Iron wire rust cleaning-wire drawing combination apparatus and its working method

A combined device and iron wire technology, applied in the cleaning method of tools, metal wire drawing, metal processing equipment, etc., can solve the problems of low production efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

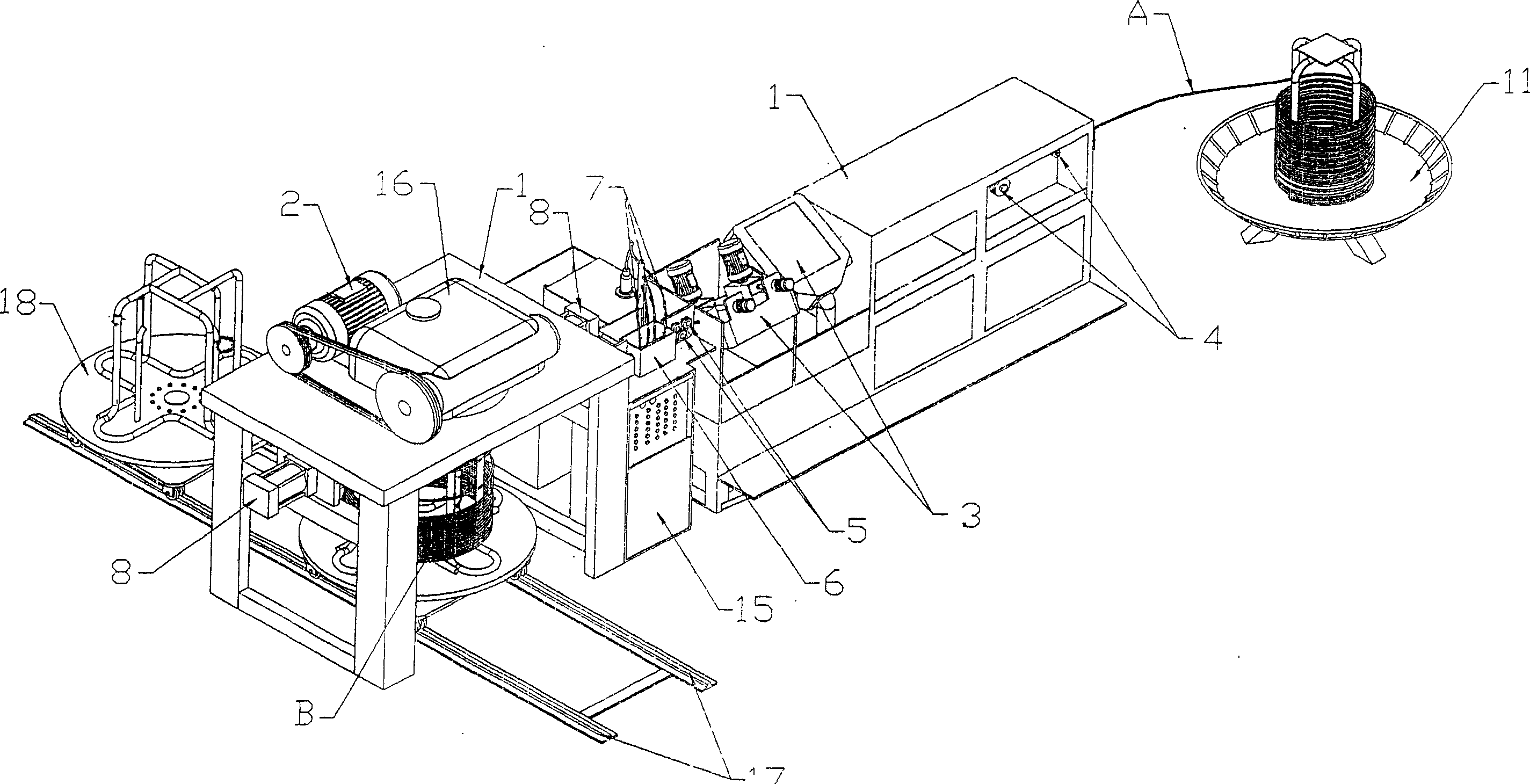

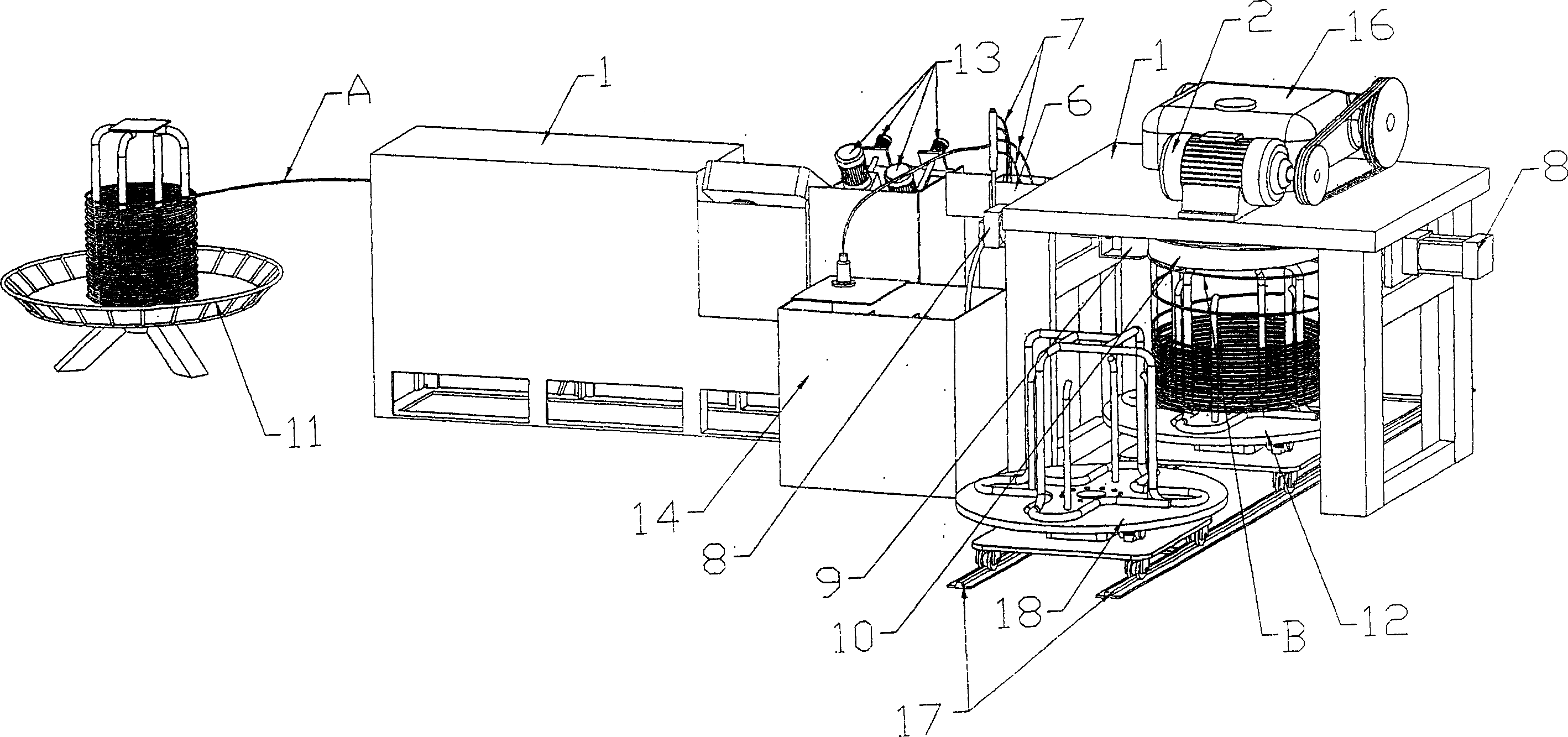

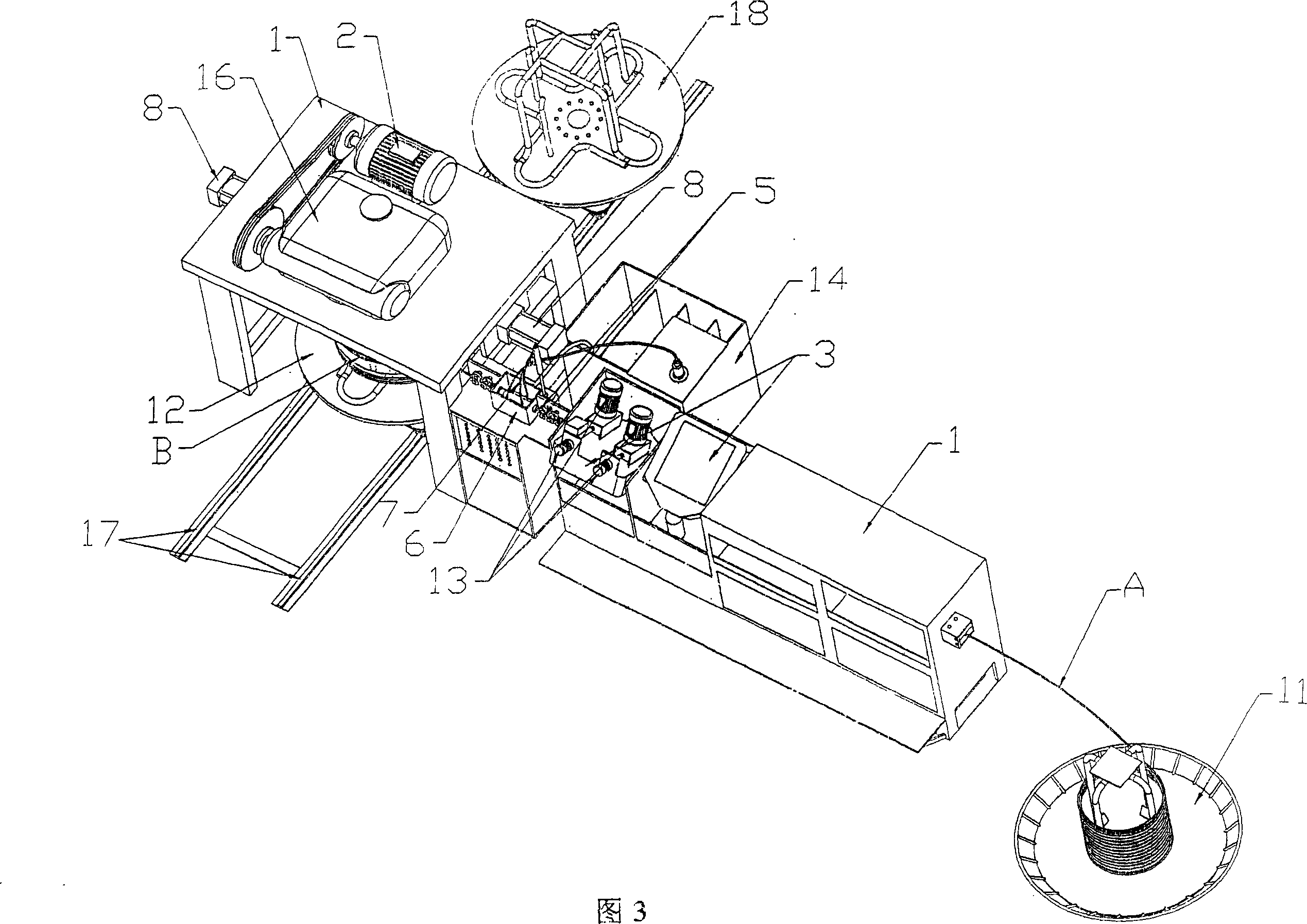

[0015] Such as Figure 1 to Figure 6 As shown: the present invention consists of a machine base 1, a main motor 2, a derusting mechanism 3, a crimping wheel set 4, a wire passing pulley 5, a wire drawing die 6, a fuel injection pipe 7, a hydraulic cylinder 8, a molding crimping wheel 9, Reel 10, pay-off stand 11, take-up stand 12, derusting control motor 13, automatic filter oil supply tank 14, electrical control box 15, gearbox 16, rail 17, auxiliary take-up stand 18, iron wire A and finished product Composed of wire B. Wherein the main motor 2 and the gearbox 16 are installed on the upper end of the support 1, and the reel 10 is located at the bottom of the support 1, and forms a shaft connection with the main motor 2, and is driven by the main motor 2 and the gearbox 16 to work; The two ends of the reel 10 are respectively provided with a forming crimping wheel 9; meanwhile, the bottom of the reel 10 is provided with a take-up frame 12 that can slide along the rail 17; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com