Production method and pipe-coiling device of non-ferrous metal coil pipes

A technology for non-ferrous metals and production methods, applied in metal processing equipment, metal wire drawing, straightening equipment, etc., can solve the problems of excessive ovality of pipes, easy sliding and bumping, excessive residual nitrogen, etc., and achieve uniform mechanical properties and sliding collision. Less damage and less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

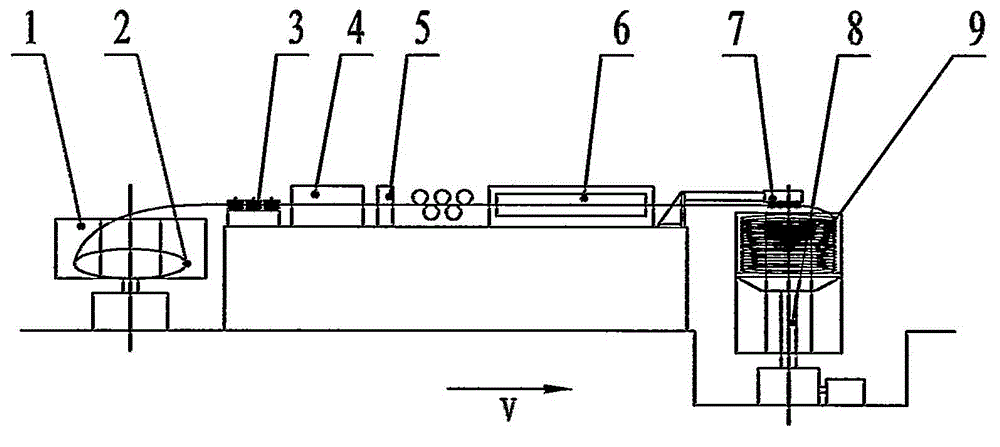

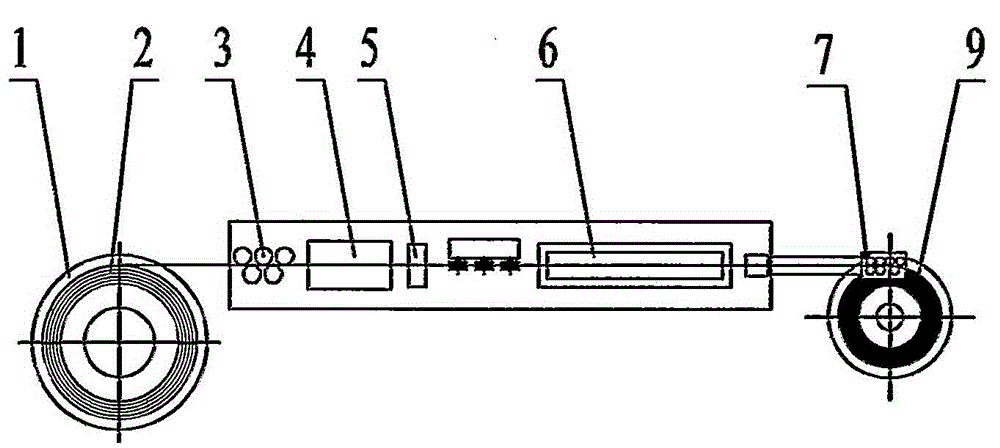

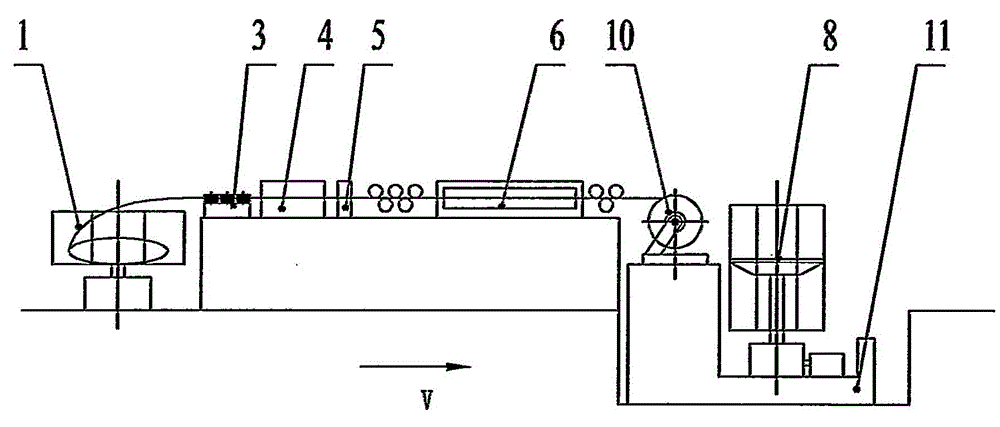

[0049] Embodiment one, such as Figure 1~4 as shown,

[0050] A method for producing a non-ferrous metal coiled tube, comprising the steps of:

[0051] The first step is to wind the hard metal pipe horizontally;

[0052] In the second step, the annealing treatment is performed on the coiled pipe after the horizontal cable is wound.

[0053] The annealing treatment can be, but is not limited to, annealing in an annealing furnace. To illustrate in detail, take a volumetric annealing furnace as an example, and the wound coil is directly annealed in the furnace.

[0054] The aforementioned hard metal pipes are relative to the soft pipes that have undergone online annealing in the background art. With this method, without online annealing treatment, the pipe material is directly wound with horizontal wires, and the coiled pipe after the horizontal wires is then annealed.

[0055] Because it is a hard pipe, its mechanical properties are greatly improved compared with soft pipes...

Embodiment 2

[0058] Embodiment two, such as Figure 1~4 said,

[0059] The difference between Embodiment 2 and Embodiment 1 lies in the first step. That is to add uncoiling, straightening, cleaning, flaw detection and drying in the first step. The hard metal pipe is uncoiled, straightened, cleaned, flaw detected, dried, and then horizontally wound.

Embodiment 3

[0060] Embodiment three, such as Figure 1~2 as shown,

[0061] Non-ferrous metal coil equipment, which includes: uncoiling equipment 1, winding machine 8, wherein:

[0062] Uncoiling equipment 1, which uncoils the hard pipe 2 to be processed;

[0063] The winding machine 8 is a horizontal wire winding machine, which winds the hard metal pipe to make the pipe into a horizontal wire coil 9;

[0064] After the pipe 2 passes through the uncoiling equipment 1, it enters the horizontal wire winding machine without online annealing, so as to realize the horizontal wire winding of the hard metal pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com