Automatic wire-welding surface treatment process and device for stainless steel

A surface treatment and automatic welding technology, applied in metal wire drawing, manufacturing tools, metal processing equipment, etc., can solve the problems of surface oxidation of welding wire, impurity pollution, poor linearity, etc., to eliminate stress, prevent acid mixing, and eliminate residual stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

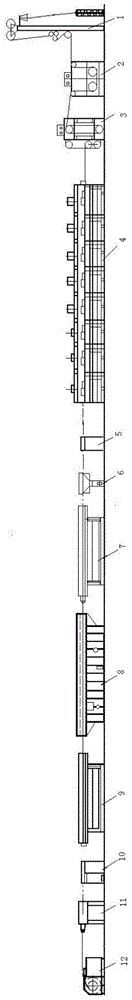

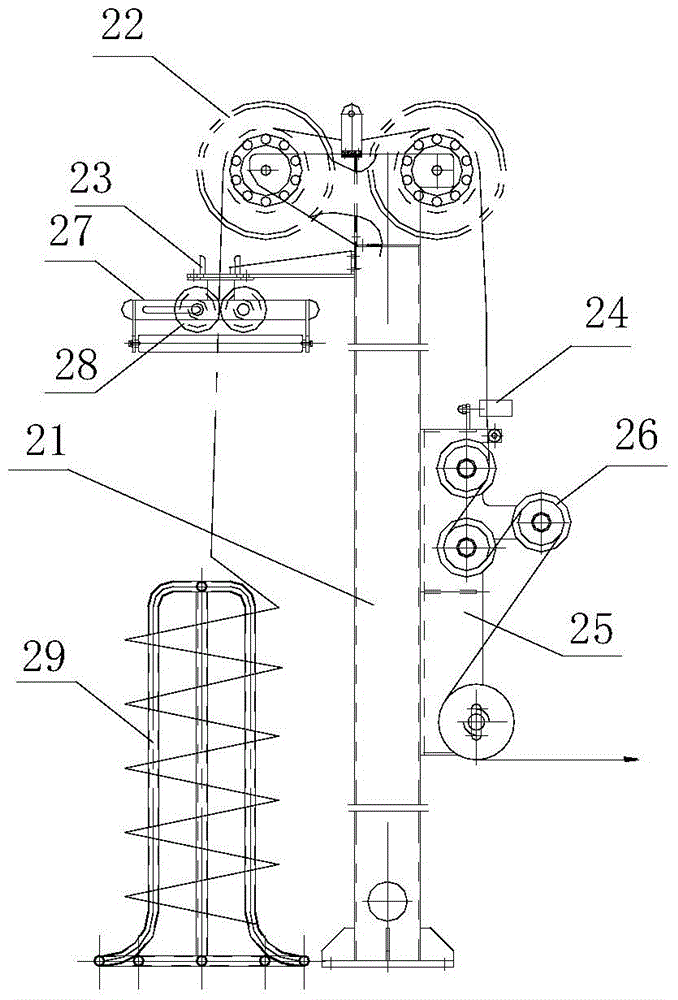

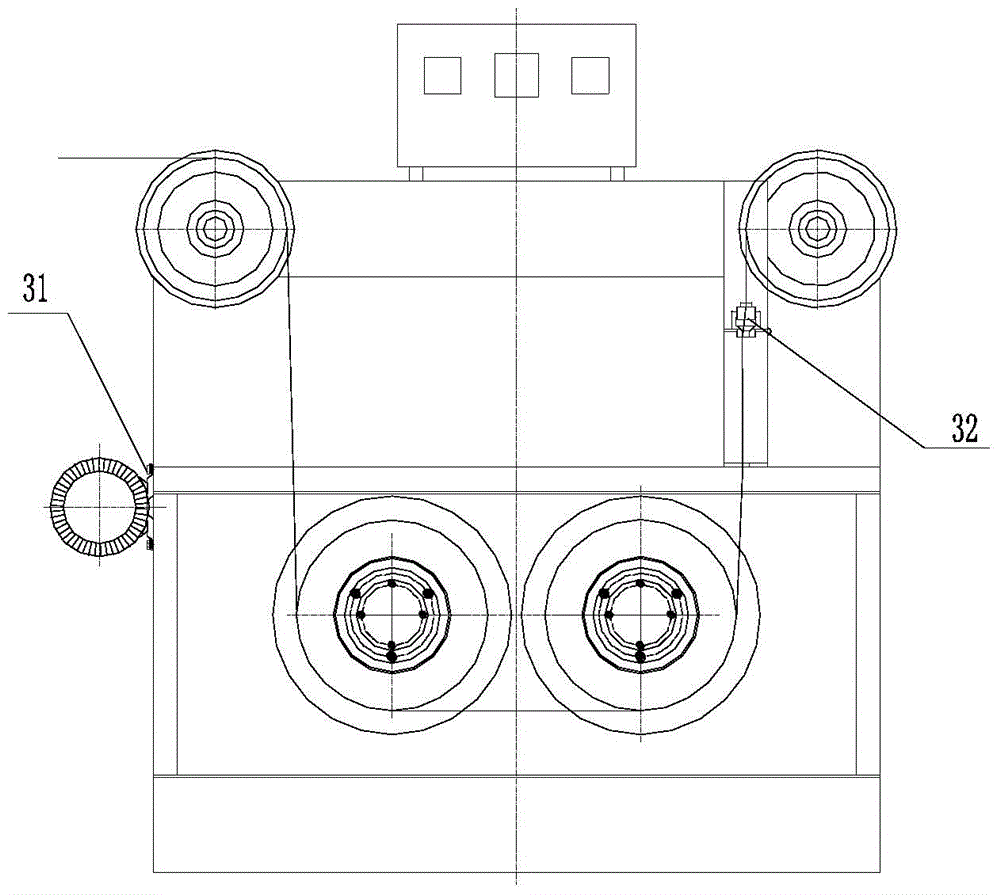

[0033] Such as figure 1 As shown, a device for stainless steel automatic welding wire surface treatment includes a high-position pay-off frame 1, and the high-position pay-off frame 1 is provided with a wire feeding mechanism 27 and a well-tac-toe roller structure 28, and the welding wire busbar is rolled into the wire, reducing The friction between the welding wire busbar and the wire frame is eliminated during drawing, and the surface quality of the welding wire busbar is improved; There is a film solution, a pump for circulating the film solution is provided in the coating tank 2, a fan 31 is provided in the coating tank 2, and an air nozzle 32 is provided at the outlet; the coating tank 2 is connected with the vertical drying box 3, and the The vertical drying box 3 is provided with a circulation channel, and the air is blown into the circulation channel by the fan after being electrically heated, and the running direction of the hot air is opposite to that of the welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com