Patents

Literature

230results about "Wire straightening devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

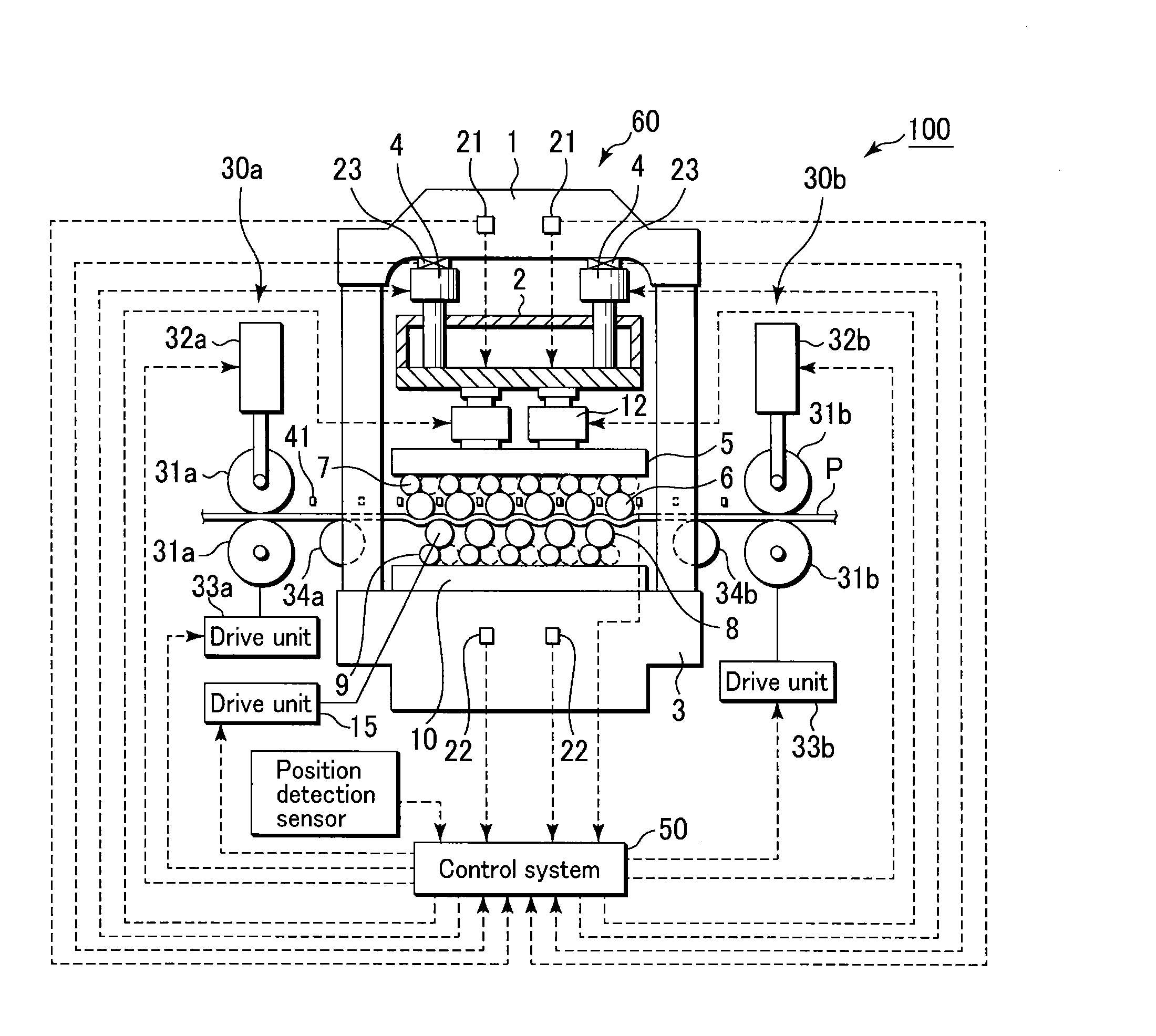

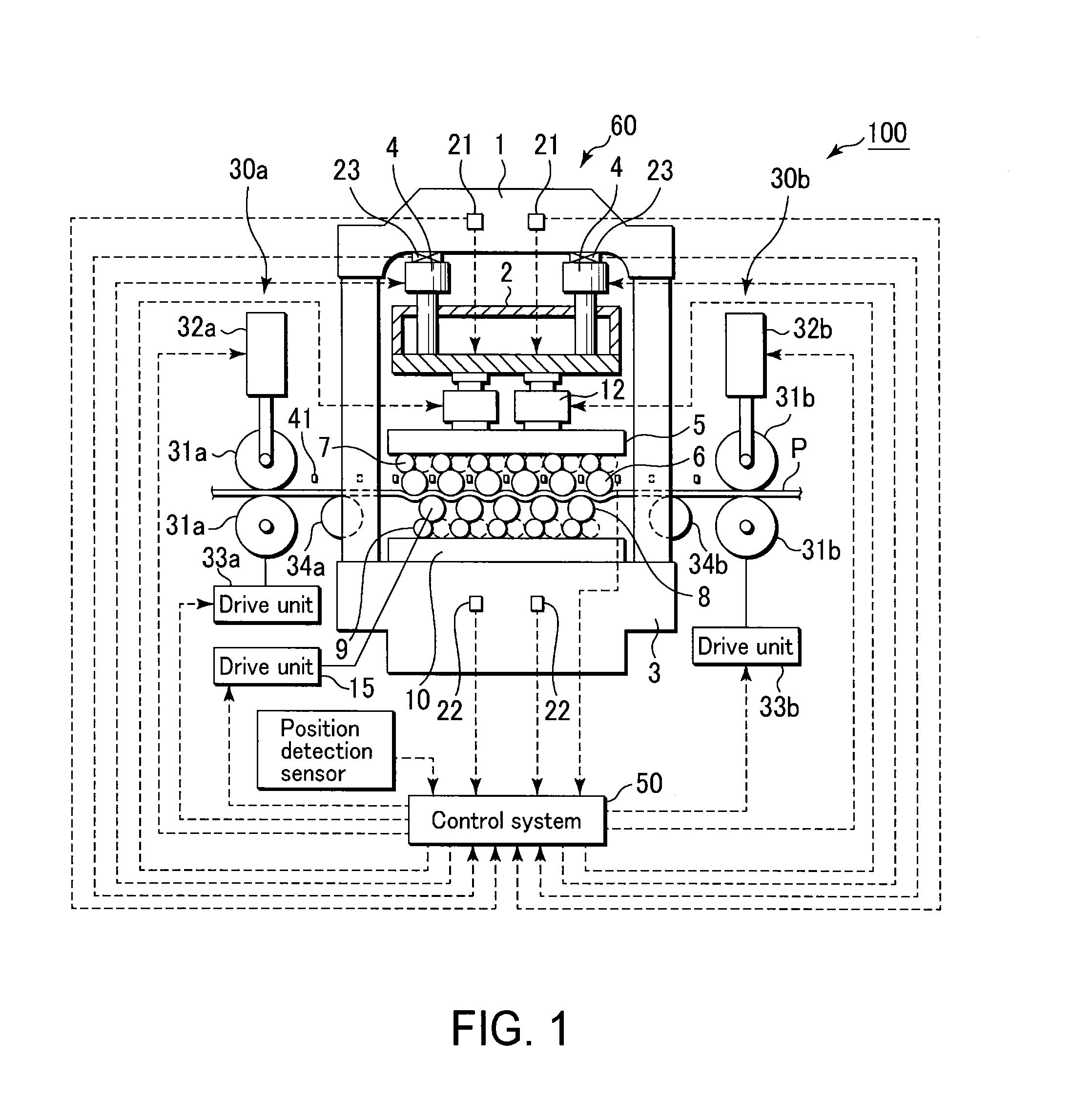

Roller leveler and metal sheet flattening method

ActiveUS20130327109A1Small thicknessLarge yield stressWire straightening devicesMetal rolling stand detailsPull forceMetal sheet

A roller leveler for flattening a metal sheet or plate having a cut-sheet form includes leveling rolls disposed in a staggered state on upper and lower sides of a pass line and configured to sandwich and flatten the metal sheet while pressing it therethrough, a hydraulic pressing cylinder configured to press the metal sheet via the leveling rolls, a drive unit configured to rotate the leveling rolls, and a pinch roll unit disposed on one side of a leveling roll array area and including a pair of pinch rolls. The pressing cylinder presses the metal sheet via the leveling rolls with a pressing amount necessary for flattening the metal sheet, while the metal sheet is passed by a drawing force applied by the pinch rolls and a driving force applied by the drive unit.

Owner:JP STEEL PLANTECH

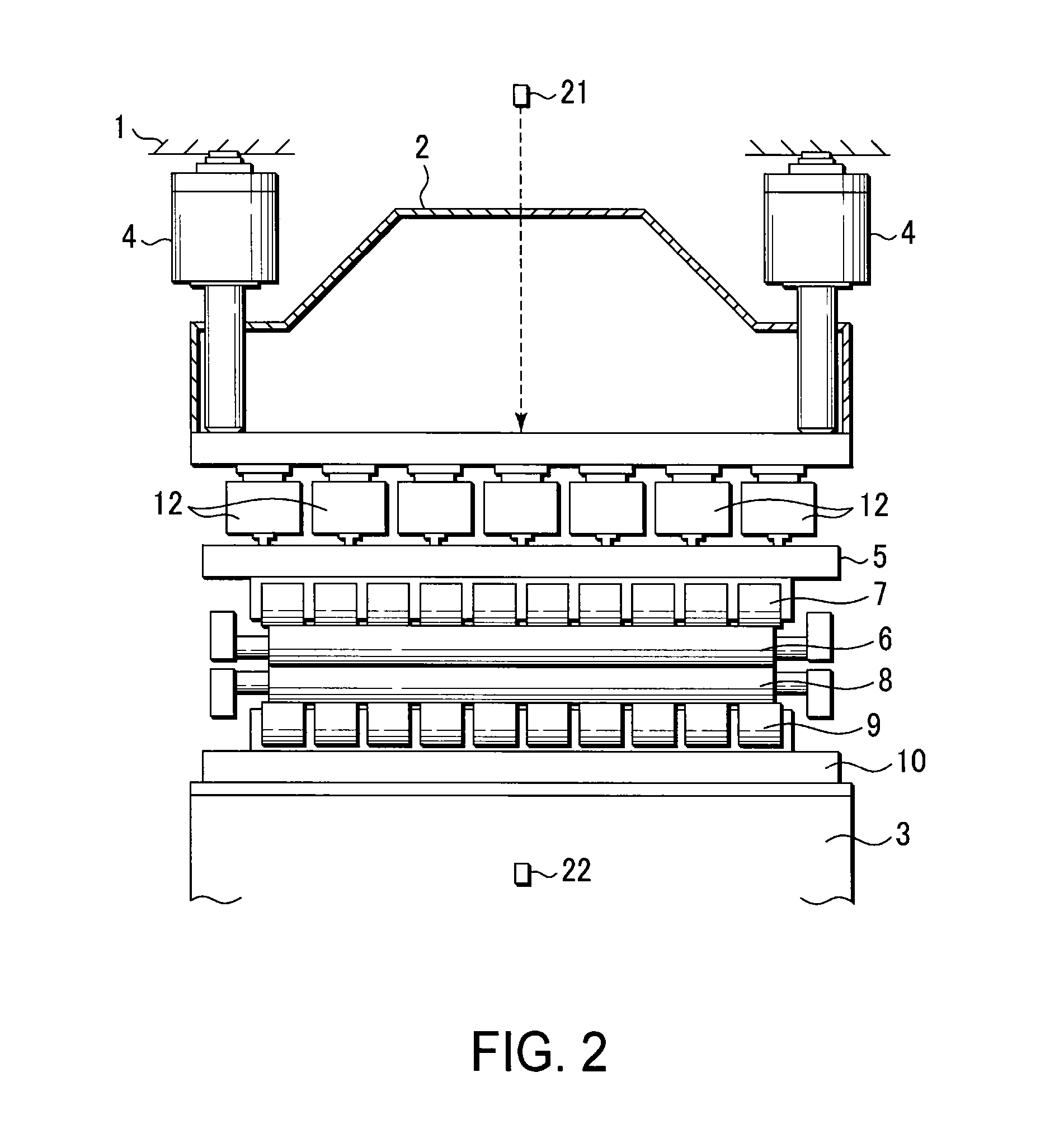

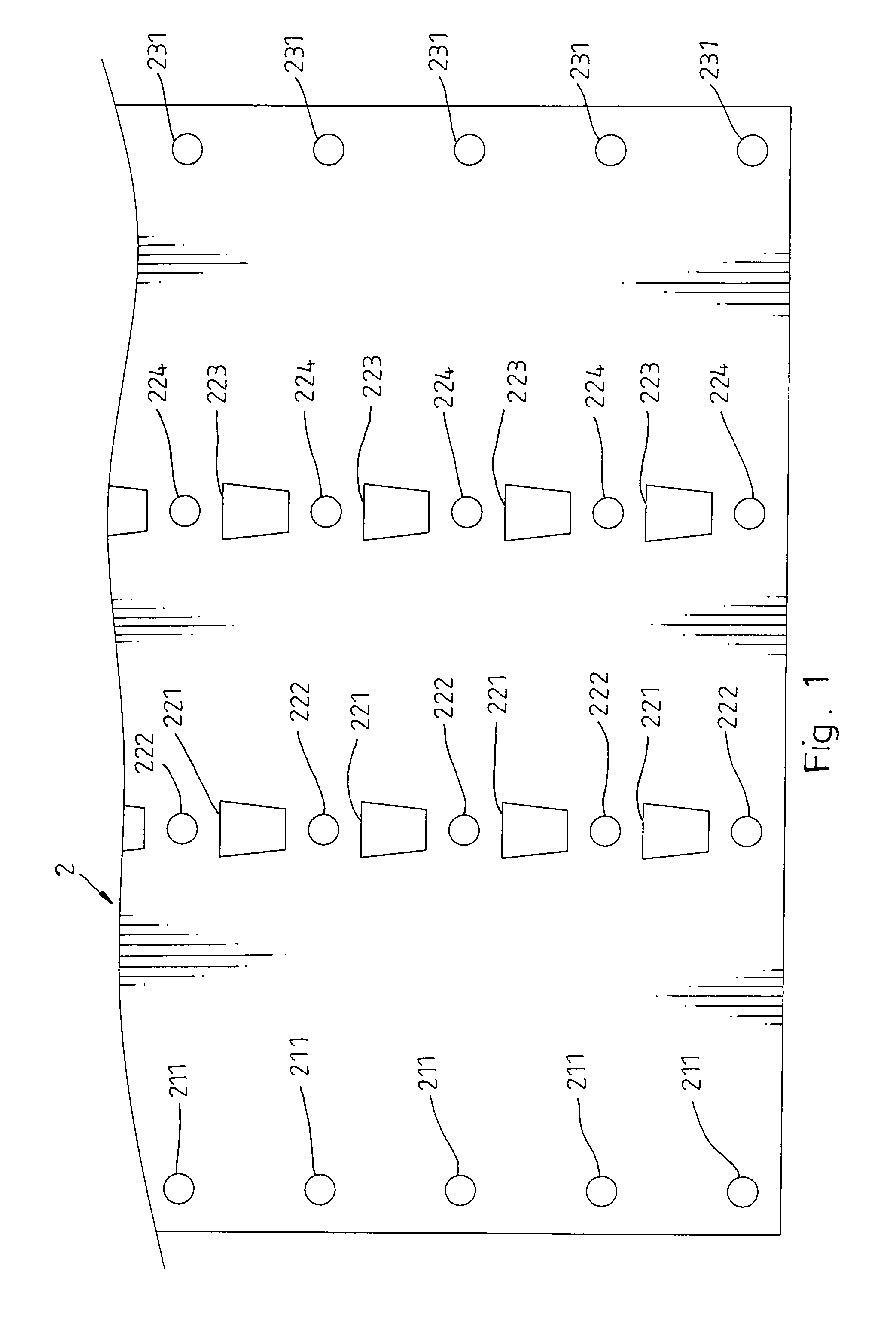

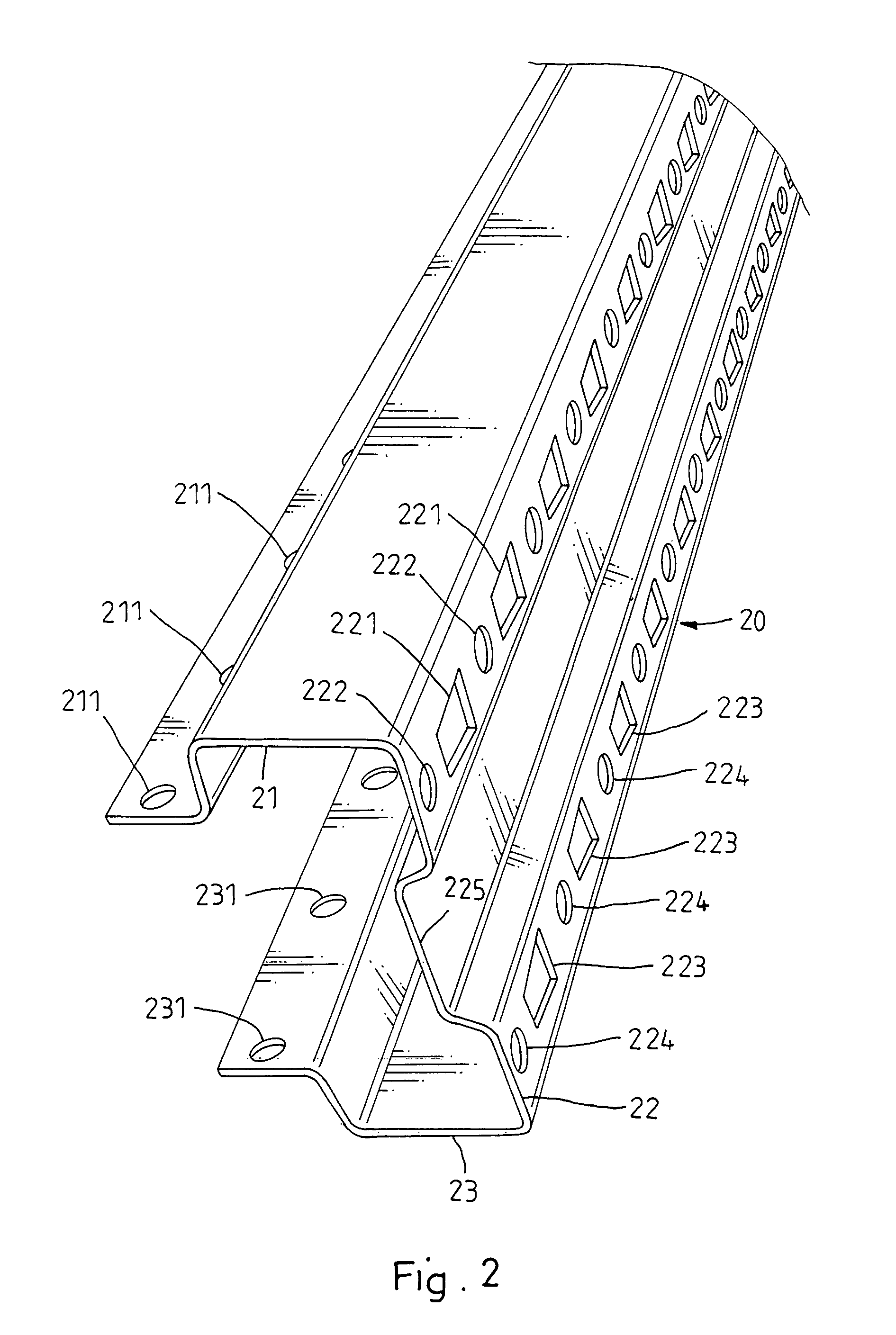

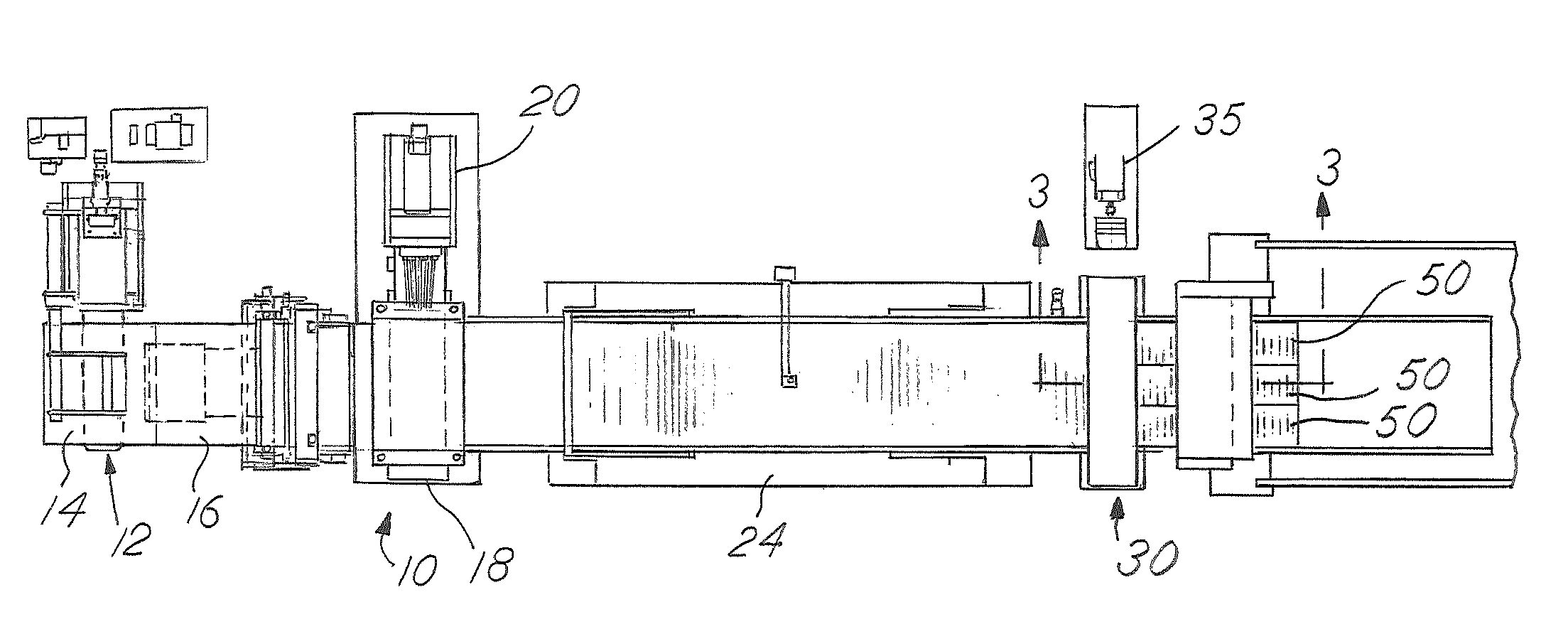

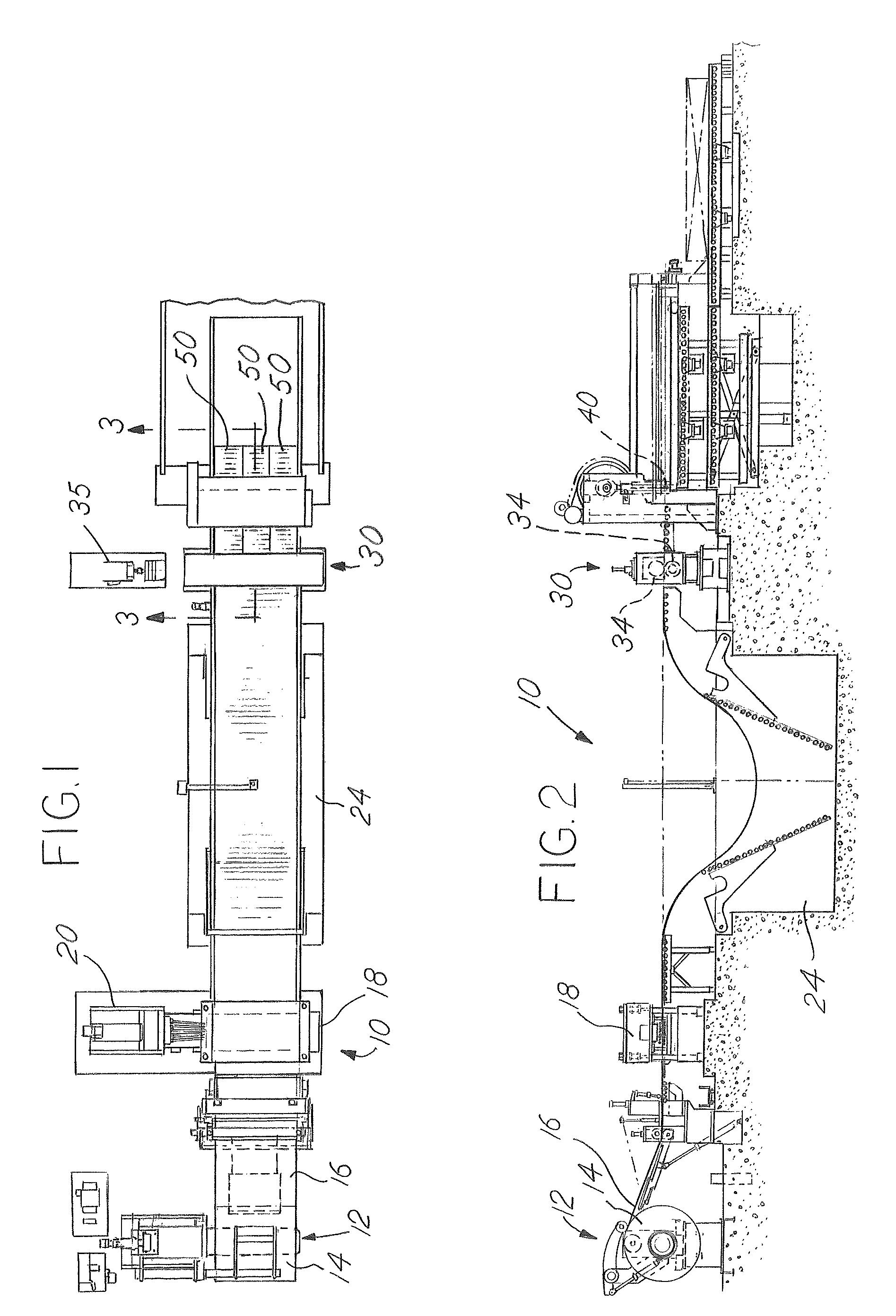

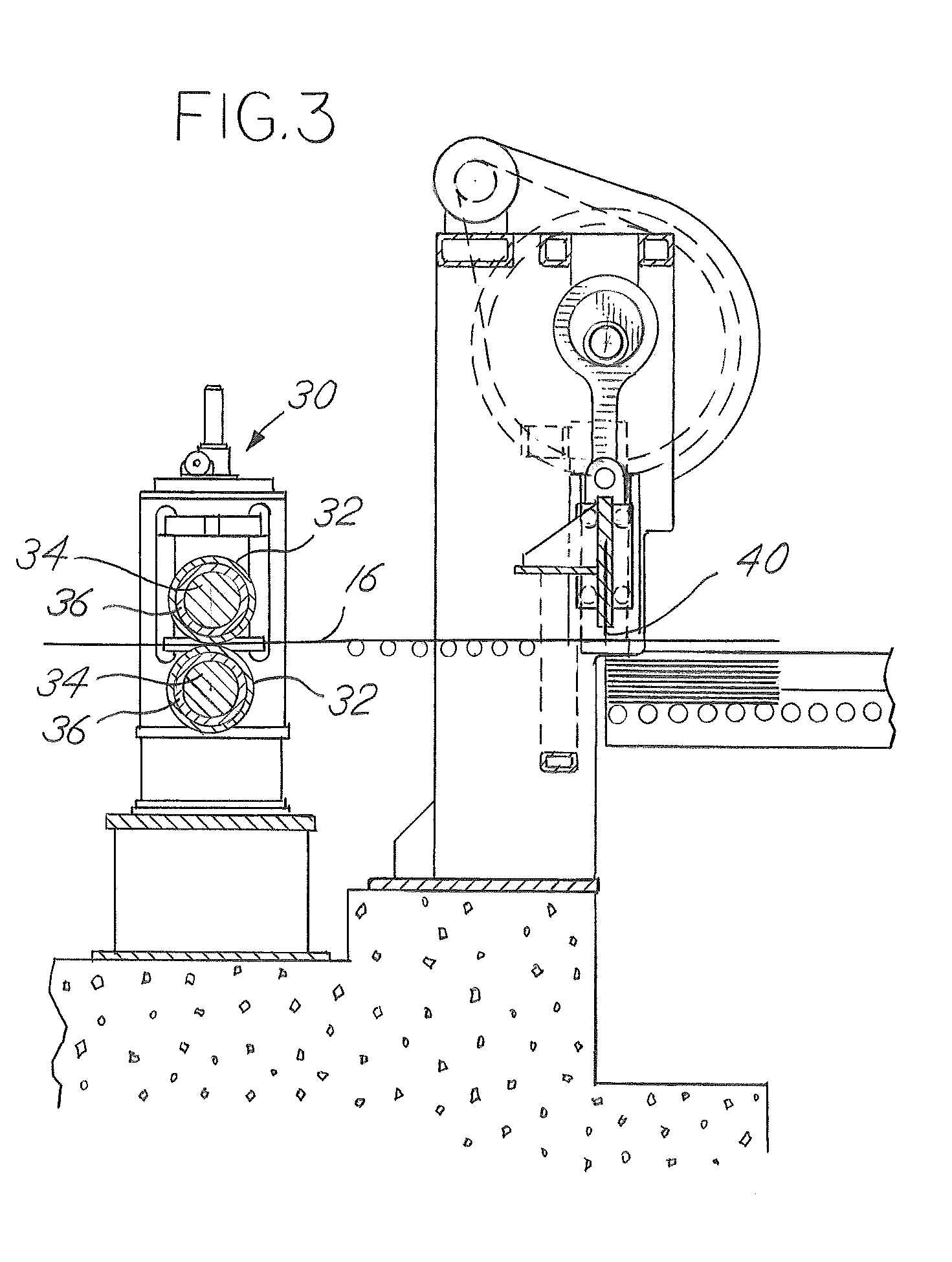

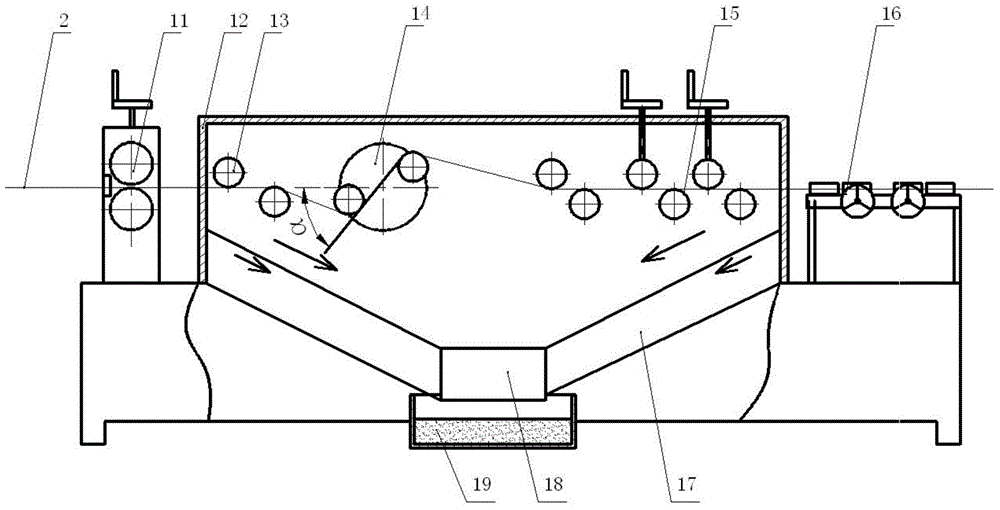

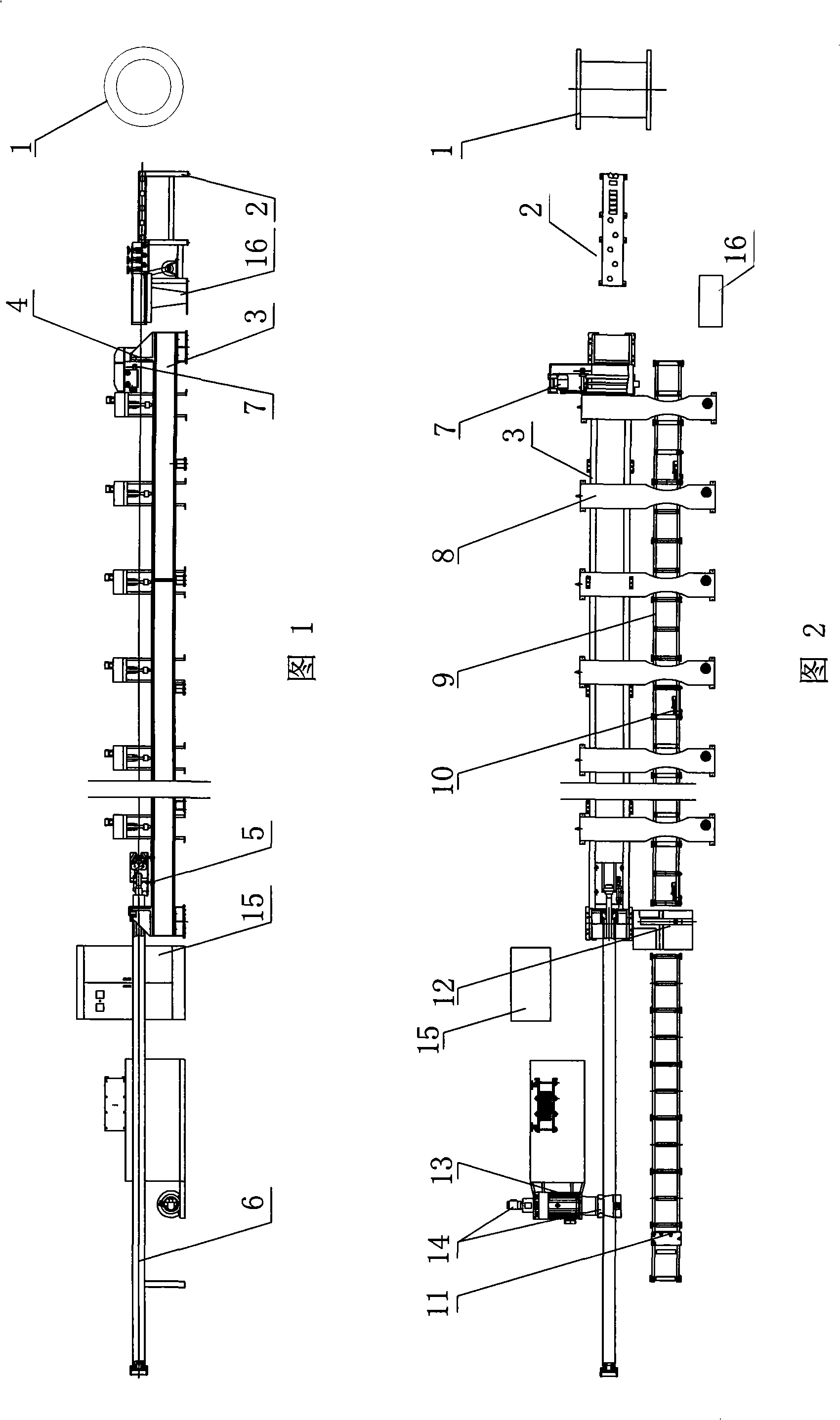

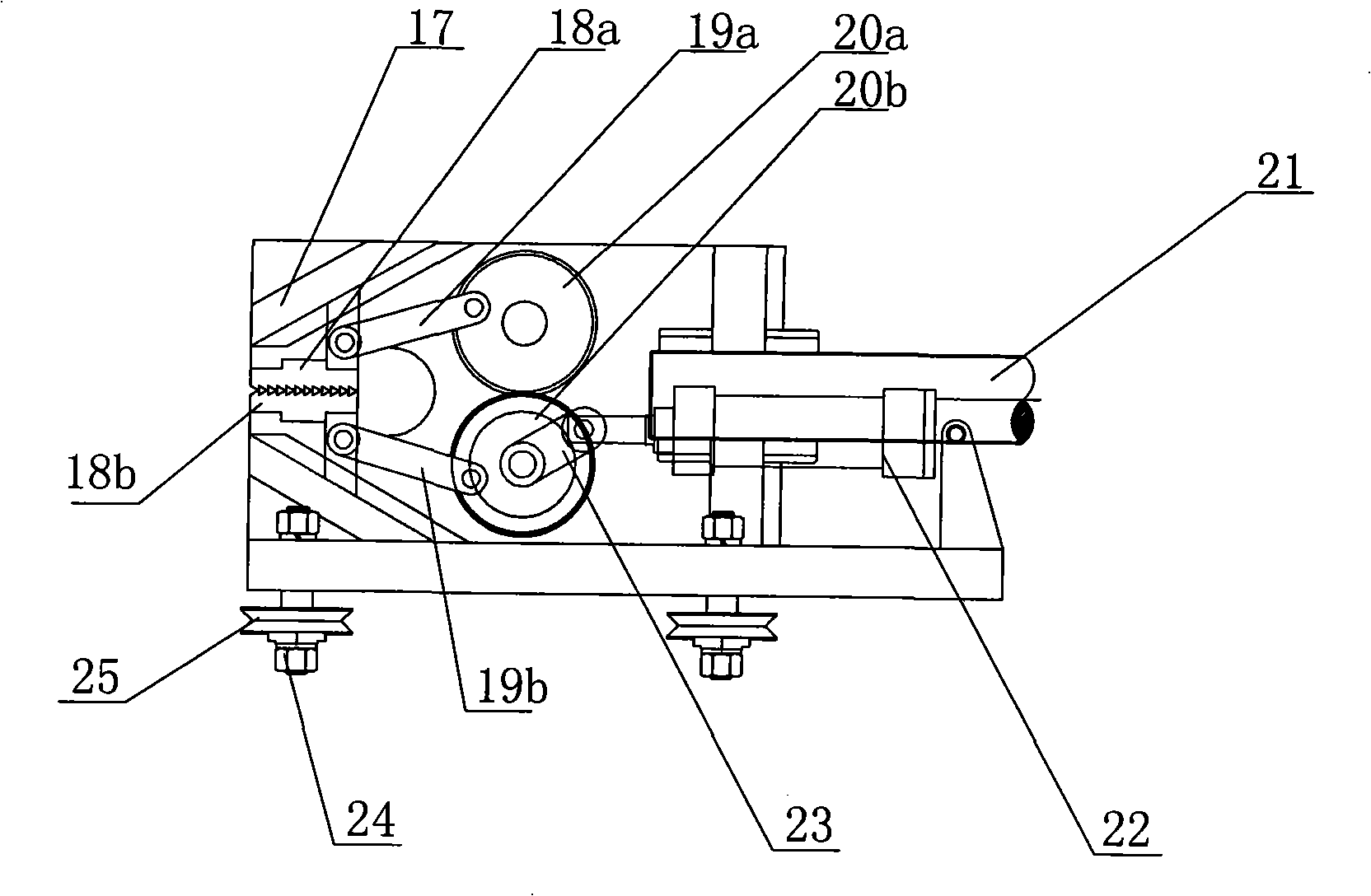

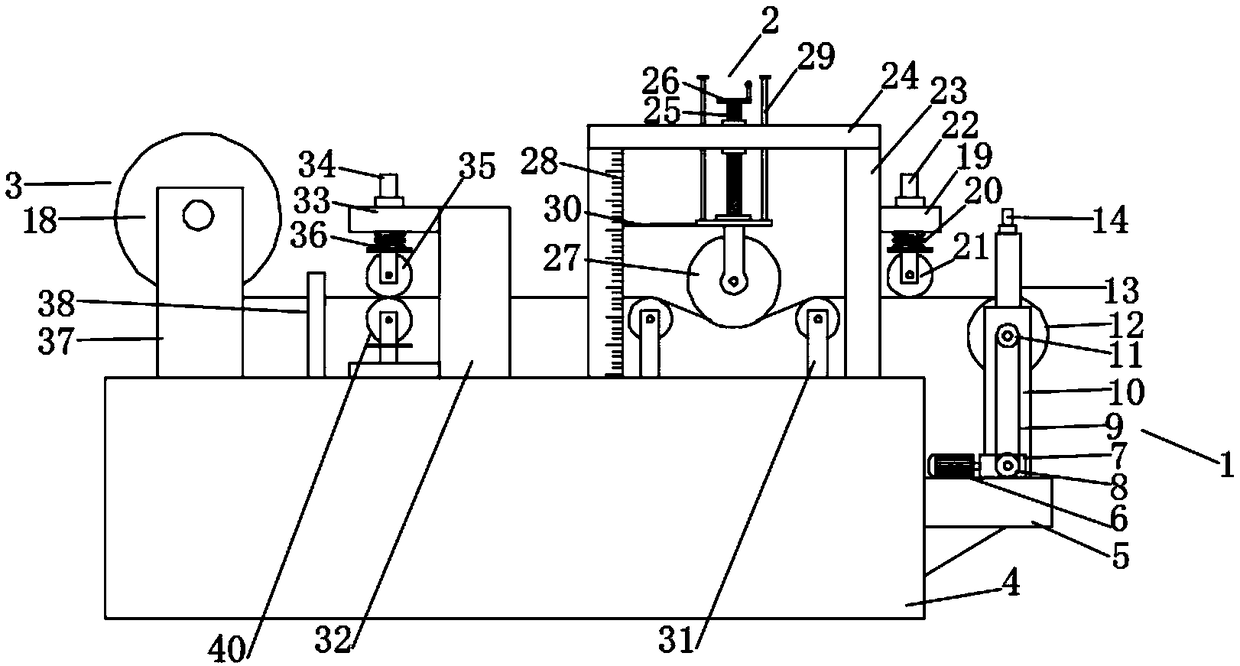

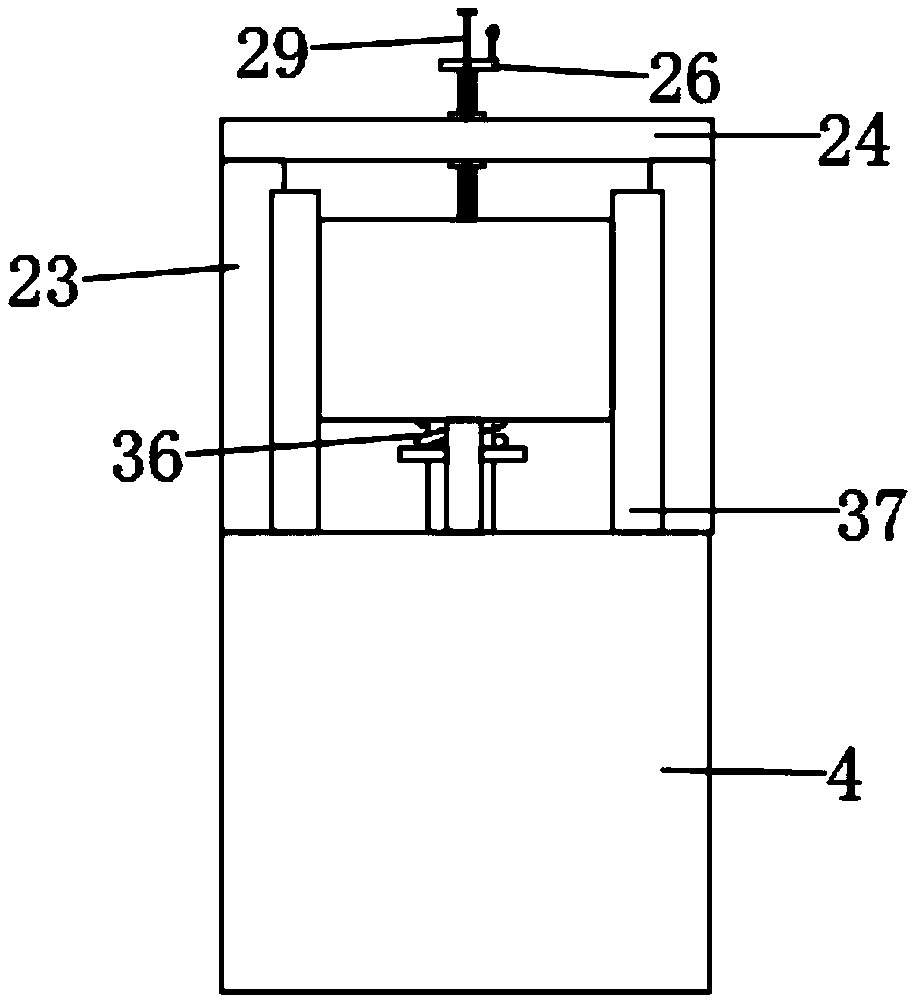

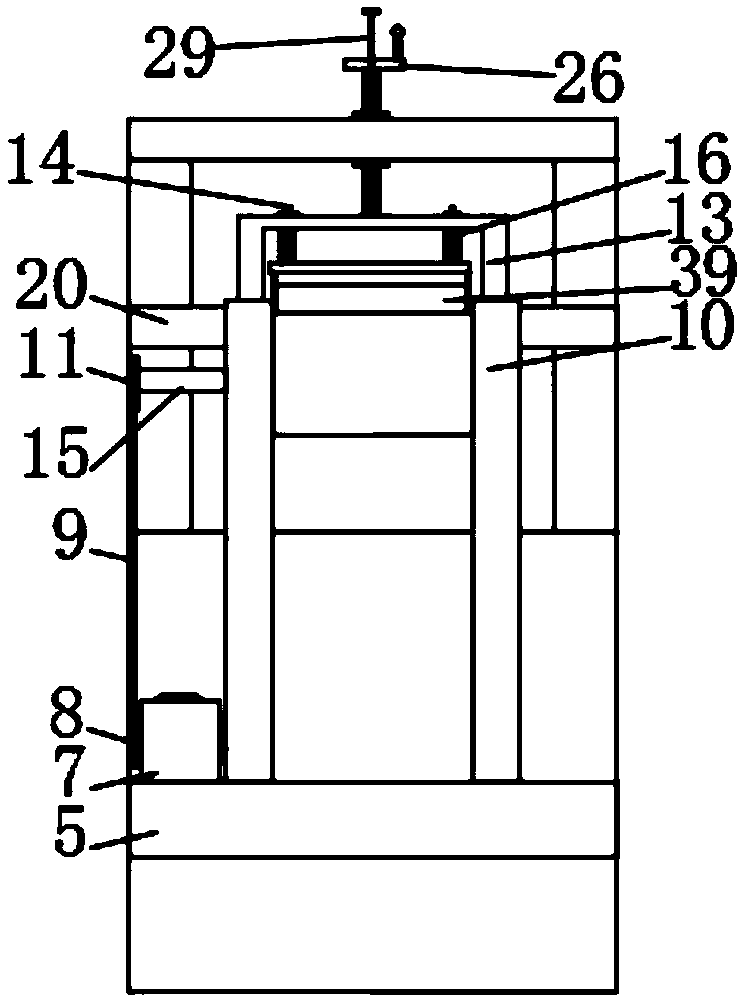

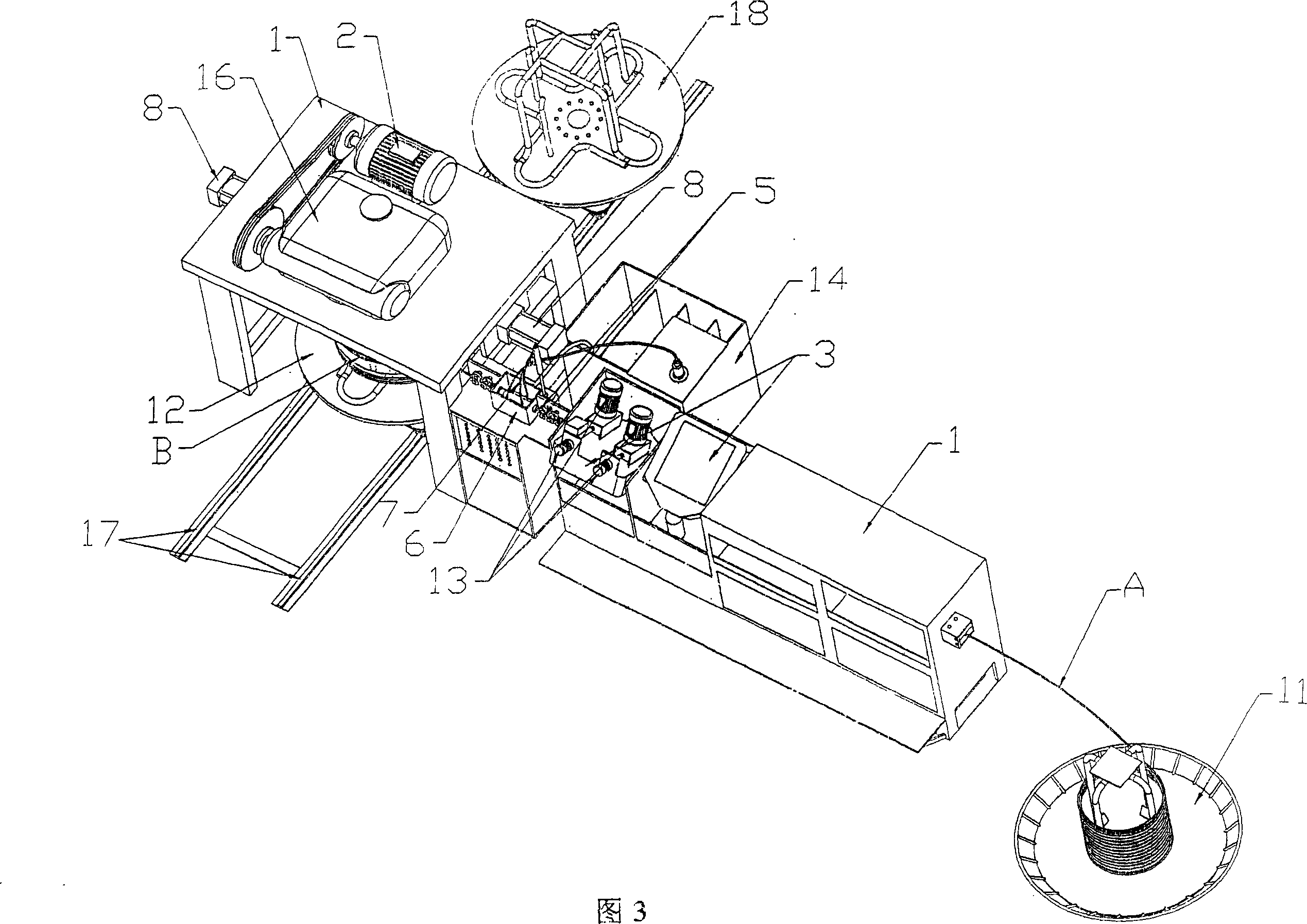

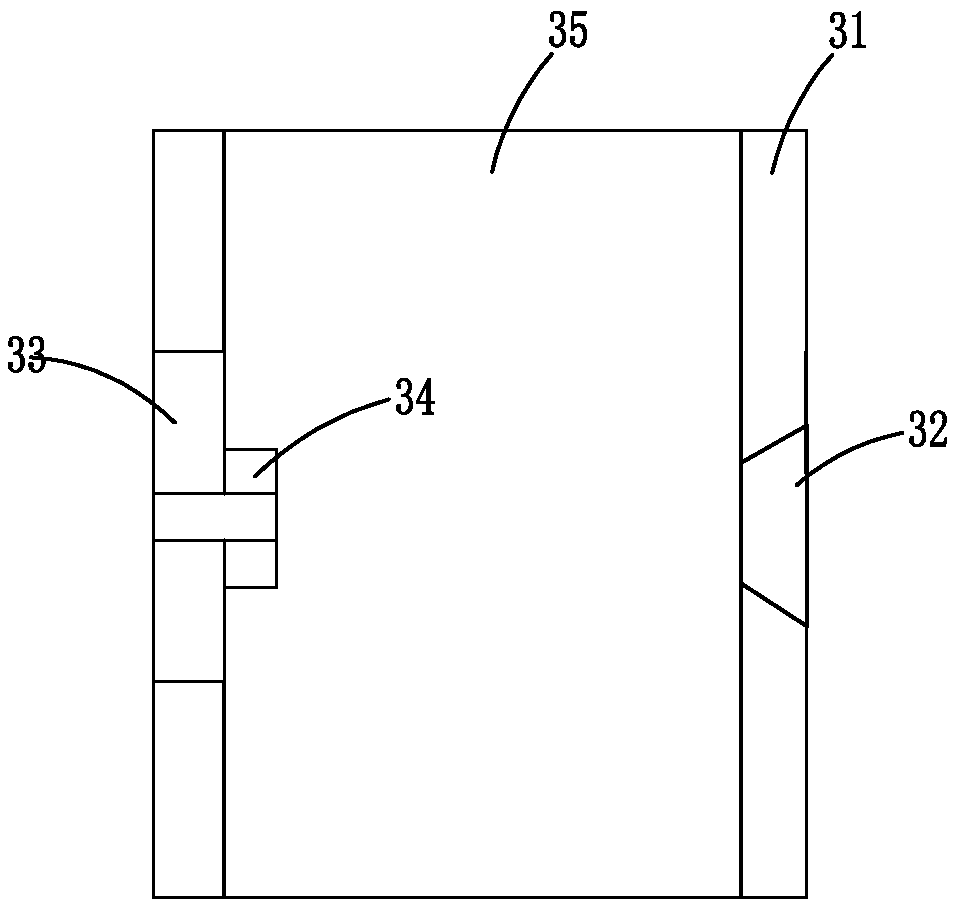

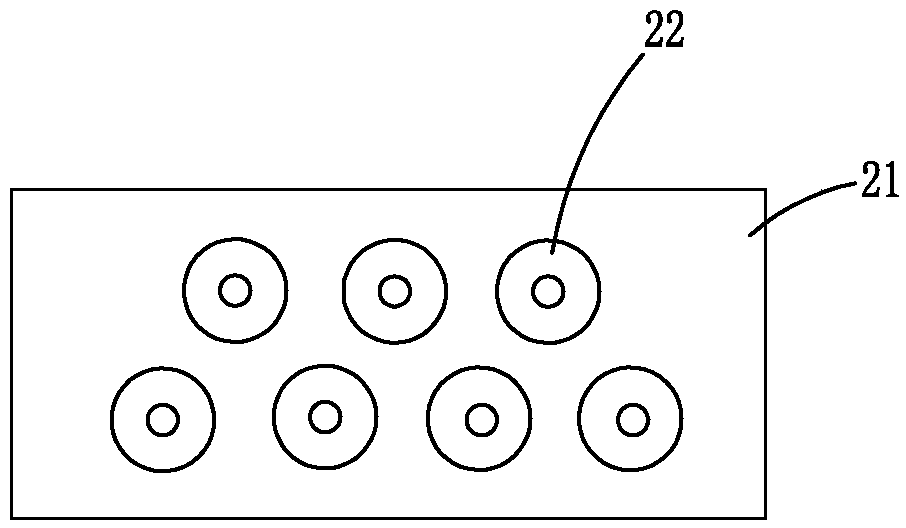

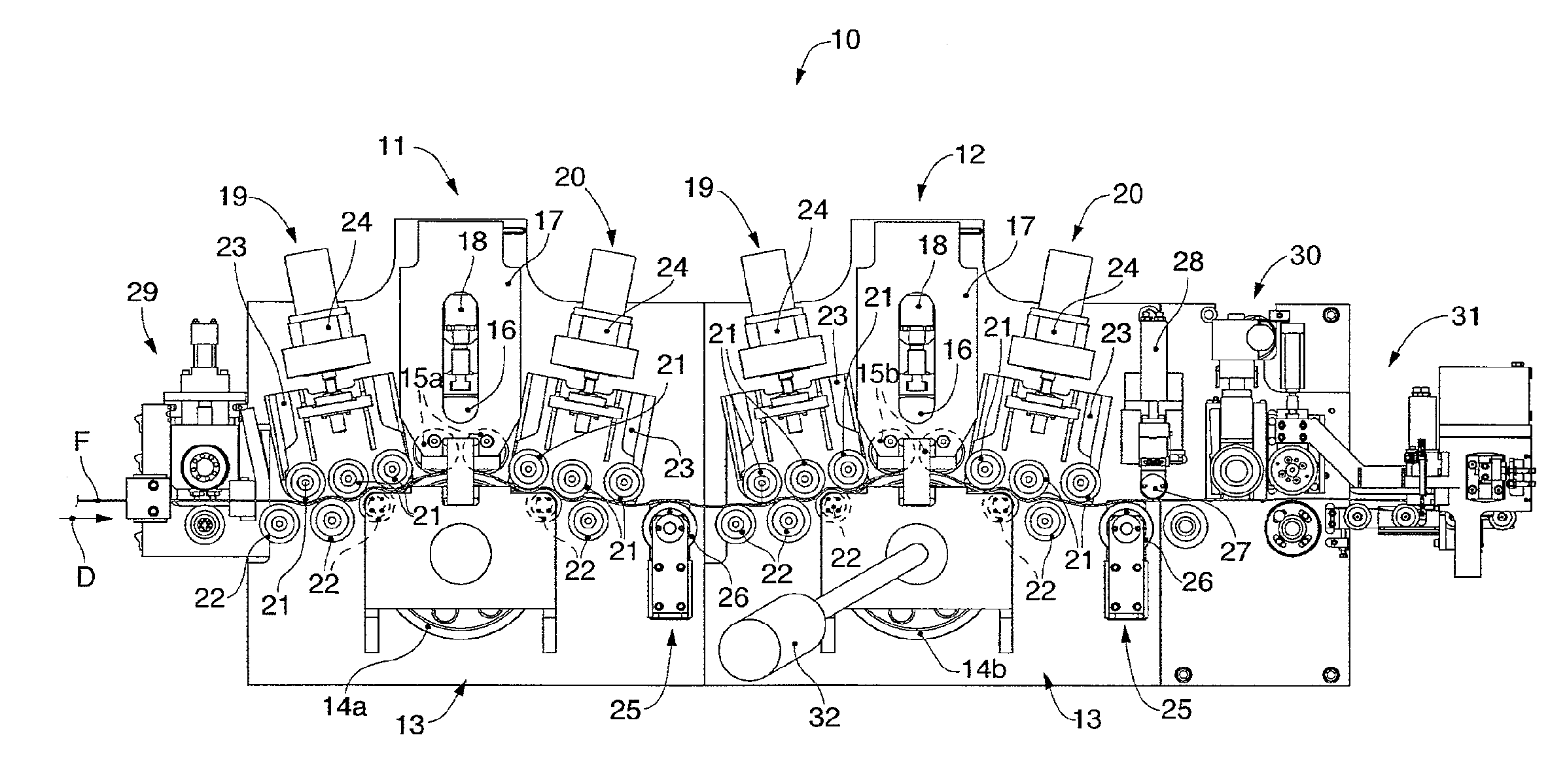

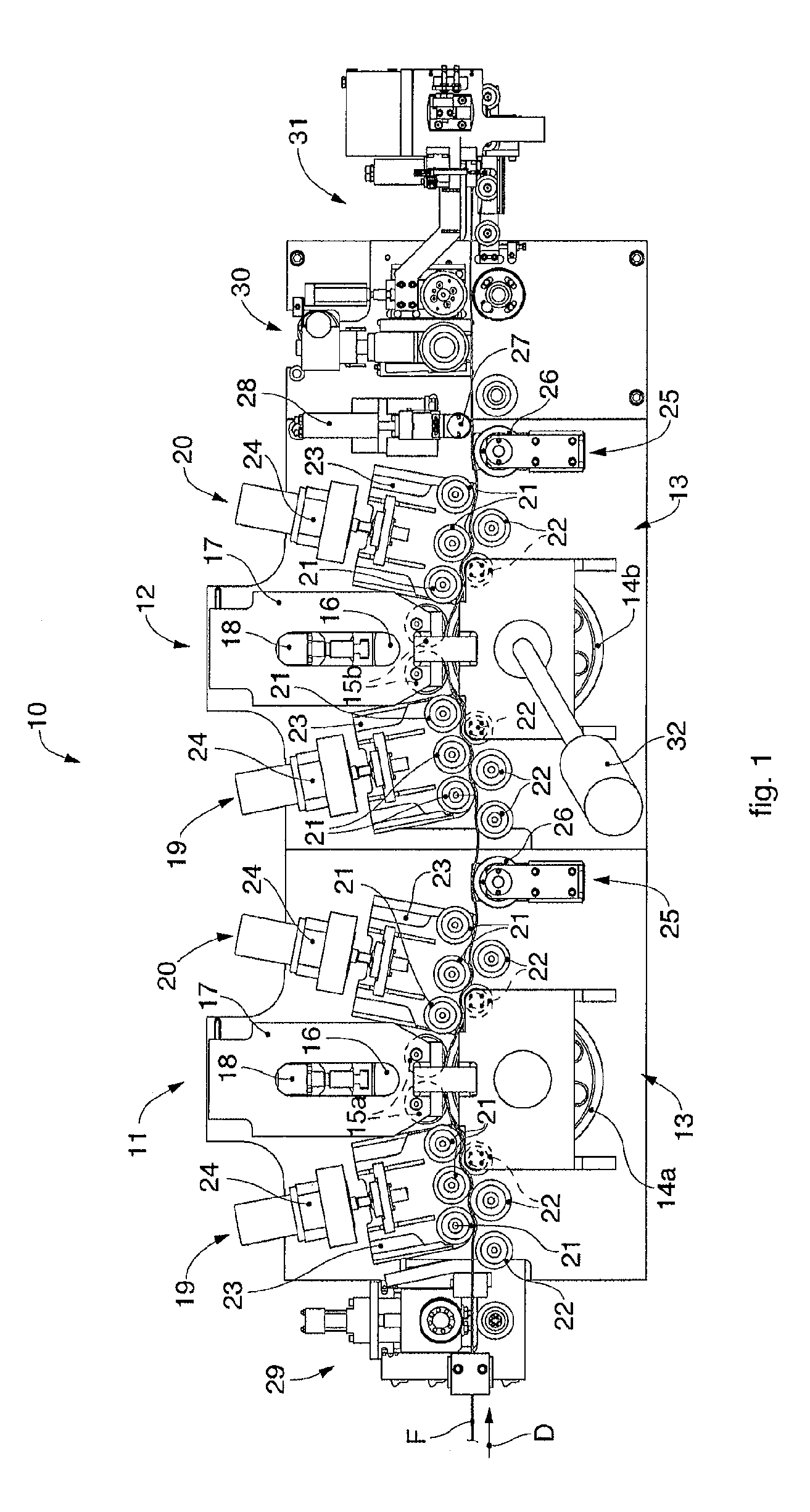

Main beam fabrication procedure and system for making a main beam for warehouse framework

InactiveUS7712345B1Much labor timeMuch processing timeWire straightening devicesMetal rolling arrangementsPunchingEngineering

A main beam fabrication procedure and system for making main beams for warehouse framework through feeding, auto-forwarding and flattening, punching, roller shape-forming, cutting-off and finished product collection steps, in which the punching machine comprises an upper mold holder, four upper punching dies arranged in two longitudinal rows on the bottom side of the upper mold holder and adjustable to change the transverse pitch between the two longitudinal rows of upper punching dies, a bottom mold holder, and four bottom punching dies arranged in two longitudinal rows on the top side of the bottom mold holder and adjustable to change the transverse pitch between the two longitudinal rows of bottom punching dies.

Owner:CHEN CHUN LIANG

Blanking line using slitter as feeder

A blanking line including an uncoiler, a first feeder, a slitter, and a shear. A coil of metal is carried by the uncoiler. The first feeder removes the material from the coil and typically includes a leveler for leveling the metal. The metal is fed from the leveler into a looping pit that is located between the leveler and slitter. The slitter feeds and slits the material a predetermined distance and is driven with servo motors. The looping pit acts as an accumulator allowing the metal to hang so the slitter can move metal intermittently into a shear while the leveler runs at a constant rate. The shear cuts the material to a predetermined length corresponding with the distance that the material is fed by the slitter. A measuring wheel may be included to measure the distance that the material is moved by the slitter.

Owner:BRANER USA

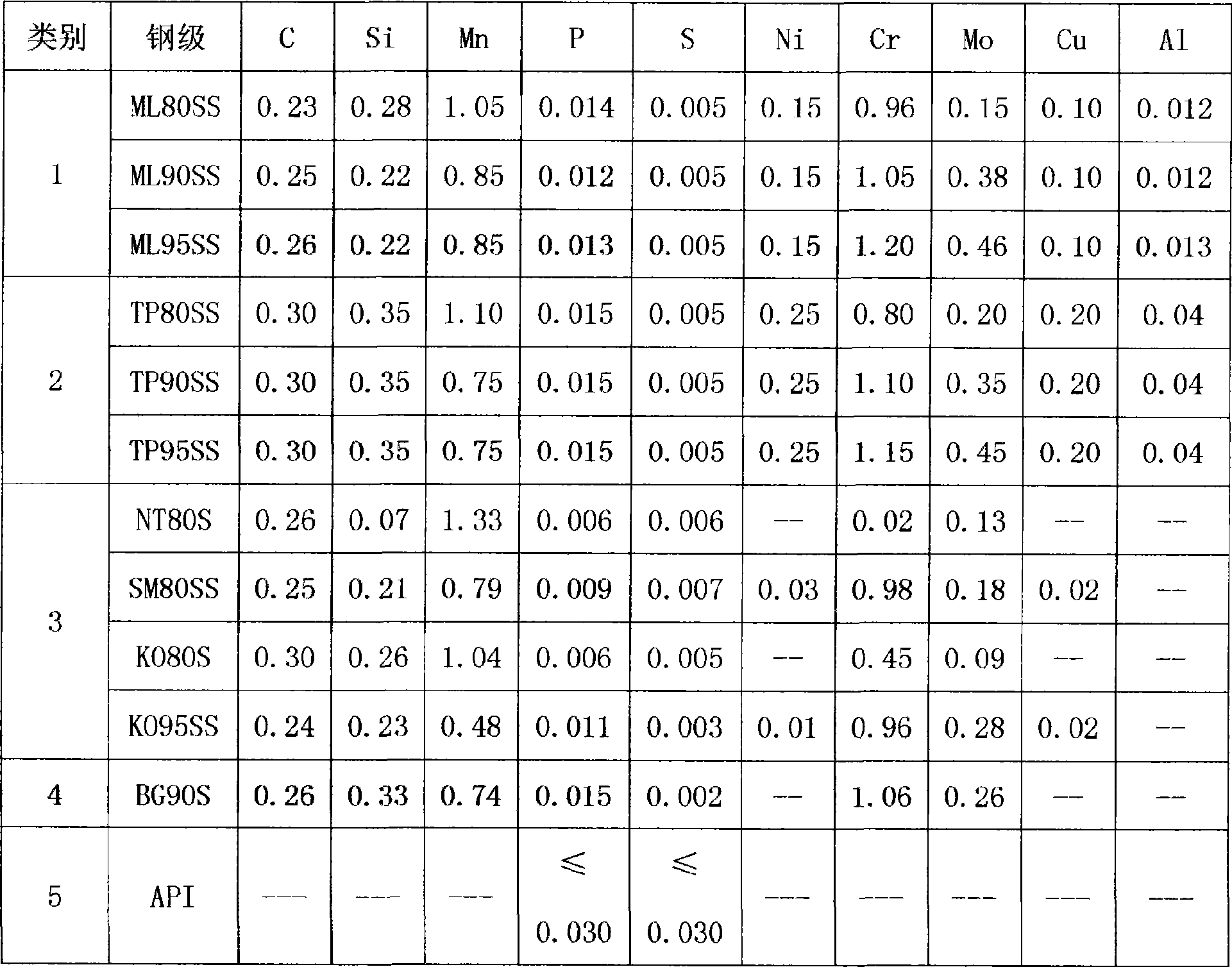

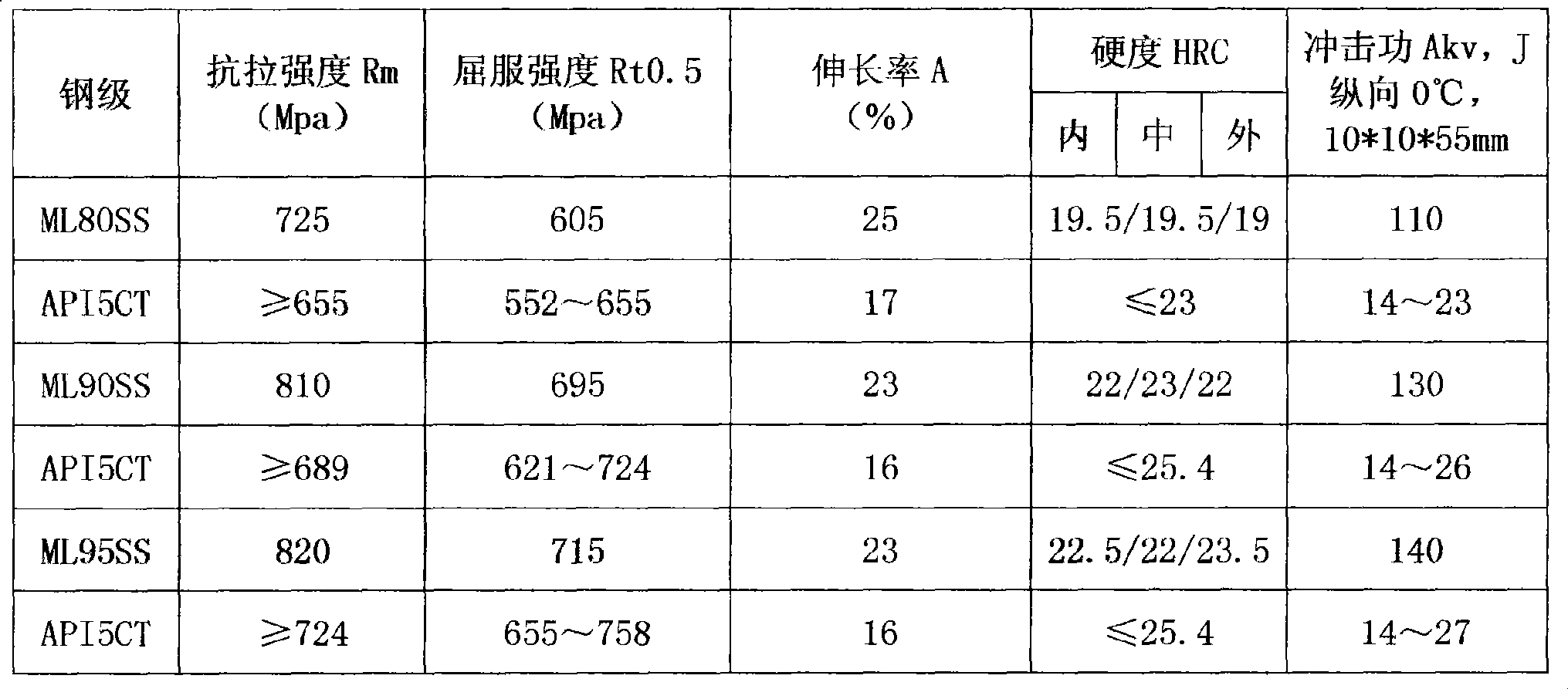

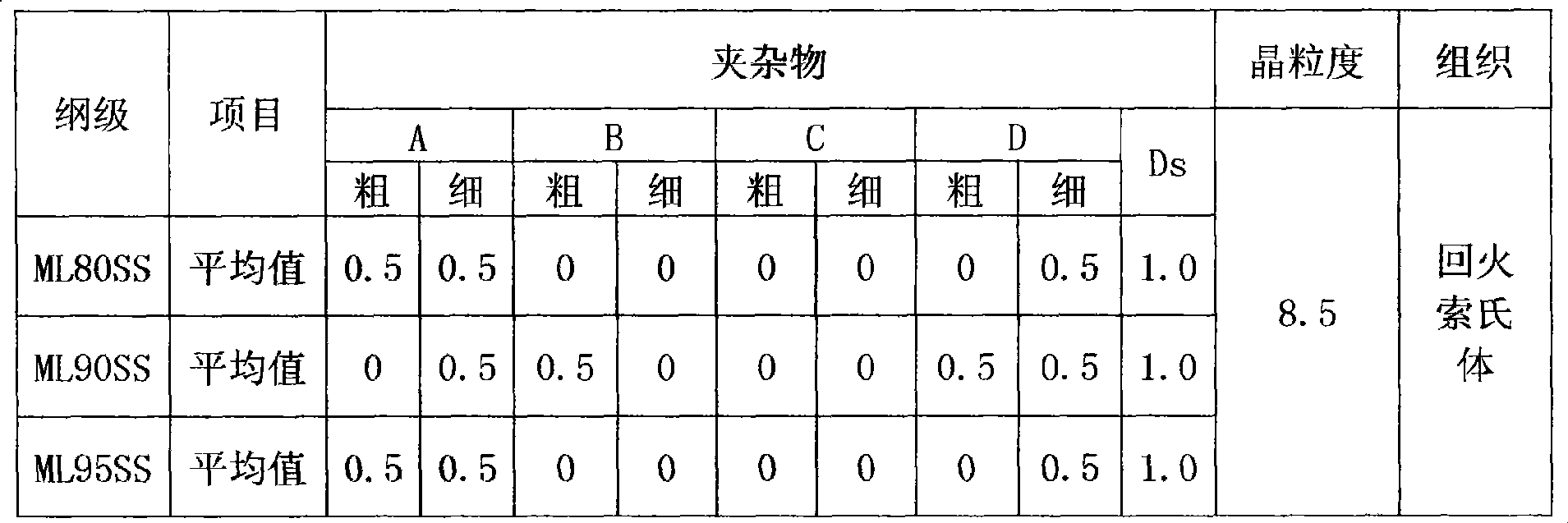

Medium and high strength oil casing for resisting sulfurated hydrogen corrosion and manufacturing method thereof

InactiveCN101440460AExcellent physical and chemical propertiesEasy to useWire straightening devicesFurnace typesHydrogenUltimate tensile strength

The invention discloses a middle-high strength oil sleeve used for resisting hydrogen sulfide corrosion and a manufacture method thereof. The sleeve comprises the following compositions by weight percentage: 0.20 to 0.27 percent of C, less than or equal to 0.40 percent of Si, 0.80 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of Si, 0.30 to 0.75 percent of Mo, 0.95 to 1.40 percent of Cr, less than or equal to 0.30 percent of Cu, less than or equal to 0.30 percent of Ni, less than or equal to 0.02 percent of Al, and the balance being Fe. The method comprises the following steps: a circular tube blank is manufactured by molten iron and scrap steel through smelting, external refining, vacuum degassing and arc continuous casting; the circular tube blank is manufactured into a plain tube by rolling the tube blank with hot rolling; and the plain tube is manufactured into a finished product through modified thermal treatment and tube processing. The middle-high strength oil sleeve has the advantages of excellent physicochemical performance, application performance, sulfureted hydrogen stress corrosion resistance, and a threshold value of the sulfureted hydrogen stress corrosion resistance of the oil sleeve reaches over 90 percent of SMYS.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

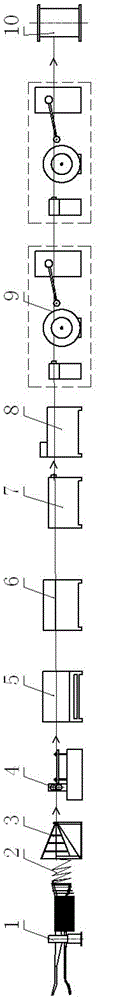

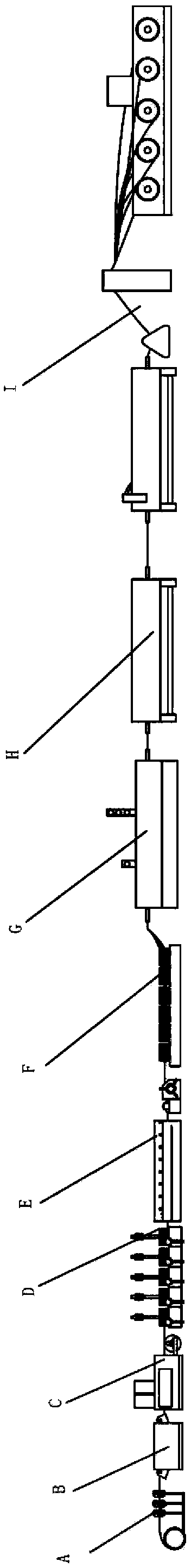

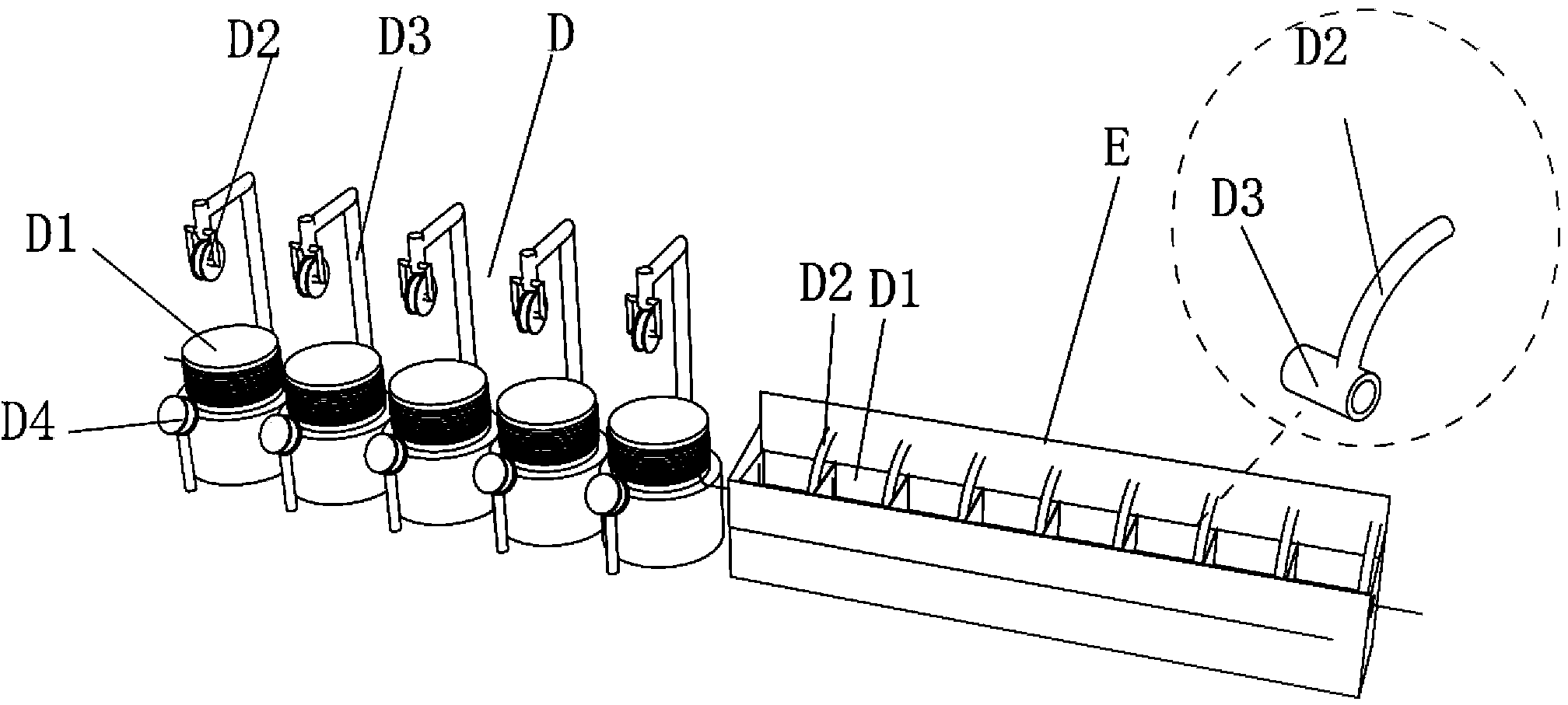

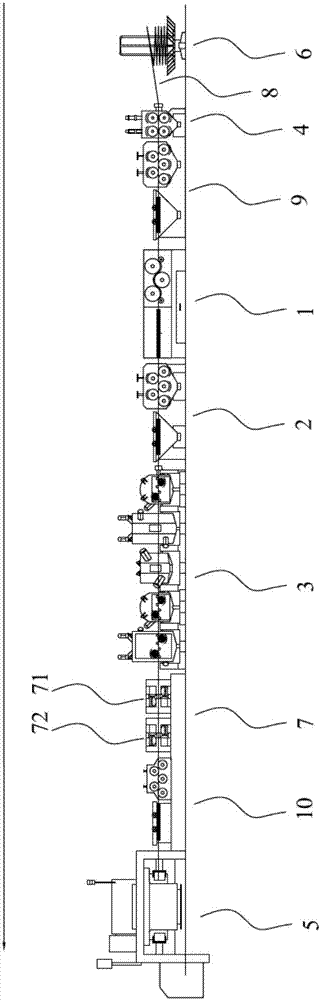

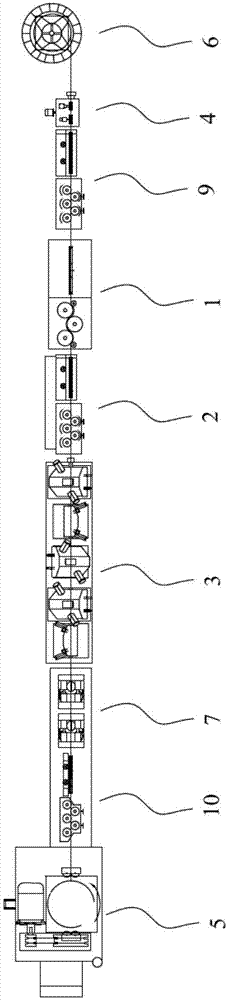

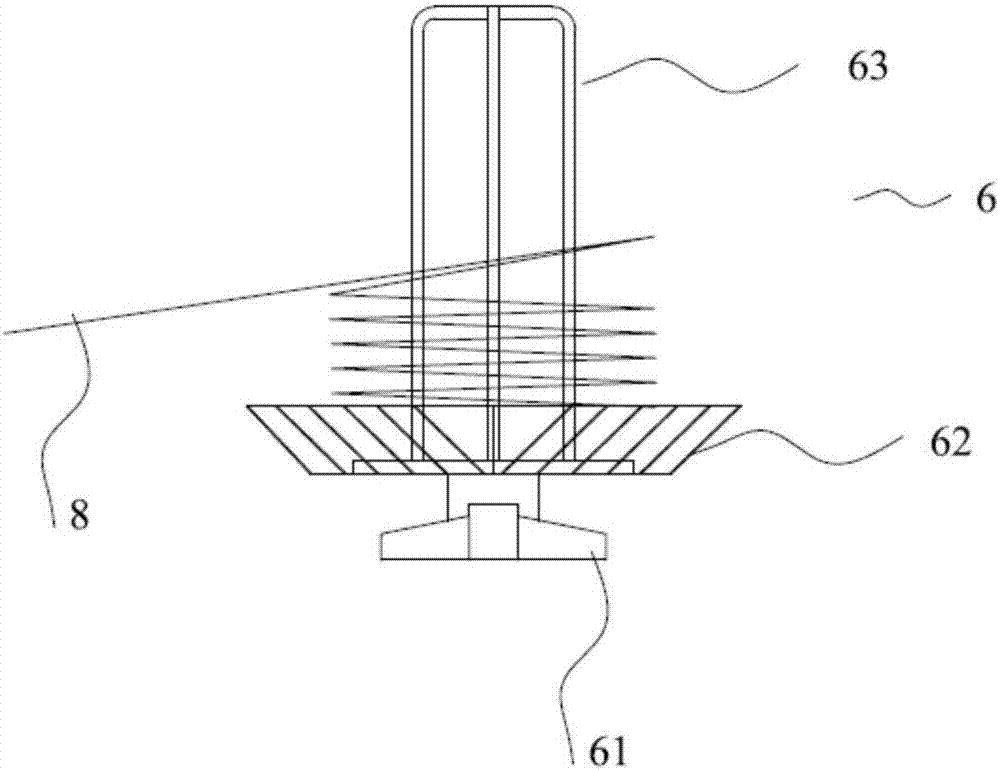

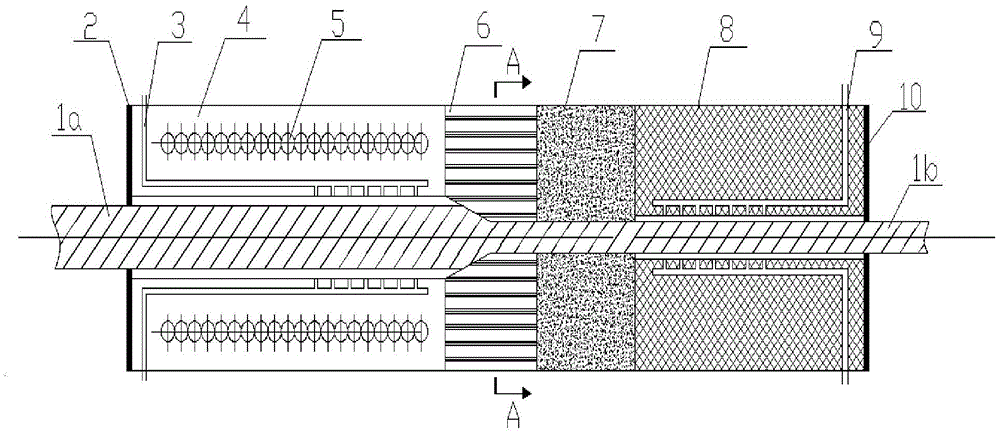

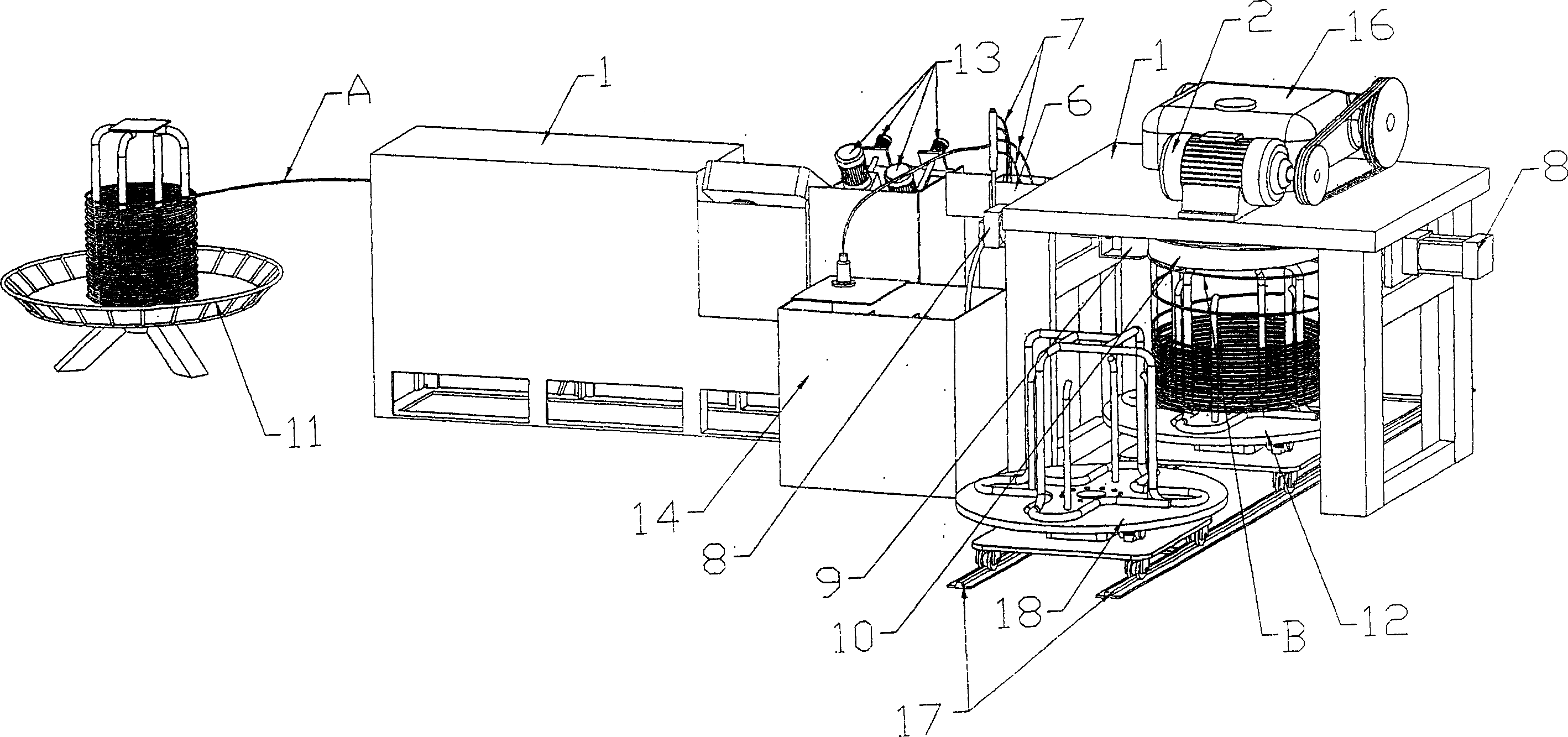

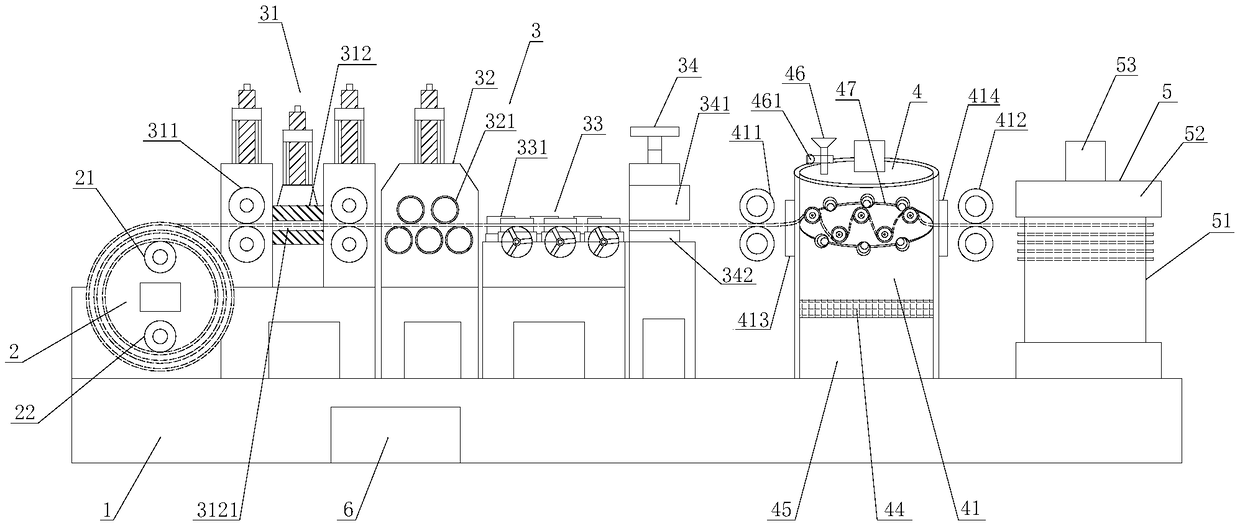

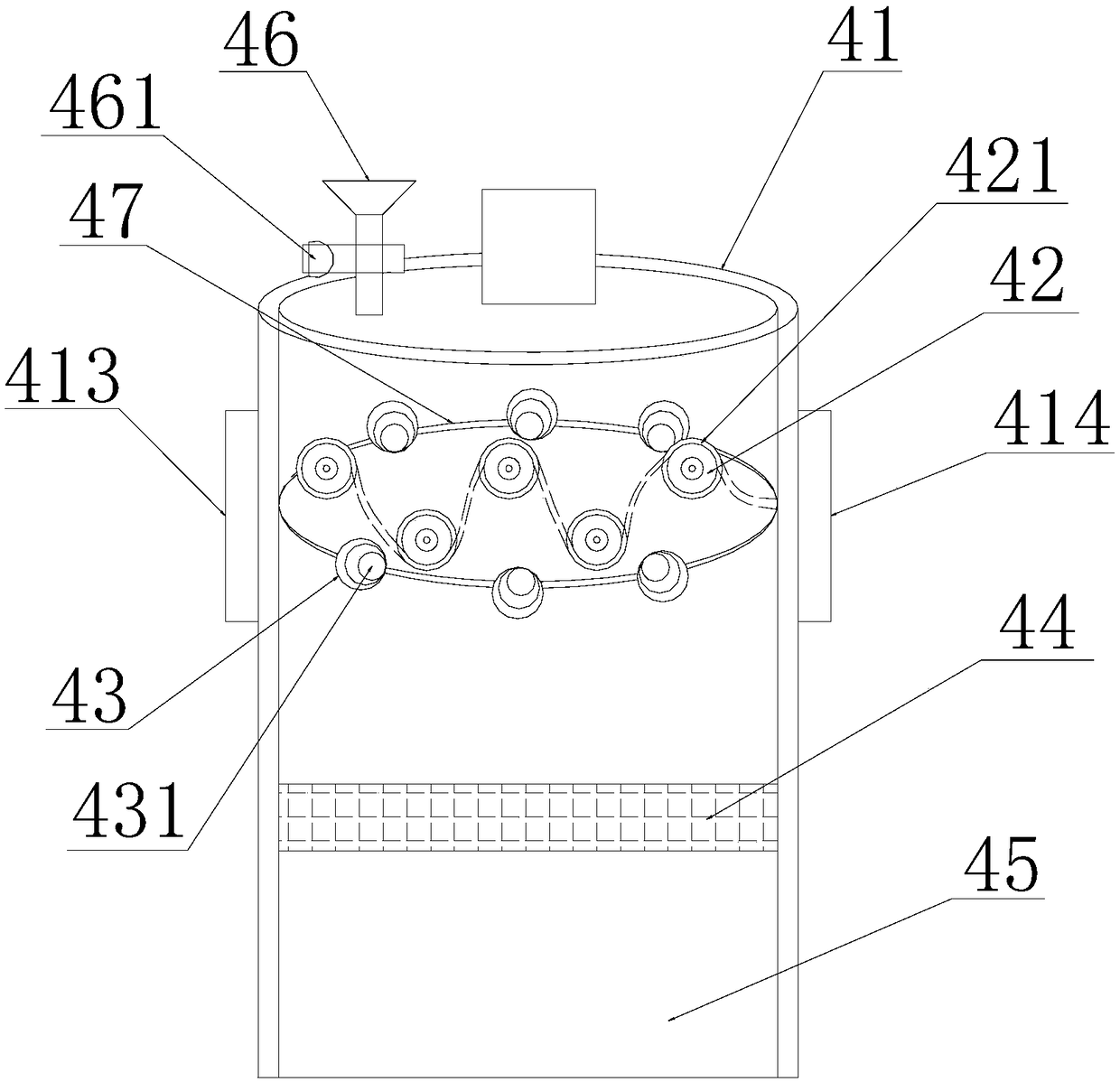

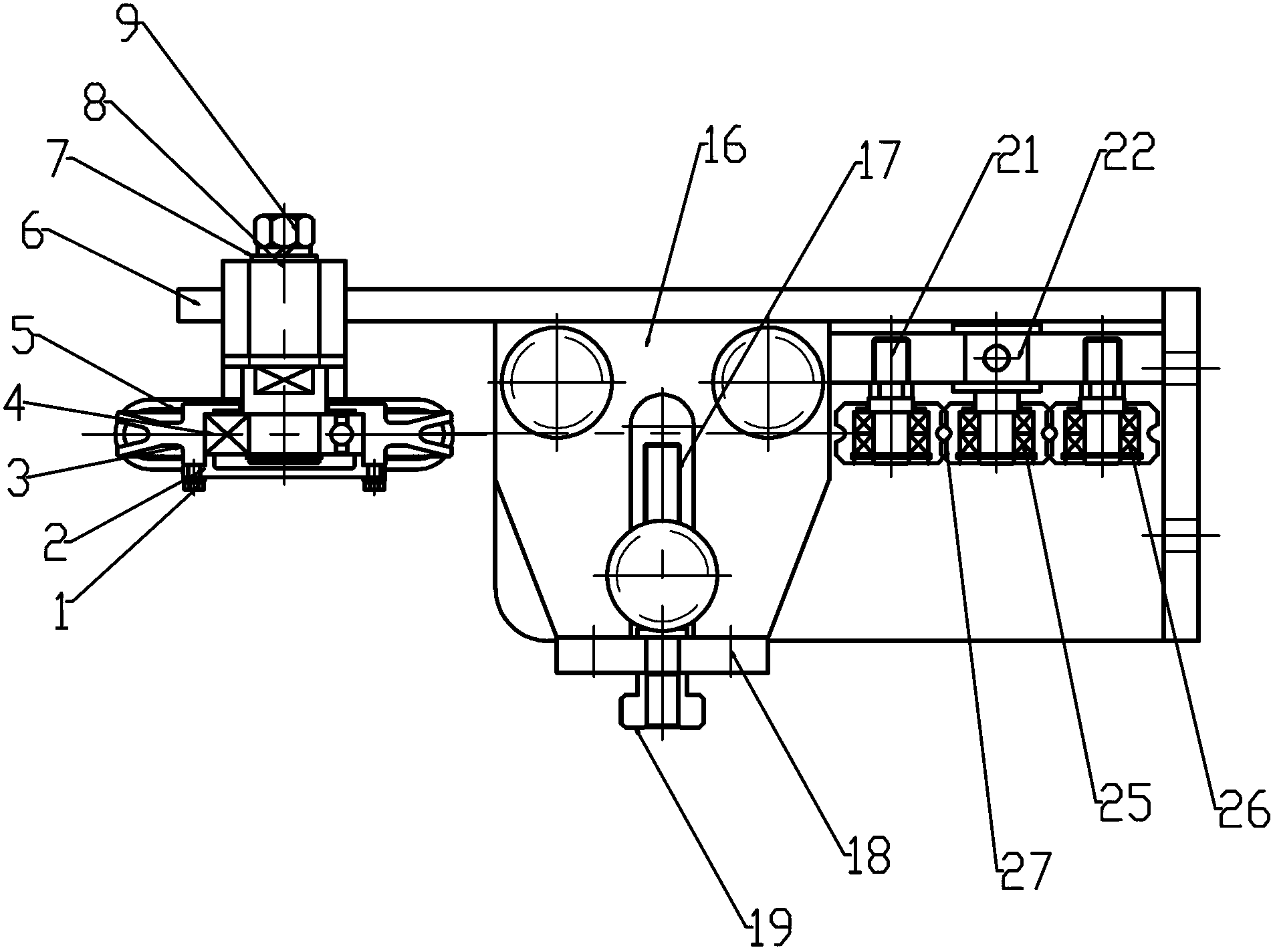

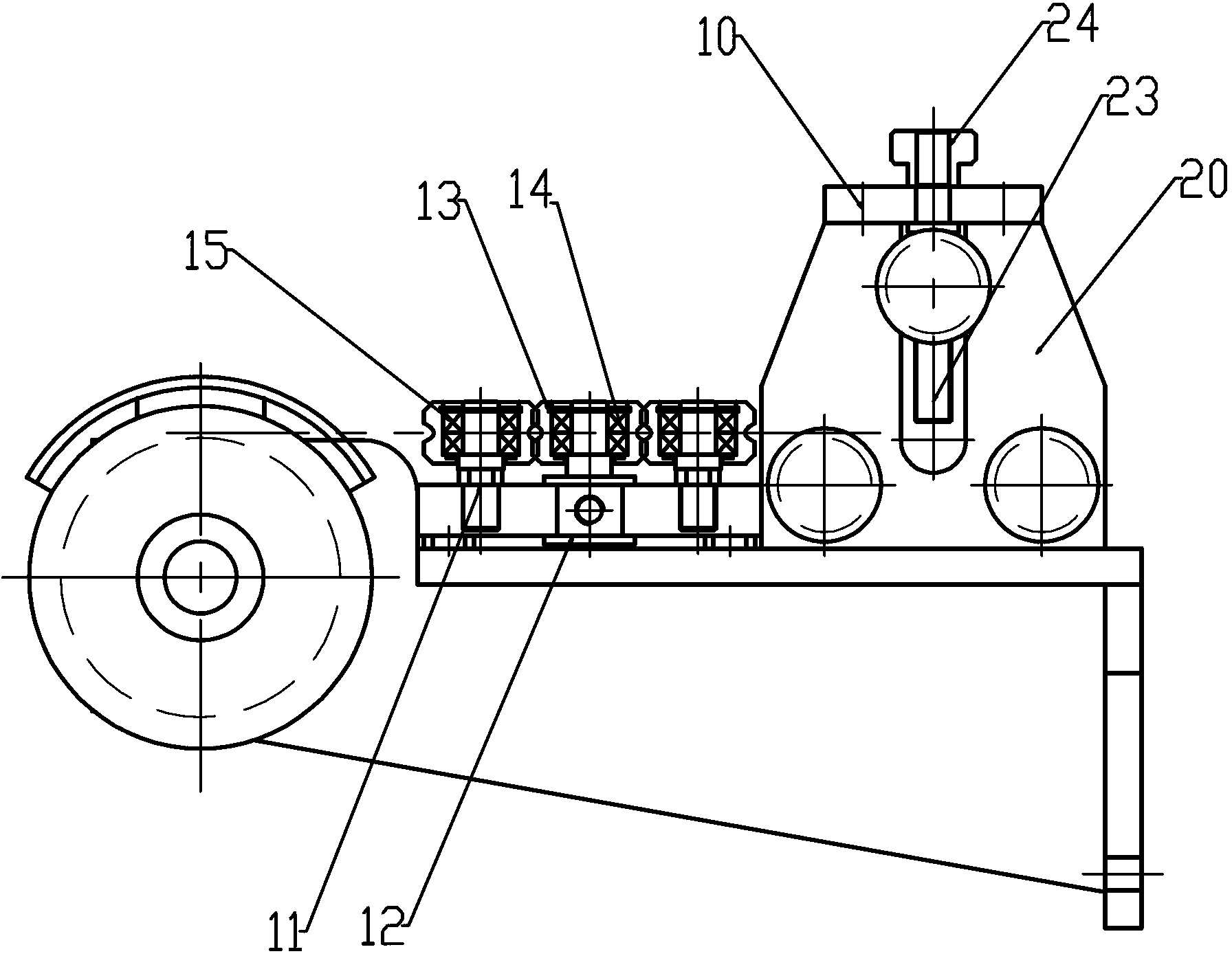

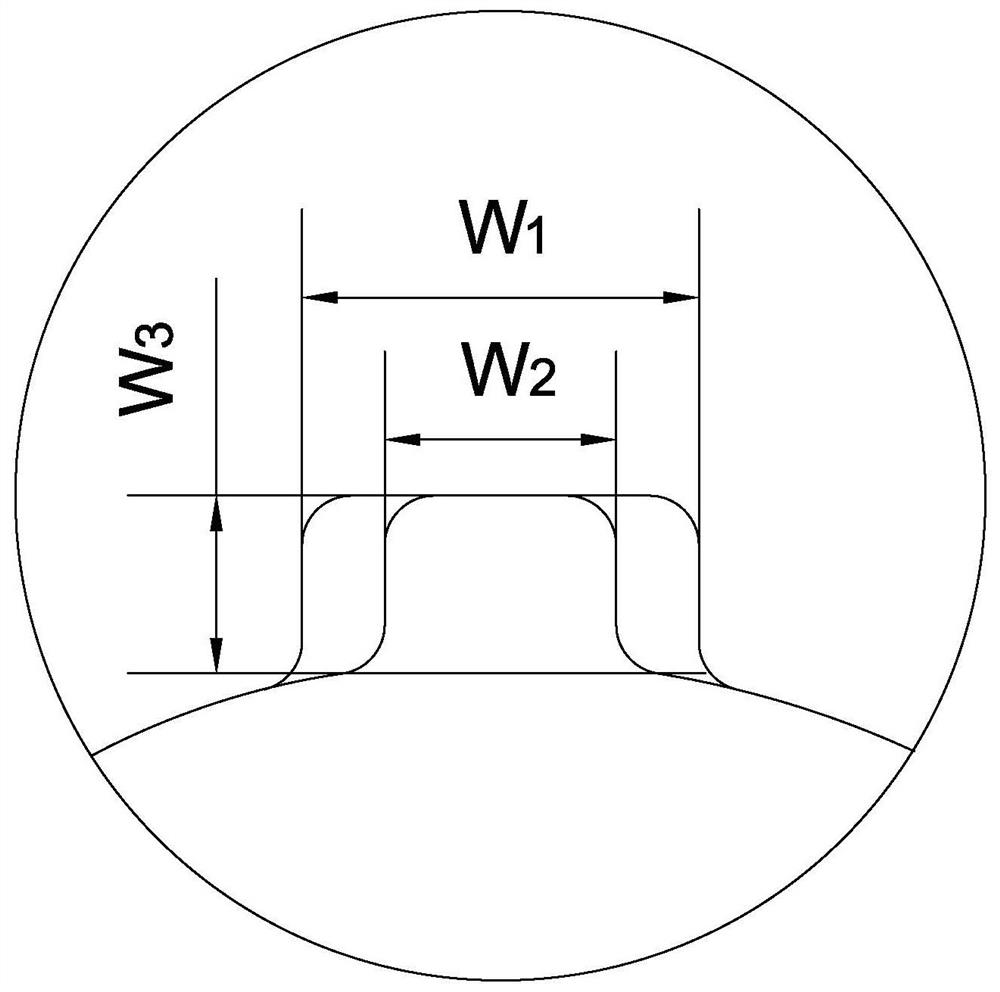

Wire drawing production system and production technology for steel wire of steel strand

InactiveCN104525591AGuaranteed uninterrupted productionIncrease productivityWire straightening devicesExtrusion cleaning devicesEngineeringFilm-coated tablet

The invention relates to a wire drawing production system for a steel wire of a steel strand. The wire drawing production system for the steel wire of the steel strand comprises a pay-off rack, a wire managing rack, an aligning and guiding device, a physical unshelling device, a descaling and grinding device, a film coating device, a drying device, multiple drawing devices and a take-up rack which are sequentially arranged. The descaling and grinding device comprises a box body. A pair of vertical brush wheel assemblies and a pair of horizontal brush wheel assemblies are arranged inside the box body. An electrical machine drives brush wheels of the vertical brush wheel assemblies and brush wheels of the horizontal brush wheel assemblies. The outlet terminal on the right side of the box body is provided with a dust absorbing device. The film coating device comprises a box body, a cleaning mechanism and a film coating mechanism. A baffle is arranged inside the box body. The box body is divided into the cleaning mechanism arranged on the left inlet end and the film coating mechanism arranged on the outlet end on the right side of the box body. The wire drawing production system and a production technology for the steel wire of the steel strand have the advantages that the structure is simple, the design is scientific and reasonable, and the system running is safe, efficient and stable. The quality of the steel wire is improved and the production efficiency is improved.

Owner:天津日吉科技有限公司

Improved automatic drawing machine

The invention relates to an improved automatic drawbench, which has the advantages that the improved automatic drawbench has less waste, convenient processing, high efficiency and high rate of finished products, and processed plates are difficult to be polluted. The improved automatic drawbench comprises a frame, wherein the frame is provided with a drawing and clamping structure and a drawing die. The improved automatic drawbench is characterized in that the side part of the drawing die is provided with a sawing machine; the frame is provided with a straightener and a discharge machine in turn on the rear of the drawing die; and the side part of the frame is provided with a material shifting structure the manipulator of which is correspondingly arranged on a discharge position of the drawing die.

Owner:唐志明

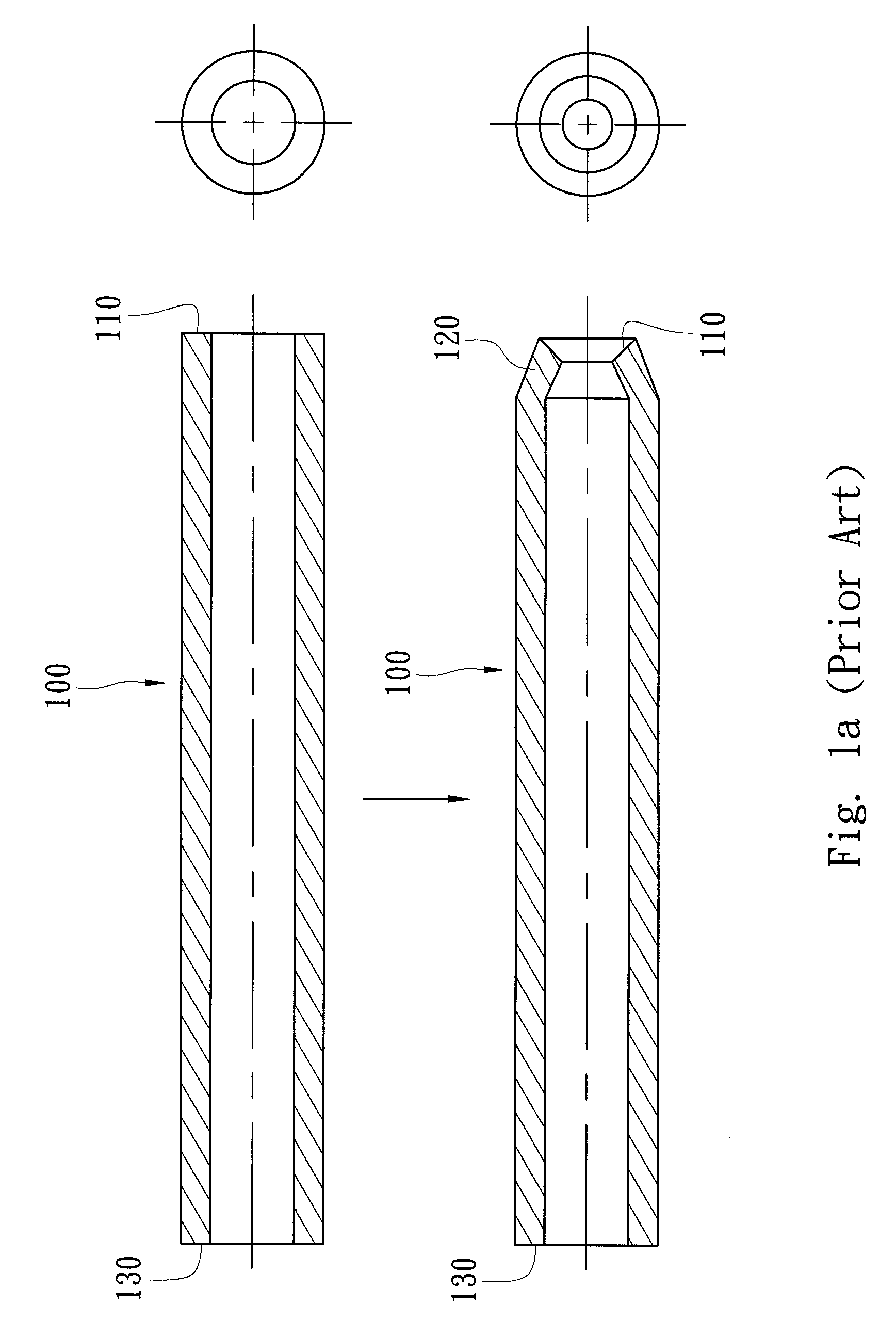

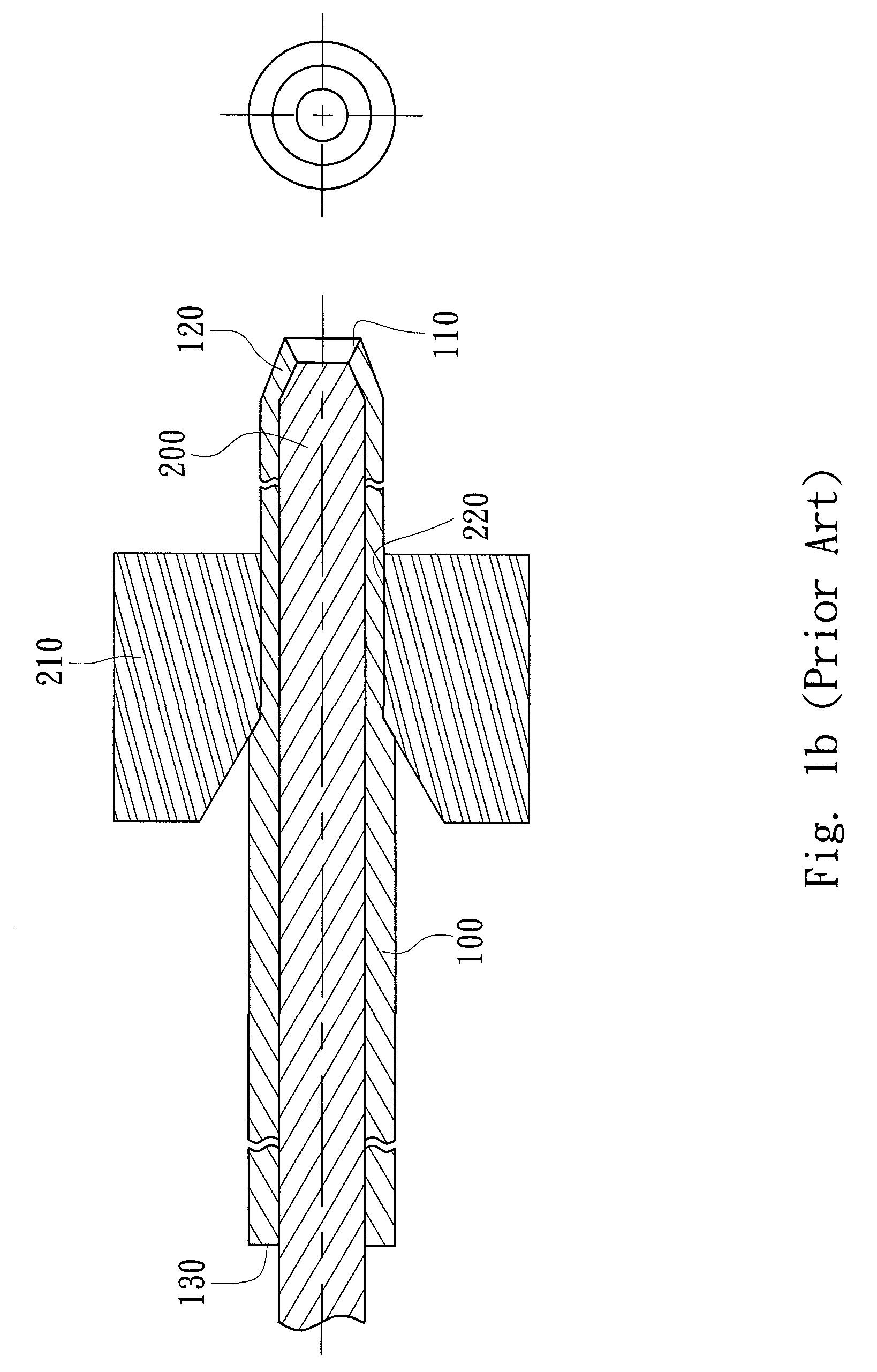

Method of machining metallic tubes

InactiveUS20090056405A1High mechanical strengthReduce thicknessWire straightening devicesEngineeringMechanical engineering

A method of machining a tube includes performing an obverse drawing process to the tube, where the obverse drawing process draws the tube in an obverse drawing direction from a first end toward a second end of the tube. The tube is turned around to perform a reverse drawing process, where the reverse drawing process draws the tube in a reverse drawing direction from the second end toward the first end of the tube. The obverse and the reverse drawing processes are alternately performed until the tube is thinned to a desired thickness.

Owner:UAN JUN YEN +1

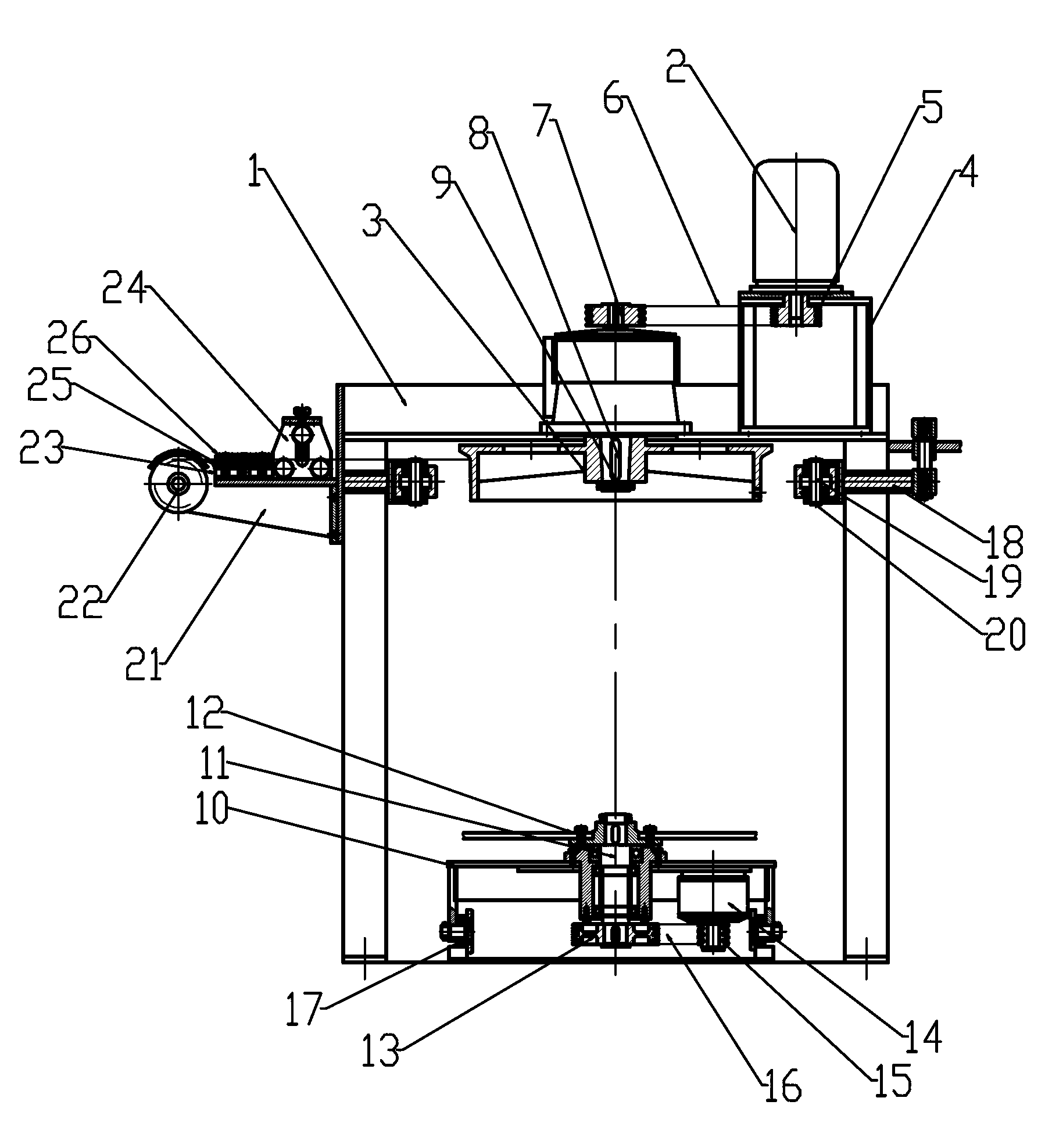

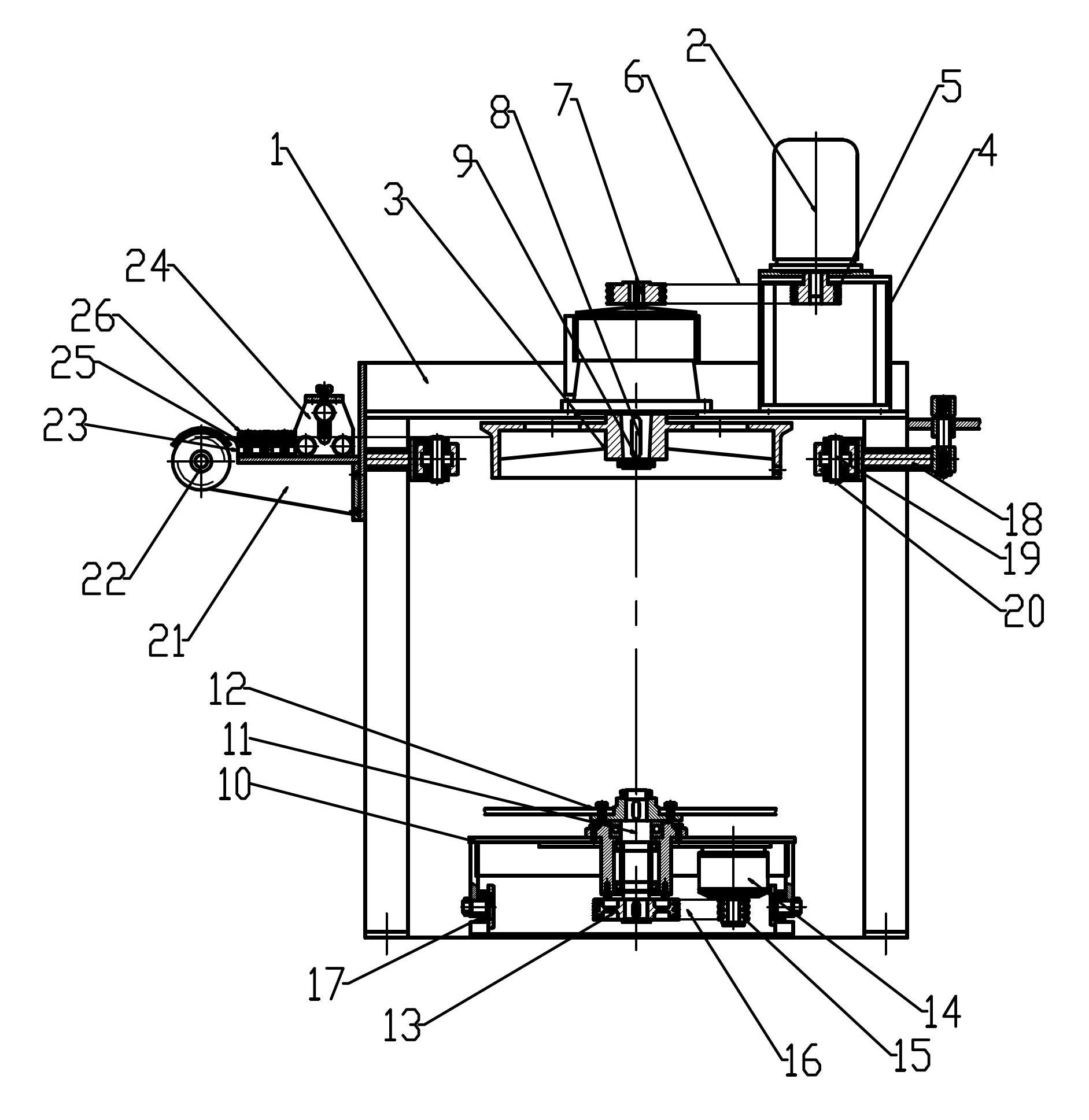

Inverse-vertical wire wrapping machine

InactiveCN102699124AExtended service lifeRing diameter adjustableWire straightening devicesConductor CoilUltimate tensile strength

The invention relates to an inverse-vertical wire wrapping machine, which specifically is used for winding metal lines and belongs to the technical field of metal drawing equipment; the inverse-vertical wire wrapping machine mainly comprises a machine frame, a motor, a winding drum, a wire wrapping trolley, a wire wrapping frame, a decelerator, a cylinder, a pinch roller, an aligning bracket, a threading guide wheel, a horizontal bottom board, a vertical base board and an aligning wheel; according to the invention, the structure of the inverse-vertical wire wrapping machine is simple, compact and reasonable; the wire wrapping frame is rotated through driving of the independent decelerator, so that adjustable circle diameters of metal wires are realized; speed is synchronous to a main shaft pulley; the inverse-vertical wire wrapping machine is operated conveniently; workload is reduced; work efficiency is increased; because a poking rod sleeve is cancelled, service life of the wire wrapping machine is prolonged greatly.

Owner:WUXI PINGSHENG SCI & TECH

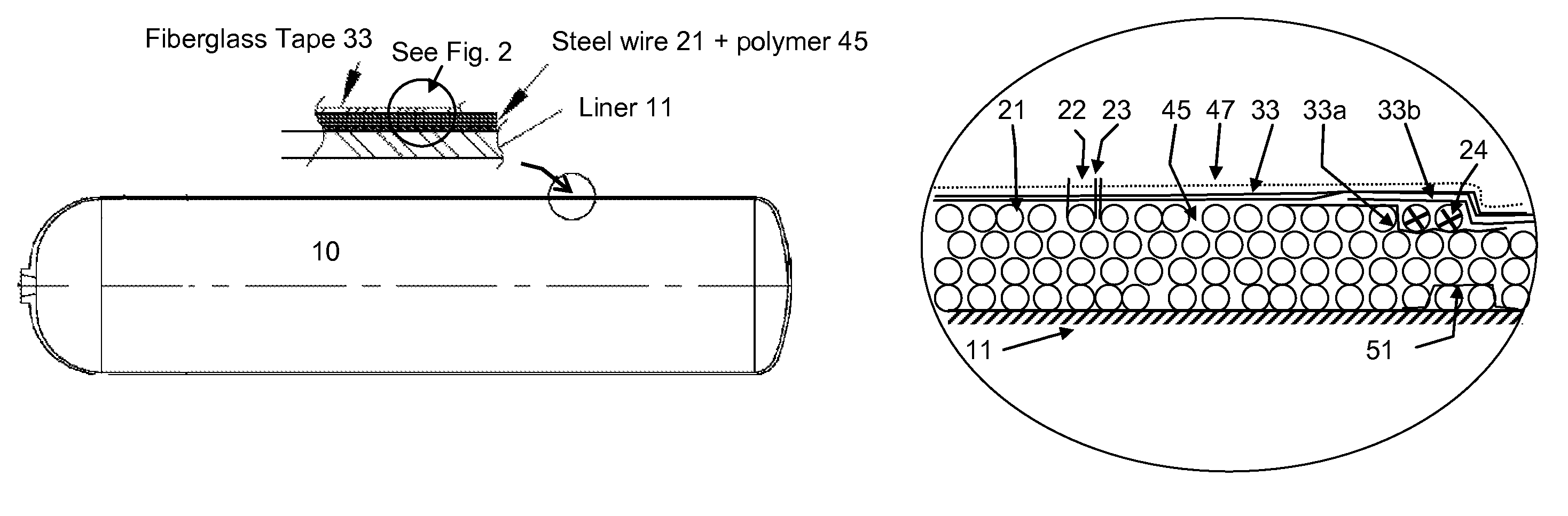

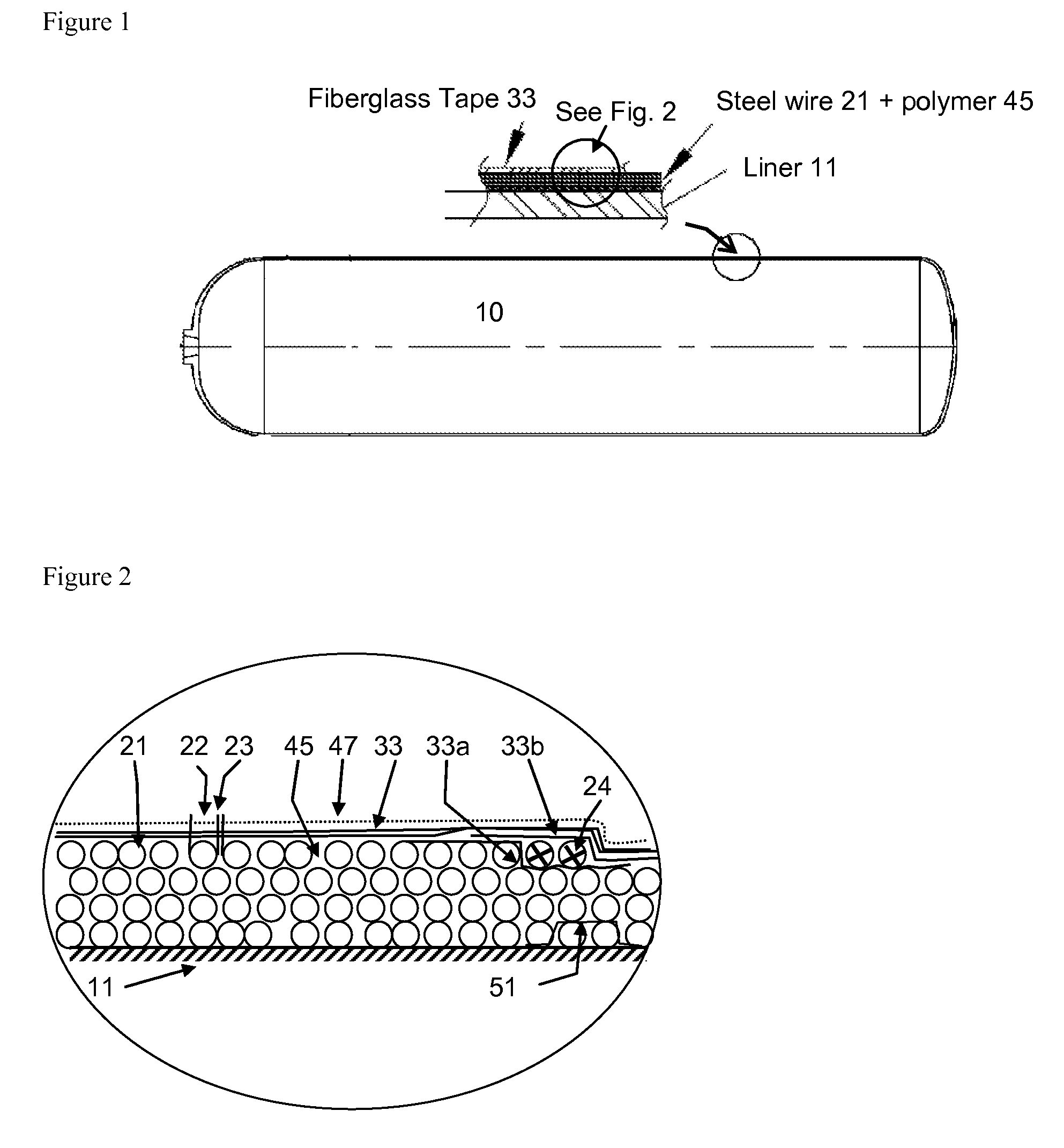

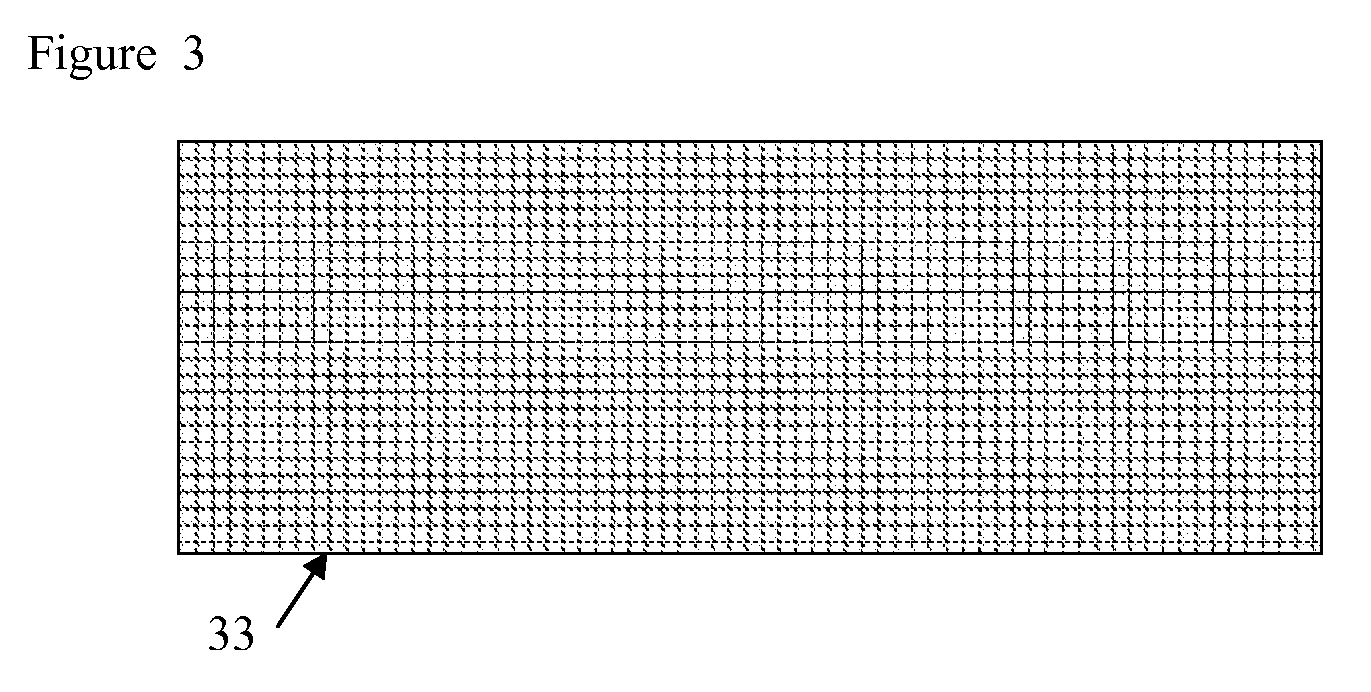

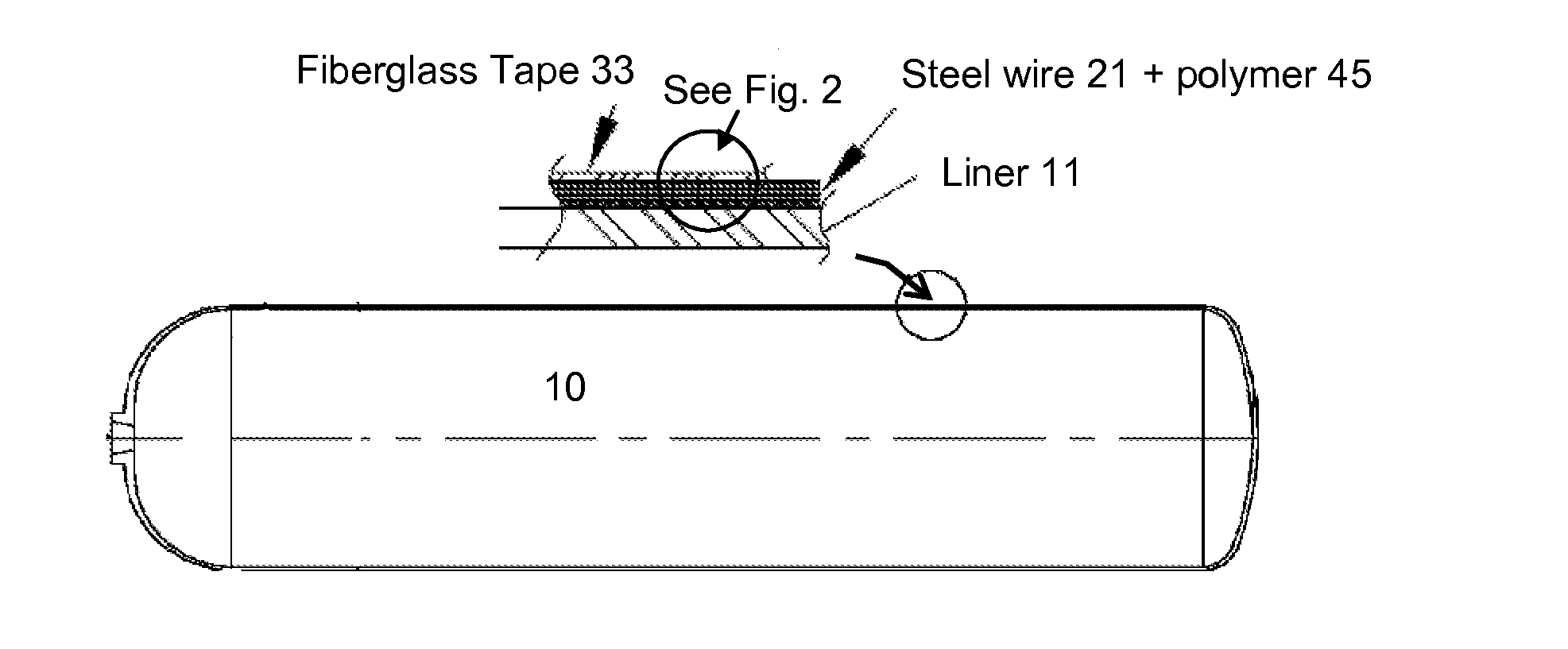

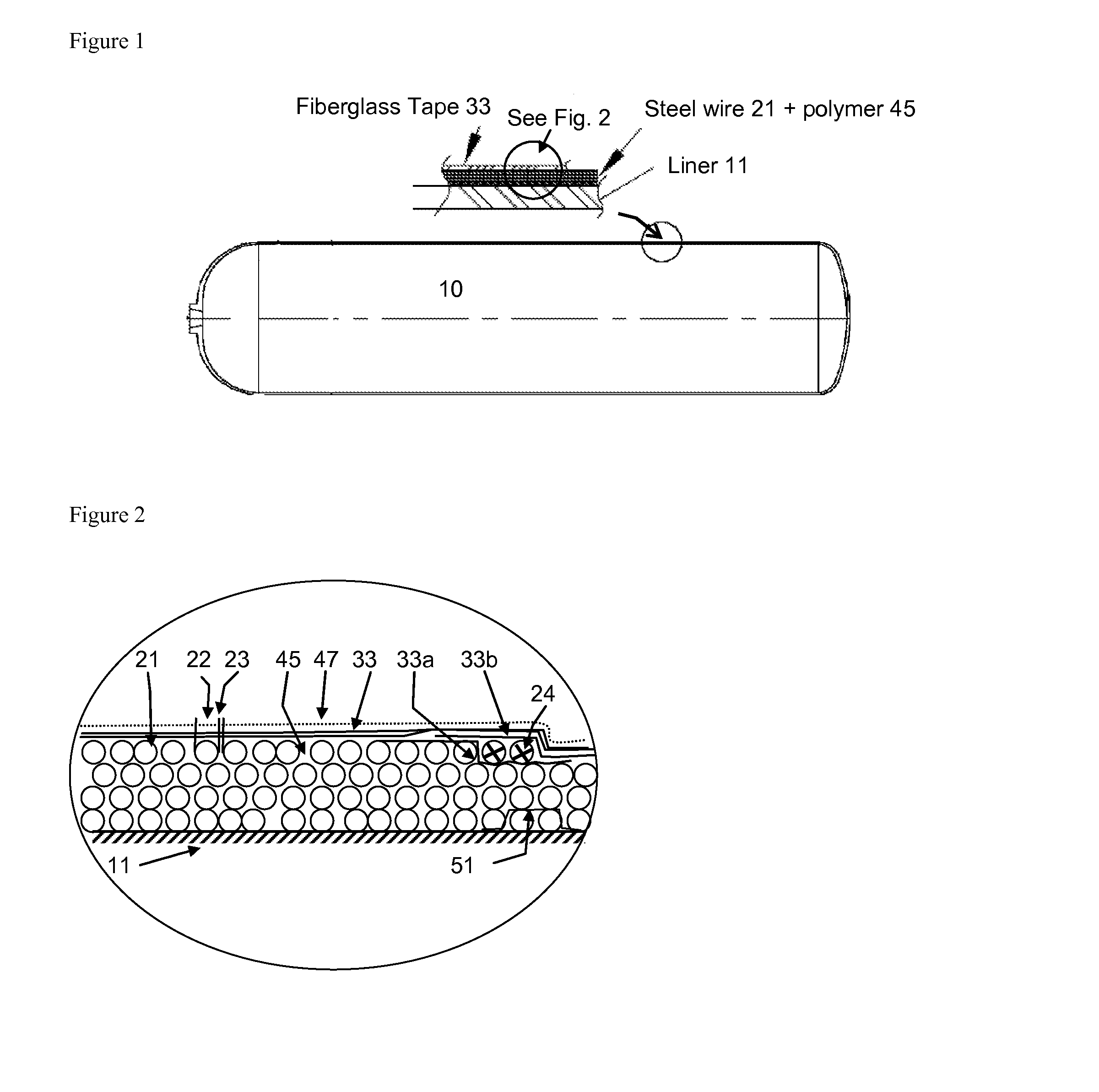

Steel wrapped pressure vessel

ActiveUS9266642B2Good damage resistant protective coatingFinish evenlyWire straightening devicesVessel manufacturingEpoxyPolyurethane coating

A light weight pressure vessel (10) has been proposed. The vessel (10) is made of a steel, aluminum or non-metal liner (11) which is reinforced with high strength steel wires (21) of 2000-7000 MPa strength. The matrix is filled with a polymer epoxy resin (45). A top layer of fabric tape (33) soaked in resin (45) has been used to embed the finish end (24) of the wire (21) and to provide a protective layer over the wire reinforced area. The mesh or net fabric wrap tape (33) has periodic openings to allow penetration of polymer epoxy resin (45). A top coat of a UV resistant polyurethane paint (47) has been applied.

Owner:WIRETOUGH CYLINDERS

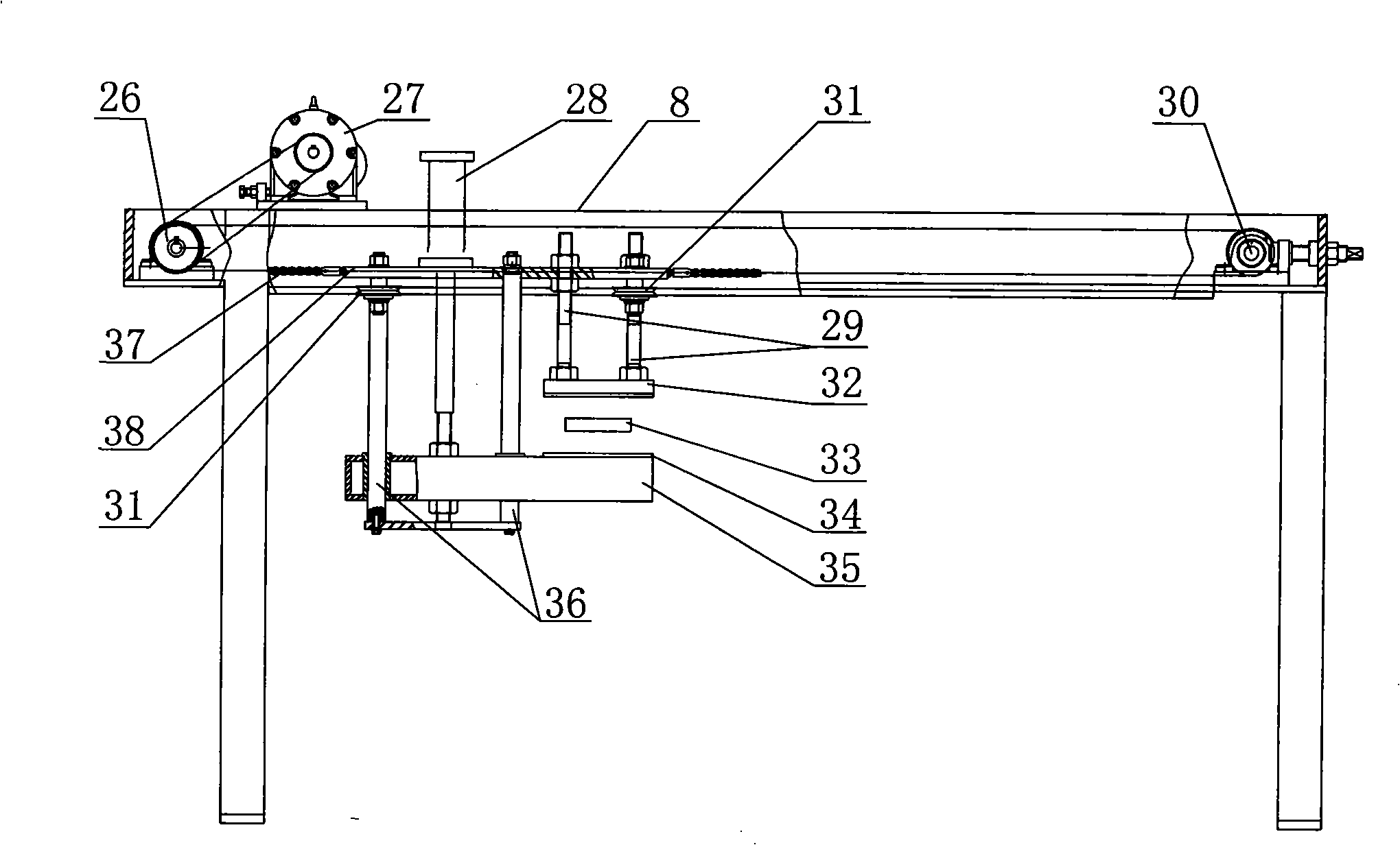

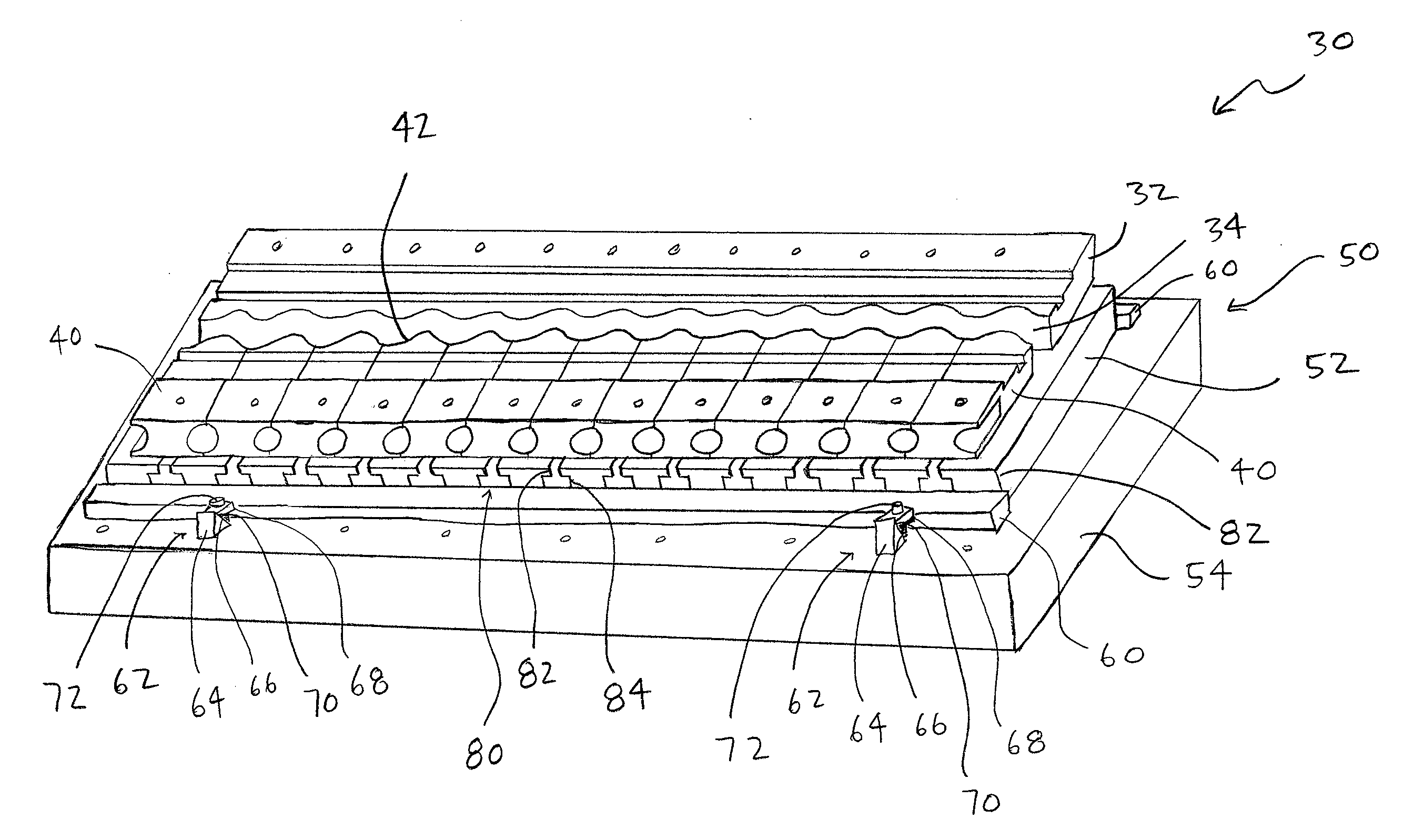

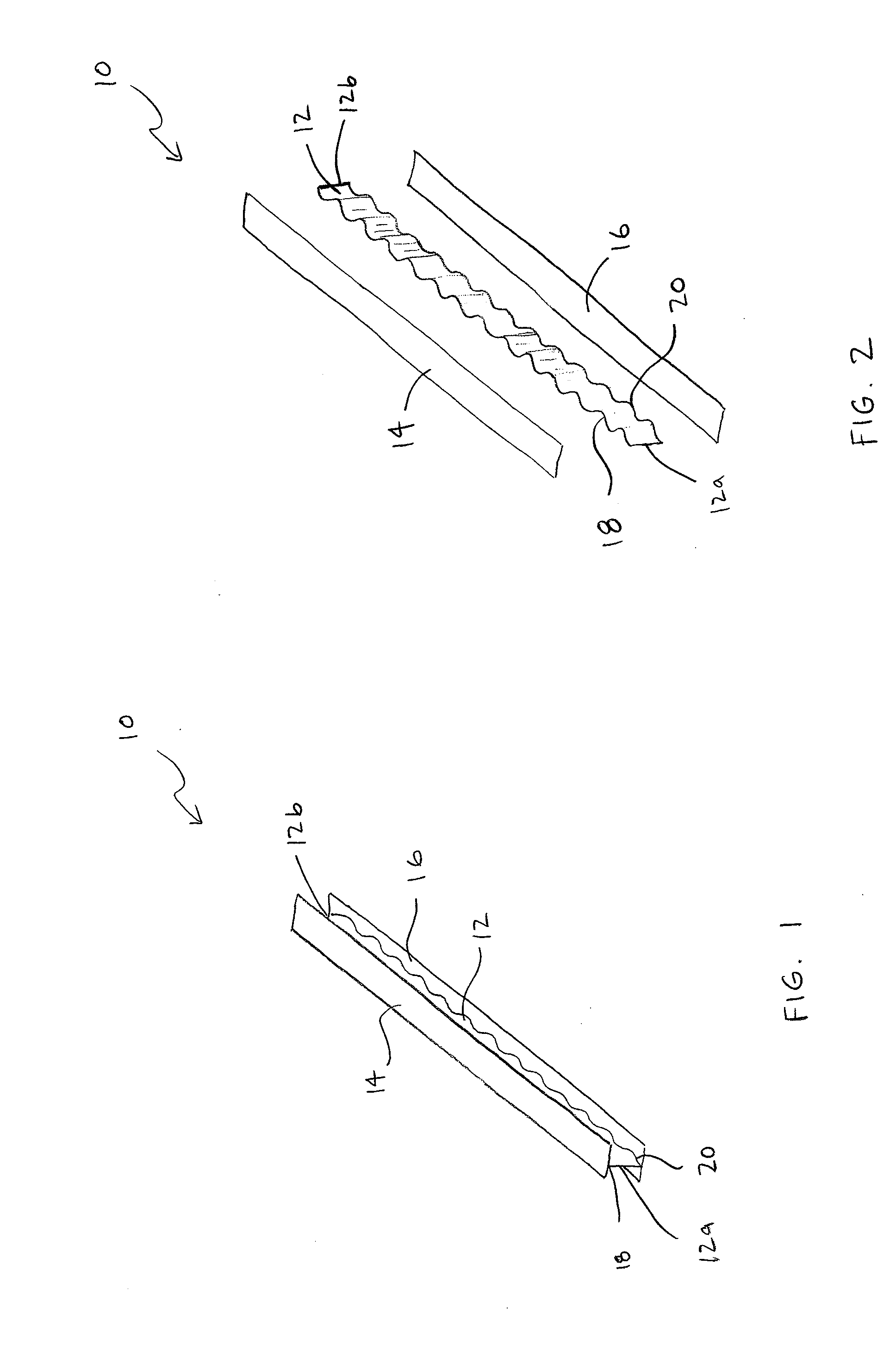

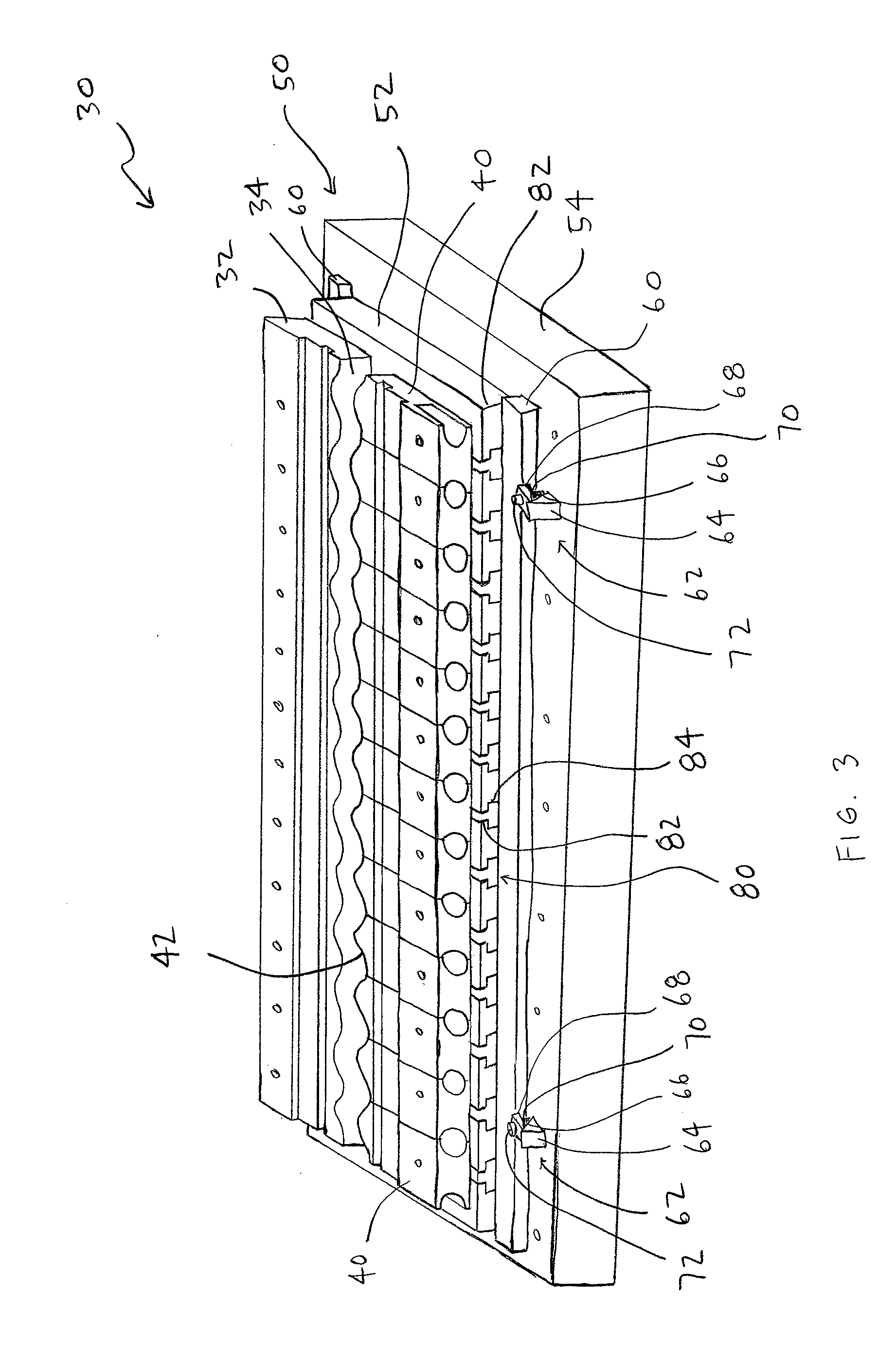

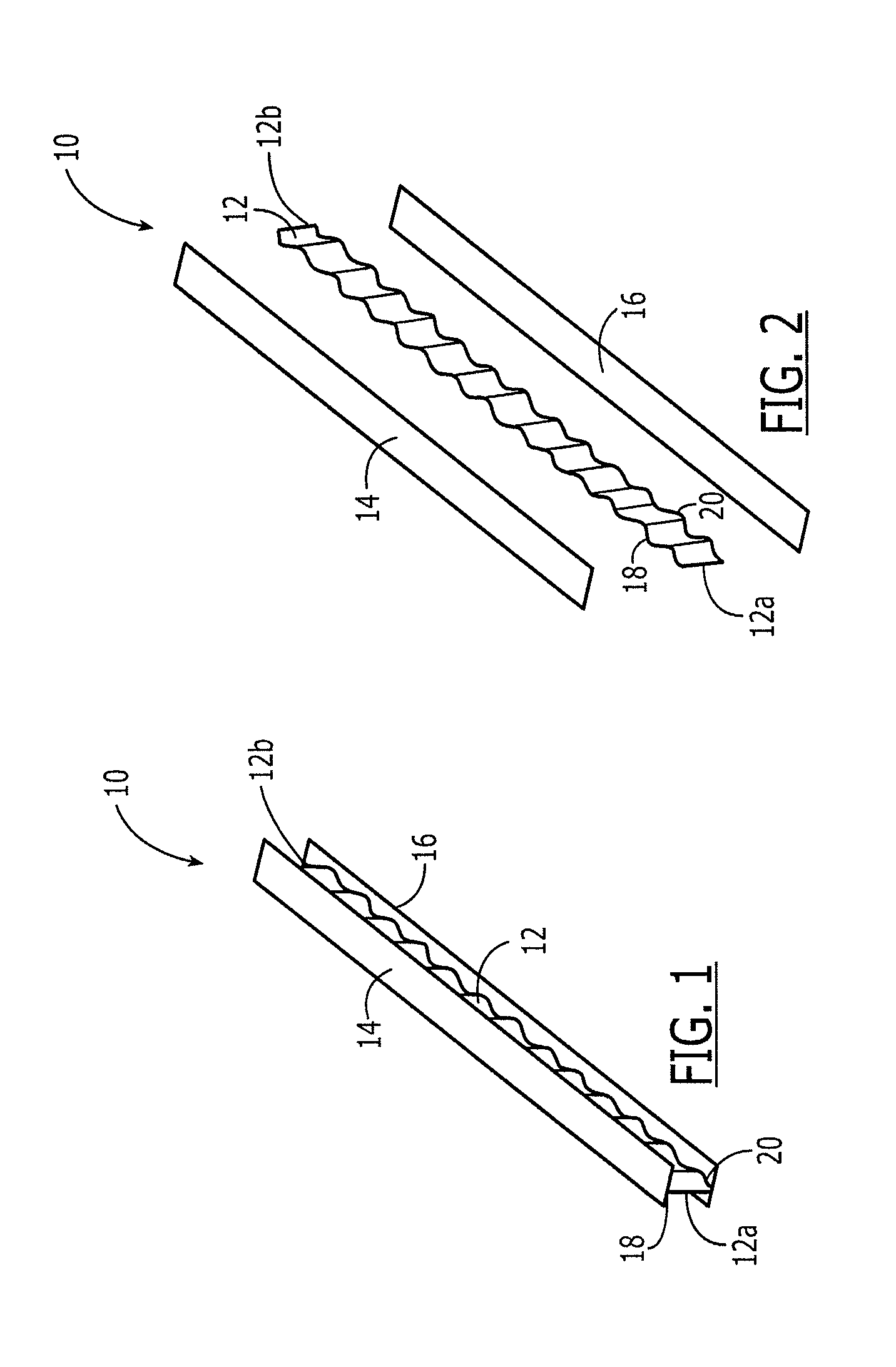

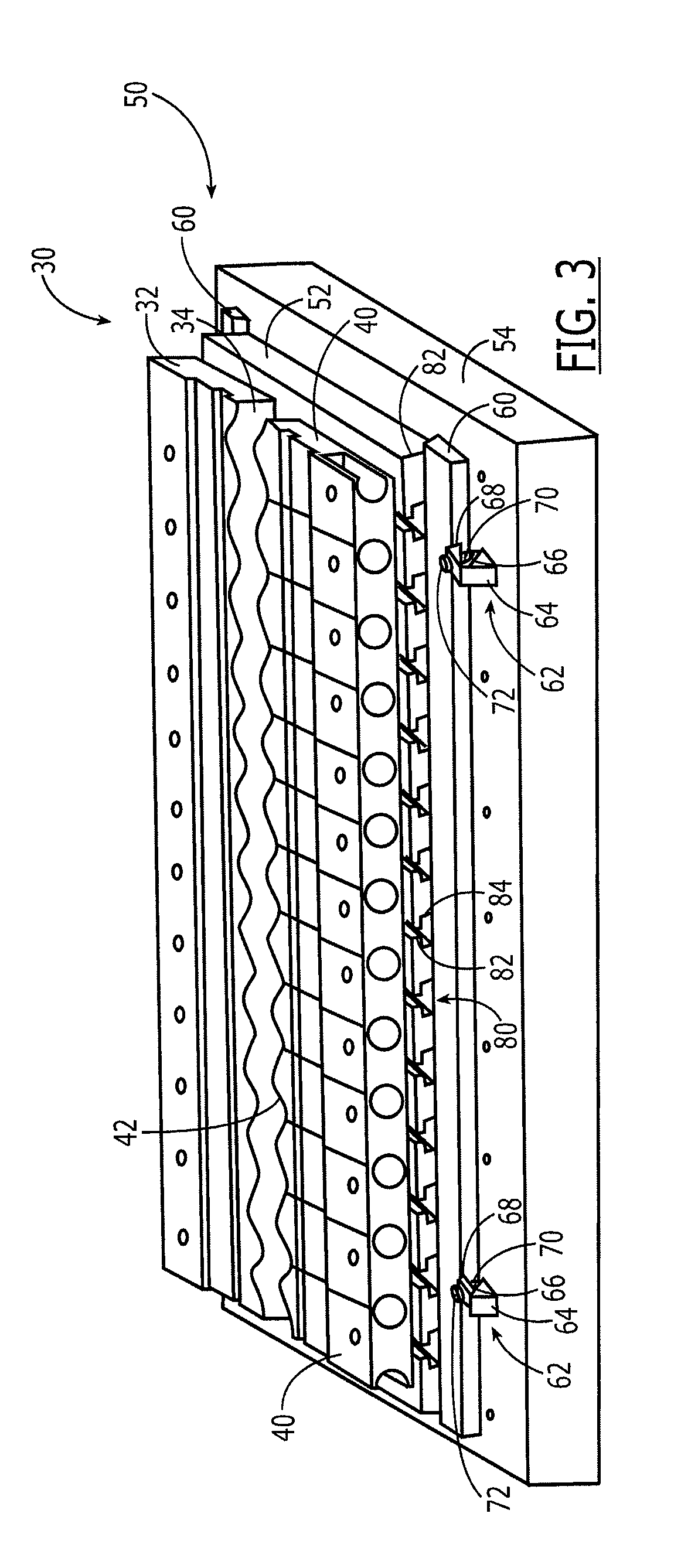

Apparatus and Method for Forming Corrugated Members

ActiveUS20080040926A1Reducing cost and complexityIncreasing shaping flexibility versatilityWire straightening devicesElectric heatingEngineeringFlange

An apparatus and method for forming a stringer are provided. The stringer generally includes a web having a desired corrugated configuration and first and second flanges welded to opposite edges of the web. The apparatus includes a support structure, a strongback that is supported by the support structure, and a plurality of dies that are adjustable relative to the strongback. The strongback defines a corrugated contour surface corresponding to the desired corrugated configuration of the web. The dies define corresponding forming surfaces and are configured to be advanced toward the strongback to thereby form the web to the desired corrugated configuration between the contour surface of the strongback and the forming surfaces of the dies. Further, the apparatus can receive the flanges of the stringer in a predetermined configuration with the web so that the flanges can be welded to the web while the web is supported by the strongback and dies in the desired corrugated configuration.

Owner:THE BOEING CO

Steel wrapped pressure vessel

ActiveUS20130082066A1Good damage resistant protective coatingFinish evenlyWire straightening devicesVessel manufacturingEpoxyUltimate tensile strength

A light weight pressure vessel (10) has been proposed. The vessel (10) is made of a steel, aluminum or non-metal liner (11) which is reinforced with high strength steel wires (21) of 2000-7000 MPa strength. The matrix is filled with a polymer epoxy resin (45). A top layer of fabric tape (33) soaked in resin (45) has been used to embed the finish end (24) of the wire (21) and to provide a protective layer over the wire reinforced area. The mesh or net fabric wrap tape (33) has periodic openings to allow penetration of polymer epoxy resin (45). A top coat of a UV resistant polyurethane paint (47) has been applied.

Owner:WIRETOUGH CYLINDERS

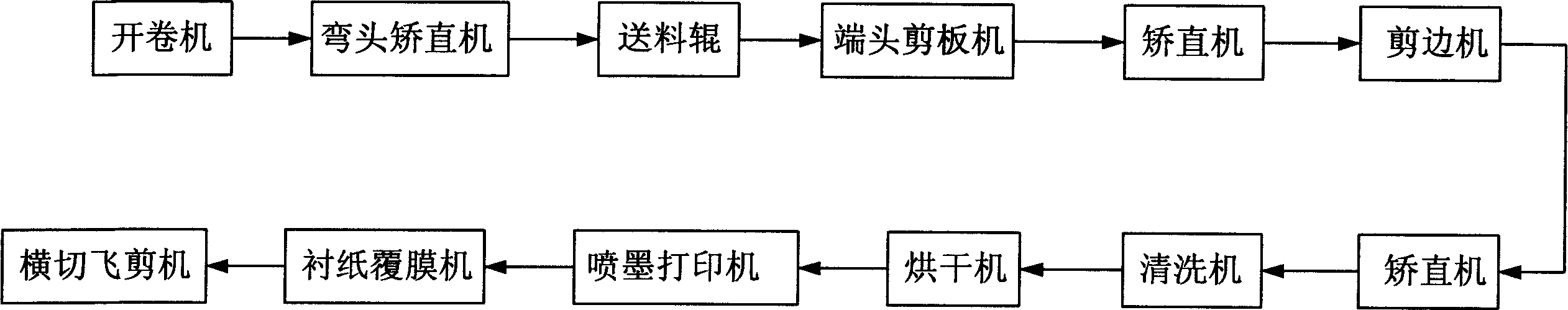

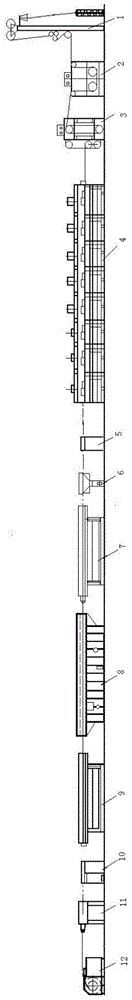

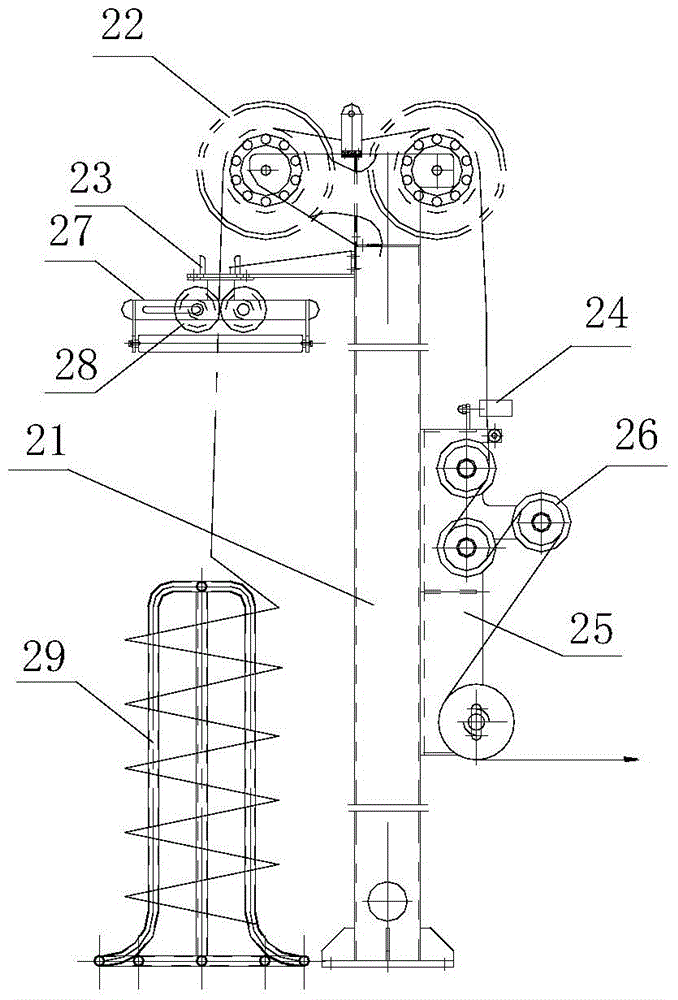

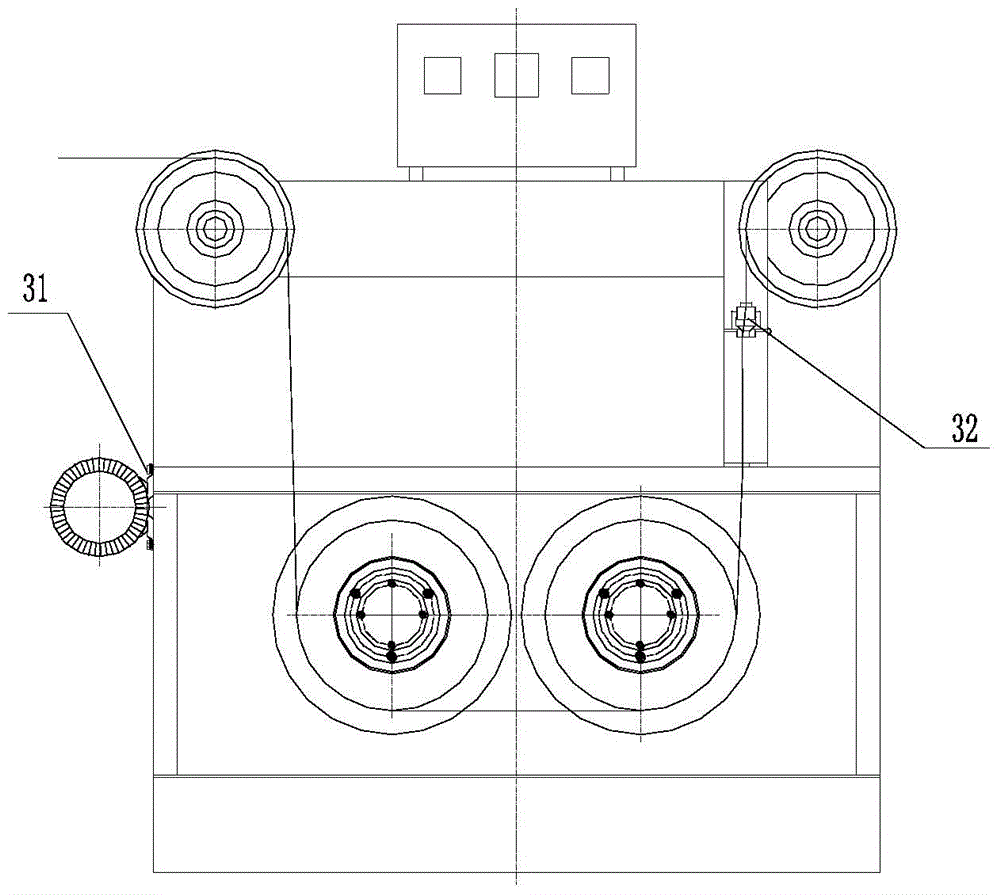

Aluminium plate transverse cutting production apparatus and method

InactiveCN1850407AImprove labor productivityReduce scratchesWire straightening devicesMetal-working feeding devicesProduction linePulp and paper industry

The present invention discloses a sheet aluminium transverse-cutting production equipment. It is characterized by that said equipment utilizes the following machines to successively form its production line; taking-off machine, elbow straightening machine, feeding roll, end head plate shears, straightening machine, edge-shearing machine, straightening machine, cleaning machine, drying machine, lining paper coating machine and transverse-cutting shearing machine.

Owner:SOUTHWEST ALUMINUM GRP

Automatic wire-welding surface treatment process and device for stainless steel

ActiveCN104438391AReduce frictionQuality improvementWire straightening devicesExtrusion cleaning devicesSurface layerLinearity

The invention discloses an automatic wire-welding surface treatment process for stainless steel, which comprises the following steps: (1) paying off by using a high pay-off rack, wherein the welding wire generatrix is fed in a rolling manner into a coating grove filled with a skin film solution for skin film treatment; (2) feeding the dried welding wire subjected to skin film treatment in the step (1) into a drawbench to be subjected to drawing; (3) feeding the drawn welding wire into a straightener for eliminating residual stress generated in the drawing process to straighten; (3) feeding the straightened welding wire which is dried and rubbed and washed into an electrolytic bath for electrolytic washing; (5) cleaning the electrolyzed welding wire to remove electrolyte on the surface layer and drying. The invention further discloses an automatic wire-welding surface treatment device. By means of the process and device provided by the invention, the problems of oxidization of welding wire surface layer, pollution of impurities, poor linearity and the like are effectively solved.

Owner:SHANDONG TENGDA STAINLESS STEEL PRODS

Preparation method of titanium alloy bar of universal resetting screw seat

ActiveCN111534715AEffective grain size refinementReduce residual stressWire straightening devicesTemperature control deviceOrthopedic departmentManufactured material

The invention belongs to the technical field of machining of medical titanium alloy materials and particularly relates to a preparation method of a titanium alloy bar of a universal resetting screw seat. The chemical ingredients of titanium alloy comprise, by mass percentage, 5.9%-6.4% of Al, 3.9%-4.4% of V, 0.15%-0.22% of Fe, 0.09%-0.13% of O, not larger than 0.05% of C, not larger than 0.005% ofH, not larger than 0.01% of N and the balance Ti. The preparation method comprises the steps that firstly, a round bar blank is obtained through the procedures of smelting, forging, and rolling; thena beta single-phase section homogenization annealing treatment process is adopted to obtain a homogeneous fine-grained acicular martensite structure, an electrifying straightening and hyperbolic straightening combined process is used for straightening, the electrifying straightening temperature is controlled to be less than 780 DEG C, and a balanced residual stress state is obtained; and finally,stress relief annealing and centerless grinding are conducted to obtain the finished bar. The preparation method of the titanium alloy bar of the universal resetting screw seat can produce a medicalTi-6Al-4V alloy bar basically free of stress, the Ti-6Al-4V alloy bar has excellent fatigue life, and a qualified raw material is provided for manufacturing of universal resetting screw seats of orthopedic medical instruments.

Owner:中科锐金山东钛业科技有限公司

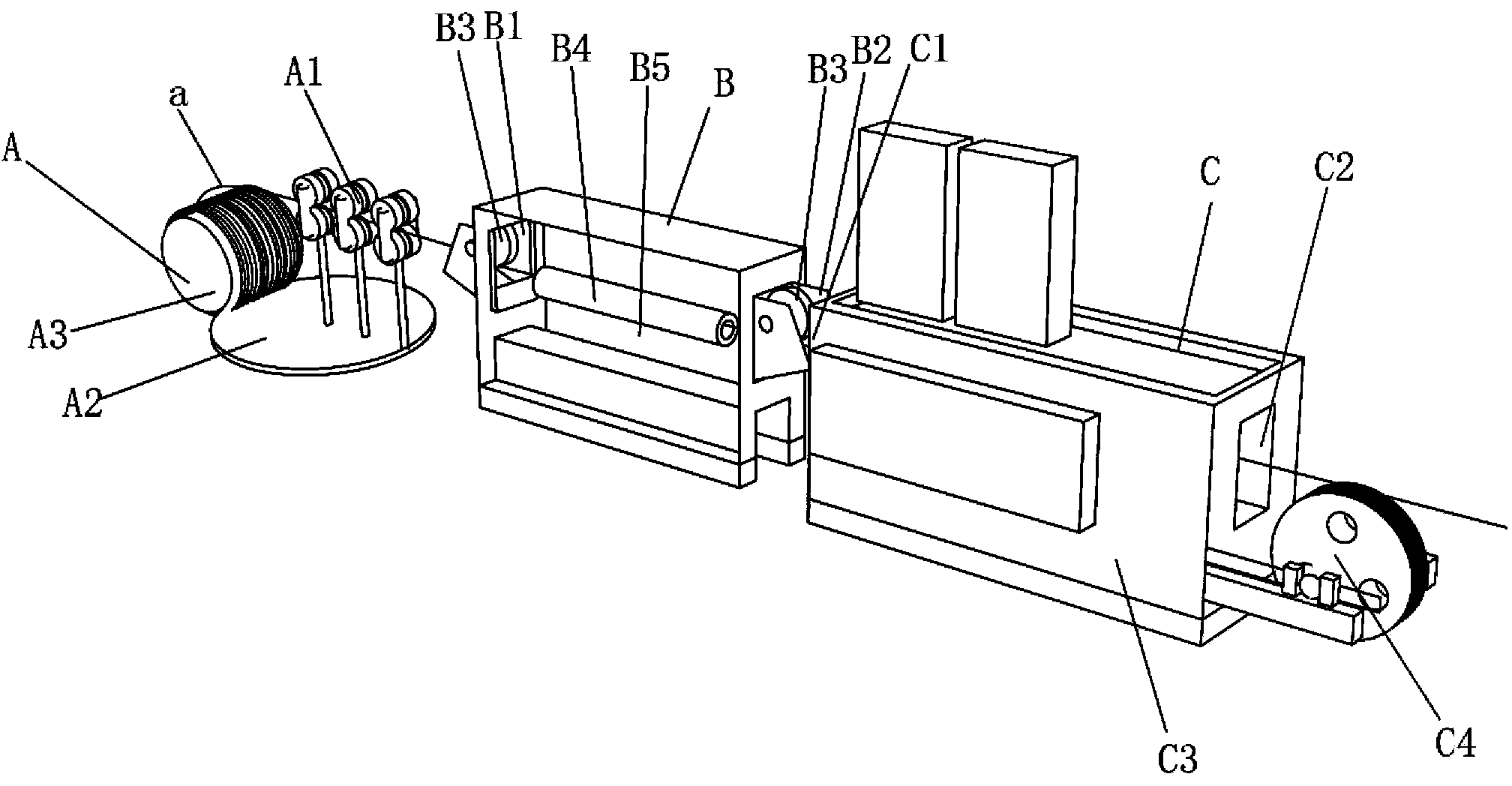

Fine metal wire drawing unit

ActiveCN104028571AReasonable structureReduce manufacturing costWire straightening devicesFurnace typesMetalMaterials science

The invention relates to a fine metal wire drawing unit. The fine metal wire drawing unit comprises a metal wire rod straightening device (A), metal wire coating equipment (B), metal wire drying equipment (C), first metal wire drawing equipment (D), first metal wire cleaning equipment (E), second metal wire drawing equipment (F), second metal wire cleaning equipment (G), metal wire annealing equipment (H) and metal wire cooling drum wire withdrawing equipment (I) arranged in sequence, wherein after metal wire rods are passed by the metal wire rod straightening device (A), the metal wire coating equipment (B), the metal wire drying equipment (C), the first metal wire drawing equipment (D), the first metal wire cleaning equipment (E), the second metal wire drawing equipment (F), the second metal wire cleaning equipment (G) and the metal wire annealing equipment (H), the metal wire rods are connected with the metal wire cooling drum wire withdrawing equipment (I) for realizing wire withdrawal.

Owner:柳城县鼎铭金属制品有限公司

Wire surface treatment machine

PendingCN107442600AAvoid bumpingSolution to short lifeWire straightening devicesGrinding machinesSurface oxidationSurface oxide

The invention relates to the field of wire processing, and discloses a wire surface treatment machine. The wire surface treatment machine comprises a shelling unit used for removing an oxide skin surface layer on the surface of a wire, a first straightening unit used for straightening the wire and a steel brush unit used for removing oxide skin on the surface of the wire. The first straightening unit is located between the shelling unit and the steel brush unit. The wire is in a tensioning state under the action of external force and moves to the steel brush unit from the shelling unit. The wire is bent through the shelling unit, and the oxide skin, poorly combined with a metal matrix, on the surface is removed. The wire enters the straightening unit from the shelling unit and is straightened from the bent state, and sufficient preparations are made for the wire for entering the steel brush unit; and the surface oxide skin is further removed in the process that the wire becomes straightened from bent. The wire enters the steel brush unit, the straightened wire can in sufficient contact with steel brushes, and omni-directional cleaning of the surface of the wire is achieved; the cleaning effect is good; the wire is level; colliding with the steel brushes is avoided; and the service life of the steel brushes is long.

Owner:鹏驰五金制品(昆山)有限公司

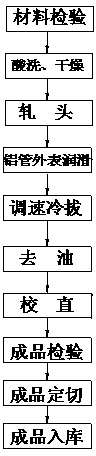

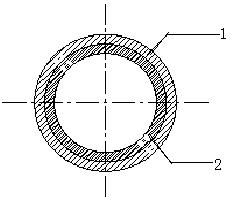

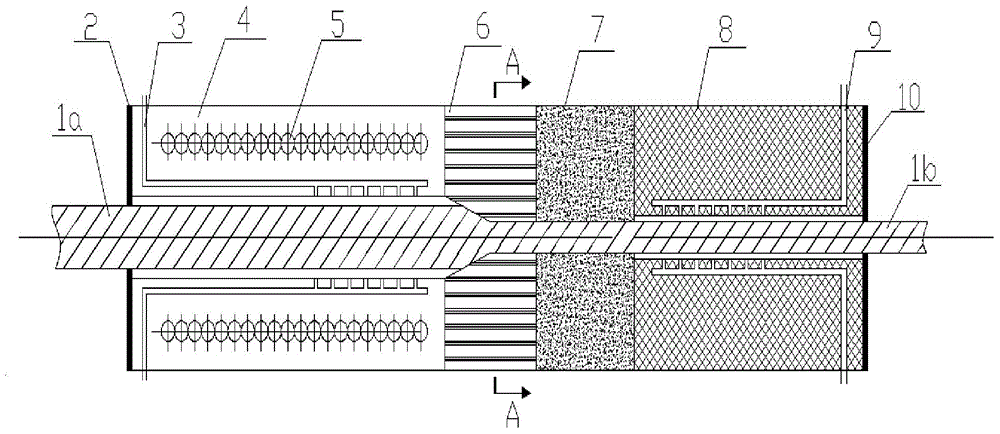

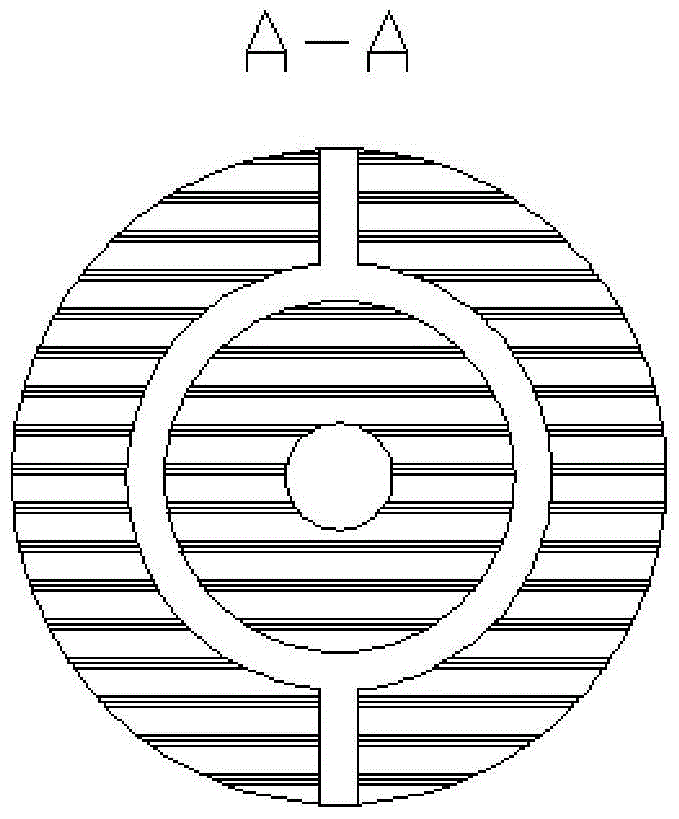

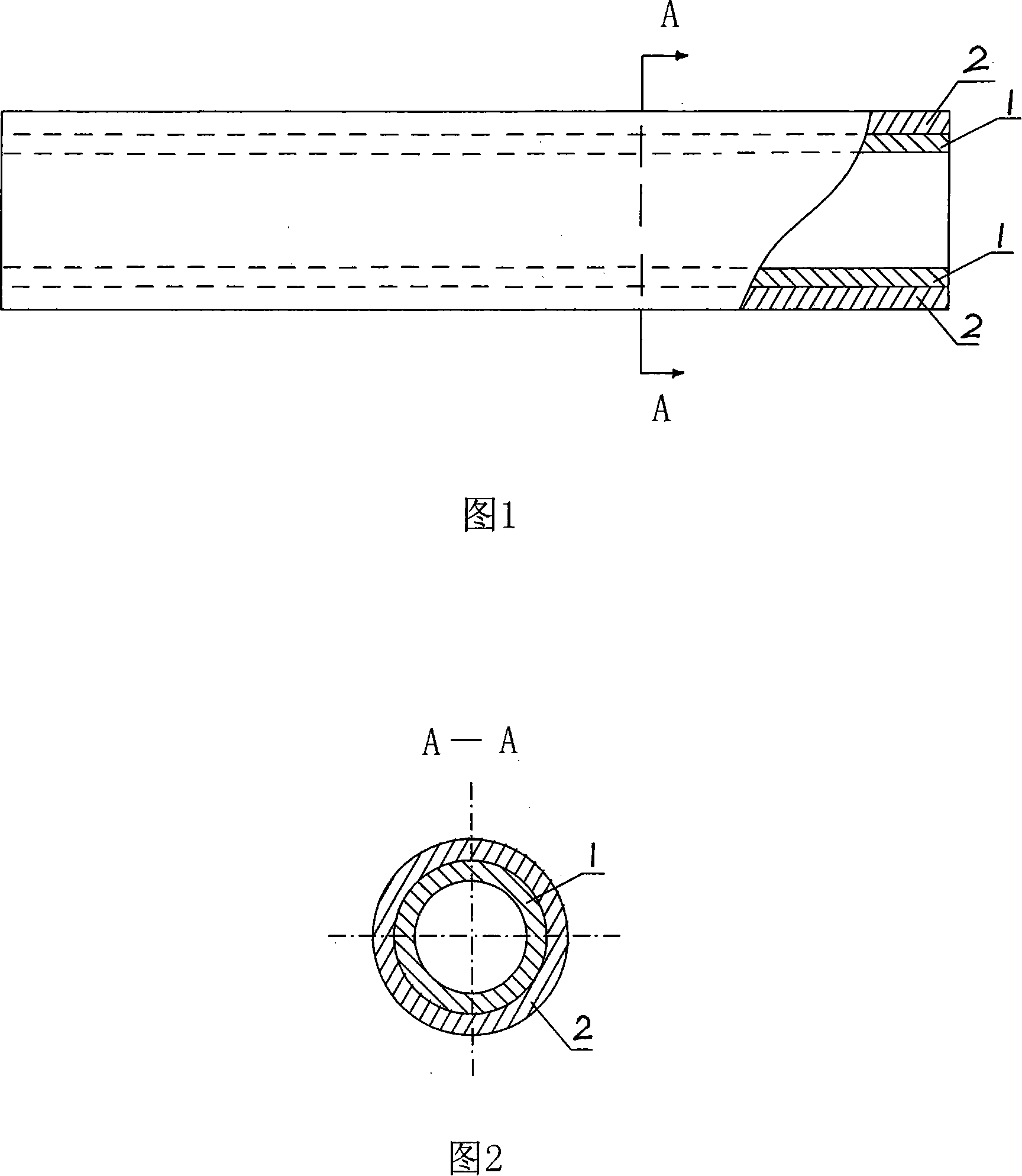

Manufacturing process of aluminum-steel composite pipe with high thermal conductivity for petrochemical

InactiveCN103372579AImprove structural rigidityExtend your lifeWire straightening devicesHeat conductingPetrochemical

The invention discloses a manufacturing process of an aluminum-steel composite pipe with high thermal conductivity for petrochemical. The adopted raw materials comprise an aluminum pipe and a steel pipe. The manufacturing process comprises the following steps: firstly, pickling and drying the aluminum pipe and the steel pipe; then, sleeving the aluminum pipe at the outside of the steel pipe, reserving a gap of 0.3-0.4 mm between the inside diameter of the aluminum pipe and the outside diameter of the steel pipe, simultaneously heating the aluminum pipe and the steel pipe through super audio induction coils, and firmly compounding the heads of the aluminum pipe and the steel pipe through a special head rolling machine; lubricating the aluminum pipe; finally, performing cold drawing through a speed drawing machine. Therefore, the produced aluminum-steel composite pipe not only has excellent heat conducting performance, and the rigidity is improved, meanwhile, the aluminum material is greatly saved and the heat dissipation efficiency is enhanced.

Owner:常熟市异型钢管有限公司

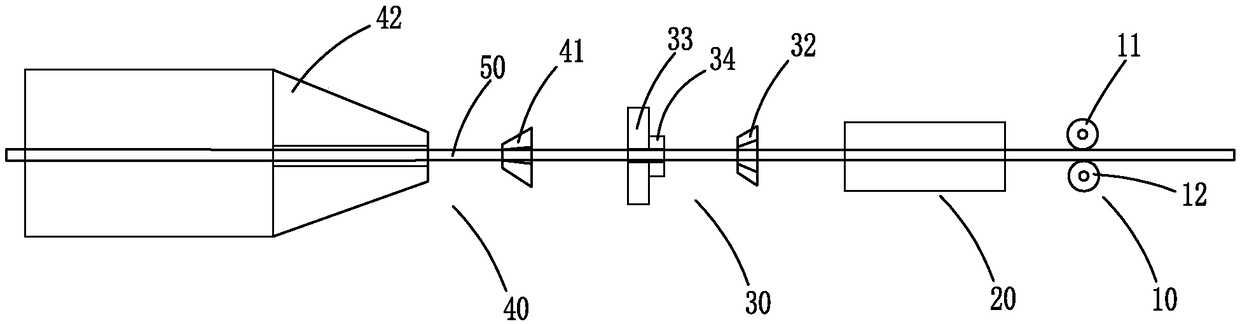

Heating-wiredrawing-finish drawing shaping-cooling wire preparing device

ActiveCN105772521AImprove plasticityAvoid the effects of performance degradationWire straightening devicesDrawing diesWire rodEngineering

The invention discloses a heating-wiredrawing-finish drawing shaping-cooling wire preparing method and device. The device mainly comprises an induction heating mechanism, a wiredrawing die, a finish drawing shaping machining mechanism, a cooling mechanism, a protection gas trough and a sealing ring. The wiredrawing device is suitable for manufacturing of high-strength welding wires and metal wires. Non-contact type induction heating is adopted, wires (or wire rods) to be drawn can be rapidly heated to a certain temperature, the ductility and toughness of the wires are improved, and wiredrawing is facilitated. The device can provide gas protection, and oxidation of the wires during heating and drawing is effectively prevented. The functions such as induction heating, wiredrawing, finish drawing shaping and structure control are integrated into the wire preparing method.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

Tension adjusting device for flat copper alloy wire processing

InactiveCN109332399AEasy to use for tension adjustmentEasy to stretchWire straightening devicesMaterials scienceCopper alloy

The invention discloses a tension adjusting device for flat copper alloy wire processing. The device comprises a wire coiling mechanism, a tension adjusting mechanism, a wire uncoiling mechanism and aworking platform, wherein one end of the working platform is fixedly connected to the wire coiling mechanism, and the other end of the working platform is provided with the wire uncoiling mechanism;and the tension adjusting mechanism is arranged at the upper part of the working platform and is positioned between the wire coiling mechanism and the wire uncoiling mechanism. According to the device, the wire uncoiling mechanism is arranged, and a metal wire is prevented from deviation through a wire guide rod and a guide wheel; in addition, the metal wire is flattened through a first flatteningwheel and a second flattening wheel, thus the wire is prevented from being bent, and the metal wire can be conveniently stretched; the tension adjusting mechanism is arranged, and the space between atension adjusting wheel and a fixed wheel can be flexibly adjusted through a hand wheel and a lead screw, and as a result, the tension adjusting flexibility is improved; the tension can be flexibly adjusted, so that the problem that the tension cannot be adjusted due to a fixed structure can be avoided.

Owner:胡海涛

Heating-wiredrawing-finish broaching shaping-cooling wire manufacturing method

ActiveCN105642688AImprove plasticityAvoid the effects of performance degradationWire straightening devicesDrawing diesWire rodShielding gas

The invention discloses a heating-wiredrawing-finish broaching shaping-cooling wire manufacturing method. A device related to the method mainly comprises an induction heating mechanism, a wiredrawing die, a finish broaching shaping treatment mechanism, a cooling mechanism, shield gas grooves and sealing rings. The wiredrawing device is suitable for manufacturing high-strength welding wires and metal wires. Non-contact induction heating is adopted so that wires to be drawn or line materials to be drawn can be rapidly heated to a certain temperature, the plasticity and toughness of the wires to be drawn or the line materials to be drawn are improved, and wiredrawing is convenient. Gas shield can be provided through the device, and the wires are effectively prevented from being oxidized in the heating and drawing process. By means of the wire manufacturing method, induction heating, wiredrawing, finish broaching shaping, tissue control and other functions are integrated.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

Method of producing Cu/NbZ metallic composite tube

InactiveCN101134209AGood quench protectionImprove processing plasticityWire straightening devicesHydrofluoric acidMagnesium diboride

The present invention discloses composite Cu / NbZr pipe making process, which includes the following steps: prickling NbZr alloy pipe in mixture solution of hydrofluoric acid and nitric acid in the volume ratio of 1 to 3, prickling Cu pipe in dilute nitric acid solution, dewatering and stoving separately, coating the NbZr alloy pipe onto Cu pipe, drawing the assembled Cu / NbZr composite inside drawing die in one drawing bench in the working modulus of 30-40 %, straightening the drawn composite Cu / NbZr pipe and cutting off two ends to obtain the composite Cu / NbZr pipe. The process is simple and feasible, and the made composite Cu / NbZr pipe has Cu and NbZr alloy interface in metallurgical combination. The composite Cu / NbZr pipe is applied in the superconductive magnesium dibroride wire, and superconductive magnesium dibroride wire in the length over 1000 m may be produced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

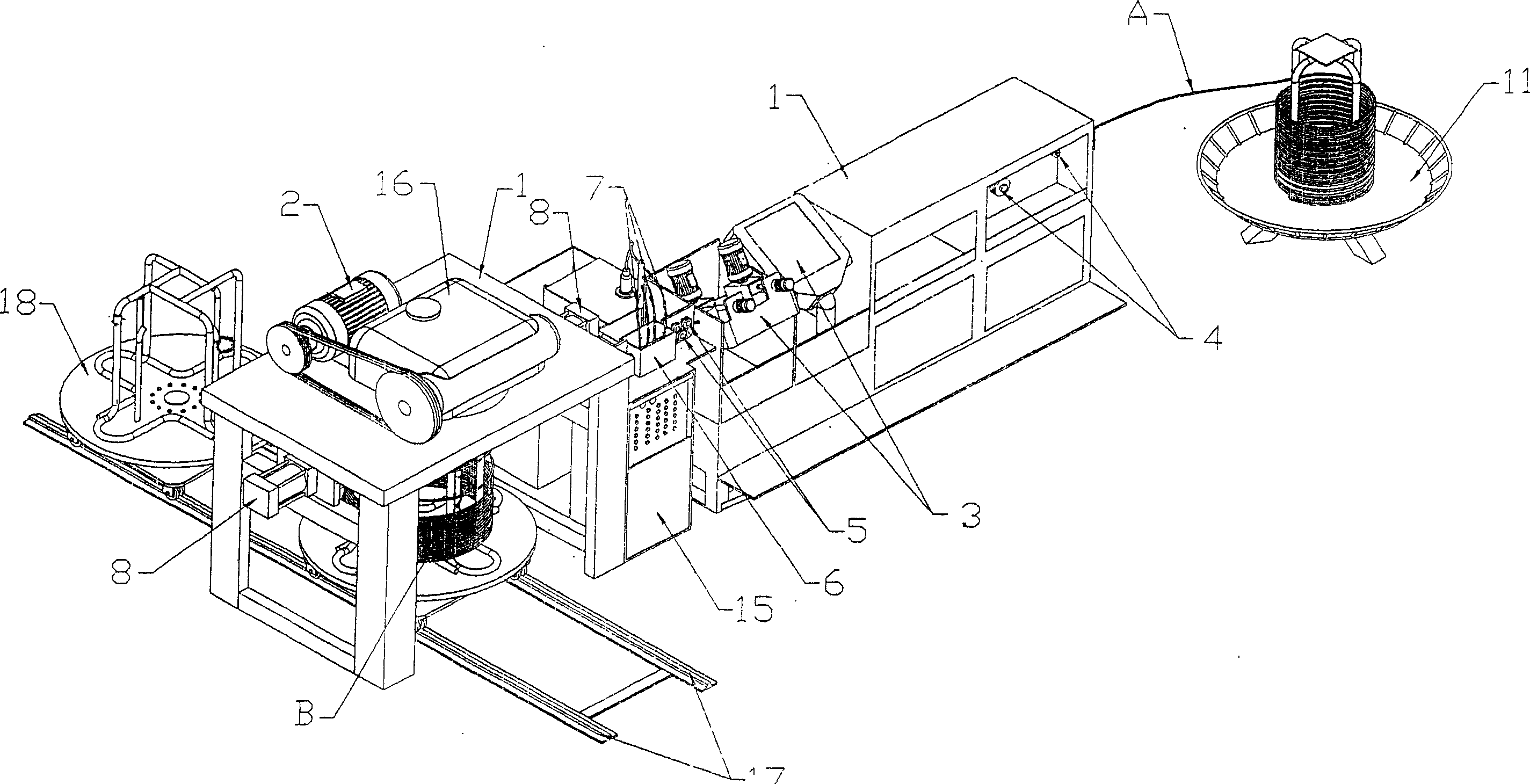

Iron wire rust cleaning-wire drawing combination apparatus and its working method

InactiveCN1850382AEasy to useHigh degree of automationWire straightening devicesCleaning using toolsFiltrationEngineering

The present invention provides an iron wire derusting-drawing combination equipment and its processing method. Said equipment includes the following several portions: machine seat, derusting mechanism, main motor mounted on the machine seat, gear box, winding wheel connected with motor shaft, automatic take-off frame mounted in the front end of machine seat, automatic take-up frame mounted in the tail end of said machine seat, automatic filtration oil-supply tank mounted by said machine seat and electric control box. Said invention also provides the concrete steps of its processing method.

Owner:宋择民

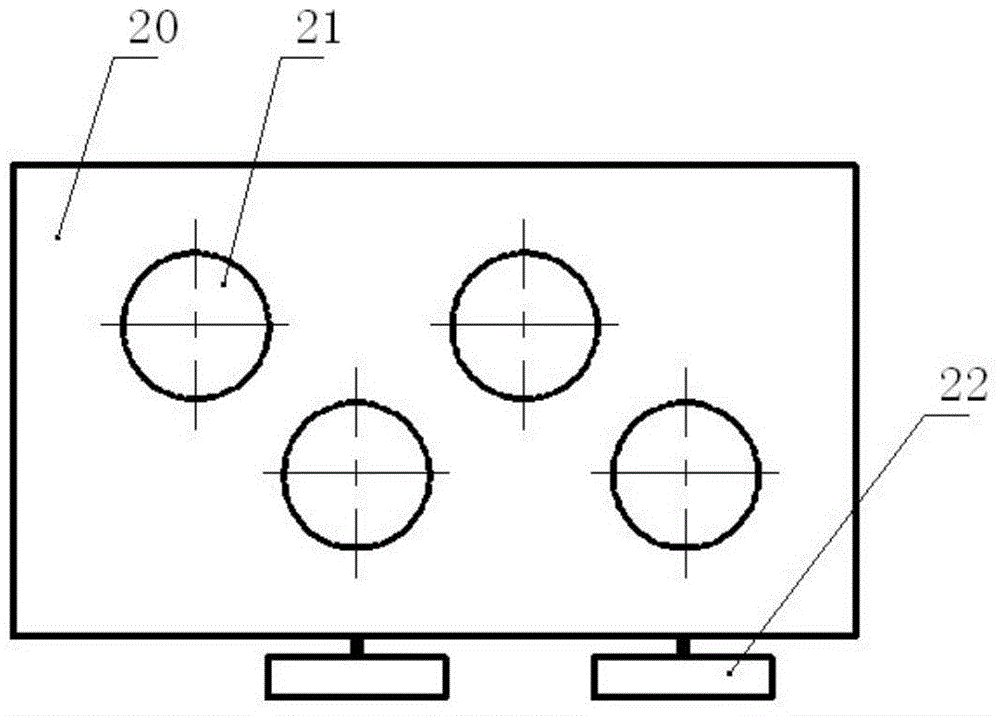

Uncoiling and wire drawing device

InactiveCN108994095AGuaranteed stabilityGuarantee processing qualityWire straightening devicesWire rodEngineering

The invention discloses an uncoiling and wire drawing device. The uncoiling and wire drawing device comprises a base, a feeding frame, an uncoiling mechanism, a wire drawing mechanism, a wire coilingmechanism and a control mechanism, wherein the uncoiling mechanism comprises a first uncoiling part, a longitudinal straightening part, a transverse straightening part and a material conveying part; the wire drawing mechanism comprises a wire drawing bin, wire drawing wheels, wire drawing liquid sprayers, a filter screen and a liquid collecting groove; and the wire coiling mechanism comprises a wire winding rotary shaft, a fixing seat and a wire winding motor. According to the uncoiling and wire drawing device, an upper positioning roller and a lower positioning roller are arranged to cooperate with each other, relative positions and rotating speed of the upper positioning roller and the lower positioning roller are adjusted according to the size of a wire rod, so that stability of the material feeding is guaranteed; the first uncoiling part, the longitudinal straightening part, the transverse straightening part and the material conveying part are arranged to cooperate with one another, the wire rod is straightened in all directions, and convenience is provided for subsequent processing; and the wire drawing wheels and the wire drawing liquid sprayers are arranged to cooperate witheach other, wire drawing operation is carried out on the wire rod in a closed environment, noise and dust pollution are reduced, the environment is protected, and the wire drawing effect is good.

Owner:XINCHANG HESHENGXIN BUSINESS CO LTD

Precise copper bar drawing device

InactiveCN109396213APractical and reliable structureIncrease productivityWire straightening devicesExtrusion cleaning devicesEngineeringMechanical engineering

The invention discloses a precise copper bar drawing device, comprising a rack. A sending mechanism, a straightening mechanism and a drawing mechanism are arranged on the rack sequentially; the sending mechanism is used for sending copper bars to the straightening mechanism to straighten the copper bars, and the straightened copper bars are conveyed to the drawing mechanism to be drawn; a peelingmechanism is arranged between the straightening mechanism and the drawing mechanism and comprises a base; a guide die is arranged at one end of the base, a peeling die is arranged, opposite to the guide die, at the other end of the base; during peeling, the copper bars are sent to the peeling die through the guide die, and are peeled by the peeling die under the traction force of the drawing mechanism; therefore, the precise copper bar drawing device is adaptable to drawing and peeling of the precise copper bars, has practical and reliable structure, and can improve production efficiency effectively.

Owner:GUANGDONG WEIQIANG COPPER IND SCI & TECH CO LTD

Inlet wire straightening device of headstand type wire winding machine

InactiveCN102699078AAdjust ring diameterAdjust flatnessWire straightening devicesWinding machineGlands secretion

The invention relates to an inlet wire straightening device of a headstand type wire winding machine, is particularly used for straightening metal inlet wires of the headstand type wire winding machine and belongs to the technical field of metal wire drawing. The inlet wire straightening device of the headstand type wire winding machine comprises a guide wheel gland, a wire passing guide wheel, a supporting plate, a guide wheel shaft, a vertical pressing plate, a horizontal fixed shaft, a horizontal moving shaft, a horizontal straightening wheel, a horizontal seat plate, a horizontal regulation lead screw, a horizontal pressing plate, a vertical seat plate, a vertical fixed shaft, a vertical moving shaft, a vertical regulation lead screw and a vertical straightening wheel. The inlet wire straightening device of the headstand type wire winding machine is simple, compact and reasonable in structure, can regulate pressing and releasing of metal wires by regulating the straightening wheels on the moving shafts so as to achieve good straightening effects, and can regulate circle diameter and evenness of the metal wires through horizontal straightening and vertical straightening.

Owner:WUXI PINGSHENG SCI & TECH

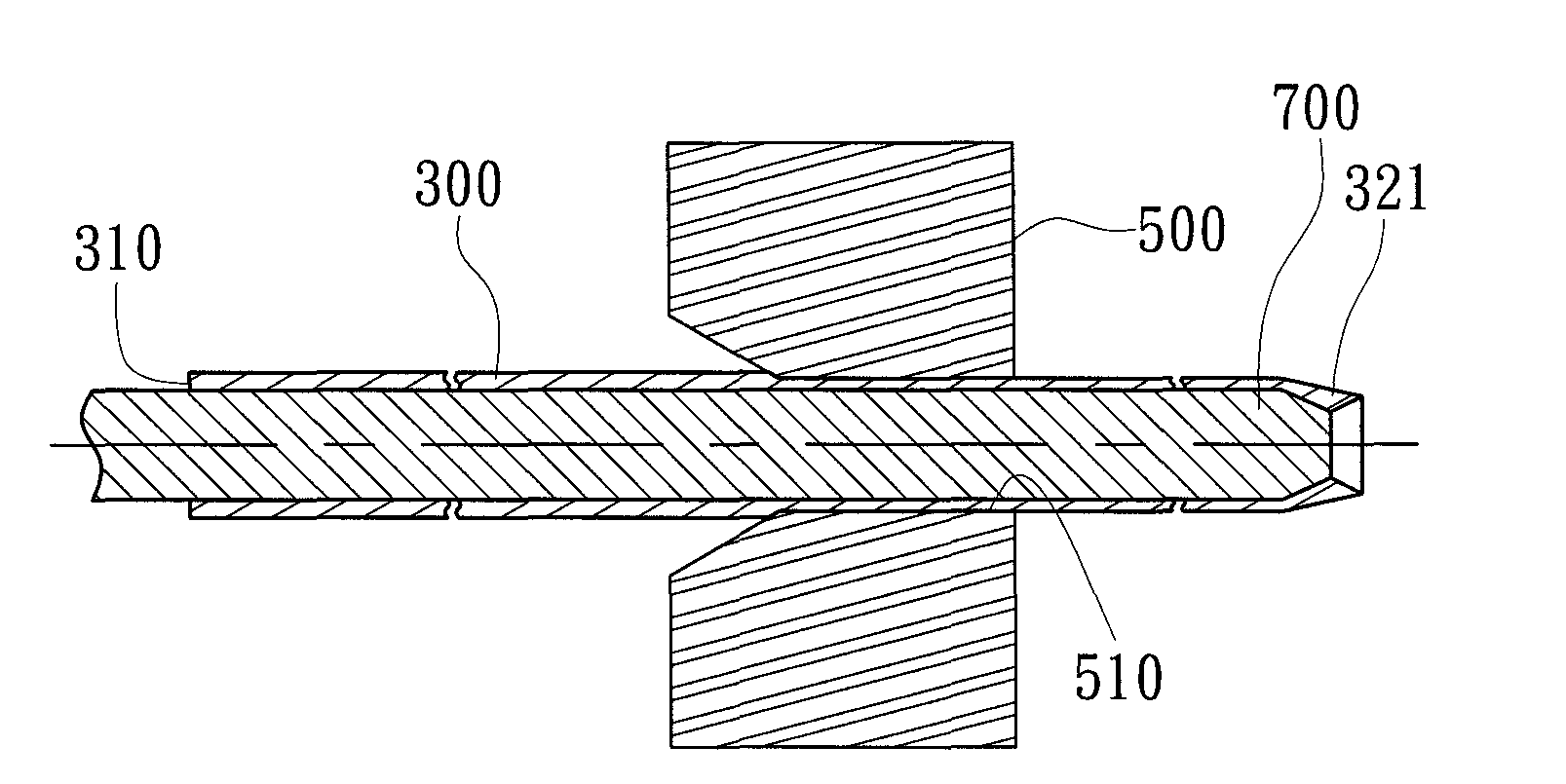

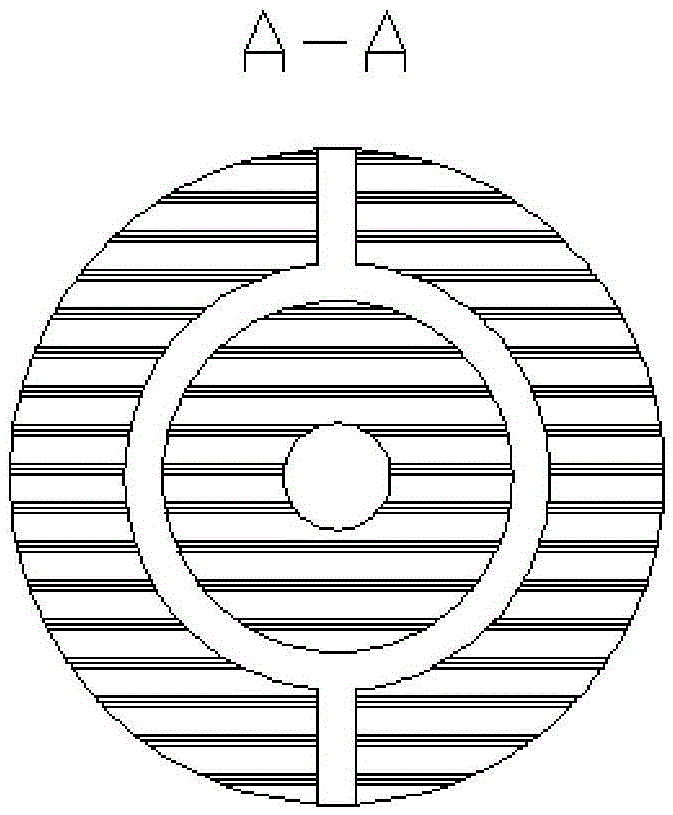

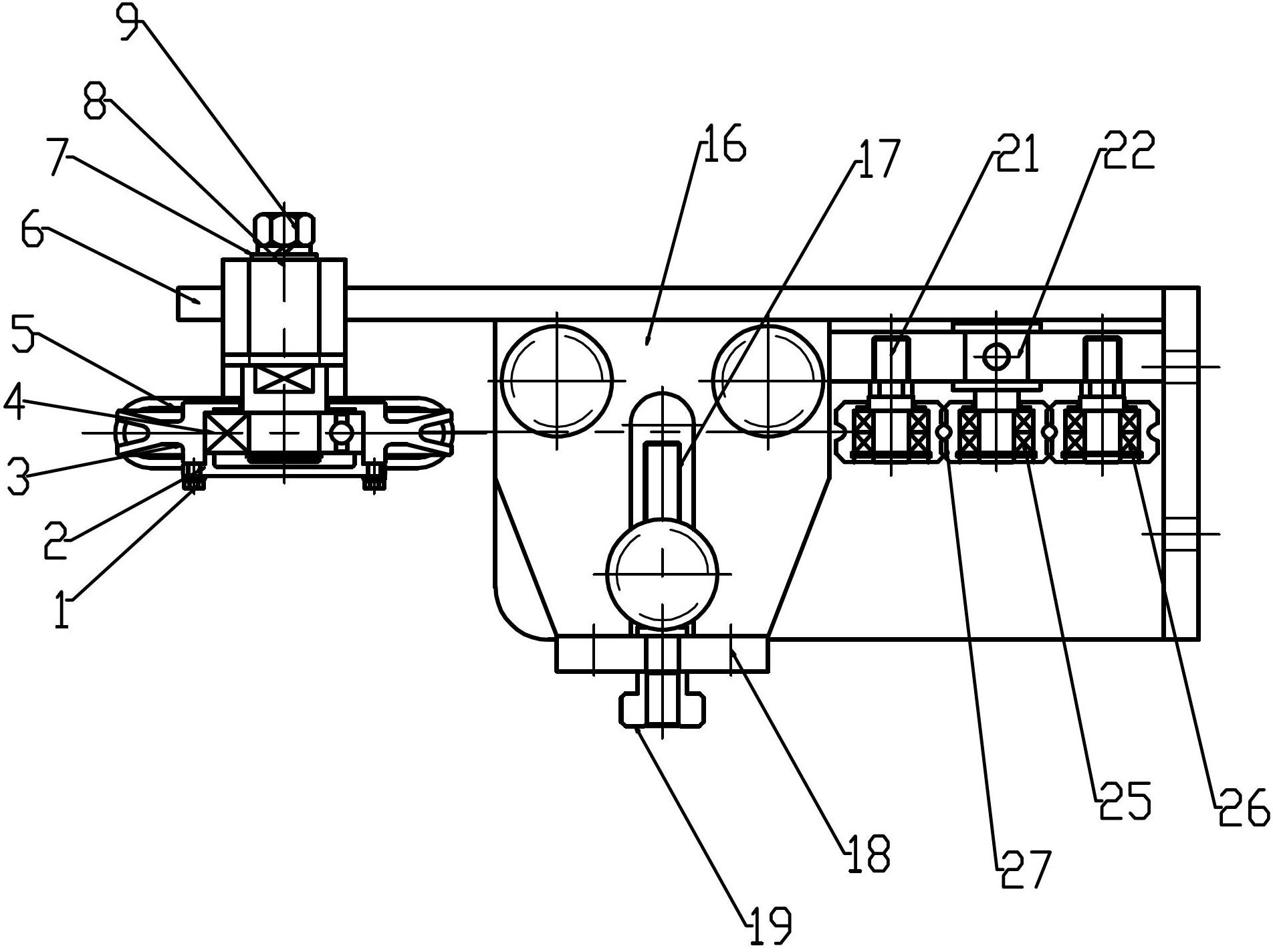

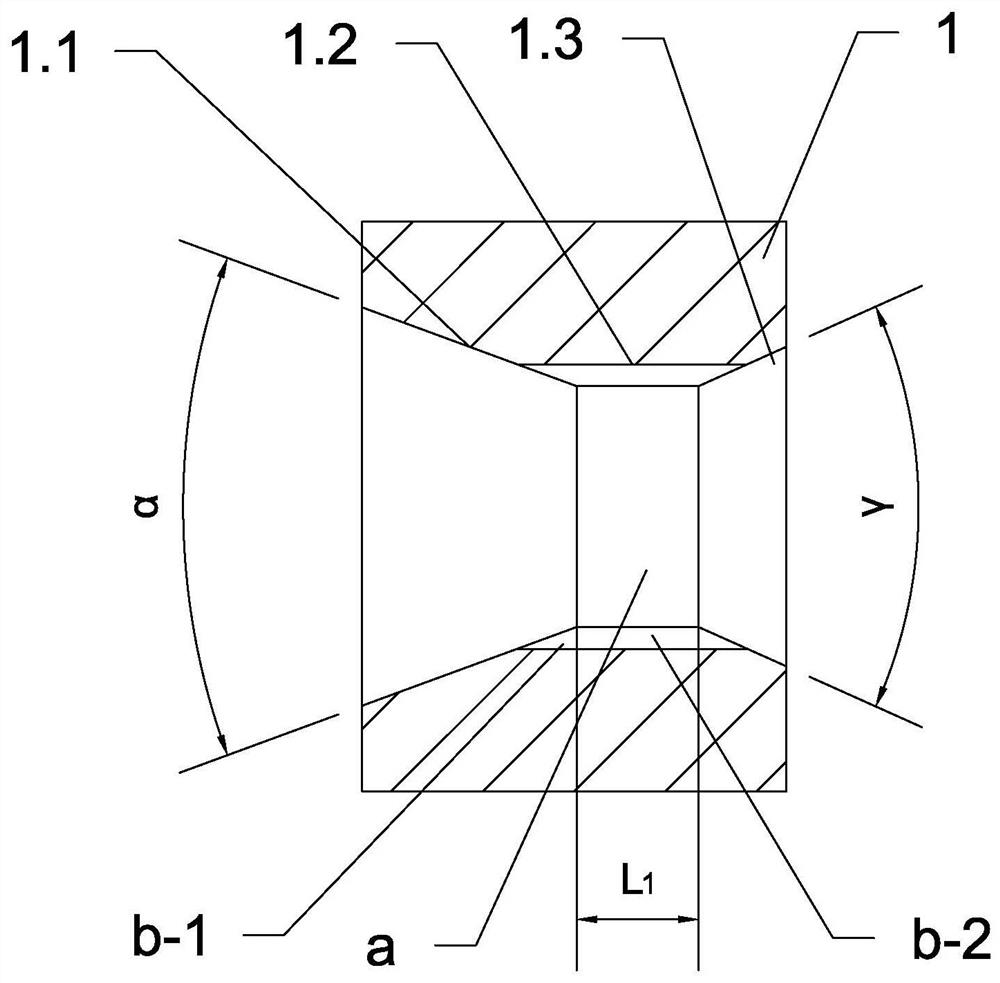

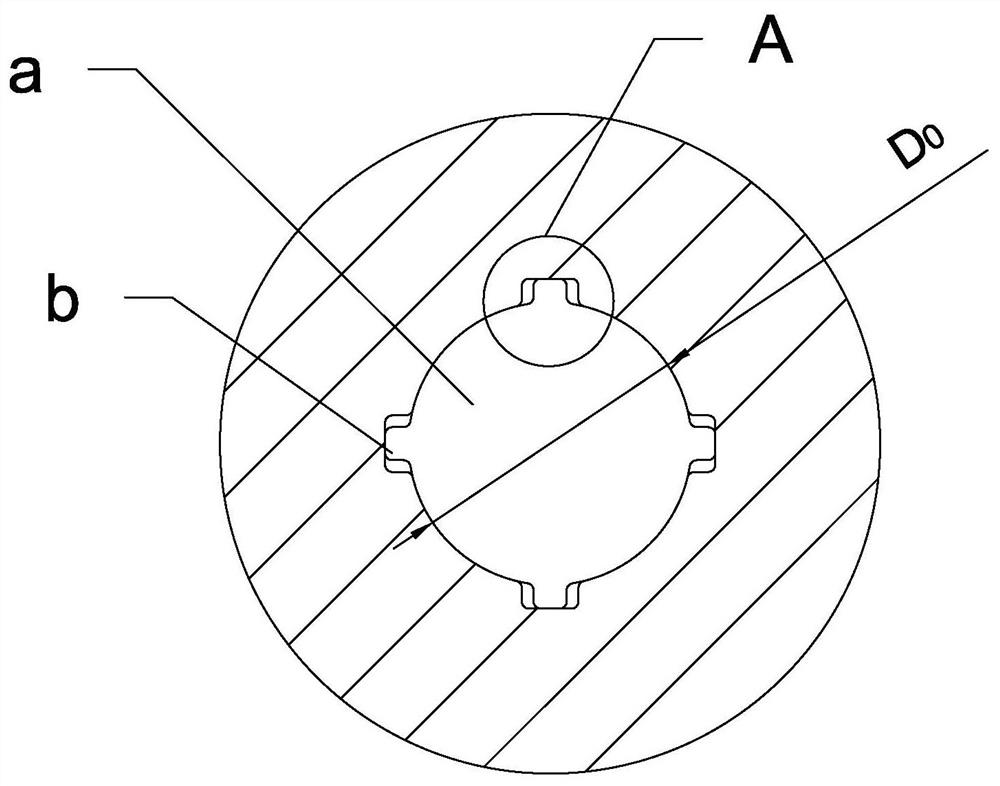

Cold-drawing die of ribbed cladding pipe, production process and finished pipe thereof

InactiveCN111842517AStructural advantageSimple structureWire straightening devicesDrawing diesSolution treatmentSolid structure

The invention relates to the field of machining and manufacturing of special-shaped section stainless steel precise seamless pipes, and particularly relates to a cold-drawing die of a ribbed claddingpipe, a production process and a finished pipe thereof. The cold-drawing die comprises a cold-drawing outer die for molding the outer contour of a pipe, and a cold-drawing core head for limiting the inner diameter of the pipe, wherein an internal molding cavity of the cold-drawing outer die comprises an inlet section, a molding section and an outlet section arranged in sequence; the inlet sectionand the outlet section are both circular table grooves; the molding section comprises an outer diameter molding hole, and at least one section of rib groove formed in the outer periphery of the outerdiameter molding hole; and the cold-drawing core head is a solid structure, and comprises a fixed inner diameter section, a circular table section and a back cylinder section arranged in sequence. Theprocess comprises the steps of preparation of machined pipes, cold-drawing pretreatment, cold-drawing molding, pipe cutting cleaning, solution treatment and straightening. The die is simple in structure and low in production cost; and the used process is high in production efficiency, excellent in surface quality, high in size precision and excellent in comprehensive performance.

Owner:ZHEJIANG JIULI HI TECH METALS

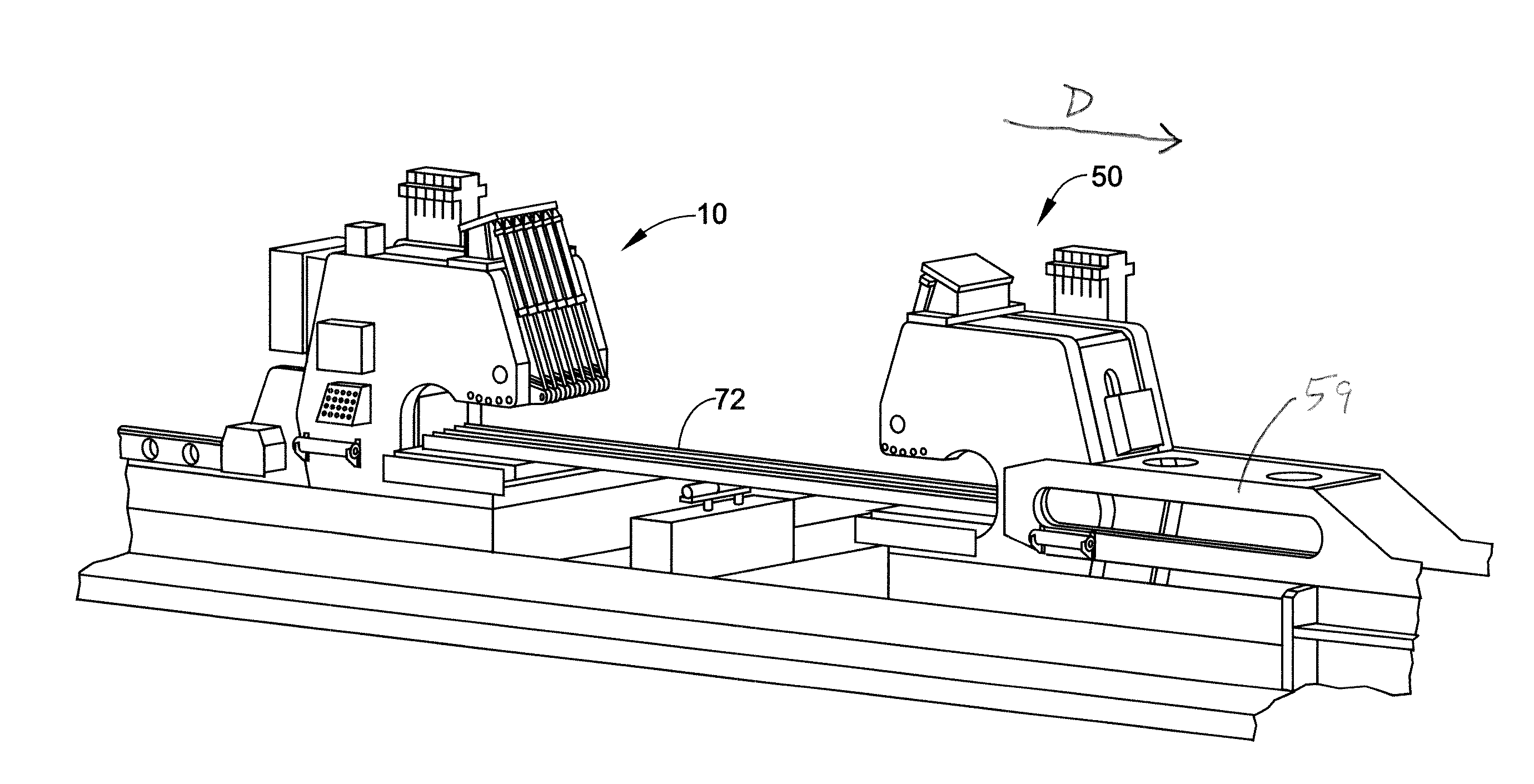

Drawing and Straightening Apparatus for Metal Wire, and Corresponding Drawing and Straightening Method

ActiveUS20160016216A1Reduce internal tensionReduce the possibilityWire straightening devicesMetal-working feeding devicesEngineeringMechanical engineering

Apparatus for drawing and straightening at least a metal wire, comprising a drawing unit of the metal wire along a direction of advance which comprises a first motorized main roll, on part of the periphery of which first idle contrast rolls are disposed, with a smaller diameter than the first main roll. The apparatus also comprises a straightening only unit of the metal wire, independent from the drawing unit, disposed along the direction of advance and upstream of the drawing unit, the straightening only unit comprising a second idle main roll, on part of the periphery of which second idle contrast rolls are disposed, with a diameter smaller than the second main roll.

Owner:M E P MASCH ELECTRONICS PIEGATRICI SPA

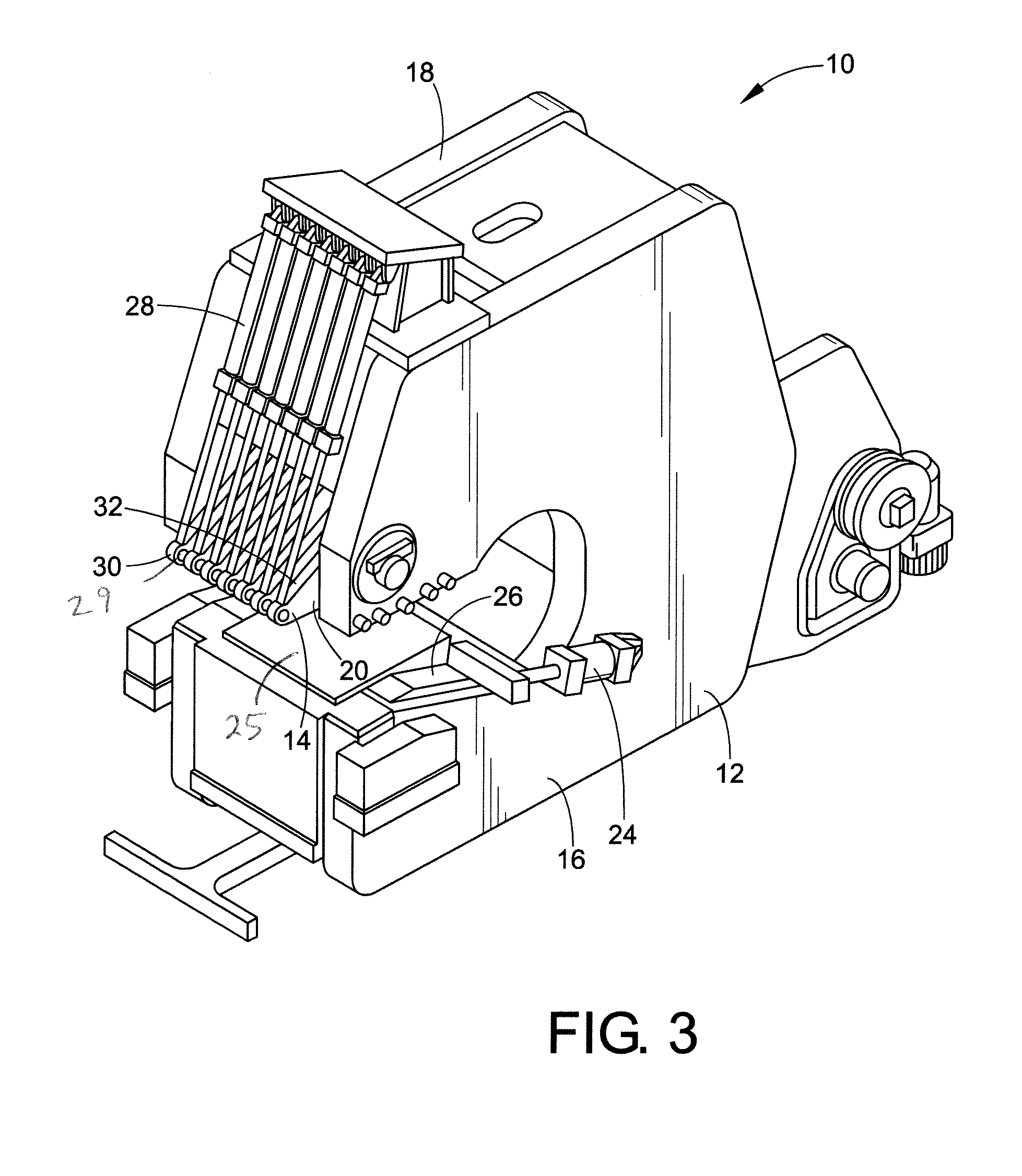

Stretching device

InactiveUS20090308127A1Eliminate slippageEffective gripWire straightening devicesMetal rolling arrangementsGrip forceEngineering

A stretching device has a housing; a first clamping member attached to a first portion of the housing; a second clamping member attached to a second portion of the housing; wherein the first clamping member has a movable pivot member such that an angle of contact between the first clamping member and a workpiece to be gripped remains constant regardless of the workpiece's thickness. A stretcher assembly has a first stretcher having a first housing having a first clamping member and a second clamping member opposed to each other; and a second stretcher having a second housing having a third clamping member and a fourth clamping member opposed to each other; and a workpiece support member interposed between the first stretcher and the second stretcher, wherein the first and third clamping members each includes a movable pivot joint such that an angle of contact of the first and third members with a workpiece to be gripped remains constant regardless of a thickness of the workpiece. The gripping force remains proportional to a stretching force.

Owner:BUTECH BLISS

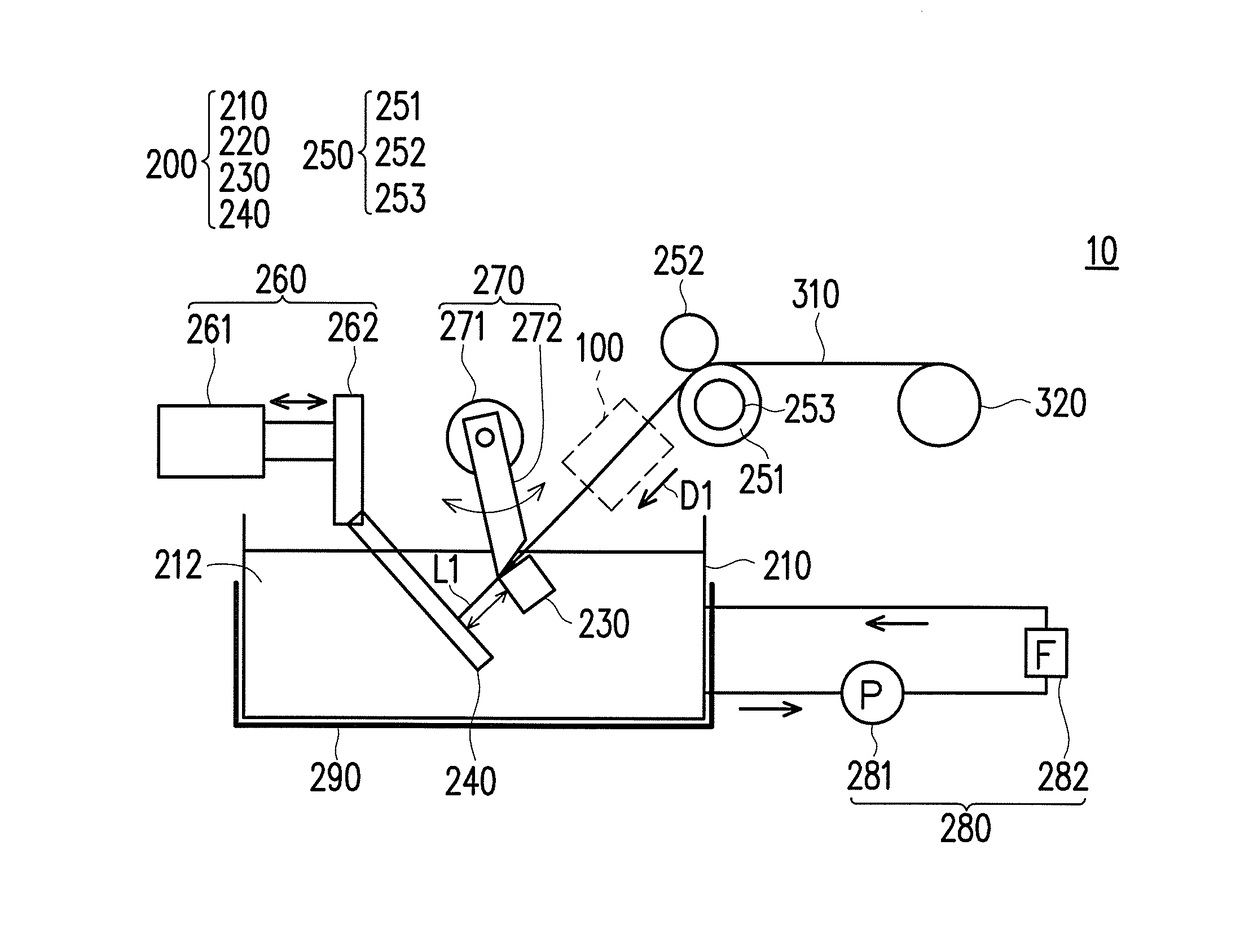

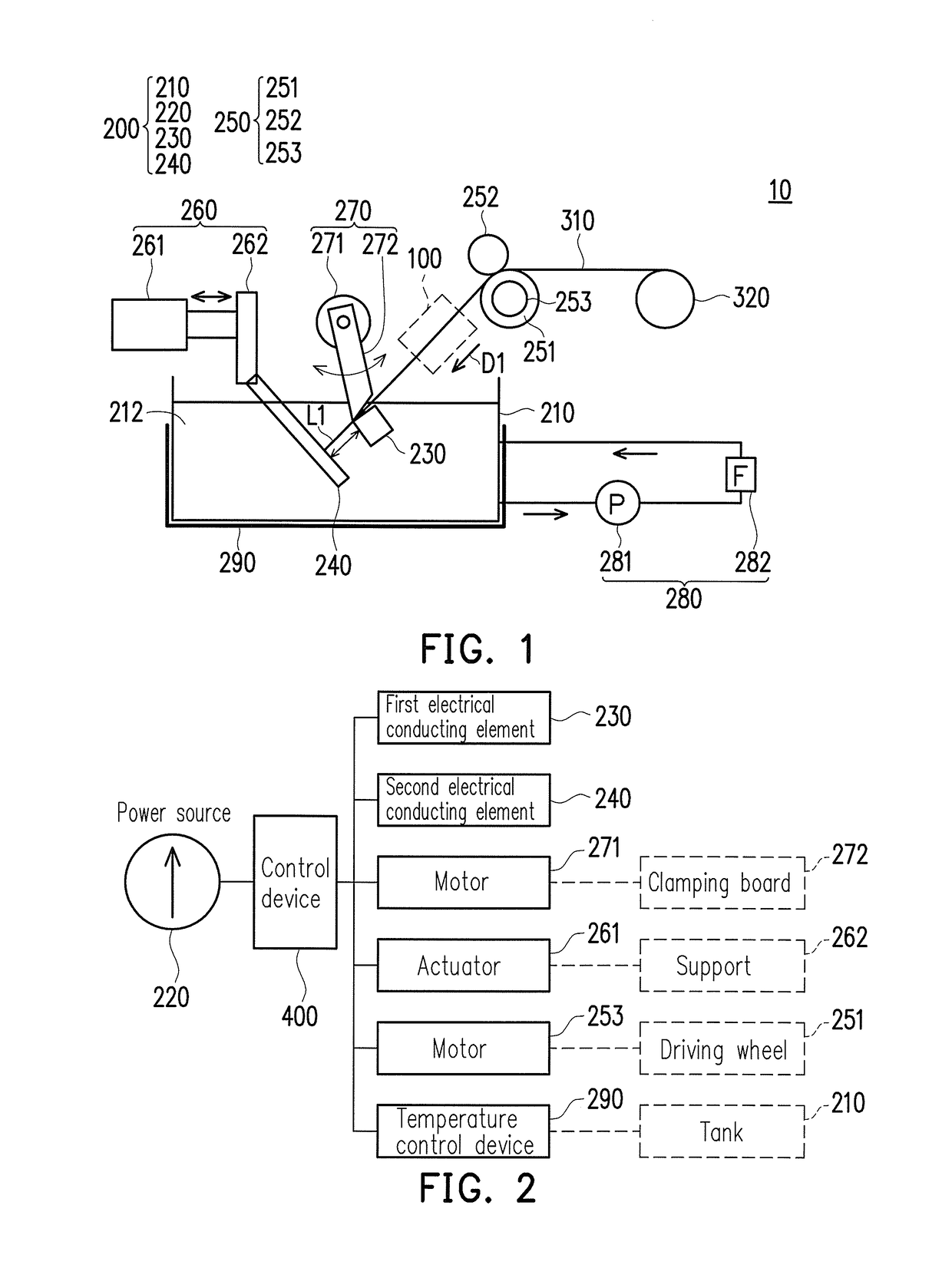

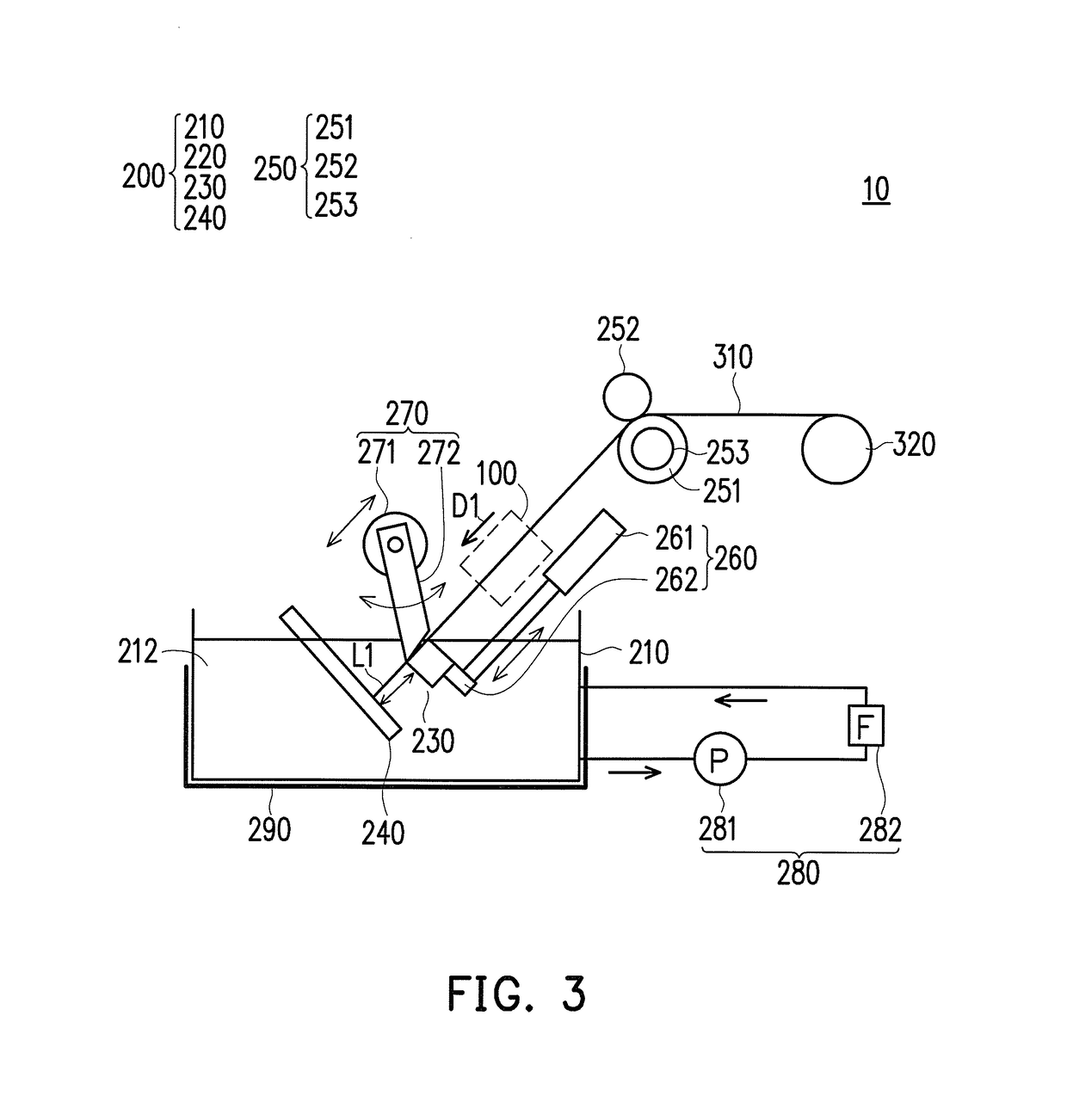

Straightening device and particle production apparatus using the same

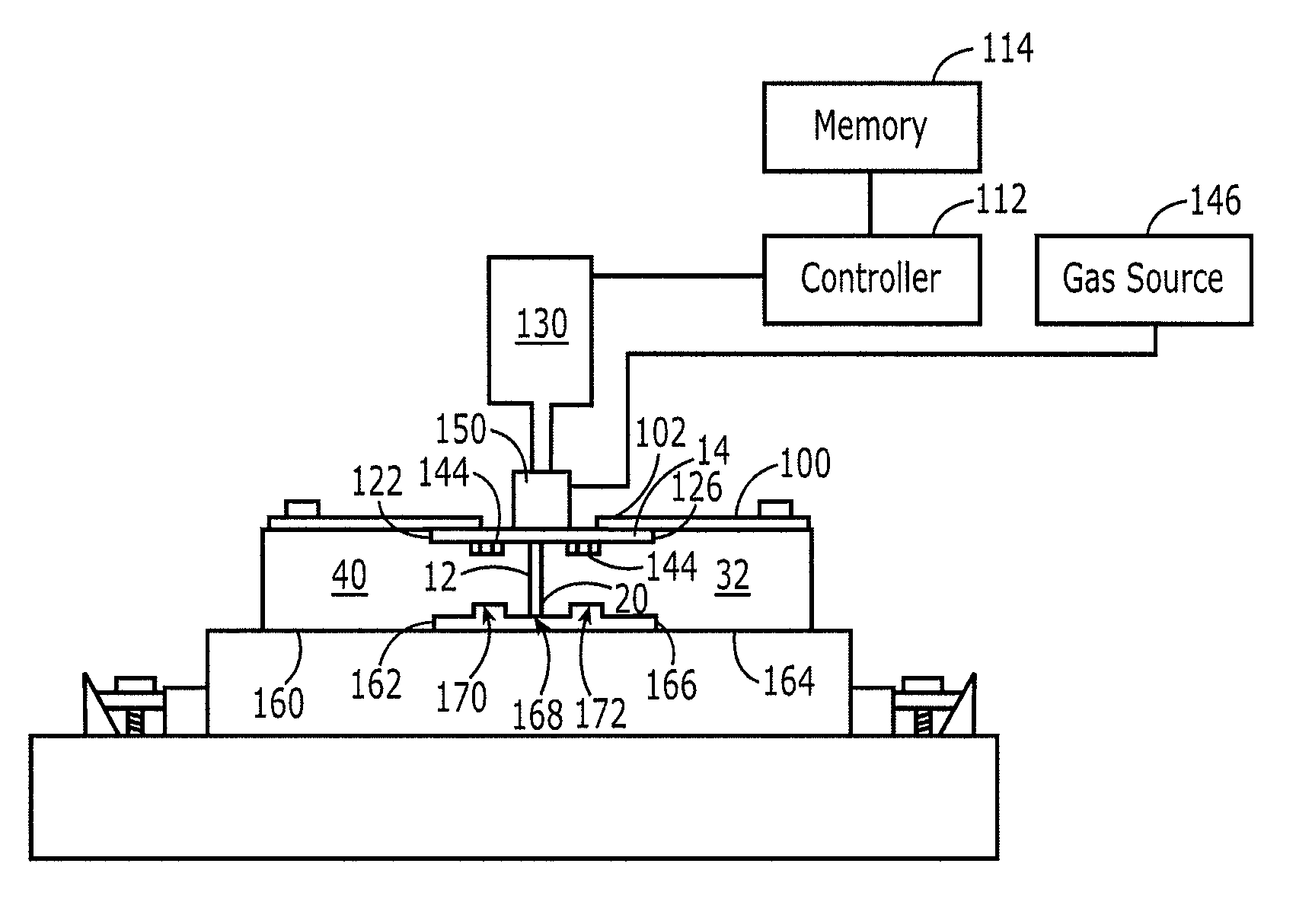

ActiveUS20170080499A1Increase productivityImprove securityWire straightening devicesTransportation and packagingElectricityEngineering

A particle production apparatus including a generating device, a conveying device, and a straightening device is provided. The generating device includes a tank filled with a dense medium, an electric power source, a first and a second electrical conducting element received in the dense medium and coupled to an anode and a cathode of the electric power source respectively. The conveying device is configured to convey a metal wire into the tank and make the metal wire to contact the first electrical conducting element and the second electrical conducting element in a straight-line direction, so as to produce an electric explosion to form a plurality of particles in the dense medium.

Owner:METAL INDS RES & DEV CENT

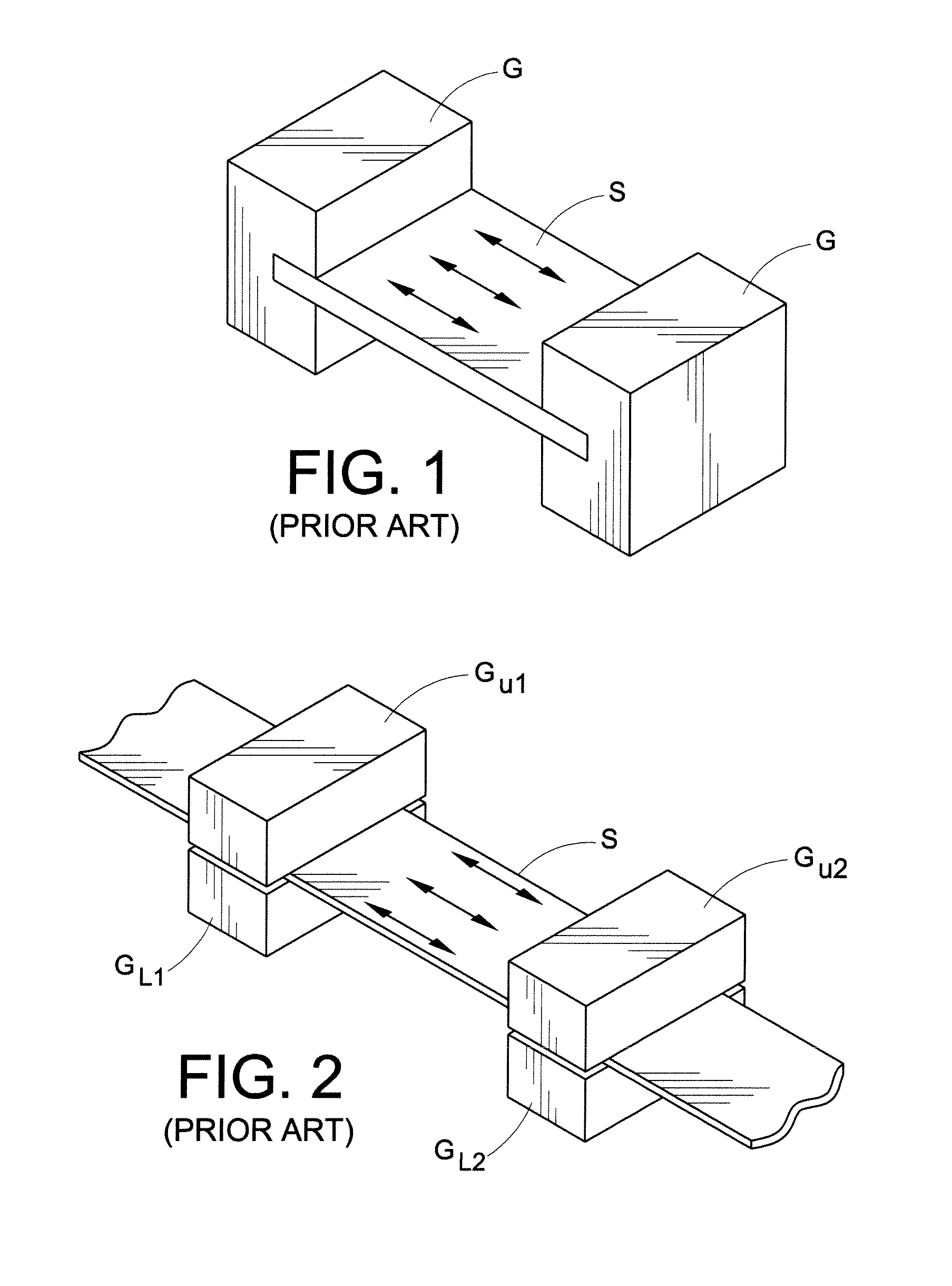

Apparatus and method for forming corrugated members

ActiveUS7642481B2Reducing cost and complexityIncrease flexibilityWire straightening devicesElectric heatingFlangeBackplane

An apparatus and method for forming a stringer are provided. The stringer generally includes a web having a desired corrugated configuration and first and second flanges welded to opposite edges of the web. The apparatus includes a support structure, a strongback that is supported by the support structure, and a plurality of dies that are adjustable relative to the strongback. The strongback defines a corrugated contour surface corresponding to the desired corrugated configuration of the web. The dies define corresponding forming surfaces and are configured to be advanced toward the strongback to thereby form the web to the desired corrugated configuration between the contour surface of the strongback and the forming surfaces of the dies. Further, the apparatus can receive the flanges of the stringer in a predetermined configuration with the web so that the flanges can be welded to the web while the web is supported by the strongback and dies in the desired corrugated configuration.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com