receptacle device, a reset button bias member having mobile contact bridges at its two arms is provided. Each of the mobile contact bridges has three triangularly spaced electrical contacts, corresponding to stationary electrical contacts of flexible input fingers, output conductors and electrical output leads of the receptacle device. In order to balance the mobile contact bridges and provide better contacts, the receptacle device of the present invention can utilize a unique system of dual directional locks, i.e., below the reset button, there are two axially symmetrical directional locks provided within a reset button bias member of the receptacle device.

Owner:HUANG HUADAO

Receptacle device having protection against arc faults and leakage currents

InactiveUS20050012575A1Easy to installEasy to useSwitch operated by falling currentEmergency protective arrangement detailsElectrical resistance and conductanceElectricity

A receptacle device for protection against arc faults and leakage currents, including an arc fault test button, a leakage test button, and a reset button. Test resistors are arranged below the arc fault test button and the leakage test button wherein the test resistors are coupled to an electrical circuit board. The electrical circuit board includes an arc sampling resistor to detect arc faults and a leakage detection differential transformer to detect leakage currents. In order to provide good contacts between mobile and stationary electrical contacts of the receptacle device, a reset button bias member having mobile contact bridges at its two arms is provided. Each of the mobile contact bridges has three triangularly spaced electrical contacts, corresponding to stationary electrical contacts of flexible input fingers, output conductors and electrical output leads of the receptacle device. In order to balance the mobile contact bridges and provide better contacts, the receptacle device of the present invention can utilize a unique system of dual directional locks, i.e., below the reset button, there are two axially symmetrical directional locks provided within a reset button bias member of the receptacle device.

Owner:HUANG HUADAO

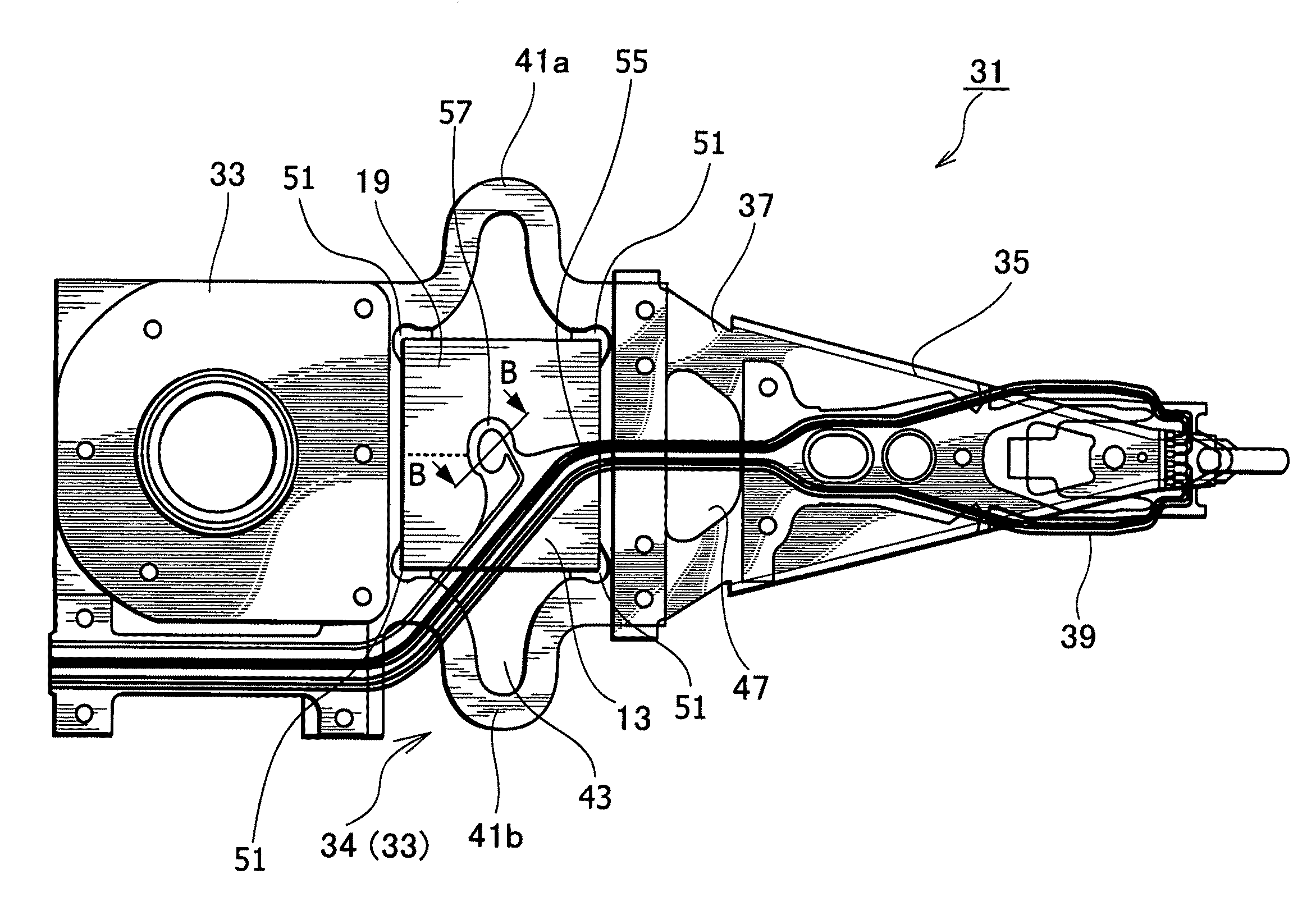

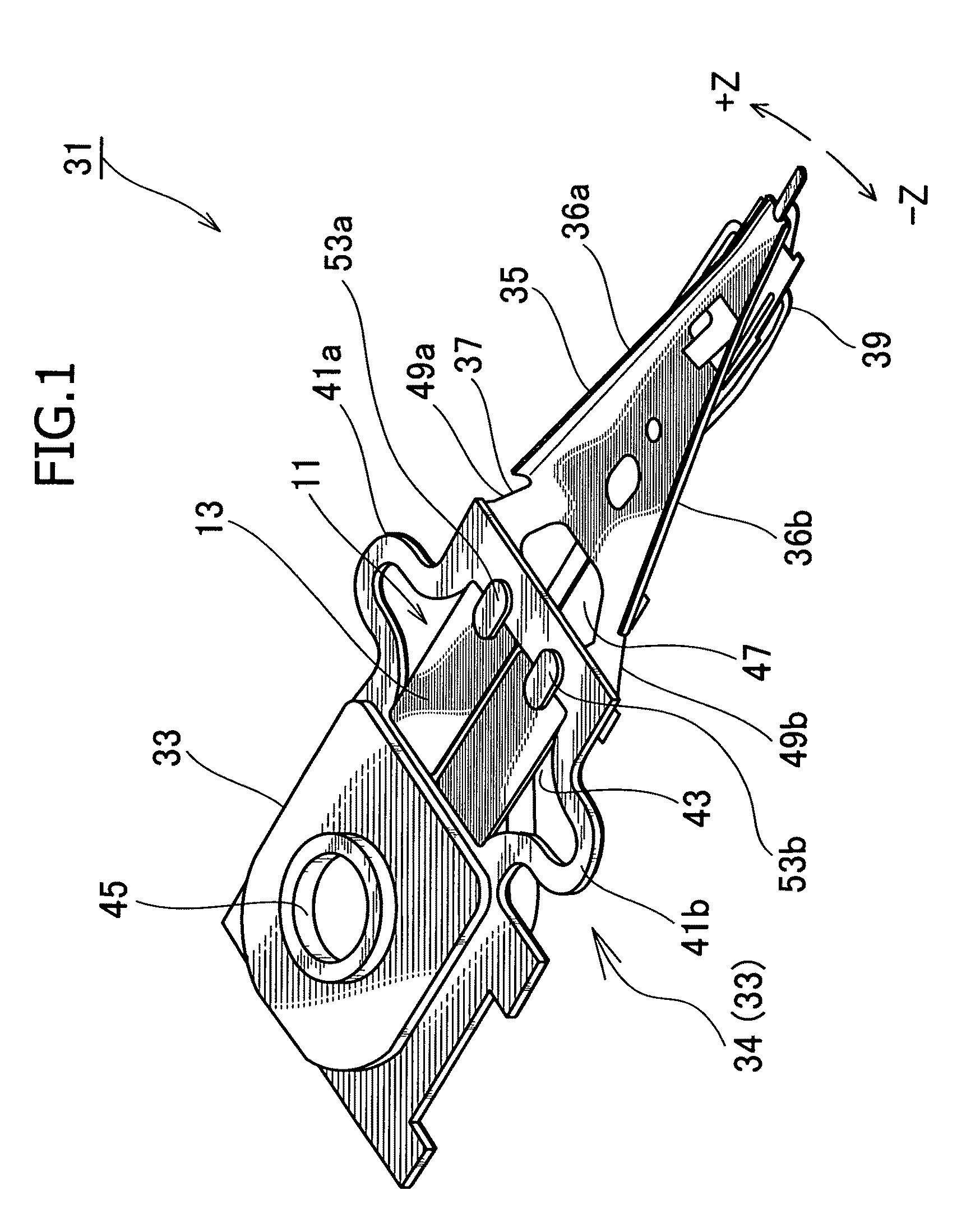

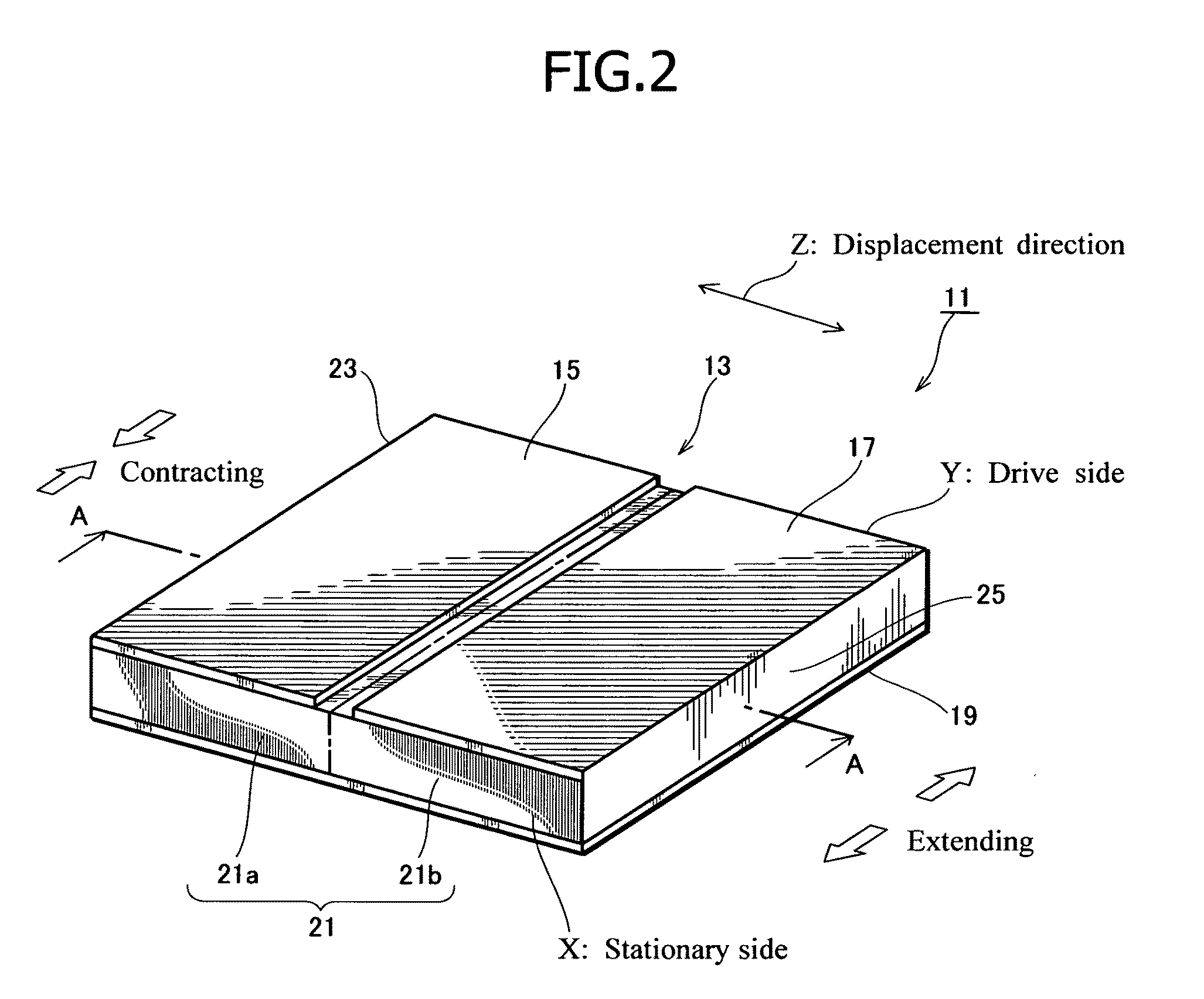

Electrical connecting structure for piezoelectric element, piezoelectric actuator, head suspension, and electrical connecting structure for conductive part

ActiveUS8199442B2Without deteriorating productivity and reliabilityAccurate wiringTrack finding/aligningArm with actuatorsElectricityAdhesive

A piezoelectric element 13 has a common electrode 19 that receives electricity from a terminal 57. The terminal 57 has a through hole 67 and an electric insulating layer 61. The piezoelectric element 13 is arranged so that the common electrode 19 faces the electric insulating layer 61 of the terminal 57. A liquid stopper 69 is formed around the through hole 67 so as to come between the common electrode 19 and the terminal 57 when the common electrode 19 and terminal 57 are set to face each other. A liquid conductive adhesive 71 is injected into the through hole 67 to fill a gap defined by the liquid stopper 69 between the terminal 57 and the common electrode 19 and secure electric connection between the terminal 57 and the common electrode 19. This configuration improves the reliability of wiring to the piezoelectric element and prevents the piezoelectric element from being damaged.

Owner:NHK SPRING CO LTD

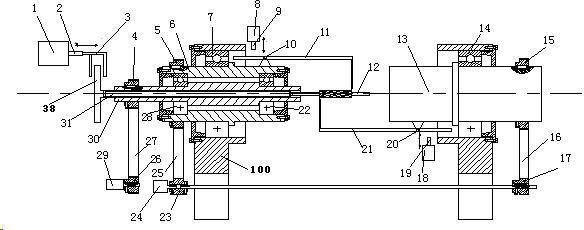

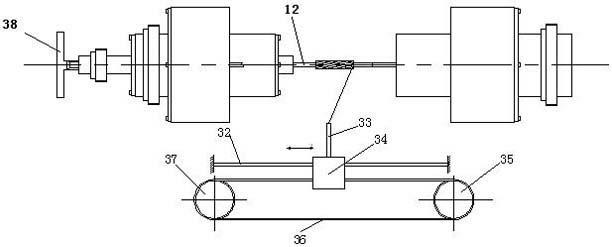

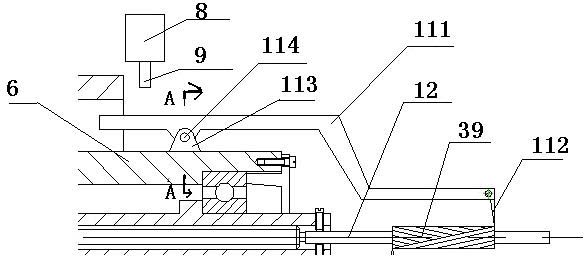

Coil winding machine of coreless motor

InactiveCN102684417AQuality improvementHigh control precisionManufacturing dynamo-electric machinesWinding machineDisplacement - action

The invention relates to a coil winding machine of a coreless motor, and the coil winding machine comprises a stander, and a winding mechanism, a feeding mechanism and a withdrawing mechanism, which are arranged on the stander, wherein the winding mechanism comprises a first traverse unit, a second traverse unit, a first rotary bushing, a rotary drum, a second rotary bushing, a first power device, a second power device and a winding mandrel, the first traverse unit is fixed on the first rotary bushing, and the second traverse unit is fixed on the rotary drum; and the feeding mechanism comprises a feeding needle for feeding a wire to the winding mandrel, a feeding slide block for fixing the feeding needle and a rotating device for driving the feeding slide block to move forwards and backwards, and the withdrawing mechanism comprises a withdrawing air cylinder which is used for driving the winding mandrel to move leftwards and rightwards. The winding mechanism has high control precision and is precise in winding displacement, winding displacement action is simultaneously completed in the winding process, and a coil is withdrawn after the winding is completed so as to begin a next winding action, the actions are coherent, so that the quality of the wound coil is greatly improved, and the production efficiency is improved.

Owner:KUSN KUKE AUTOMATION TECH

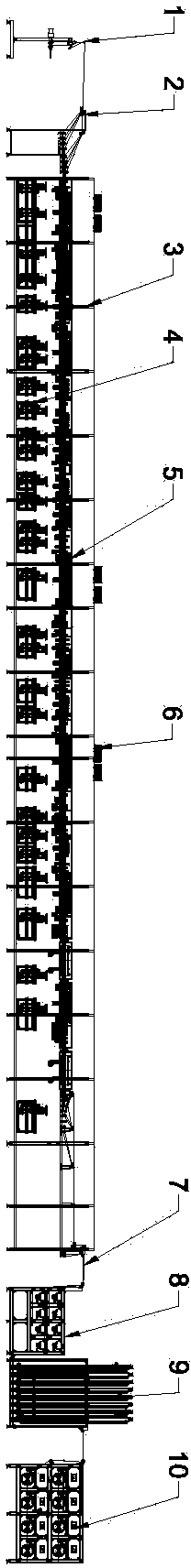

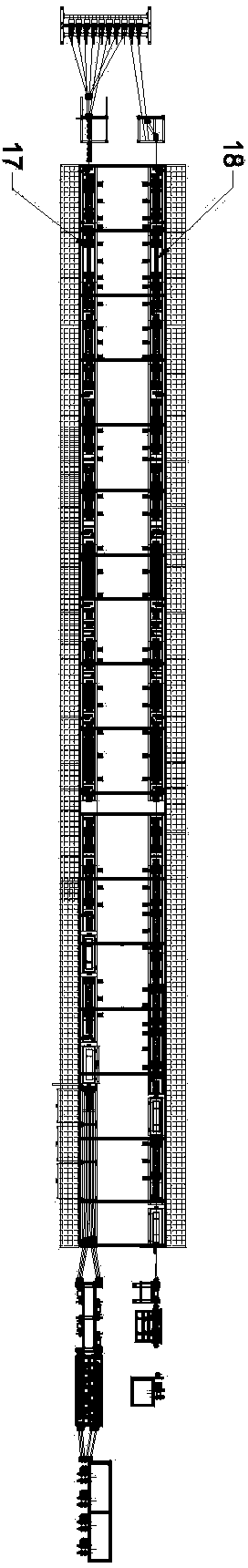

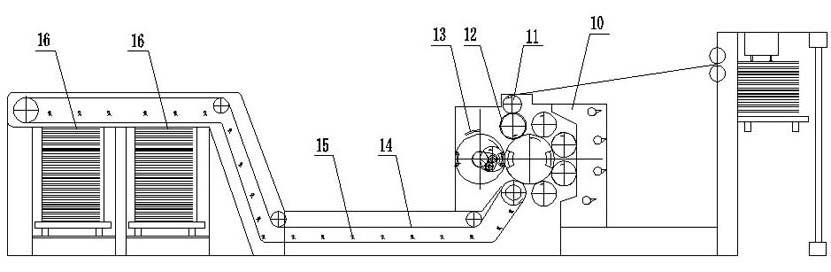

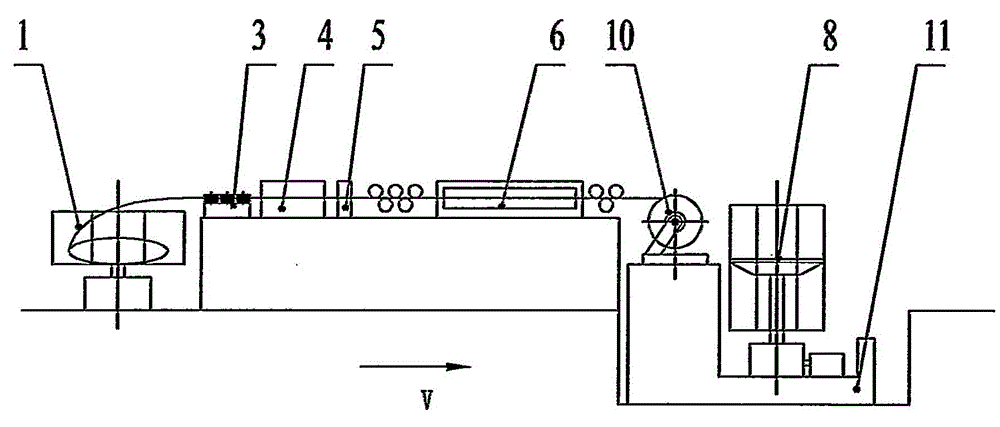

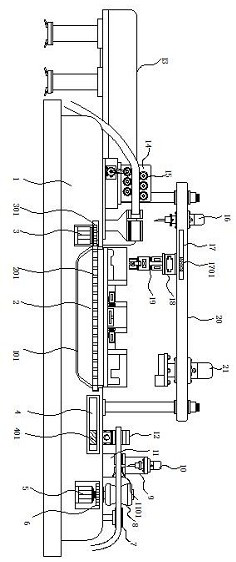

Automatic production line for continuous electroplating of ultrafine metal wire

InactiveCN103741186AGuaranteed constant tensionFlat and beautiful wiringFilament handlingProduction lineSurface layer

The invention relates to the technical field of electroplating equipment, and in particular relates to an automatic production line for continuous electroplating of an ultrafine metal wire, which is used for a solution of equipment for electroplating a surface layer of an ultrafine metal wire with other metal plating layers in the electroplating industry. A brand new unwinding mechanism is adopted for performing constant-tension unwinding, so that the tension of the metal wire during the unwinding keeps constant; by virtue of a brand new driving mechanism, the linear speed keeps constant when the metal wire moves in the production line and can be adjusted as required so as to meet requirements of an electroplating process; a winding mechanism can be used for performing constant-torque winding during winding, and the winding torque can be adjusted according to the thickness of the metal wire; by virtue of the brand new winding mechanism, the wire can be accurately arranged according to the winding speed, so that the metal wire can be smoothly and attractively arranged; a buffer mechanism is additionally arranged between the driving mechanism and the winding mechanism, and can be used for balancing the speed difference between the driving mechanism and the winding mechanism.

Owner:PLASTIC ENG

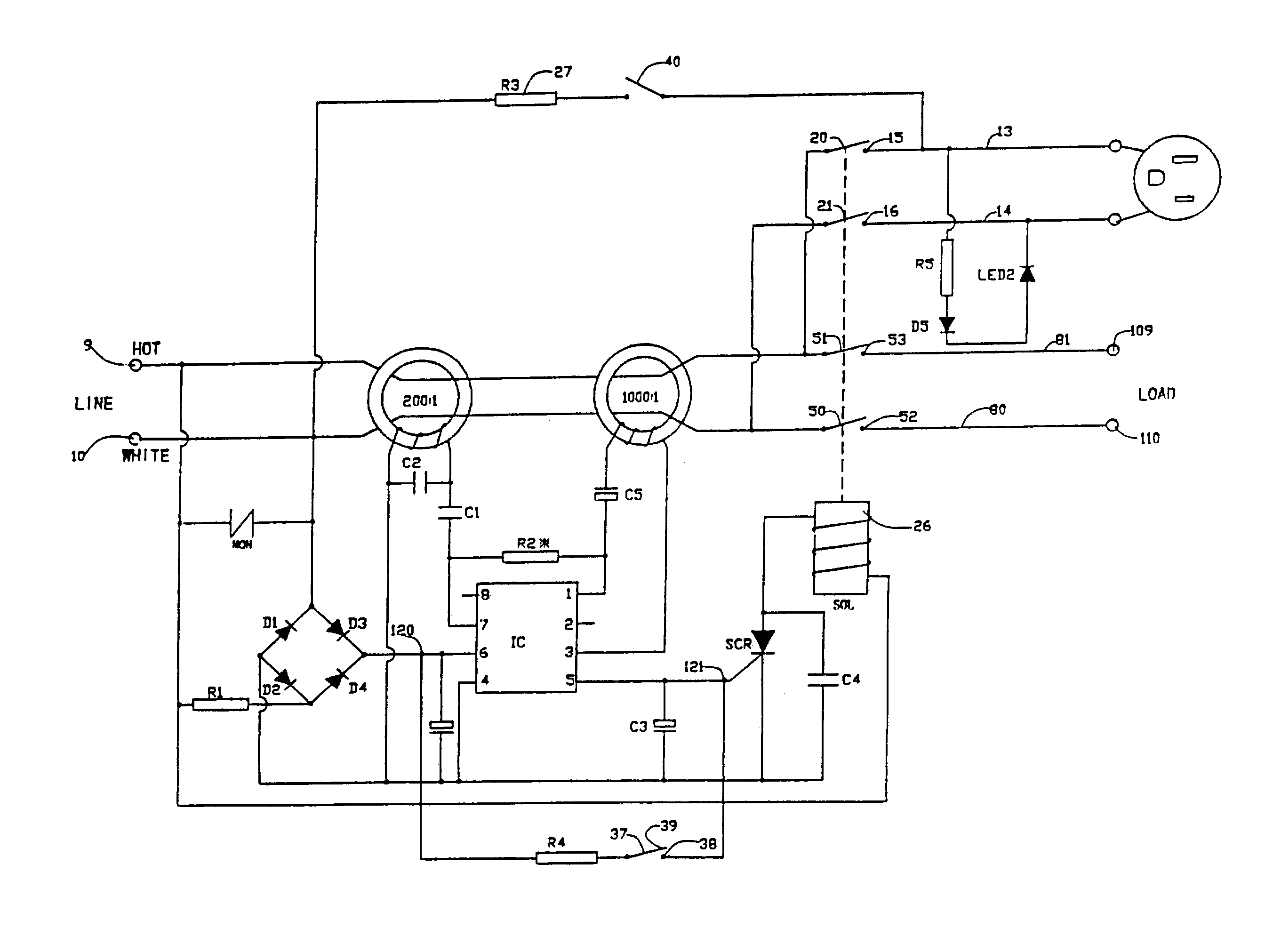

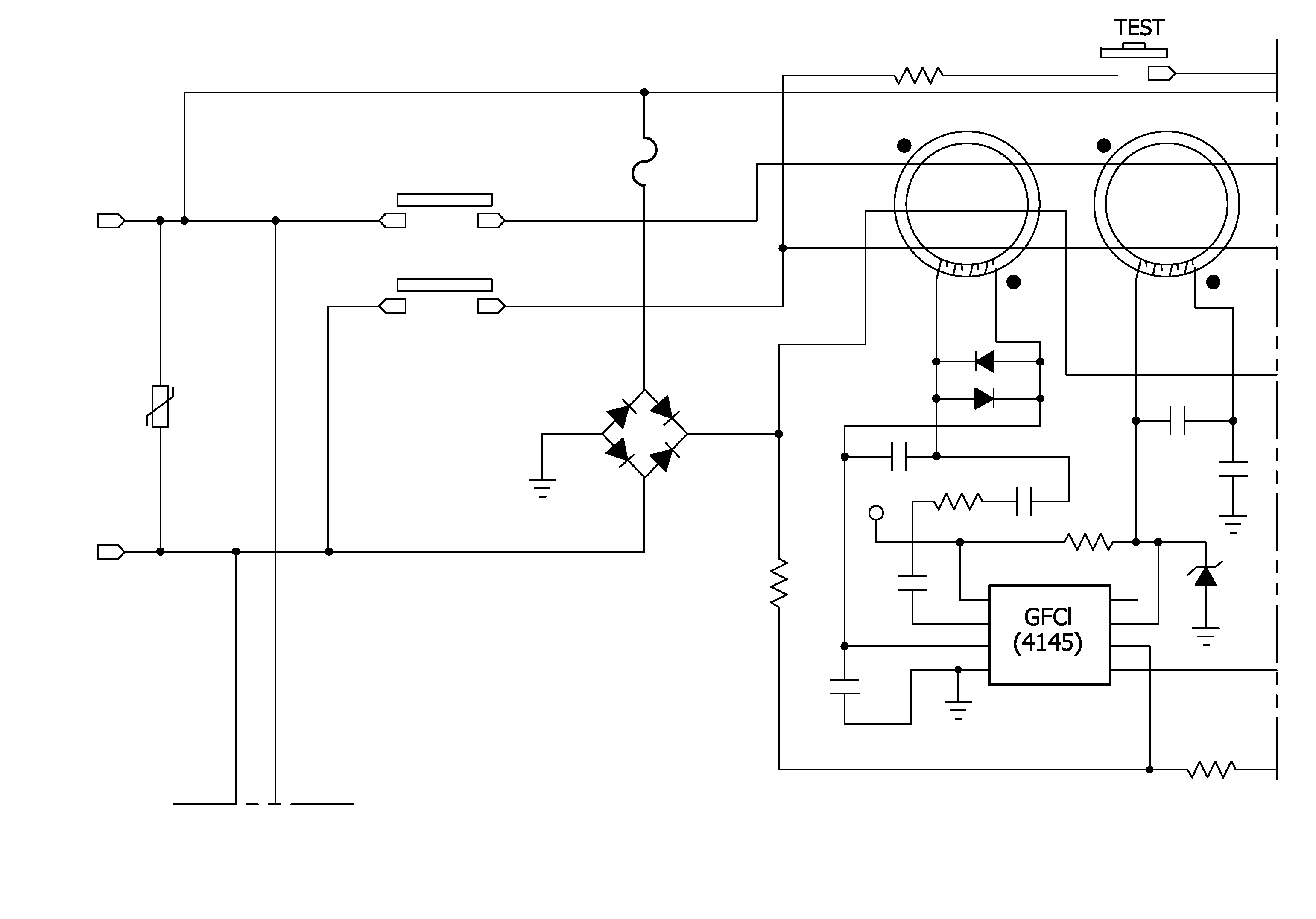

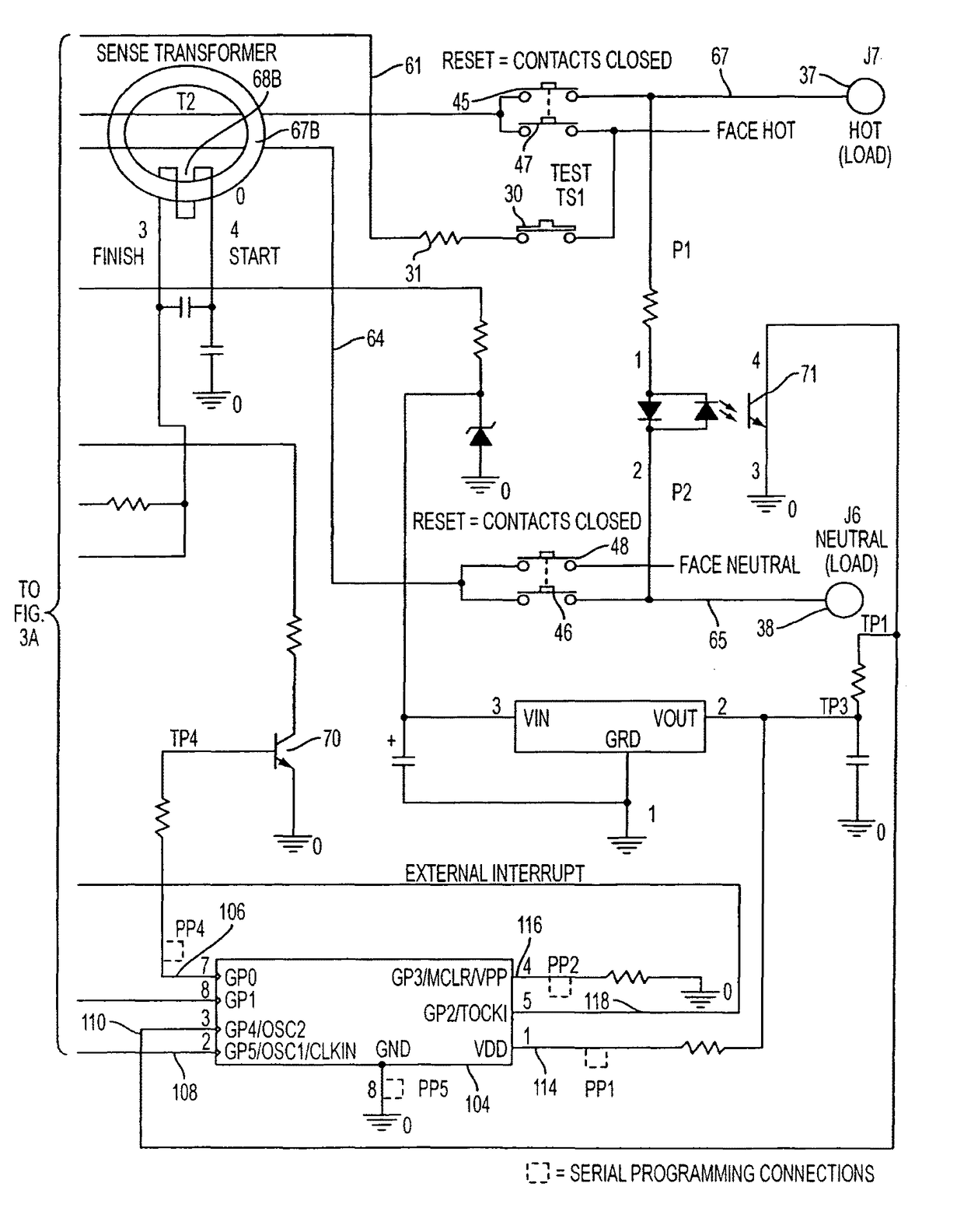

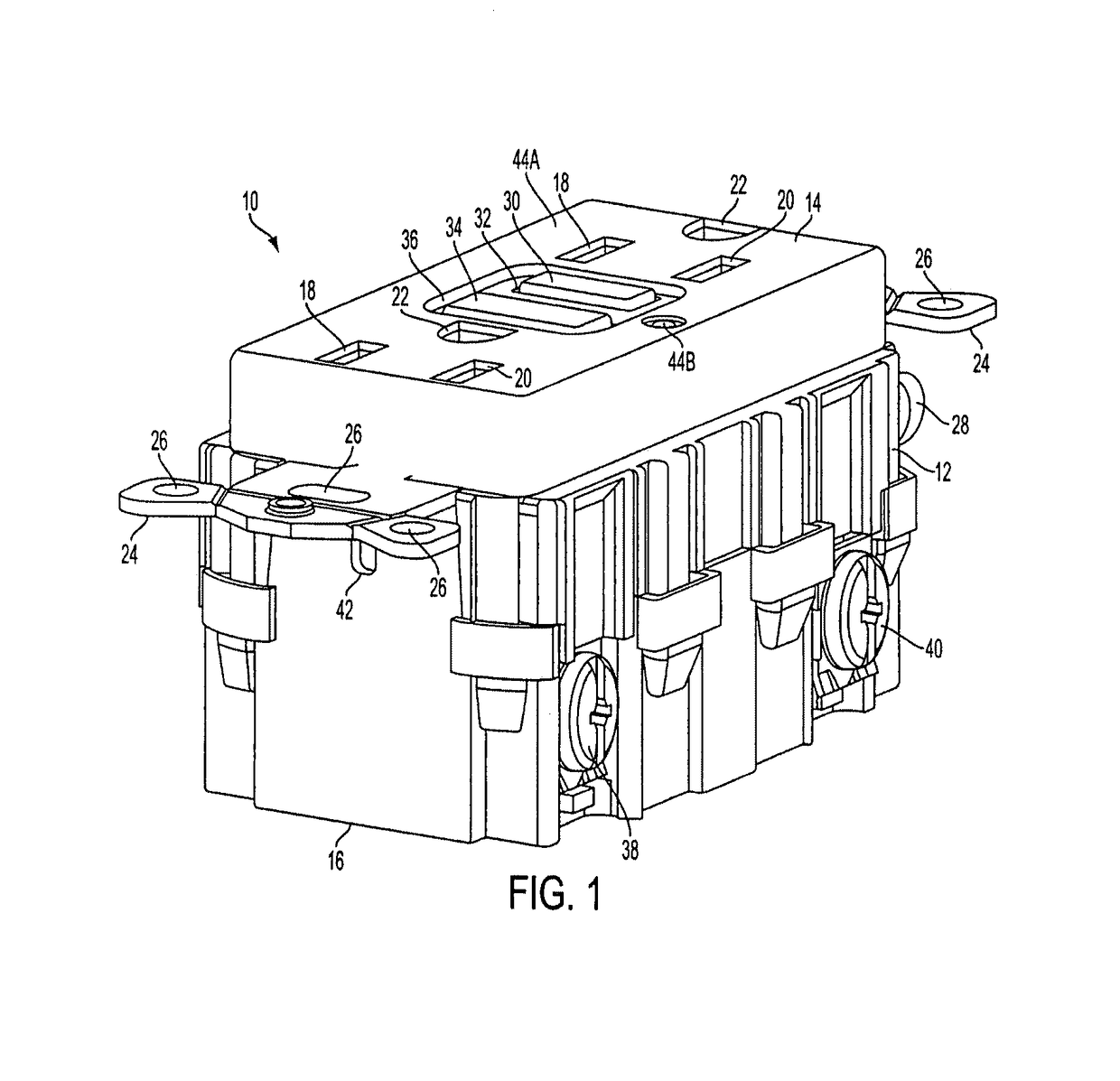

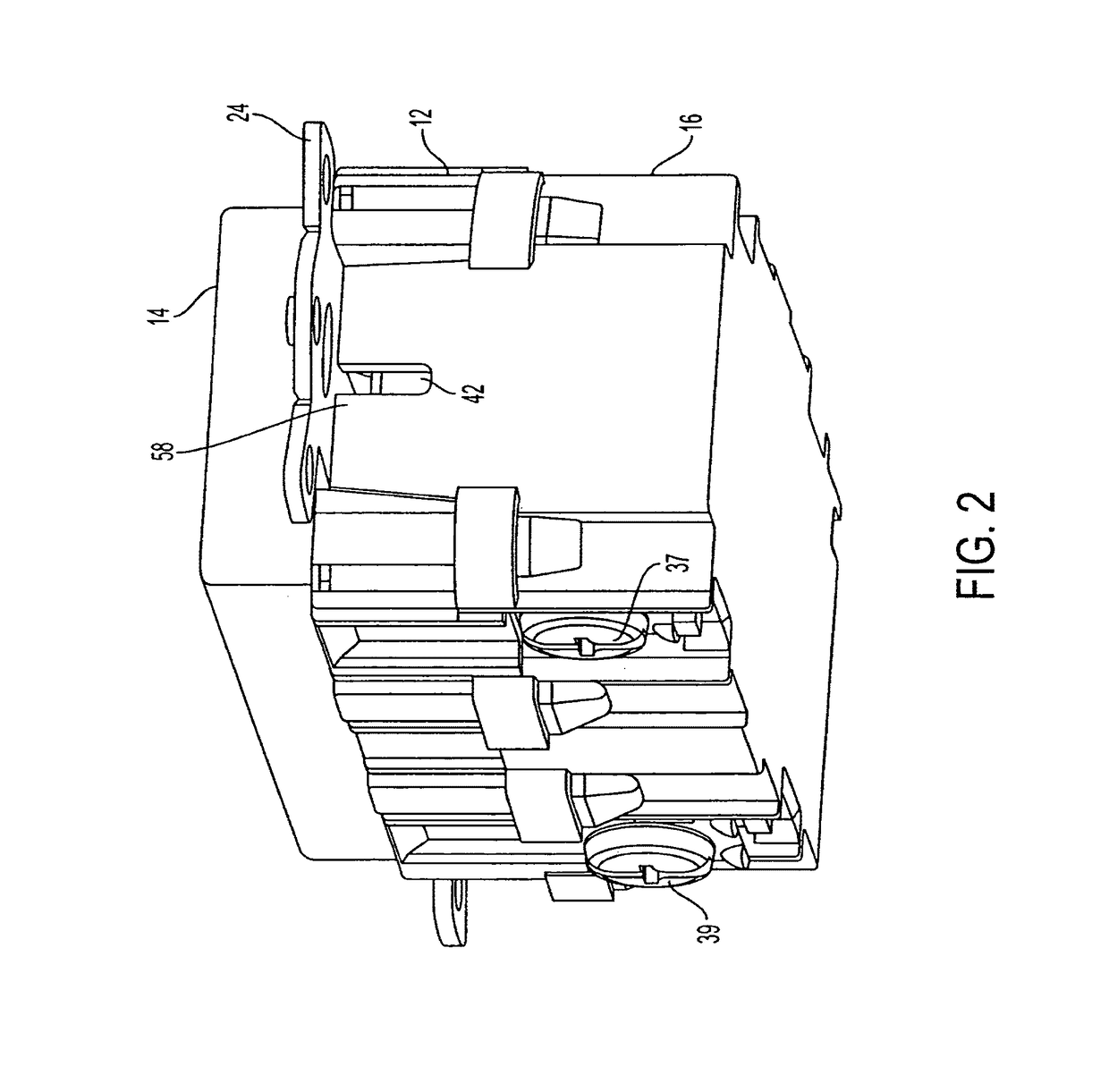

Self-testing auto monitor ground fault circuit interrupter (GFCI) withpower denial

ActiveUS20140347768A1Prevent trippingChoose accuratelySwitch operated by earth fault currentsShort-circuit testingElectricityCircuit breaker

A self-testing fault detector having a line side and a load side and a conductive path there between is provided. The self-testing fault detector includes an auto-monitoring circuit electrically coupled to a fault detection circuit and an interrupting device and it continuously monitors one or more signals to determine an operating state of the fault detector. At least one of the monitored signals includes a fault detection signal, wherein if said automonitoring circuit determines that the fault detection circuit is not properly driving the interrupting device, the automonitoring device converts an input-output port receiving the fault detection signal from an input to an output and drives the interrupting device into a tripped condition using the input-output port.

Owner:HUBBELL INC

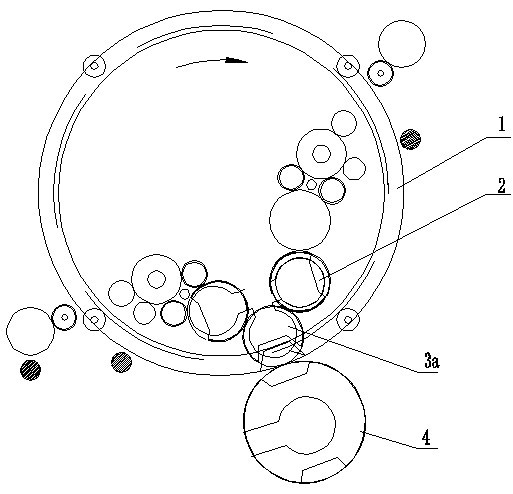

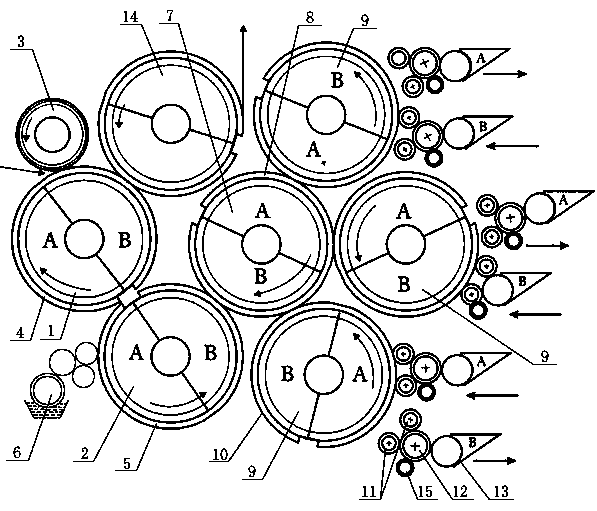

Polychrome connection silk screen printing process and equipment thereof

ActiveCN101982319AImprove anti-counterfeiting performanceSolve process problemsScreen printersPattern printingScreen printingPrinting ink

The invention discloses a polychrome connection silk screen printing process and equipment thereof, and relates to the technical field of sheet-fed rotary screen printing. The printing process comprises the following steps: transferring the printing ink to relief printing plates on four color mould drums by utilizing a four-color-group ink supply unit in satellite-type layout; converging the different colors onto the color gathering rubber blankets of a double-diameter impression cylinder in different zones by different color mould relief printing plates; transmitting the different colors onto a connection cylinder printing plate in a silk screen cylinder by combining a special money printing connection process through a big neutral position to form an accurate printing ink pattern; and finally rolling the printing ink pattern onto the paper sheet through the silk screen plate to form a polychrome connection pattern. The invention can realize the connection silk screen printing process of different-color counterfeiting inks, such as OVI and OVMI, and also can realize a puzzle connection silk screen printing process and a mixed-color silk screen printing process of common printing ink, OVI, OVMI and colorless fluorescent ink and the like. The printing production has high yield and accurate connection, and is convenient in operations of washing, replacing and tightening the silk screen plates.

Owner:CHENGDU BANKNOTE PRINTING +1

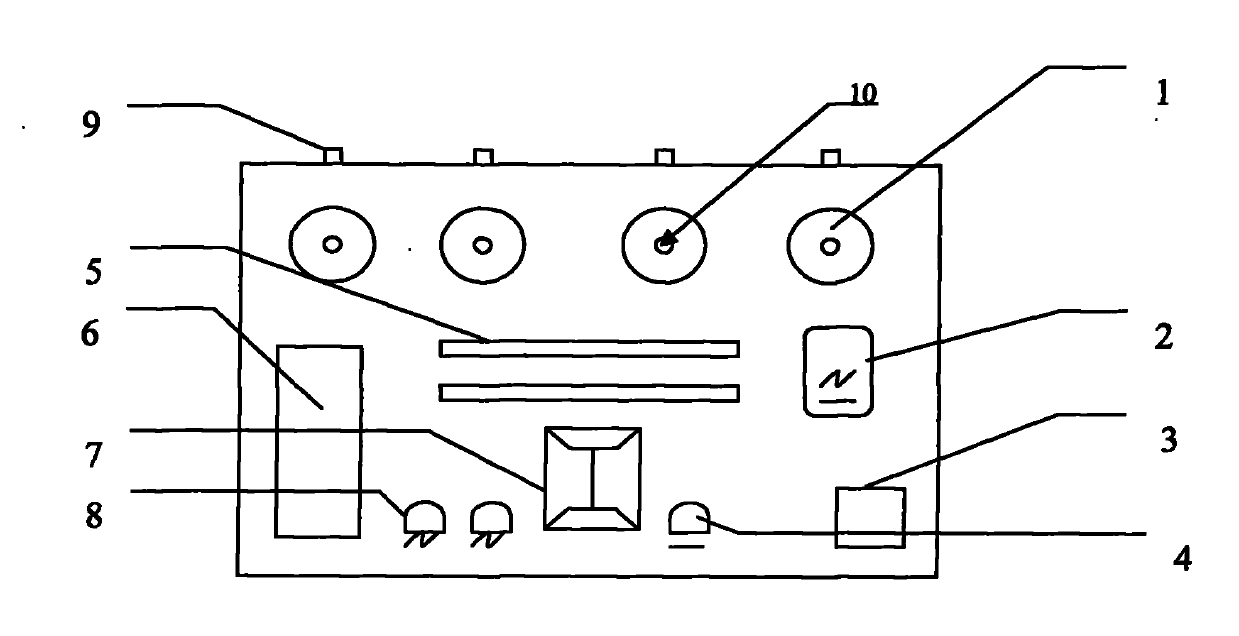

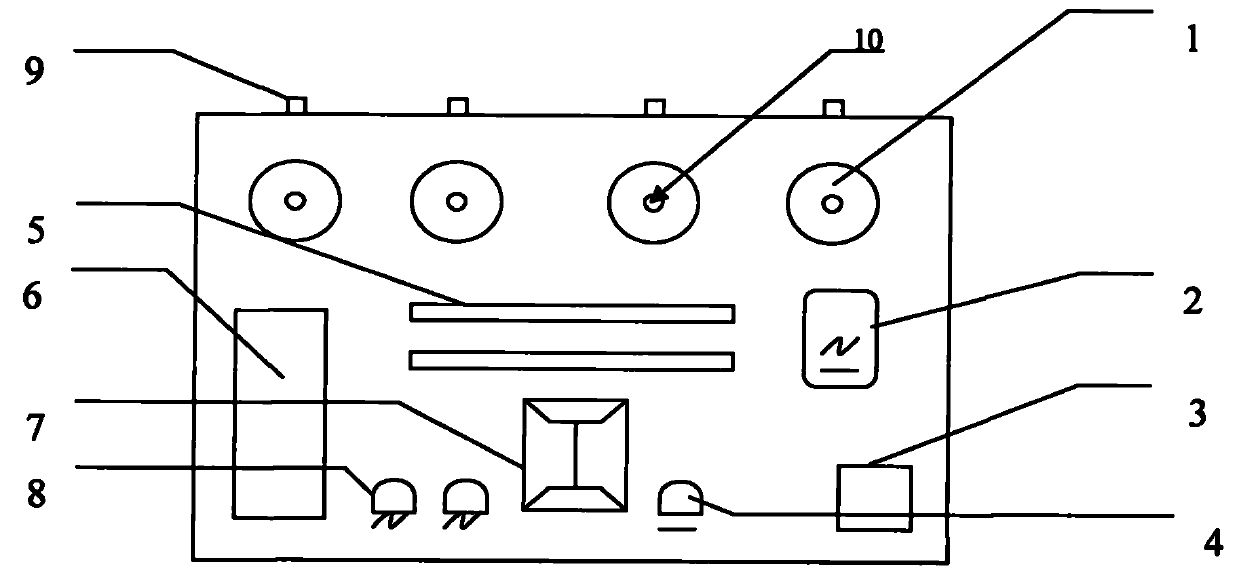

Junction box for switch mechanical characteristic tester

InactiveCN102087171AControl changesReduce damage rateStructural/machines measurementCircuit interrupters testingElectric machineTester device

The invention discloses a junction box for a switch mechanical characteristic tester, comprising at least two test wire coils, test wire outlets corresponding to the test wire coils, a motor, a leakage protector, a direct current inlet wire plug and an alternating current inlet wire plug, wherein the test wire coils are provided with a clutch device for resetting wire coils; the clutch device is driven by the motor; the test wire coils are coiled with test connecting rods connected with the direct current inlet wire plug and the alternating current inlet wire plug by a change-over switch; and the circuits in the junction box are all arranged on a printed circuit board. The junction box is arranged between a middle switch cabinet and a mechanical property tester of a switch to protect an instrument, the damaging possibility of the test instrument is greatly lowered, and the test efficacy is obviously improved. Adverse factors, such as easiness of wrong wiring, short circuit, damages of instrument terminal blocks because of repeatedly disassembling and connecting and the like in the electrical test of the equipment can be eliminated. The junction box for the switch mechanical characteristic tester is convenient to carry, and is safe and correct to wire, and no test wire is left in the equipment.

Owner:JIANGSU ELECTRIC POWER CO

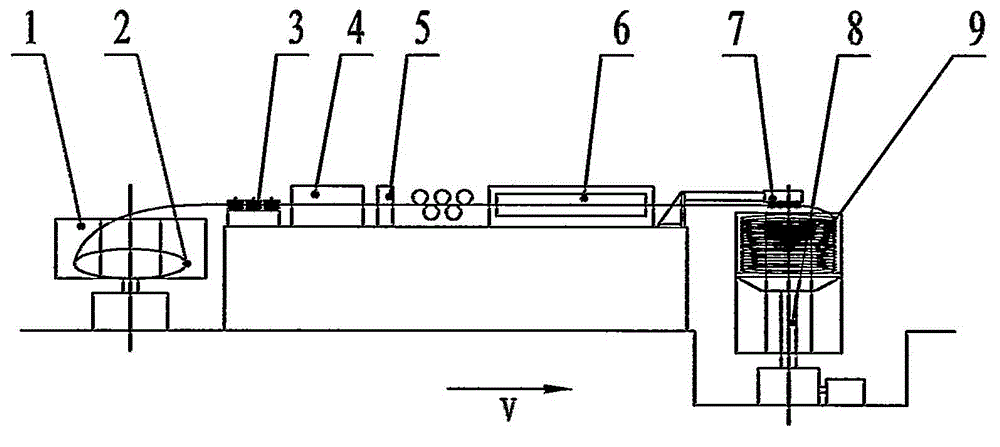

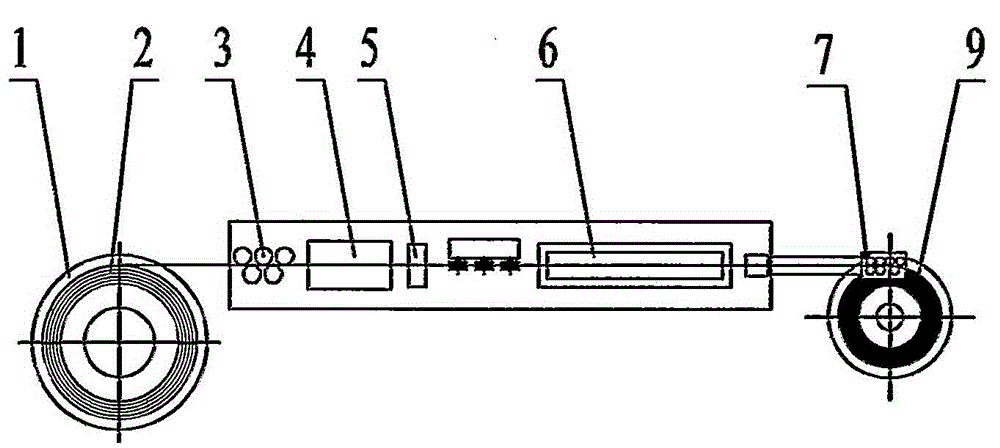

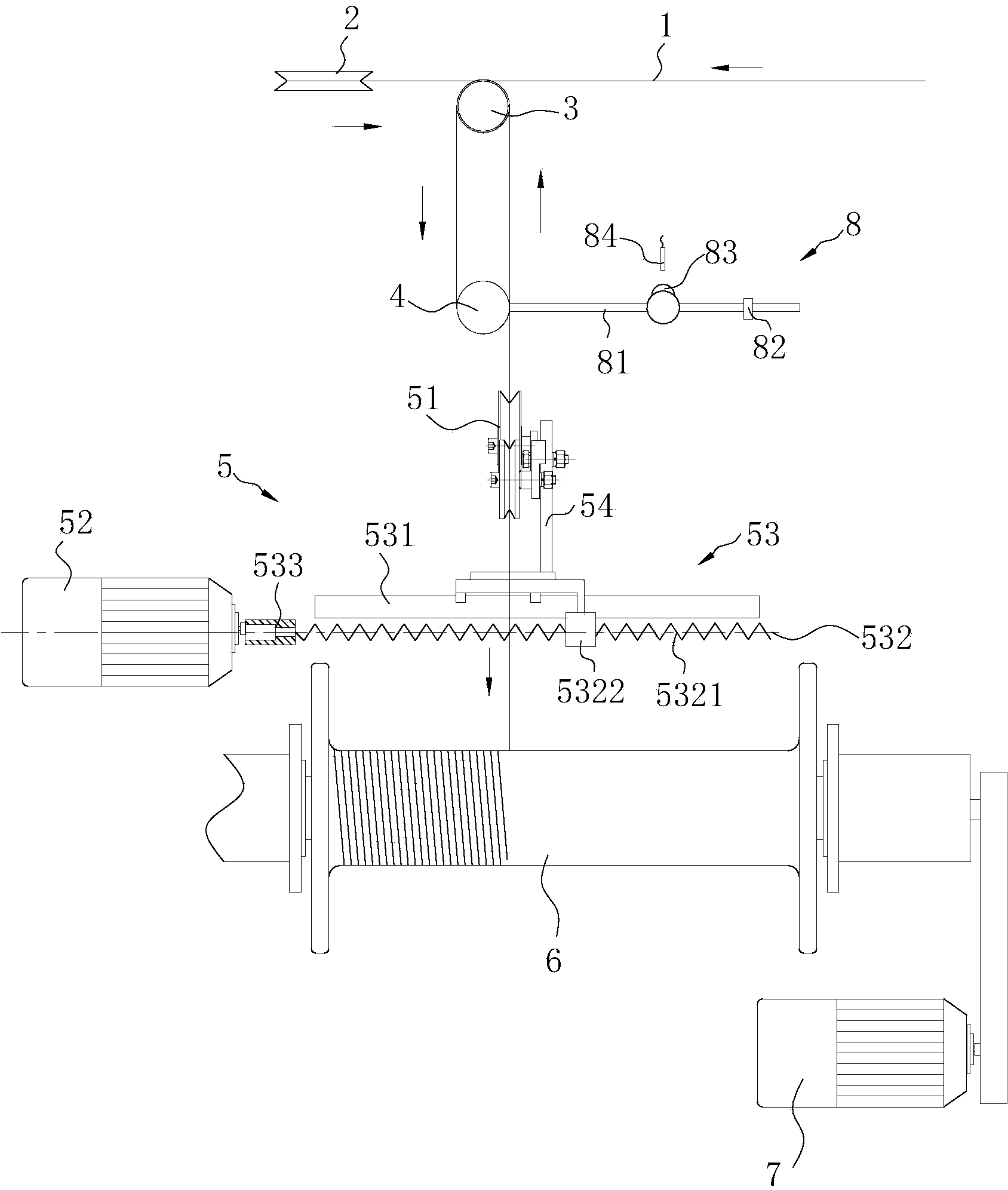

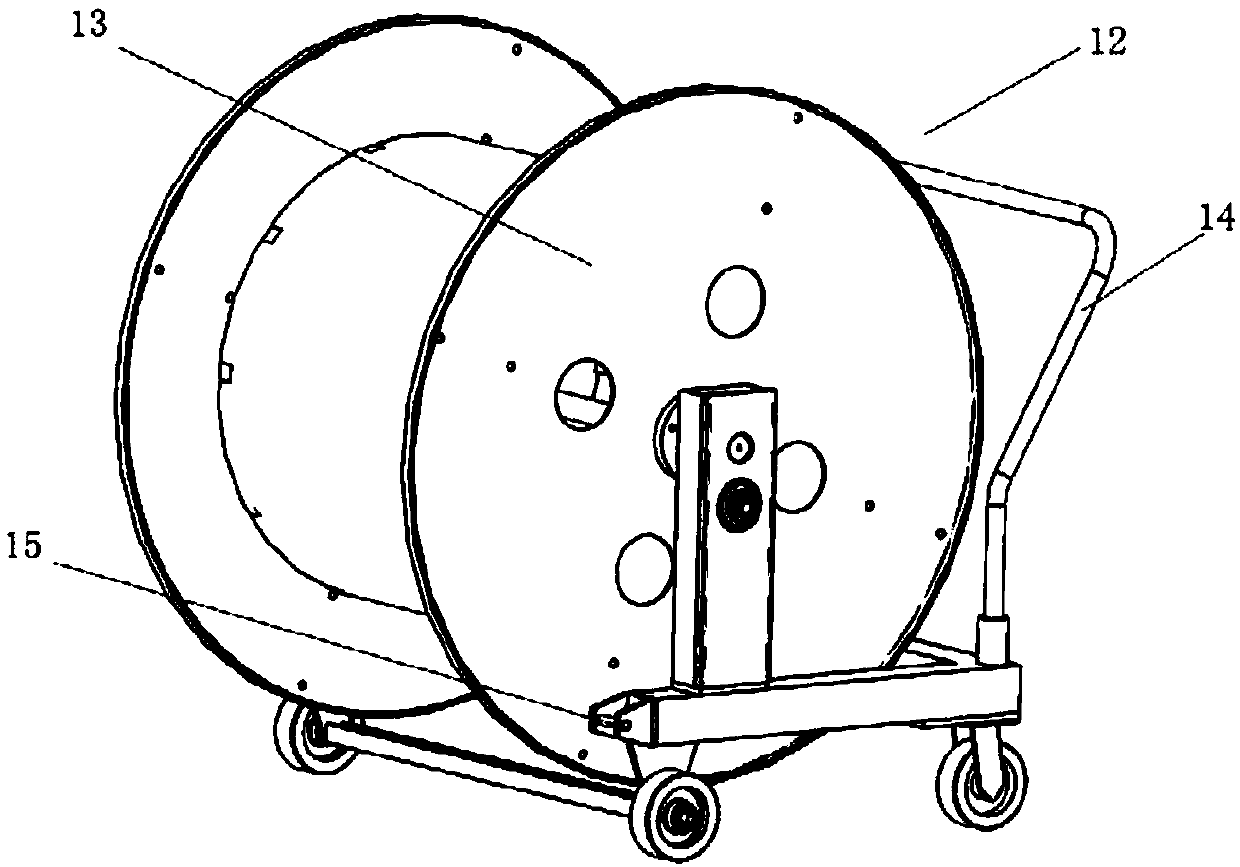

Production method and pipe-coiling device of non-ferrous metal coil pipes

InactiveCN104588437AReduce distortionSlip and bruise is smallWire straightening devicesConductor CoilNonferrous metal

The invention relates to a production method and a pipe-coiling device of non-ferrous metal coil pipes. The production method comprises following steps: step 1, rigid metal pipes are subjected to transverse arranging and winding; and step 2, coil pipes obtained via transverse arranging and winding are subjected to annealing processing. The pipe-coiling device comprises an un-coiling device (1), and a transverse arranging and winding device (8); and the tail end of the un-coiling device (1) is connected with the transverse arranging and winding device. The production method and the pipe-coiling device are capable of preventing or avoiding deformation and slide bumping of pipes.

Owner:朱建平

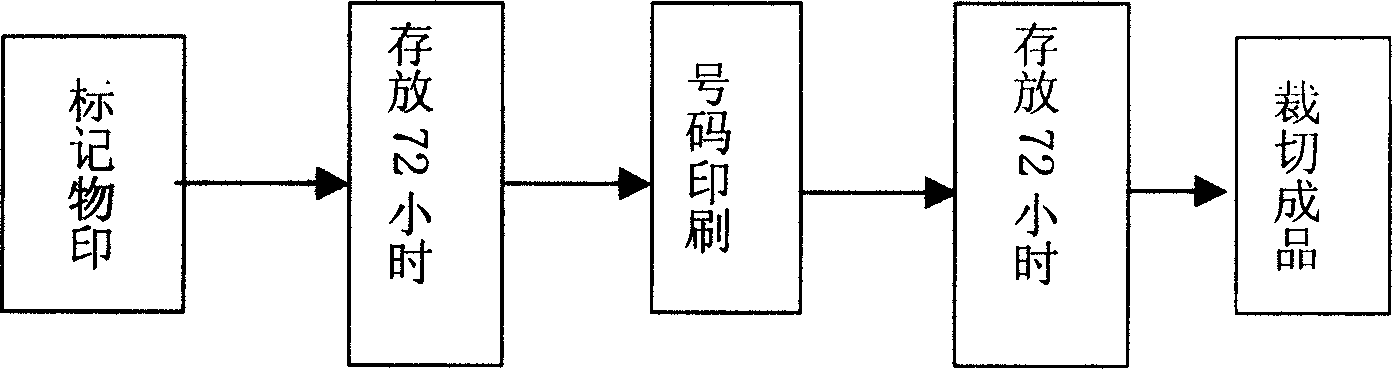

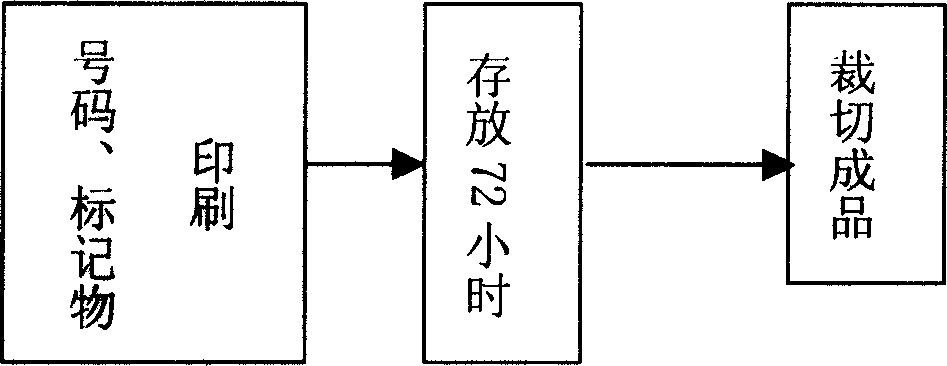

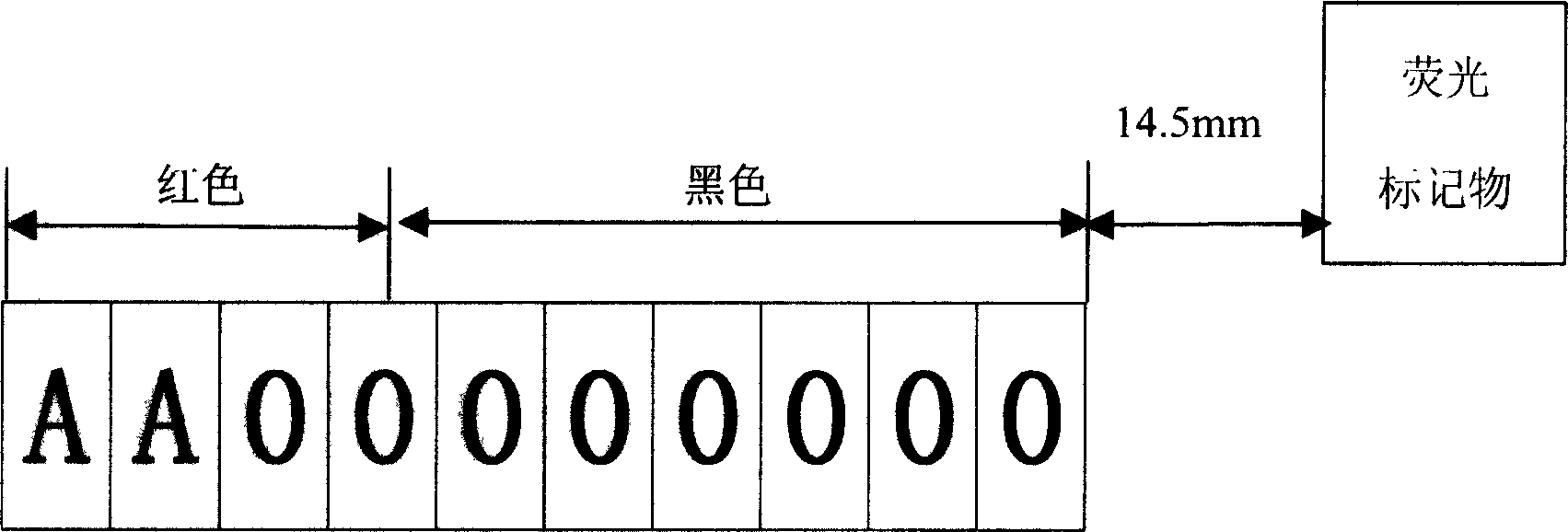

Single number two-color wiring fluorescence label typography

InactiveCN1565855AReduce storageShorten drying timePattern printingFluorescenceMechanical engineering

The invention relates to an once printing process for single-code two-color wiring and fluorescent label comprising (1) setting the axial movement of the code printing machine of the inking unit to be 0-12mm, regulating the axial movement of the ink vibrators, (2) confirming the printing positions of the code wiring and fluroscent label, dividing the ink fountain with color separation films, slitting the lower ink vibrator, ink transfer roller, ink distributing roller, plate approaching roller, and outputting three different inks from the same ink fountain, (3) milling a groove which is 5mm below the fluorescent ring surface and in which the code machine ektexine can move up and down. The invention can shorten the process period, and decrease the production cost, and the printing articles produced thereby are anti-counterfeiting and machine readable.

Owner:CHINA BANKNOTE PRINTING & MINTING

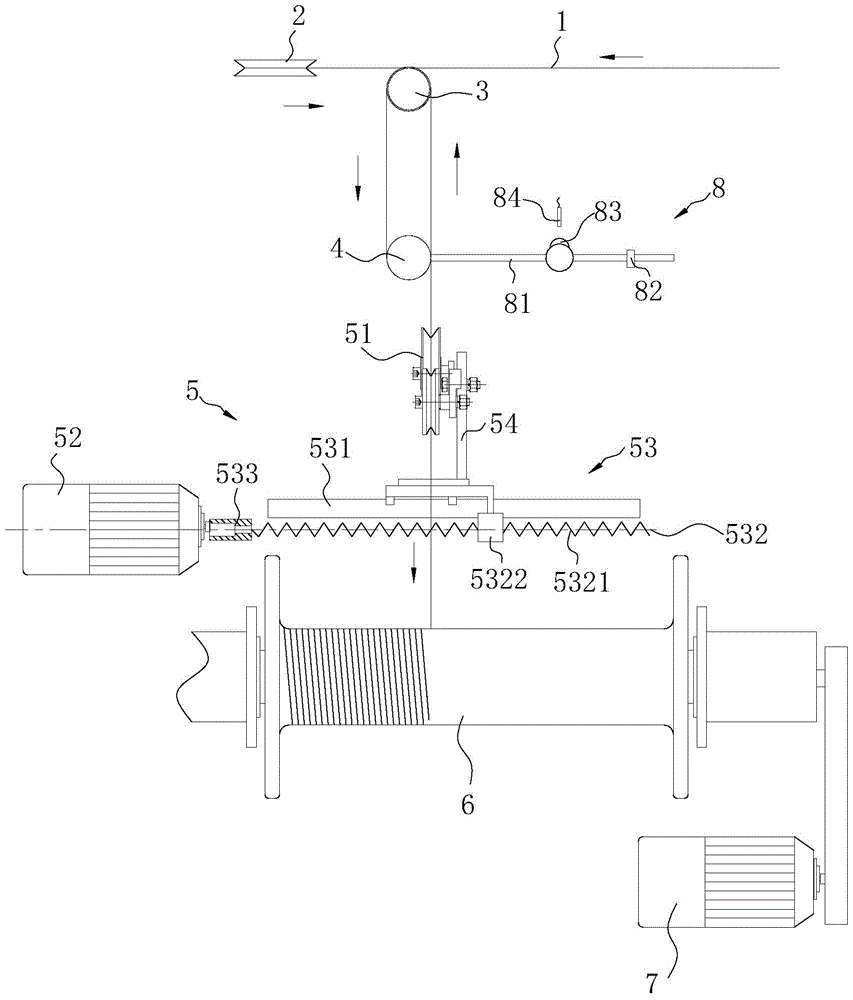

Wire arranging compensation device and wire arranging compensation method of wire cutting all-powerful winding machine

ActiveCN103588025AReduce changeover timeCommutation neatlyFilament handlingWinding machineWire cutting

The invention discloses a wire arranging compensation device of a wire cutting all-powerful winding machine. The wire arranging compensation device comprises steel wires, a first guide wheel, a second guide wheel, a third guide wheel, a wire arranging device and a winding wheel. The steel wires are sent in the main machine direction, sequentially pass through the guide wheels and the wire arranging device and are wound around the winding wheel. One end of the winding wheel is provided with a winding motor. The wire arranging device comprises a wire arranging guide wheel and a wire arranging motor. The output shaft end of the wire arranging motor is connected with the wire arranging guide wheel through a horizontal moving assembly so that the wire arranging motor can push the wire arranging guide wheel to move in the horizontal direction in a reciprocating mode. One side of the third guide wheel is provided with a tension oscillating bar device used for detecting tension variation of the steel wires, and the tension oscillating bar device is connected with a PLC. The output end of the PLC is connected with the wire arranging motor and the winding motor, and the wire arranging motor is a servo motor. The wire arranging compensation device of the wire cutting all-powerful winding machine is simple in structure, convenient to operate, capable of reducing reversing time of the wire arranging guide wheel, free of slip frequency, and capable of ensuring neatness of the wires arranged on the winding wheel.

Owner:WUXI SUNLIT SCI & TECH

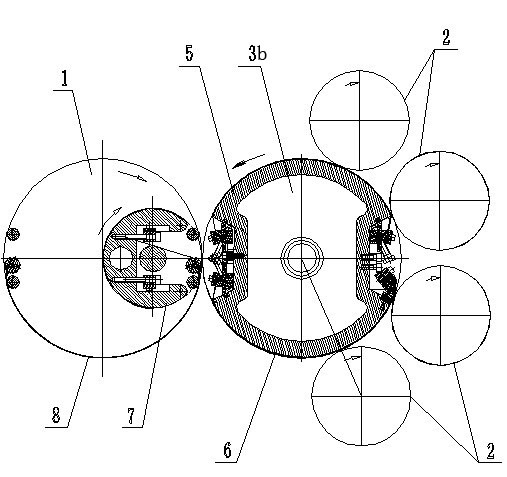

Single-sided and double-sided dual-purpose connecting line face-to-face printing offset press and printing method thereof

ActiveCN103552363AImprove versatilityThe factors that affect the accuracy of printing are smallRotary lithographic machinesPrinting press partsIndustrial engineeringPaper sheet

The invention discloses a single-sided and double-sided dual-purpose connecting line face-to-face printing offset press. The single-sided and double-sided dual-purpose connecting line face-to-face printing offset press comprises a paper control mechanism, a blanket cylinder, a plate cylinder, an impression / offset cylinder and an ink supply system. The blanket cylinder and the plate cylinder are respectively provided with a printing blanket and a printing plate which press each other correspondingly, the printing blanket is of a single-blanket two-unit structure, the printing plate is of a single-plate two-unit structure, the impression / offset cylinder and the printing blanket of the blanket cylinder correspondingly press each other, and the ink supply system is used for supplying ink to the plate cylinder. According to the single-sided and double-sided dual-purpose connecting line face-to-face printing offset press, when the single-sided offset printing and two-sided offset printing are performed simultaneously, a single-piece continuous paper feeding mode is utilized, and any adjustment to the device is not needed; when a face-to-face printing function is utilized, front images and texts and back images and texts are manufactured on the same printing plate, so that factors affecting precise face-to-face printing in an engineered mass production can be reduced to the minimum, front-back printing errors can be less than 0.1 mm, transmittance and color changing can be guaranteed, and the stable operation of height-class printing anti-counterfeiting technologies of datumized watermark, two-sided connecting lines and front-back connecting lines and the like in the mass production can be achieved.

Owner:CHENGDU BANKNOTE PRINTING +1

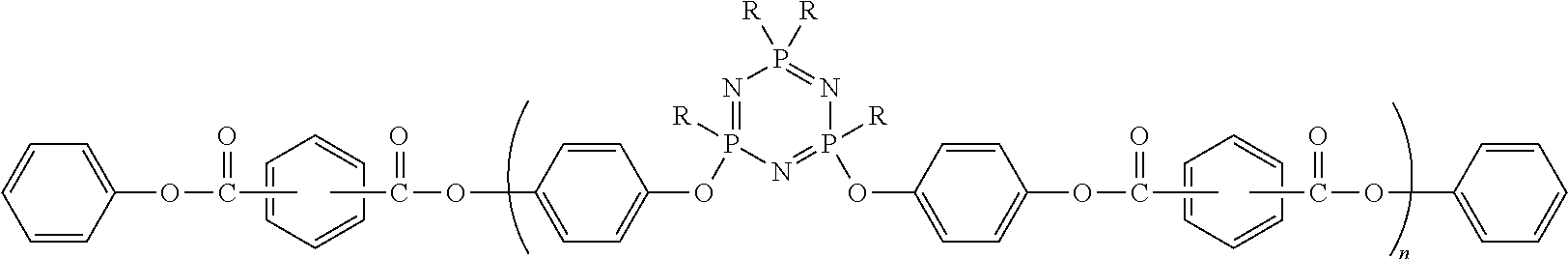

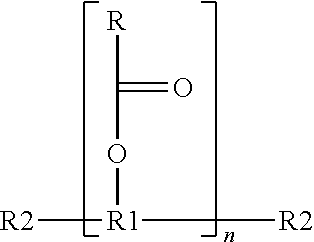

Phenoxycyclotriphosphazene active ester, halogen-free resin composition and uses thereof

InactiveUS20160244471A1Accurate wiringImprove signal transmission ratePlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsInorganic fillerHalogenation

The present invention discloses a phenoxycyclotriphosphazene active ester, a halogen-free resin composition and uses thereof. The phenoxycyclotriphosphazene active ester comprises at least 65 mol. % of a substance having the following structural formula. The halogen-free resin composition comprises 5-50 parts by weight of a phenoxycyclotriphosphazene active ester, 15-85 parts by weight of a thermosetting resin, 1-35 parts by weight of a curing agent, 0-5 parts by weight of a curing accelerator and 0-100 parts by weight of an inorganic filler. The present invention discloses introducing phenoxycyclotriphosphazene active ester into a thermosetting resin, reacting active esters with thermosetting resins, such as epoxy resin, without producing hydroxy groups, which not only satisfies the requirements on being halogen-free and flame retardancy, but also improves the electrical properties (decreasing and stabilizing Dk and Df) of the system, so as to make non-halogenation of high frequency and high speed substrate materials possible.

Owner:GUANGDONG SHENGYI SCI TECH

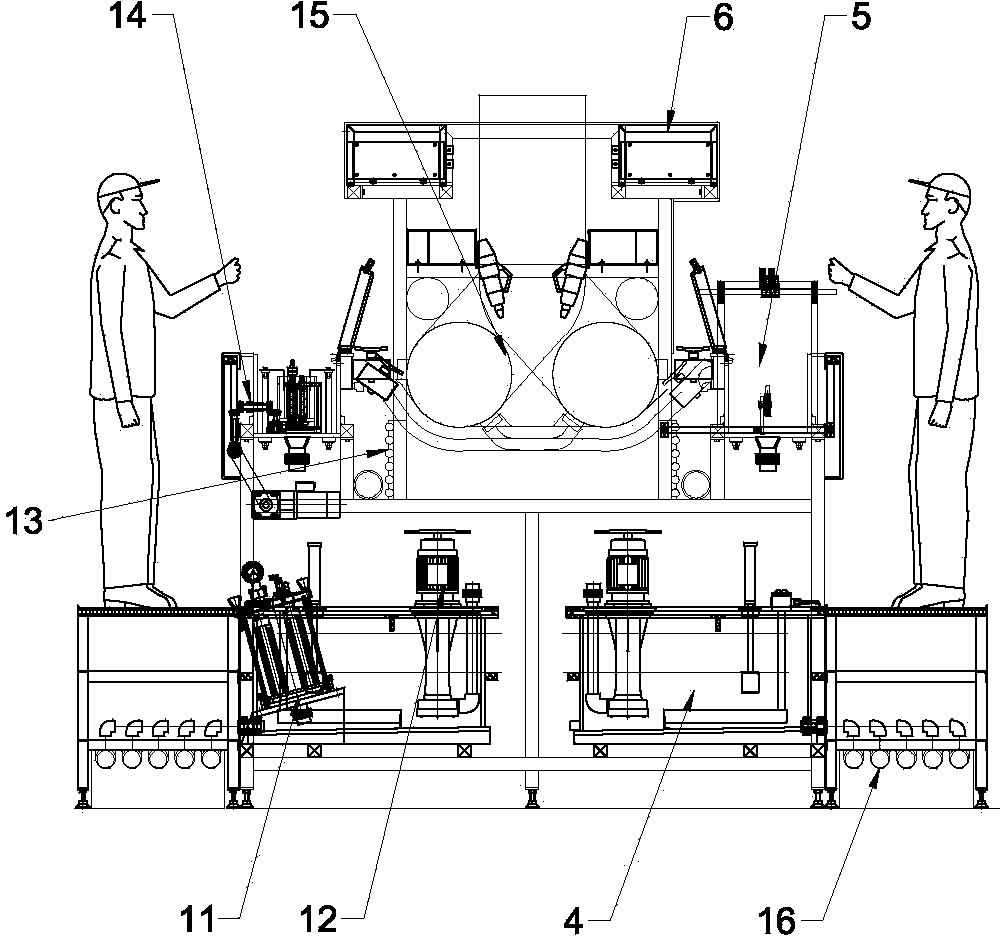

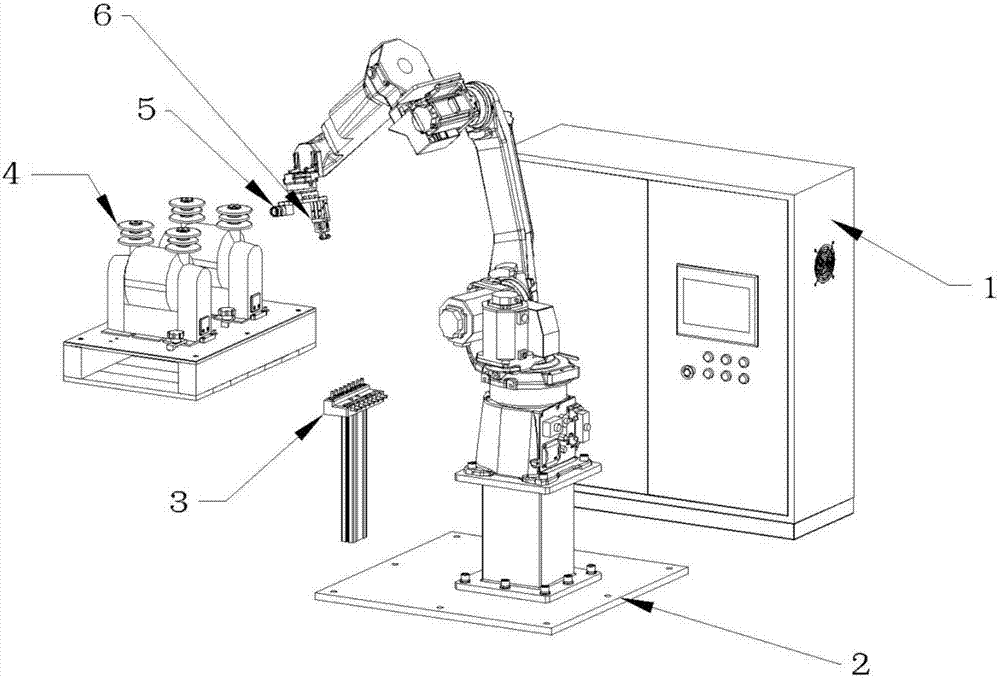

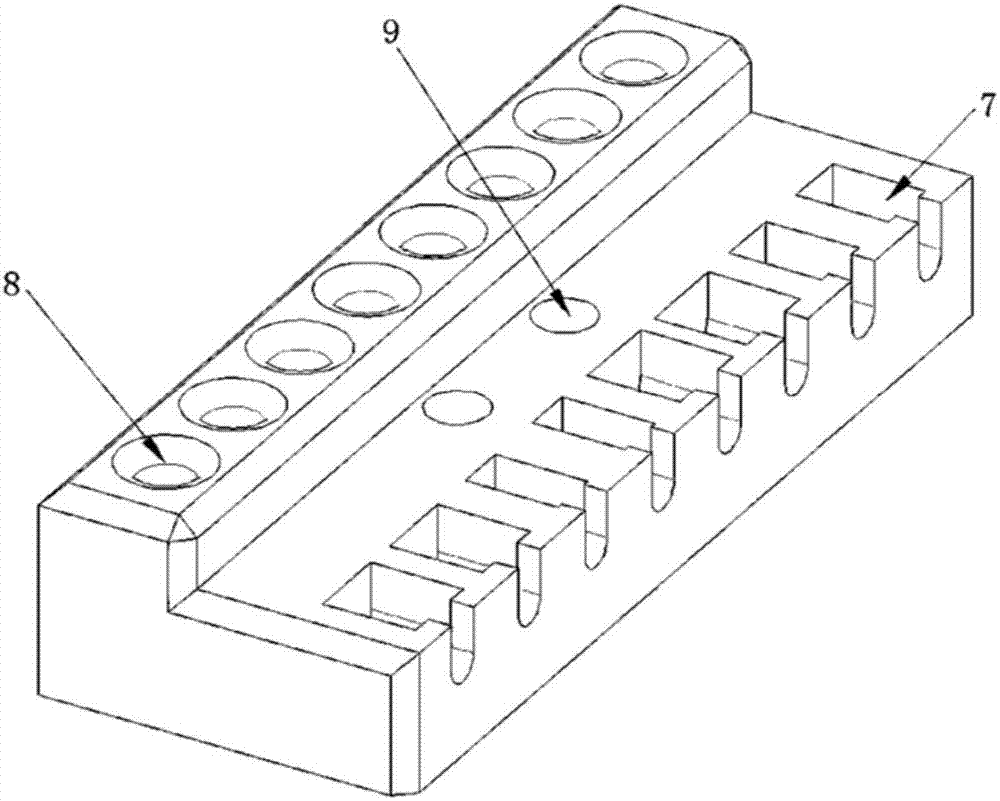

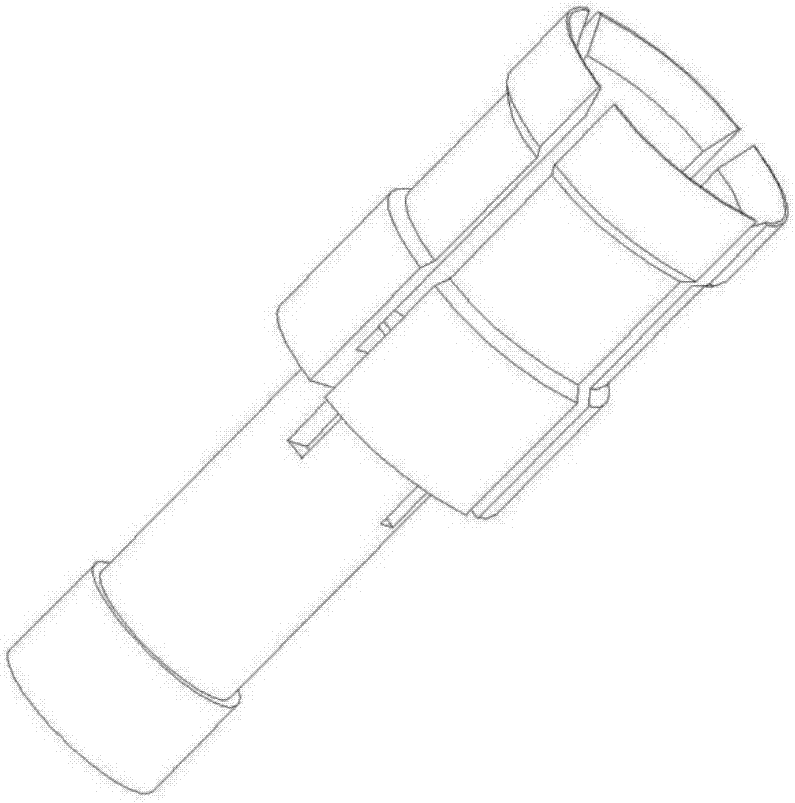

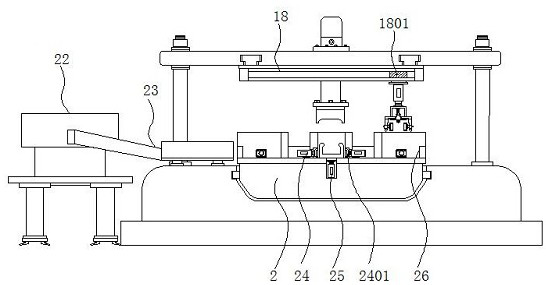

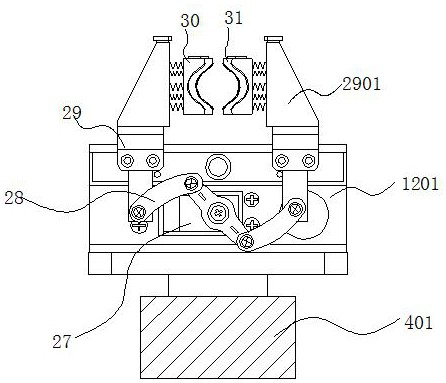

Voltage transformer automatic wiring device

InactiveCN107271728AReduce connection difficultyHigh precisionElectrical testingMeasurement instrument housingProduction lineTransformer

The invention relates to a voltage transformer automatic wiring device used for performing primary wiring and secondary wiring on a voltage transformer to be calibrated on a production line, and the device includes a robot located on a side face of the production line and used for performing precise recognition on the position of the voltage transformer and realizing primary wiring and secondary wiring of the voltage transformer; a clamp module mounted on the production line, connected with a test line and the voltage transformer during wiring and used for serving as an intermediate connecting device of the test line and the voltage transformer to improve wiring efficiency; and a controller connected with the robot and used for providing a wiring scheme for the robot and controlling an operation path of the robot. Compared with the prior art, the voltage transformer automatic wiring device has the advantages of accurate wiring, high degree of automation, cost saving and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

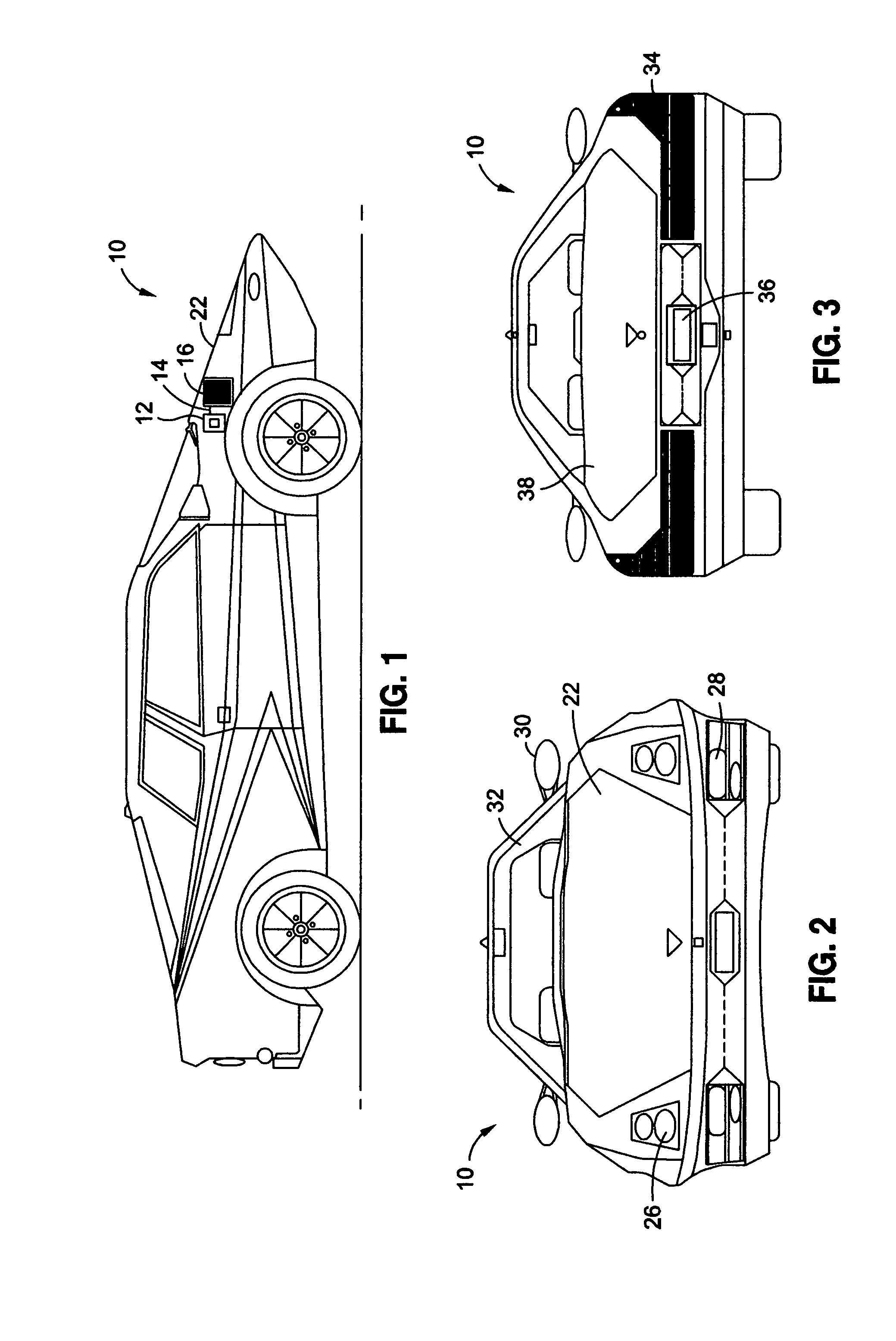

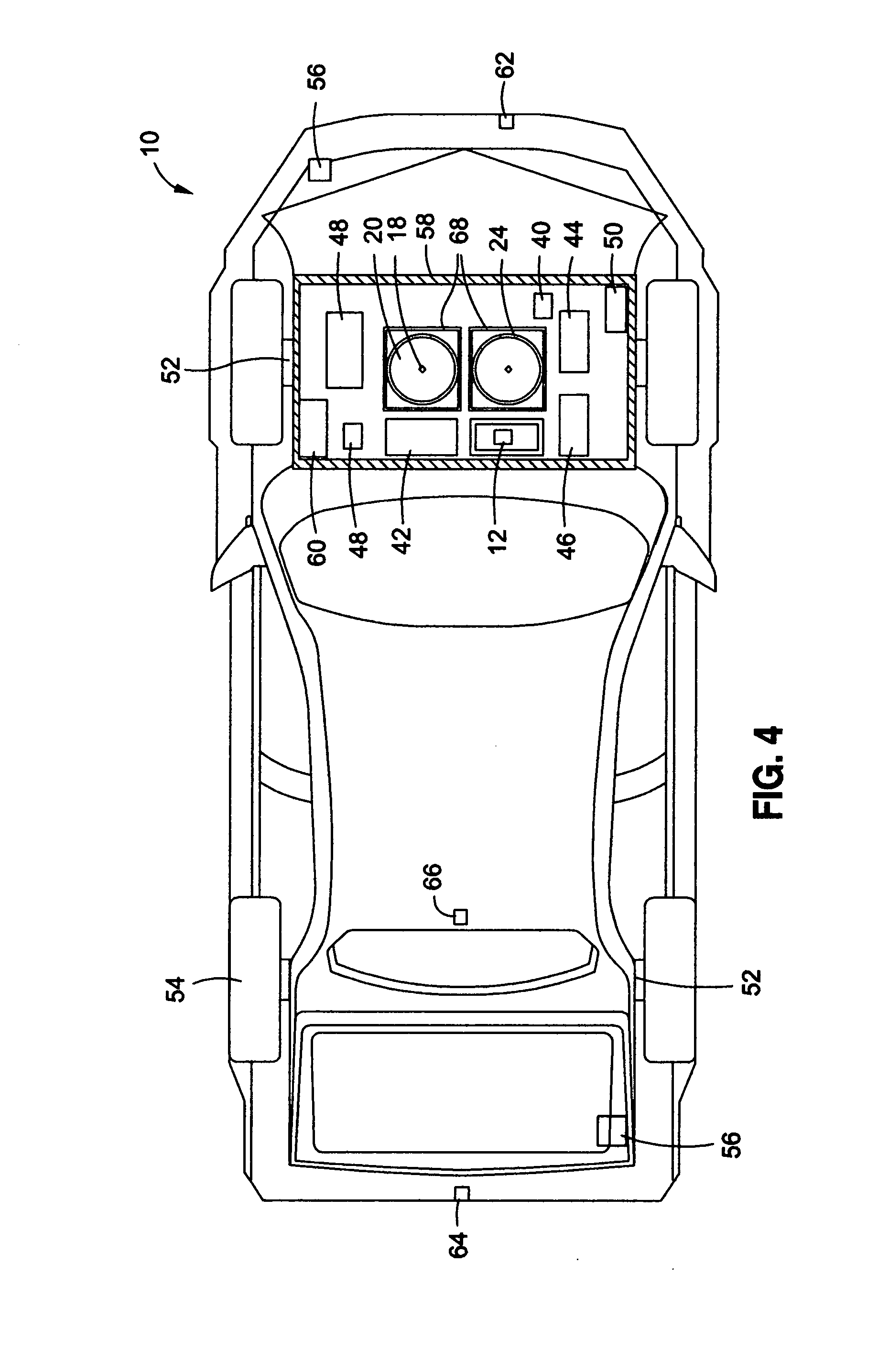

Radioisotope powered engineless vehicle

InactiveUS20110233990A1Maximize mass movementImprove worldAuxillary drivesElectric devicesReed relayDistribution system

A radioisotope powered thermoelectric vehicle lacking an internal combustion engine. The vehicle may include a commercially available, federally-approved encased radioisotope, sensors, an encased metal heat conductor, a heating element embedded within a heat sink, a plurality of thermoelectric chips mounted around the outer surface of the heat sink, a hollow body surrounding the heat sink with a space present between the heat sink and the hollow body, a power converter, an electric power regulation and distribution system, a magnetic reed relay unit, operational and directional controls, radioisotope thermoelectric power generator, and at least one DC motor mounted to a wheel of the vehicle. A portable lead-lined metal, climate-controlled, and airtight lockbox may house the entire power generating unit providing for more than redundant systems protection. The vehicle is capable of running indefinitely under all weather conditions, without “refueling” for decades and without introducing toxic emissions into the environment.

Owner:BONCODIN FRANZ B

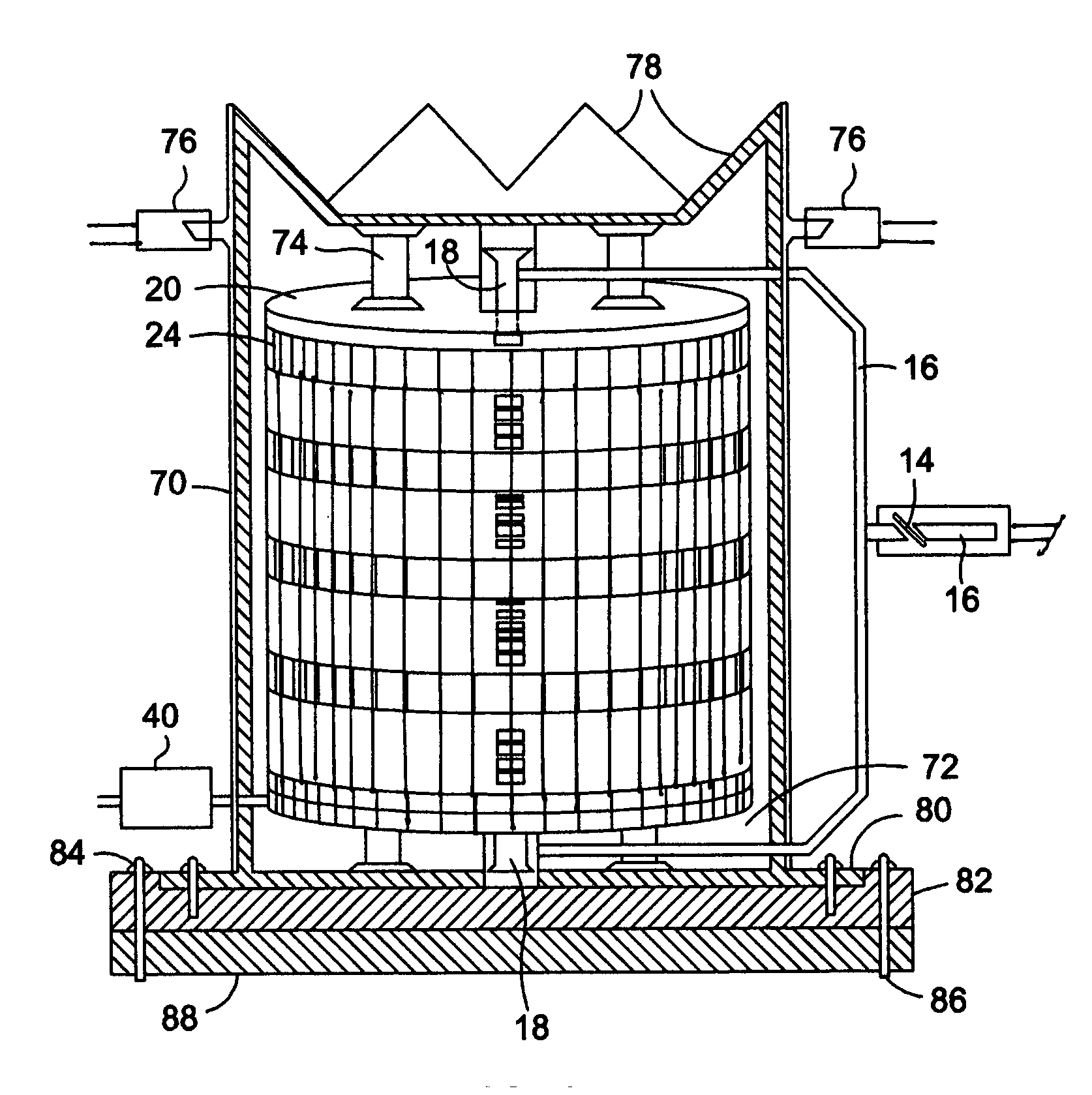

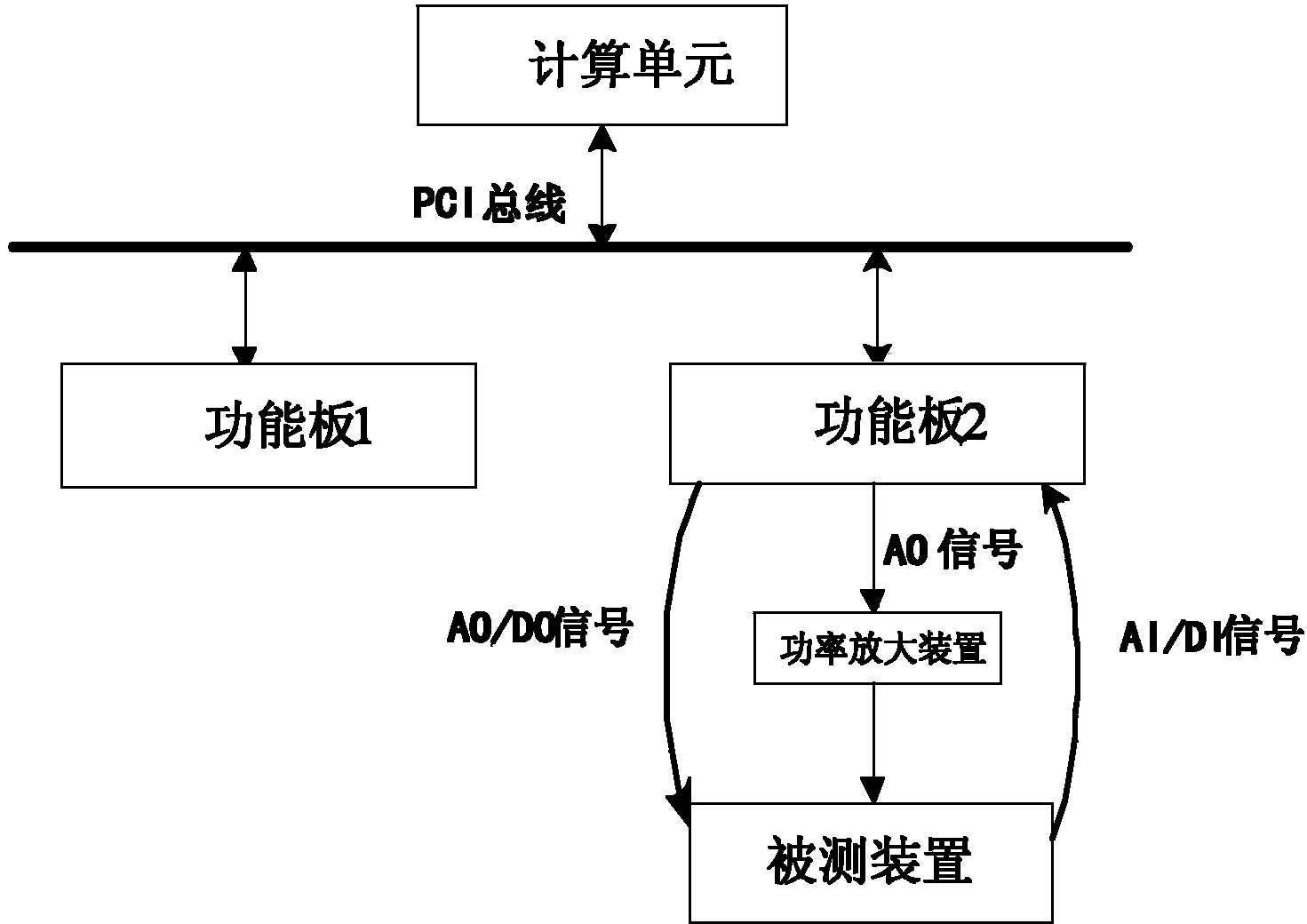

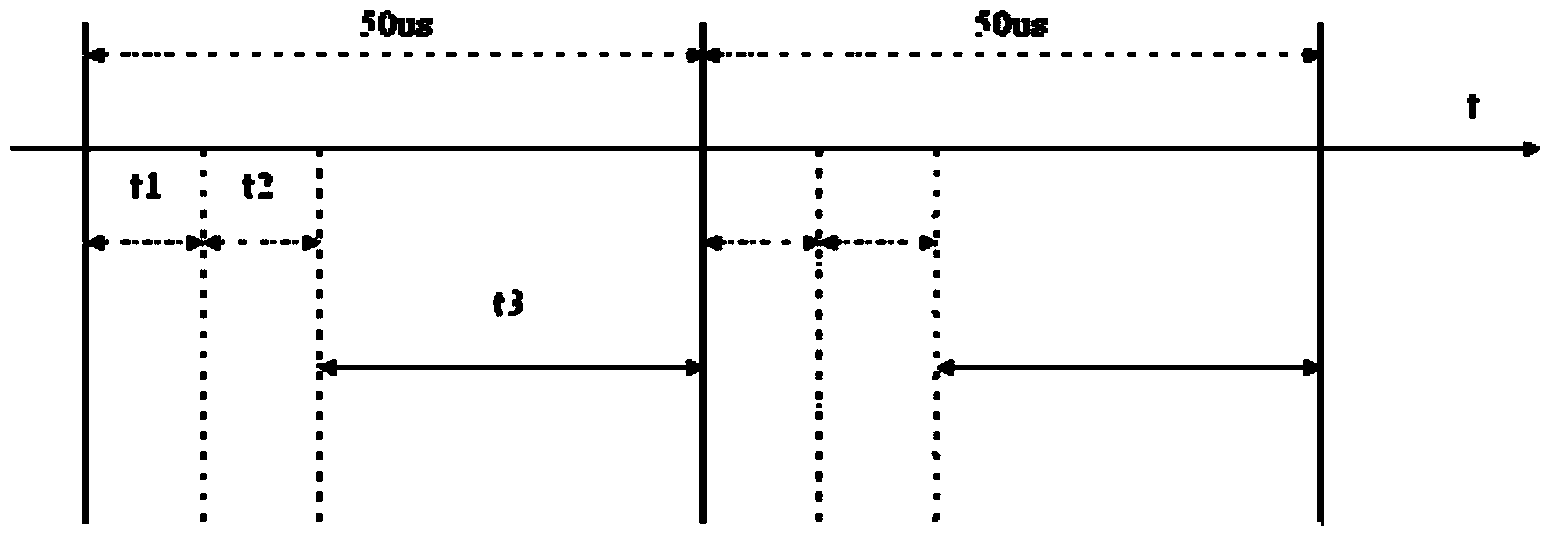

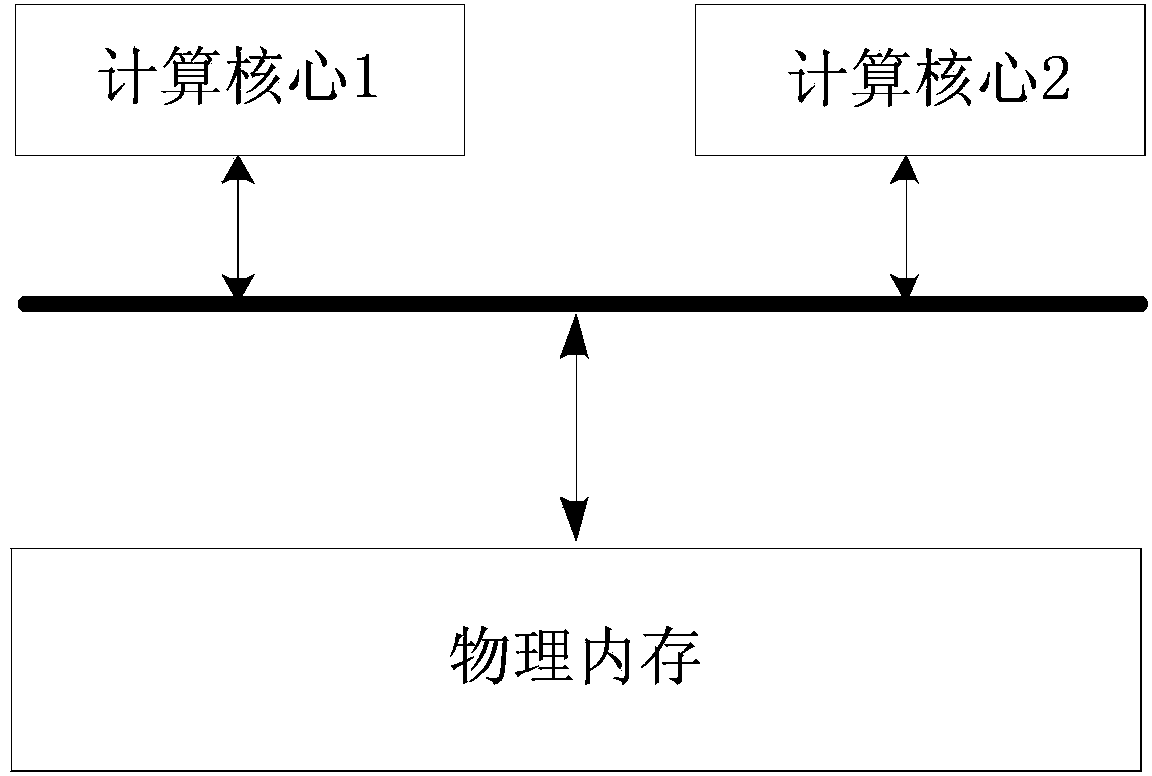

Portable all-digital real-time simulation instrument of power system

ActiveCN103488095AAccurate timingImprove linearitySimulator controlElectric power systemClosed loop testing

The invention provides a portable all-digital real-time simulation instrument of a power system. The portable all-digital real-time simulation instrument of the power system comprises a machine case, a main control board, a function board and a calculating unit, wherein the main control board, the function board and the calculating unit are placed inside the machine case. The main control board, the function board and the calculating unit are in mutual communication through a PCI bus, and the main control board controls the operation and communication between the function board and the calculating unit. The function board comprises an AI channel, an AO channel, a DI channel and a DO channel which are in communication connection with the outside. The all-digital real-time simulation instrument comprises the three working modes of an idle mode, an opened loop mode and a closed loop mode. When the all-digital real-time simulation instrument operates in the closed loop mode, the function board and an outside power amplifier device are connected through a simulation signal line. The closed loop test process is based on a precision operation sequence, a mature multi-core processor industrial platform is selected and used as a computing platform core, a shared memory communication mode is based, and the simulation instrument is made to meet the demands of site testing from the aspects of computing performance, IO interfaces and the like through a network parallel computing technology.

Owner:STATE GRID CORP OF CHINA +1

Automatic terminal riveting machine capable of carrying out sleeve processing on terminal

ActiveCN112397967AEasy to limitEasy to cut offContact member assembly/disassemblyOptically investigating flaws/contaminationIntelligent machineHeat gun

The invention discloses an automatic terminal riveting machine capable of carrying out sleeve processing on a terminal. The machine specifically comprises a base, a rotating disc, a functional clamp,a grabbing mechanism and a wiring terminal, a conveyor belt is mounted at one end of one side of the top of the base, and a heat shrink tube feeding mechanism is fixed at the other end of one side, close to the conveyor belt, of the top of the base; a rotating groove is formed in the middle of the top end of the interior of the base, the rotating disc is arranged in the rotating groove, limiting bases are evenly arranged at the edge of the top of the rotating disc, and hydraulic ejector rods are arranged in the portions, below the limiting bases, of the rotating disc. According to the automatic terminal riveting machine capable of carrying out sleeve processing on the terminal, by arranging the heat shrink tube feeding mechanism and the heat shrink tube limiting base, intelligent mechanical operation is achieved, manual tube penetrating or handheld hot air gun working is not needed, the machining efficiency is higher, the potential safety hazard that the hands of staff are scalded is avoided, and the use safety is higher.

Owner:佛山市顺德区恒沃电器有限公司

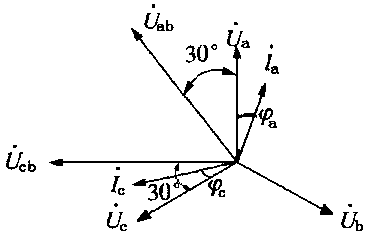

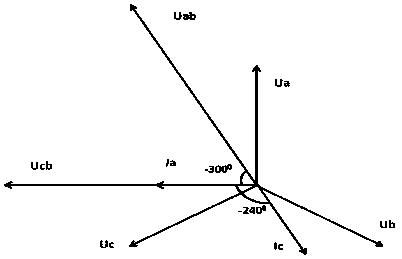

Method for judging wiring correctness of electric energy meter under condition of no load

InactiveCN108107313AAccurate wiringImprove the efficiency of on-site acceptance workElectric connection testingPower compensationPhase currents

The invention provides a method for judging the wiring correctness of an electric energy meter under the condition of no load, which belongs to the technical field of on-site inspection and acceptanceof electric energy metering devices. The method comprises the following steps: S1, switching on a reactive power compensation capacitor bank, and measuring the secondary current of an electric energymeter, wherein the magnitude of current should conform to the requirements of the regulation; S2, recording the voltages of the phases A, B and C as Ua, Ub and Uc respectively, recording the line voltage combinations under the condition of wiring along the phase sequence as Uab and Ucb, recording a first phase current as Ia, and recording a second phase current as Ic; S3, using a volt-ampere phase meter to measure the voltage and the current of the wiring of the electric energy meter and the phase between the voltage and the current in turn, and recording corresponding data; and S4, determining whether the wiring of the electric energy meter is correct according to the recorded data. The problem that the wiring of an electric energy meter cannot be measured under the condition of no loadcan be solved. The work efficiency of on-site acceptance can be improved.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

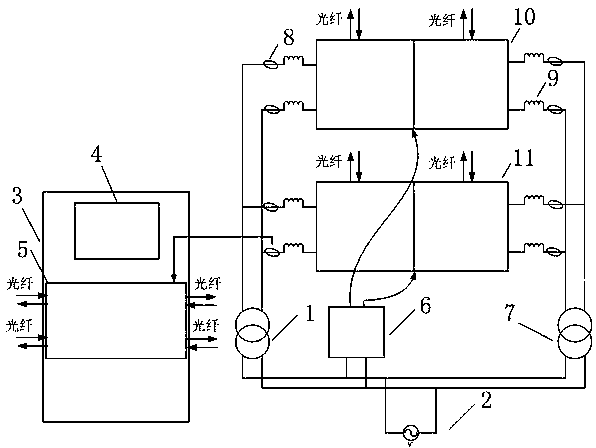

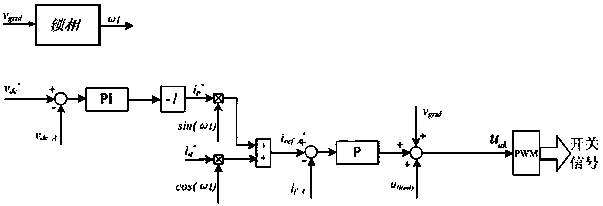

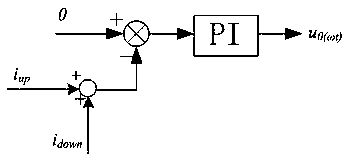

Control platform of back-to-back experiment testing used for railway power regulator power unit

InactiveCN107643455AAccurate wiringSimple and fast operationElectrical testingElectricityTransformer

The invention belongs to the railway electric power technology field and especially relates to a control platform of back-to-back experiment testing used for a railway power regulator power unit. Thecontrol platform comprises a back-to-back control cabinet. A control chassis is arranged in the back-to-back control cabinet. The control chassis is connected to a first power unit to be tested and asecond power unit to be tested. Two ends of the first power unit to be tested are connected to an output end of a boosting transformer. Two ends of the second power unit to be tested are connected tothe output end of the boosting transformer. There are several current Halls and electric reactors. An input end of one current Hall is connected in series with one electric reactor, and then is electrically connected to the boosting transformer, the output end of the first power unit to be tested and the output end of the second power unit to be tested. Output ends of the plurality of current Halls are electrically connected to the control chassis. The control platform can be simply operated and can effectively and rapidly test each power unit. An optical fiber is used to realize connection ofthe control chassis and the power units. And an anti-interference capability of an apparatus is increased.

Owner:西安奥特迅电力电子技术有限公司

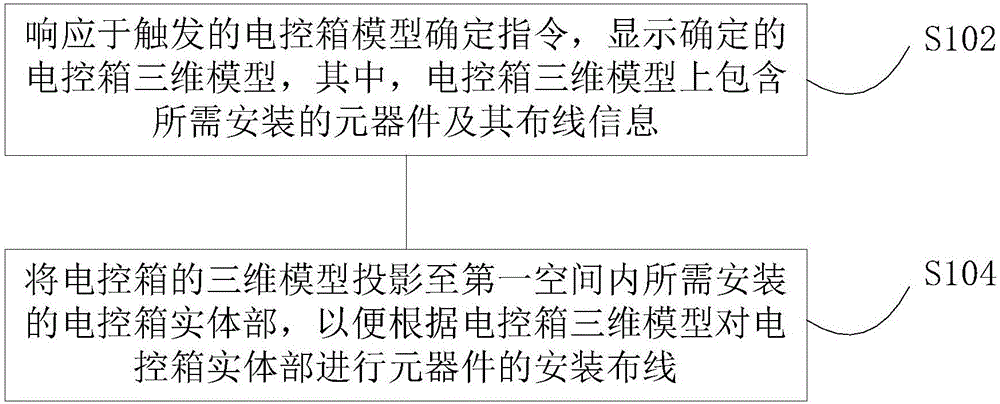

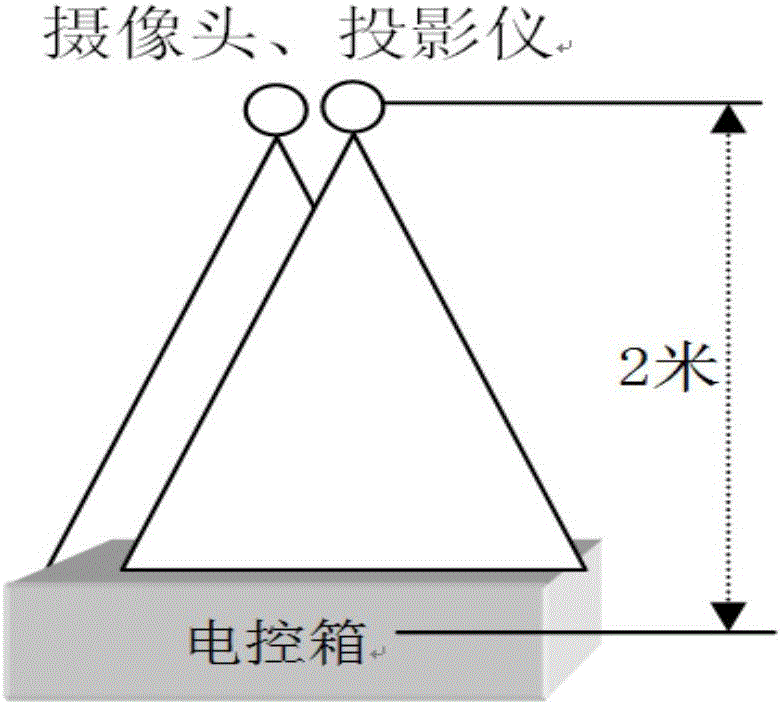

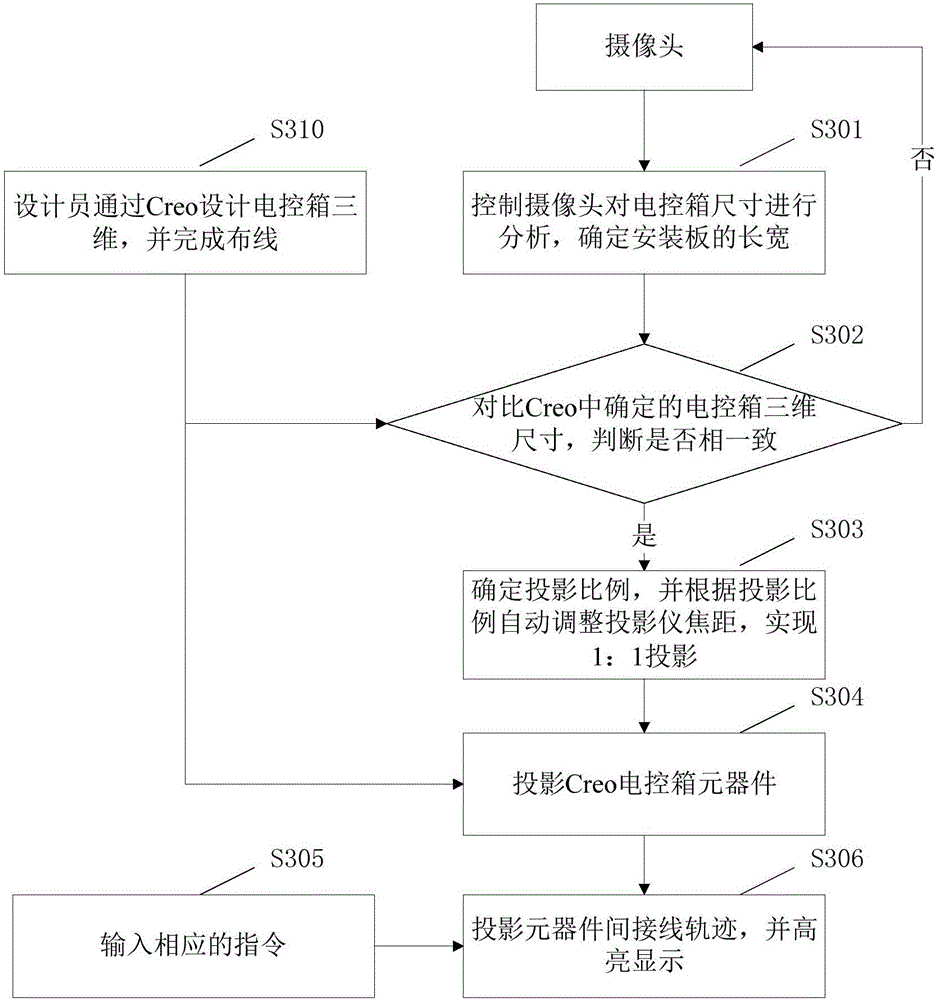

Wiring connection control method and device of electric control box

ActiveCN106227493AAccurate wiringReduce the probability of installation errorsPicture reproducers using projection devicesDigital output to display deviceEngineeringElectric control

The invention discloses a wiring connection control method and device of an electric control box, wherein the method comprises the following steps of responding to a triggered model determining instruction of the electric control box; displaying a determined electric control box three-dimensional model, wherein elements to be installed and wiring information of the elements to be installed are contained on the electric control box three-dimensional model; projecting the electric control box three-dimensional model to an electric control box entity part to be installed in the first space so that the electric control box entity part can be subjected to element installation wiring according to the electric control box three-dimensional model. The method and the device solve the problems that in the prior art, the electric control box wiring mode is a manual mode of one-by-one finding installation in a way of referring to an installation drawing, the installation efficiency is low; the error rate is relatively higher. The installation efficiency of the electric control box is improved; the installation error rate is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

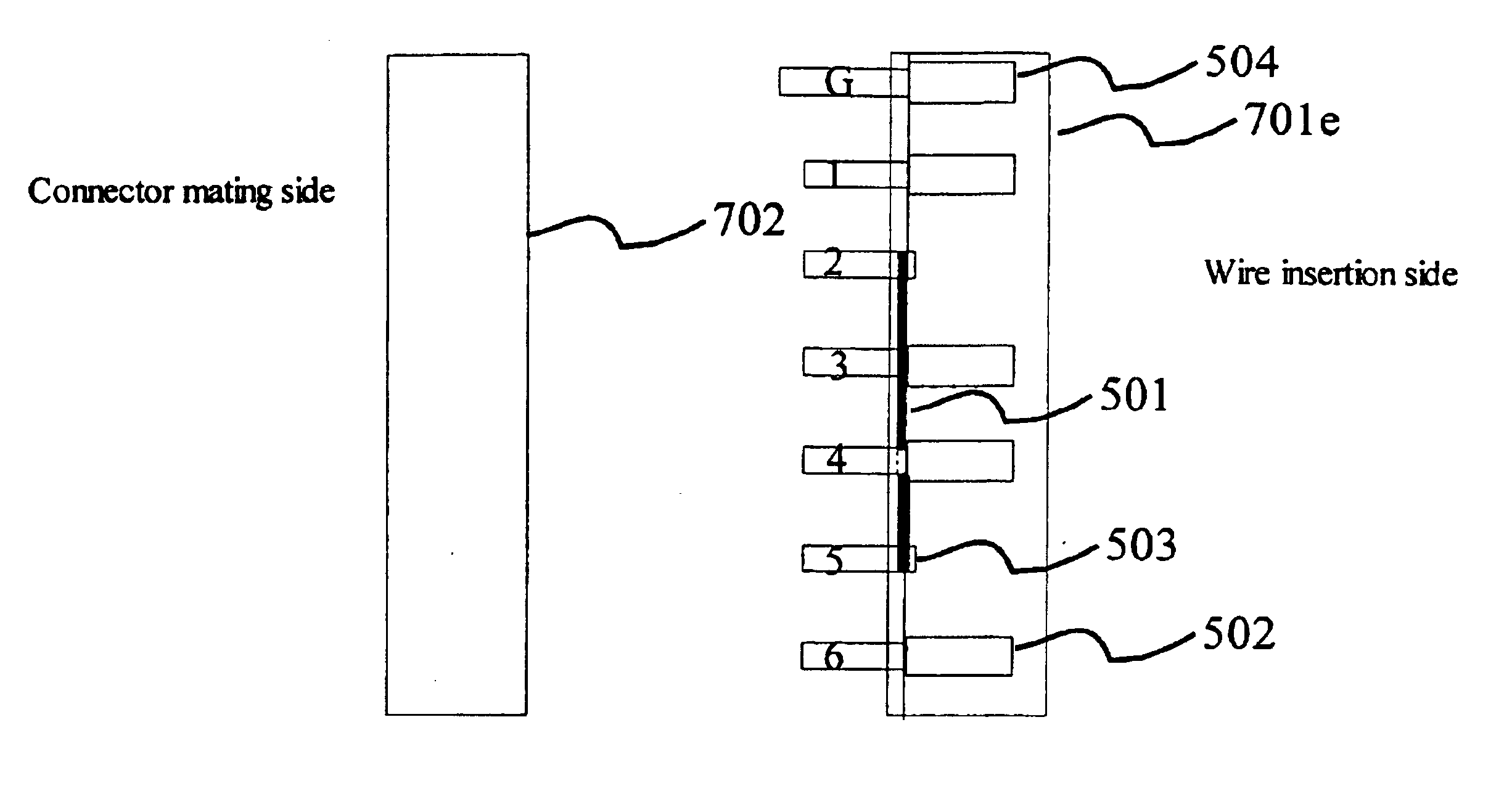

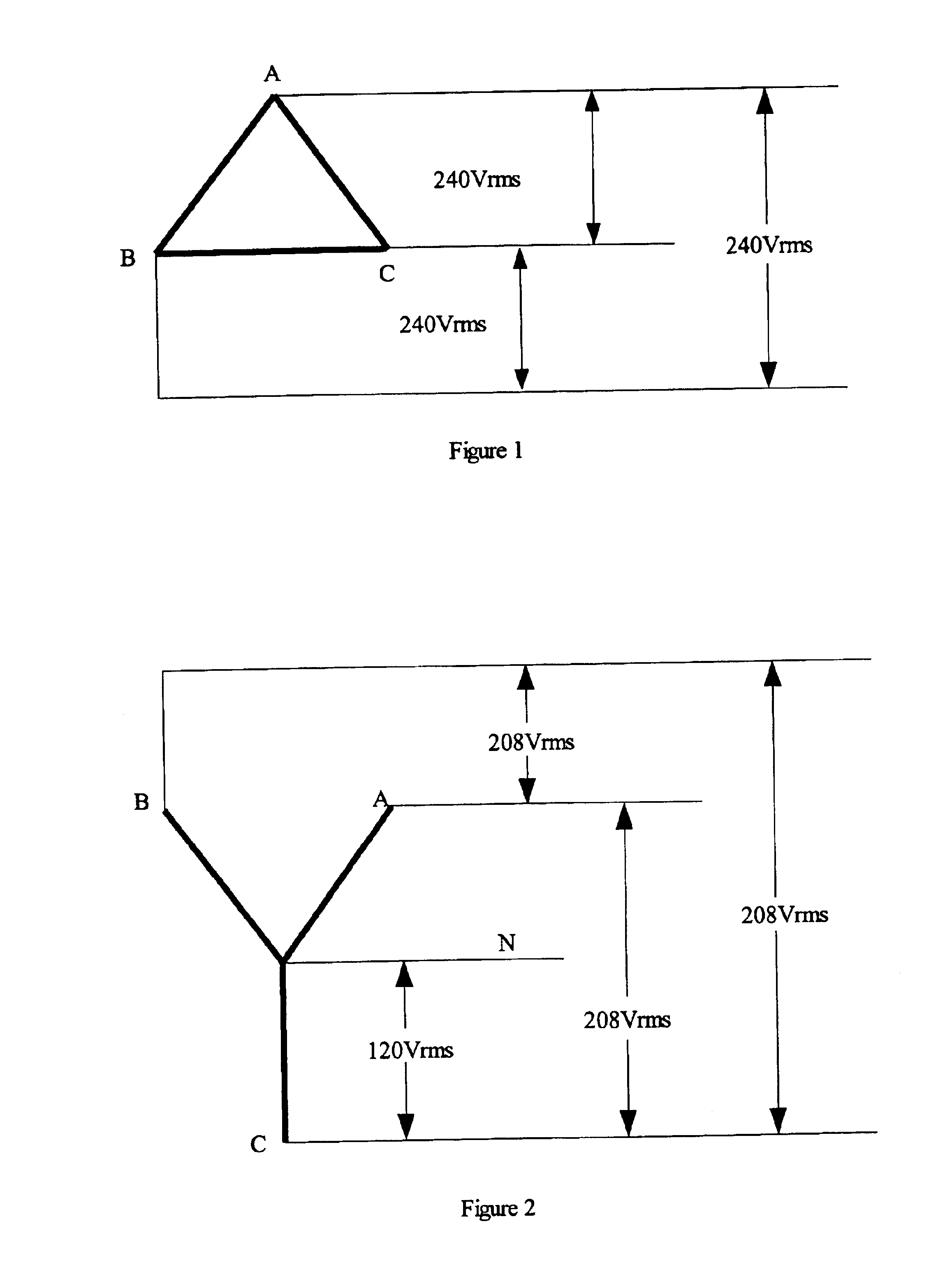

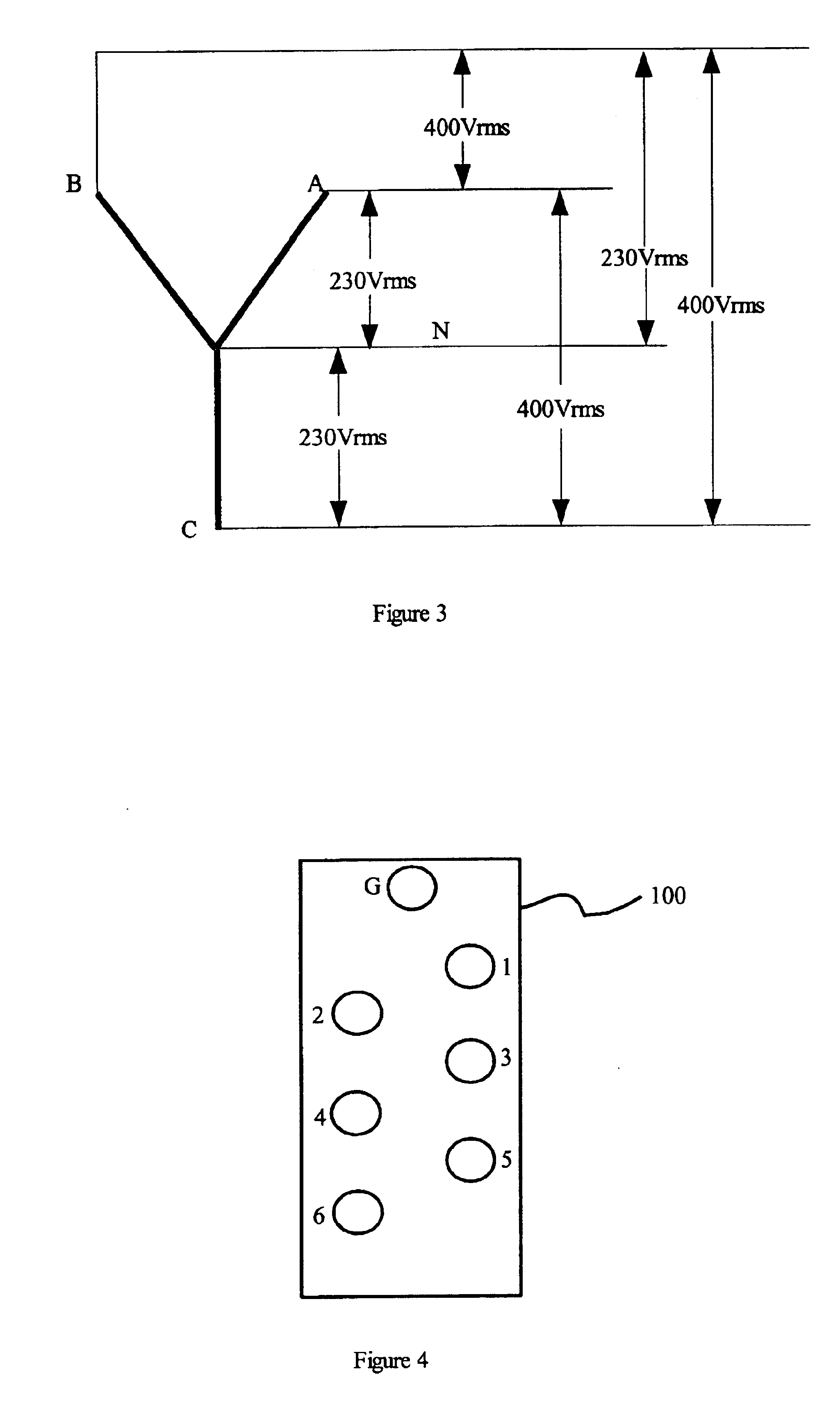

Method and apparatus for three-phase to single-phase power distribution

InactiveUS6951478B2Expense effortExpense timeCoupling device connectionsAc-ac conversionElectricityEngineering

In a piece of equipment deriving power from a three-phase power supply, a method and a connector provide a country-independent arrangement of connection pins to interface with the equipment, so as to provide one or more single-phase output voltages at designated pins. The connector includes a number of electrical terminals wired to the connection pins according to a country-dependent arrangement. In one embodiment, the connector includes one or more jumpers each configured to provide a short circuit between a designated pair of connection pins according to the country-dependent arrangement scheme. The country-independent arrangement provides a single-phase output voltage between 200-240 volts (RMS) across a designated pair of connection pins. In one application, a connector configured for the United States is used in conjunction with a 4-conductor cable having a U.S. conforming connector for plugging into a U.S. three-phase specification wall socket (e.g., NEMA). Similarly, a connector configured for Europe is used in conjunction with a 5-conductor cable having a conforming connector for plugging into a three-phase specification wall socket of the host European country (e.g., IEC 309).

Owner:CHENG CHIN Y

Air-jet electric cabinet detecting device

Owner:KARL MAYER CHINA

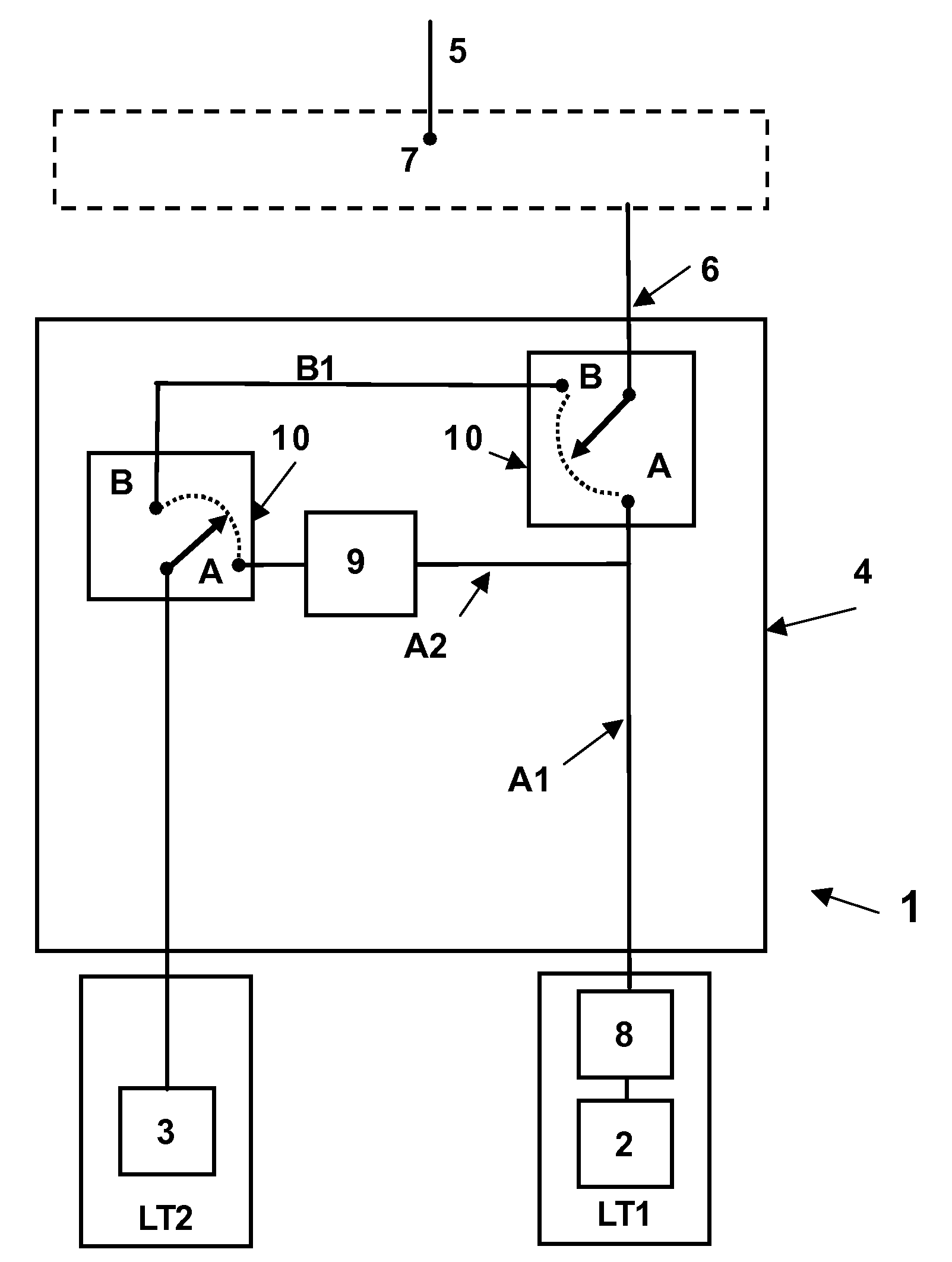

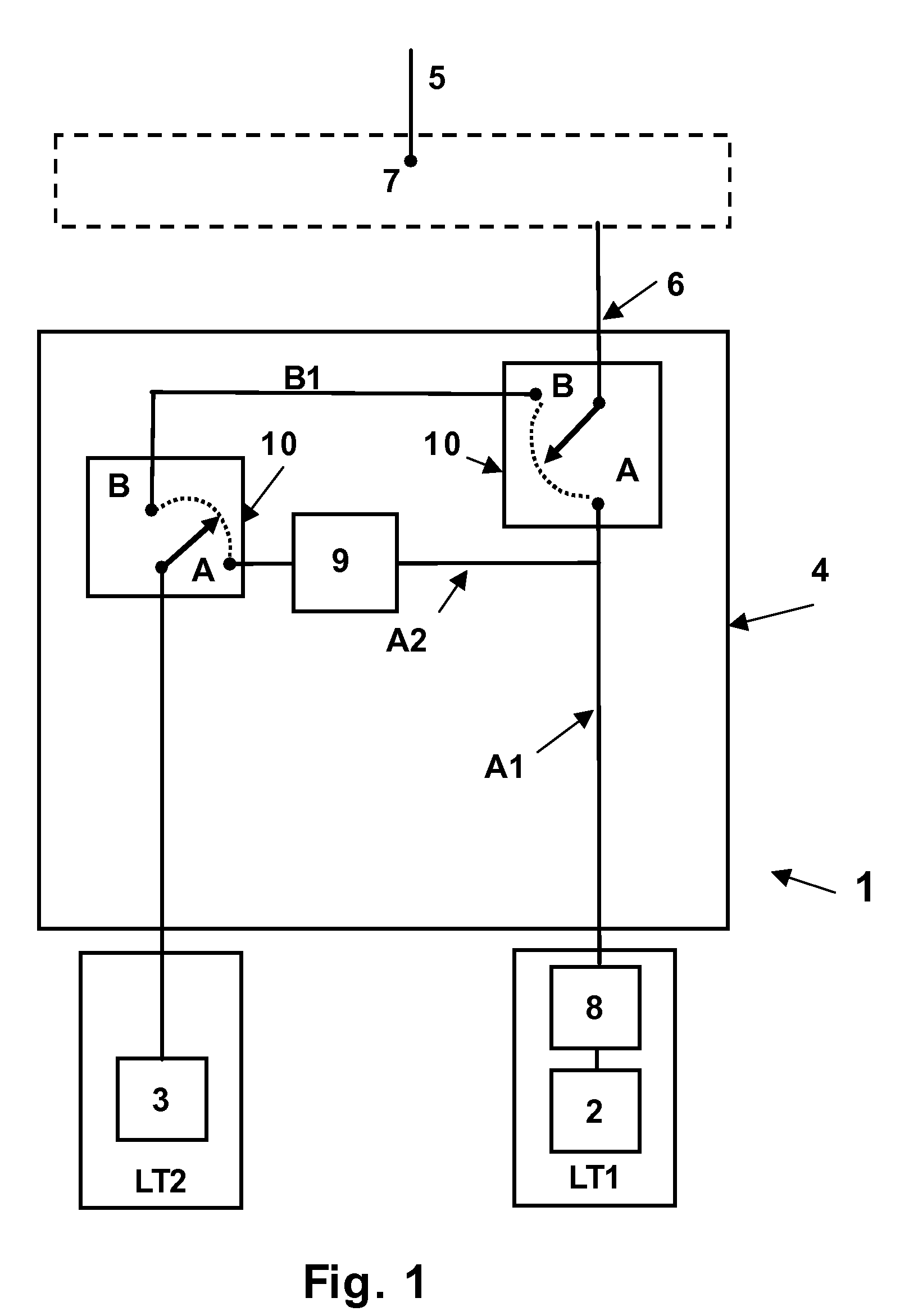

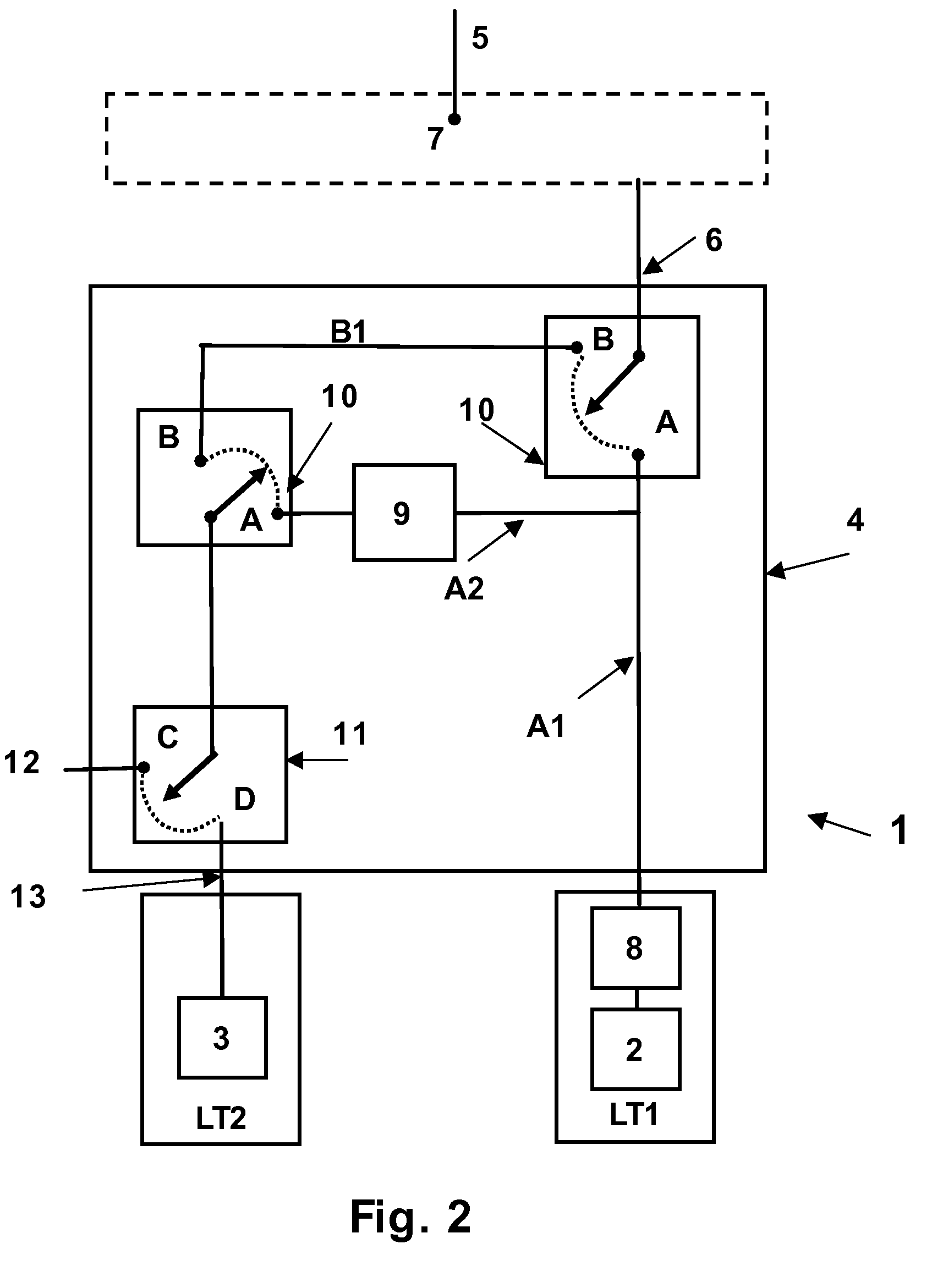

Line termination arrangement with combined broadband and narrowband services

InactiveUS20090135808A1Simple processAccurate wiringNetwork connectionsSubscriber line interface circuitsPublic interfaceBroadband transmission

A combined line termination arrangement (1) for an access system supporting broadband transmission mode and narrowband transmission mode, the combined line termination arrangement (1) comprising a common interface device (4) having a common port (6) for receiving or transmitting a signal in said transmission modes and being connected to a first line termination (LT1) and a second line termination (LT2). The common interface device further comprises switching means (11, 14, 15, 18) for selectively connecting, by switching combinations, the first line termination (LT1), the second line termination (LT2) and auxiliary sources of broadband or narrowband transmission modes.

Owner:RPX CORP

Self-testing auto monitor ground fault circuit interrupter (GFCI) with power denial

ActiveUS9595824B2Accurate wiringPrevent trippingSwitch operated by earth fault currentsShort-circuit testingElectricityEngineering

A self-testing fault detector having a line side and a load side and a conductive path there between is provided. The self-testing fault detector includes an auto-monitoring circuit electrically coupled to a fault detection circuit and an interrupting device and it continuously monitors one or more signals to determine an operating state of the fault detector. At least one of the monitored signals includes a fault detection signal, wherein if said automonitoring circuit determines that the fault detection circuit is not properly driving the interrupting device, the automonitoring device converts an input-output port receiving the fault detection signal from an input to an output and drives the interrupting device into a tripped condition using the input-output port.

Owner:HUBBELL INC

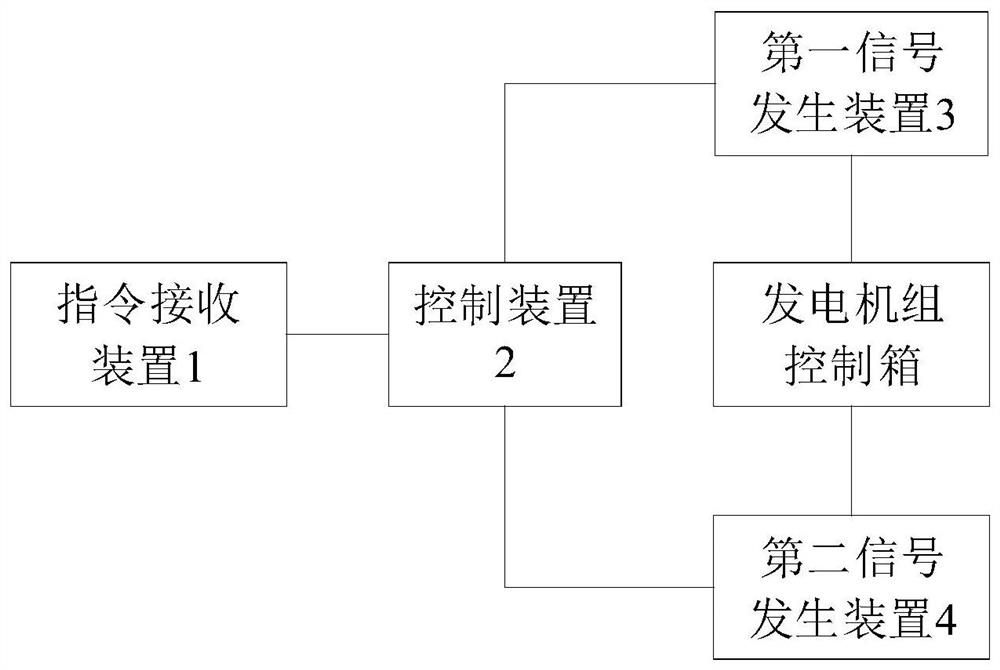

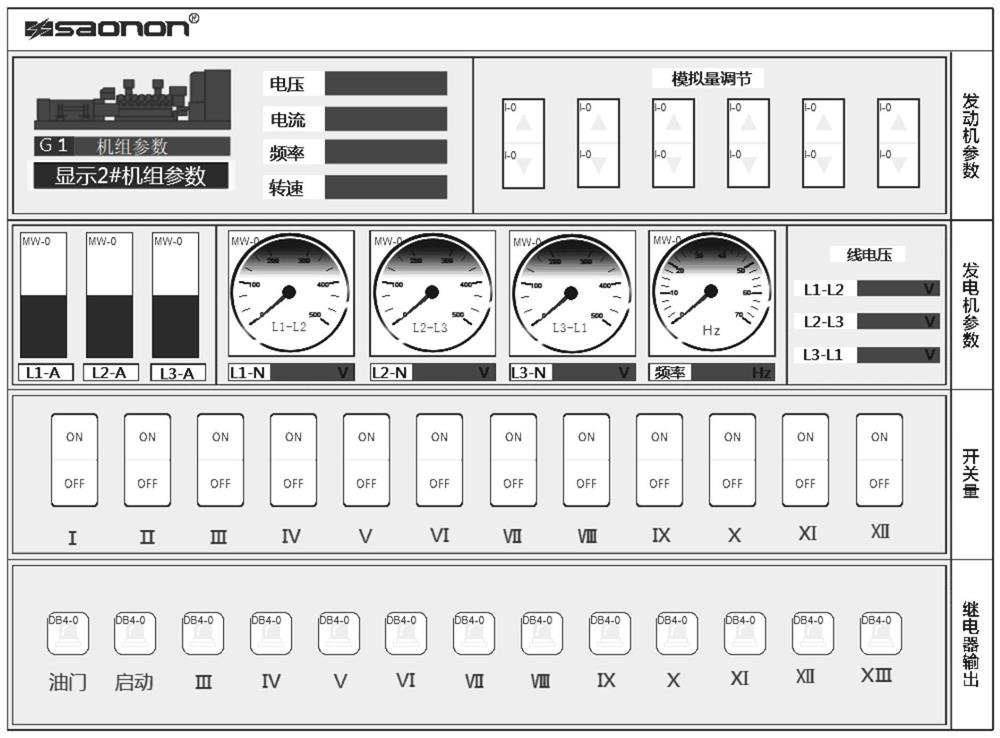

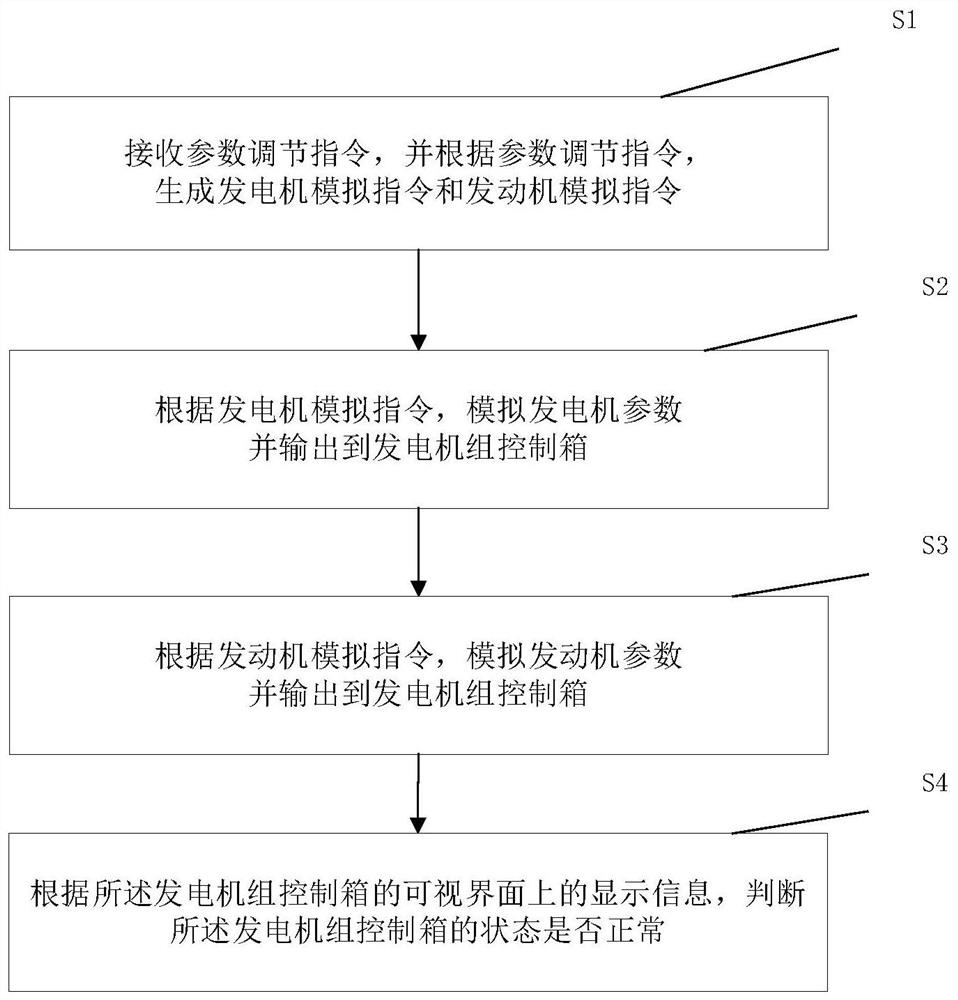

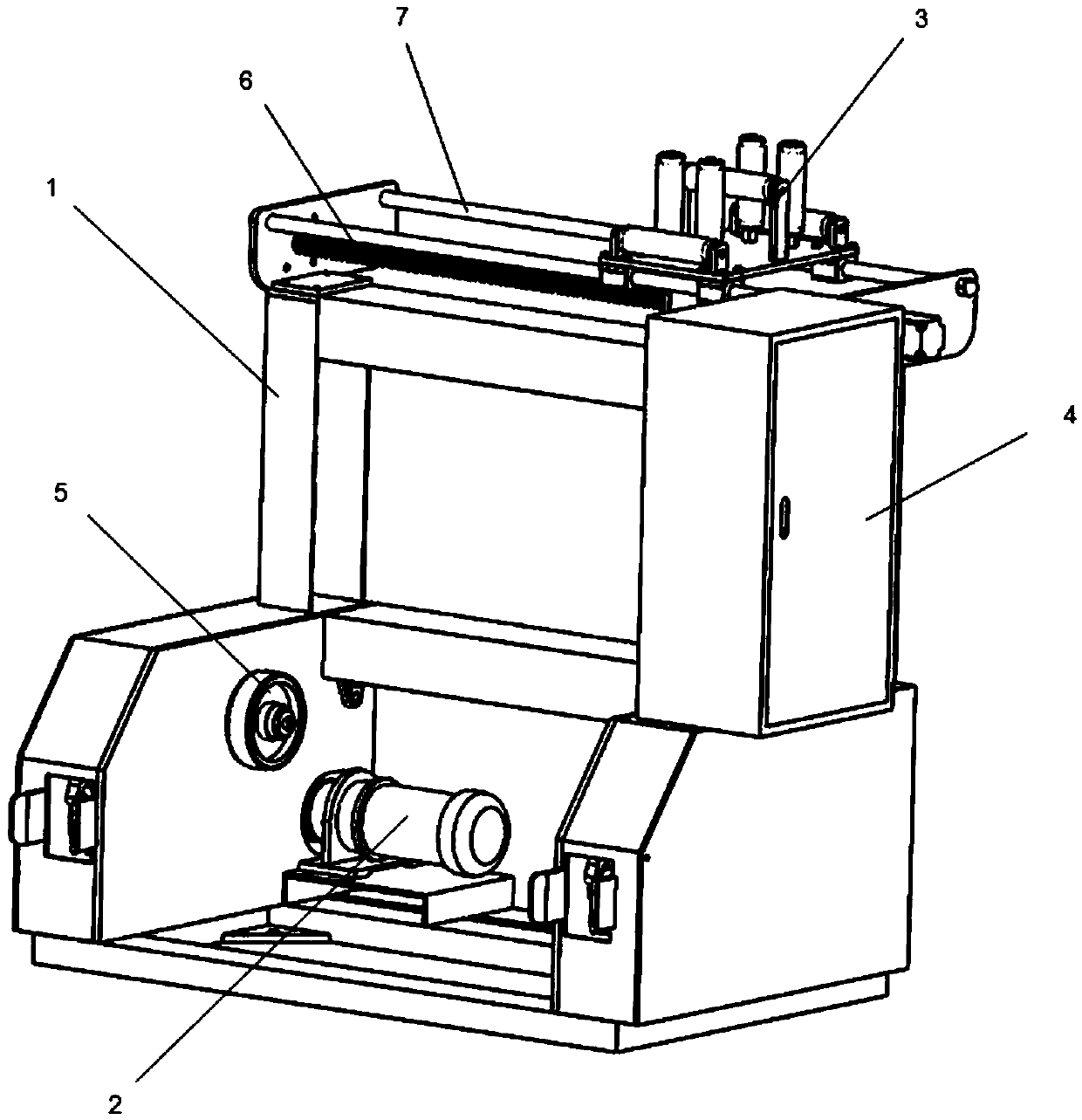

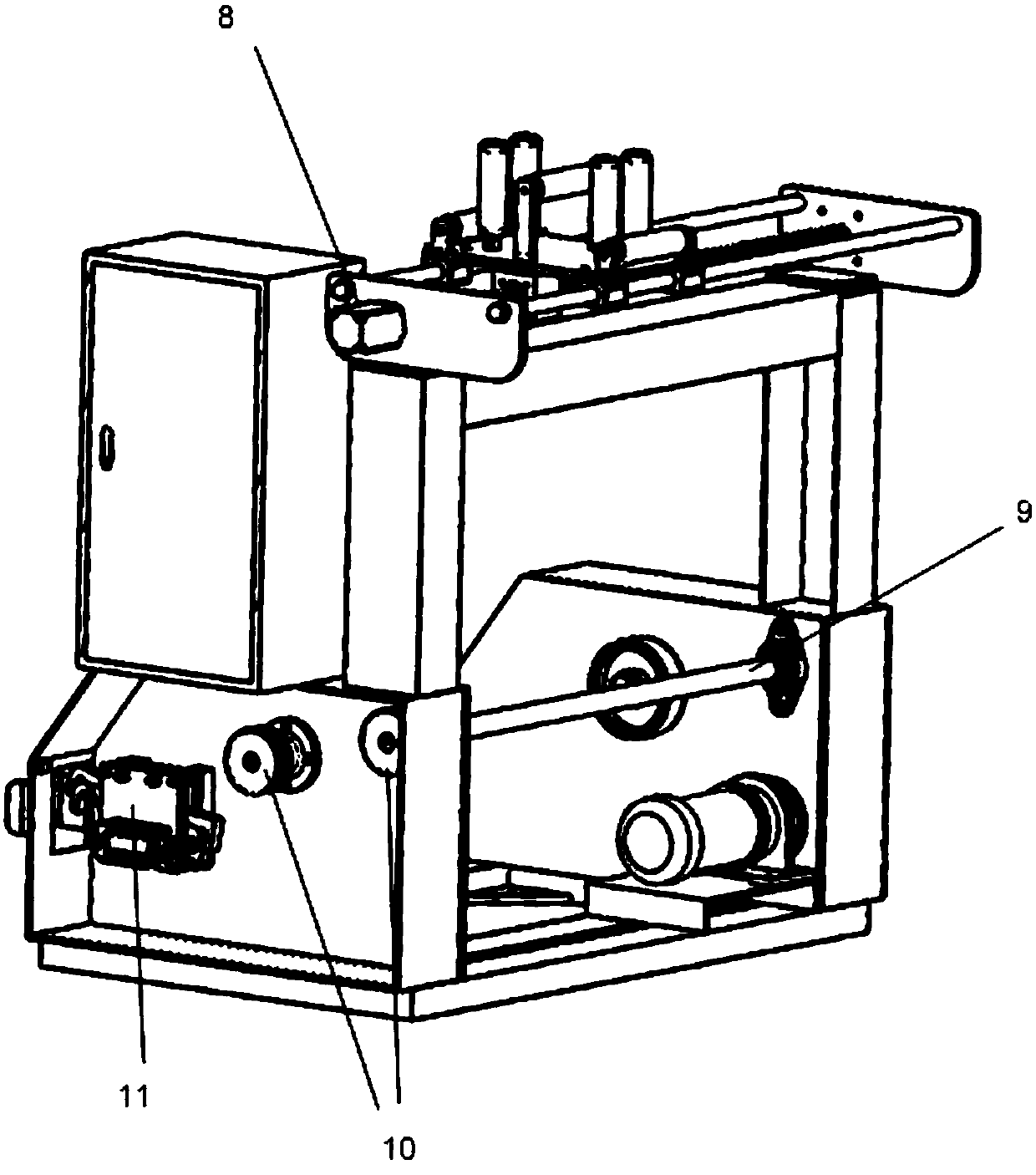

Test system, test cabinet and test method of generator set control box

PendingCN113359656AThe test conditions are no longer harshAccurate wiringElectric connection testingElectric testing/monitoringControl engineeringComputer science

The invention discloses a test system, a test cabinet and a test method for a generator set control box. The test system comprises an instruction receiving device for receiving a parameter adjustment instruction; a control device which is used for generating a generator simulation instruction and an engine simulation instruction according to the parameter adjustment instruction; a first signal generating device which is used for simulating generator parameters according to the generator simulation instruction and outputting the generator parameters to the generator set control box; and a second signal generation device which simulates engine parameters according to the engine simulation instruction and outputs the engine parameters to the generator set control box. By using the test system provided by the invention, the test environment required by the generator set control box is directly simulated without waiting for the access of an actual generator set, and the test conditions of the generator set control box are no longer harsh, so that the correct wiring of the generator set control box before the generator set is installed is ensured, and the safety of the generator set control box during testing is improved.

Owner:GUANGZHOU WANON ELECTRIC & MACHINE

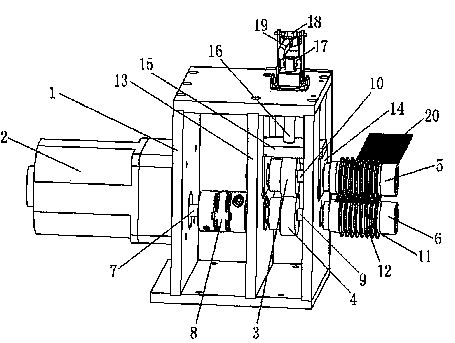

Novel winding machine

The invention discloses a novel winding machine. The novel winding machine comprises a rack, an electric box, an unwinding pitch adjusting mechanism located over the rack, a wheel hub driving mechanism located under the rack and a car wheel hub located in front of the rack; the unwinding pitch adjusting mechanism comprises a servo motor, a lead screw and a guiding wheel group, the lead screw is connected with the servo motor, the guiding wheel group is connected with a nut arranged on the lead screw, and the servo motor drives the lead screw to drive the guiding wheel group to move; and the wheel hub driving mechanism comprises a torque motor, a transmission shaft, a synchronous wheel and a frictional depended wheel, the synchronous wheel is coaxially connected with the frictional dependedwheel, the torque motor drives the synchronous wheel through the transmission shaft to drive the frictional depended wheel, the frictional depended wheel is in contact connection with the side end outer edges of the two sides of the car wheel hub, and the frictional depended wheel rotates to drive the car wheel hub to rotate. According to the novel winding machine, the unwinding pitch is convenient to adjust, the constant winding force can be supplied, and precise unwinding can be achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

Cable compensation device and cable compensation method for cutting steel wire universal take-up machine

ActiveCN103588025BReduce changeover timeCommutation neatlyFilament handlingWinding machineWire cutting

The invention discloses a wire arranging compensation device of a wire cutting all-powerful winding machine. The wire arranging compensation device comprises steel wires, a first guide wheel, a second guide wheel, a third guide wheel, a wire arranging device and a winding wheel. The steel wires are sent in the main machine direction, sequentially pass through the guide wheels and the wire arranging device and are wound around the winding wheel. One end of the winding wheel is provided with a winding motor. The wire arranging device comprises a wire arranging guide wheel and a wire arranging motor. The output shaft end of the wire arranging motor is connected with the wire arranging guide wheel through a horizontal moving assembly so that the wire arranging motor can push the wire arranging guide wheel to move in the horizontal direction in a reciprocating mode. One side of the third guide wheel is provided with a tension oscillating bar device used for detecting tension variation of the steel wires, and the tension oscillating bar device is connected with a PLC. The output end of the PLC is connected with the wire arranging motor and the winding motor, and the wire arranging motor is a servo motor. The wire arranging compensation device of the wire cutting all-powerful winding machine is simple in structure, convenient to operate, capable of reducing reversing time of the wire arranging guide wheel, free of slip frequency, and capable of ensuring neatness of the wires arranged on the winding wheel.

Owner:WUXI SUNLIT SCI & TECH

Winding displacement compensation process method

PendingCN113909318AEliminate big errorsReliable test resultsMetal working apparatusProcess engineeringMaterial resources

The invention relates to the field of wire drawing and winding displacement processes of metal products, and discloses a winding displacement compensation process method. Through error detection, overshoot treatment, reversing treatment, R angle compensation, pre-judgment compensation and dislocation compensation,winding displacement is stable and reliable, the quality is improved, the phenomena of wire releasing abnormity, wire releasing pressing and wire releasing clamping at a client are greatly reduced, in this way, the situation that products need to be rewound again is reduced, production efficiency is improved, consumption of manpower, material resources and energy is reduced, only one-time winding displacement is needed in the production process, and the working procedure is simplified.

Owner:JIANGSU HEYI AUTOMATION TECH

Cable dividing mechanism convenient for feeding of flexible flat cables

The invention discloses a cable dividing mechanism convenient for feeding of flexible flat cables. The cable dividing mechanism comprises a support and a motor and is characterized in that the lateral side of the support is provided with the motor; two fixed plates are arranged in the support; a lower rotating shaft penetrates the two fixed plates; an output shaft of the motor is connected with the lower rotating shaft; the upper portion of each fixed plate is provided with the opening which is used for placing a sliding plate; an upper rotating shaft penetrates the two sliding plates; a connecting plate is fixed at the tops of the two sliding plates; the top of the connecting plate is provided with a mobile shaft; two ends of the mobile shaft are connected with two connecting arms respectively; the top ends of the two connecting arms are fixed through a pin shaft; a handle can rotate around the pin shaft. According to the cable dividing mechanism convenient for feeding of the flexible flat cables, the problems that an upper cutting die and a lower cutting die of the cable dividing mechanism cannot move, the distance between the upper cutting die and the lower cutting die is small, the wiring time is long, the cabling error is easy to cause, and meanwhile plastic is easy to damage during wiring harness separation are solved, the wiring of the flexible flat cables is convenient and rapid, and abrasion and damage of the flexible flat cables cannot be caused.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com