Fine metal wire drawing unit

A metal wire drawing and metal wire technology, applied in metal wire drawing, metal extrusion, metal processing equipment, etc., can solve the problems of insufficient wire drawing toughness, poor wire drawing effect, insufficient cooling and cleaning, etc., and achieve reasonable production cost and high degree of automation , making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

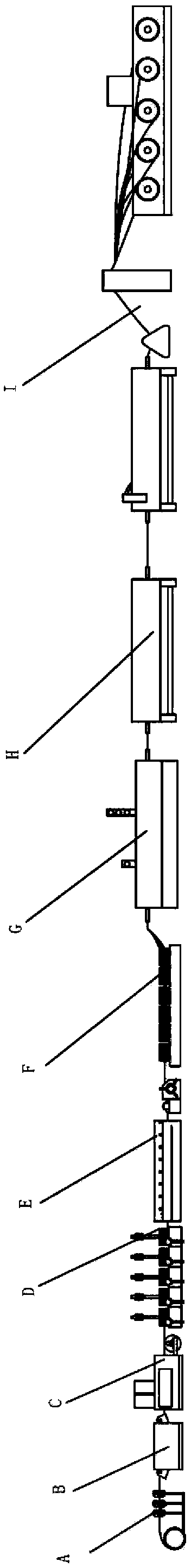

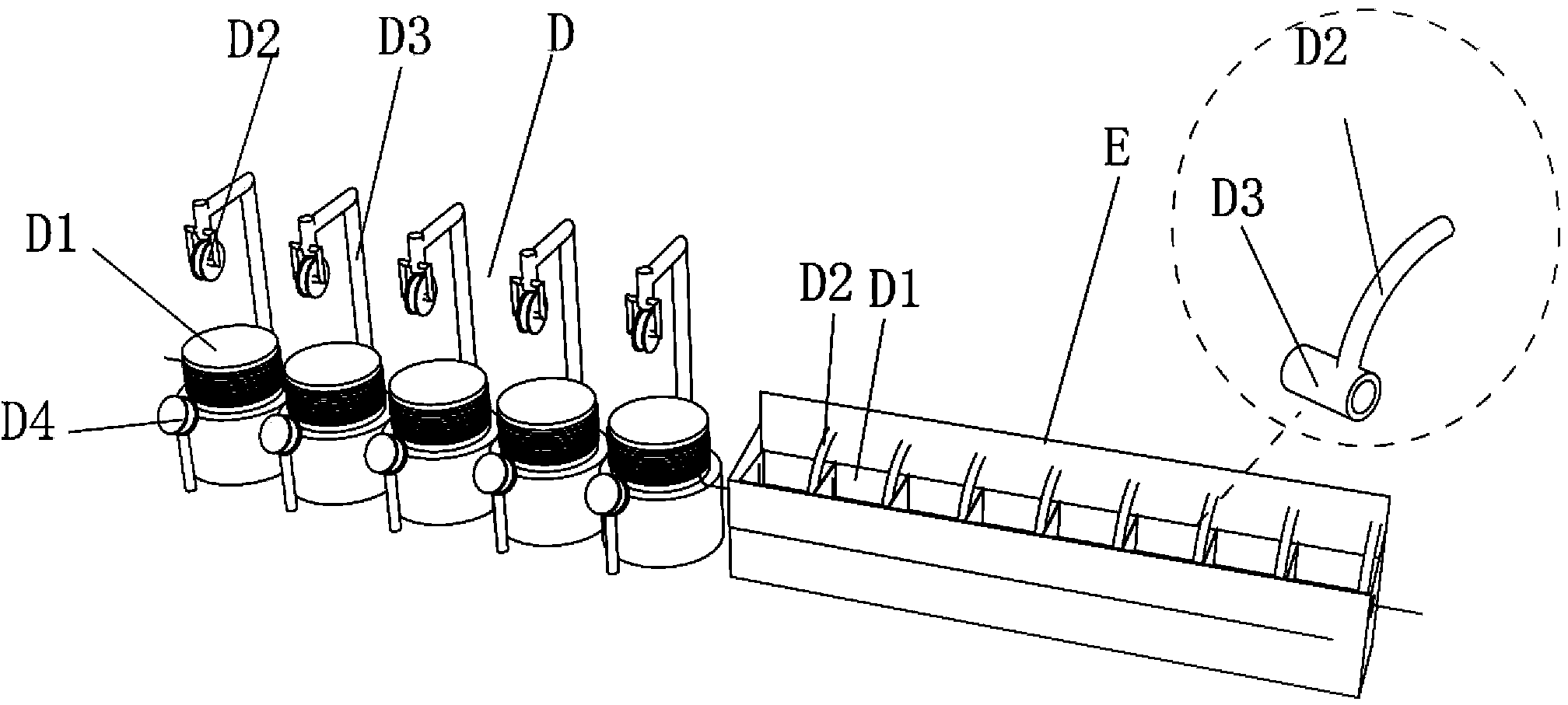

[0050] Such as figure 1 As shown, the fine metal wire drawing unit is composed of eight equipment arranged in sequence, the metal wire rod straightening device A, the metal wire coating equipment B, the metal wire drying equipment C, the first metal wire drawing equipment D, the first metal wire drawing equipment A metal wire cleaning device E, a second metal wire drawing device F, a second metal wire cleaning device G, a metal wire annealing device J, and a metal wire cooling drum wire receiving device I.

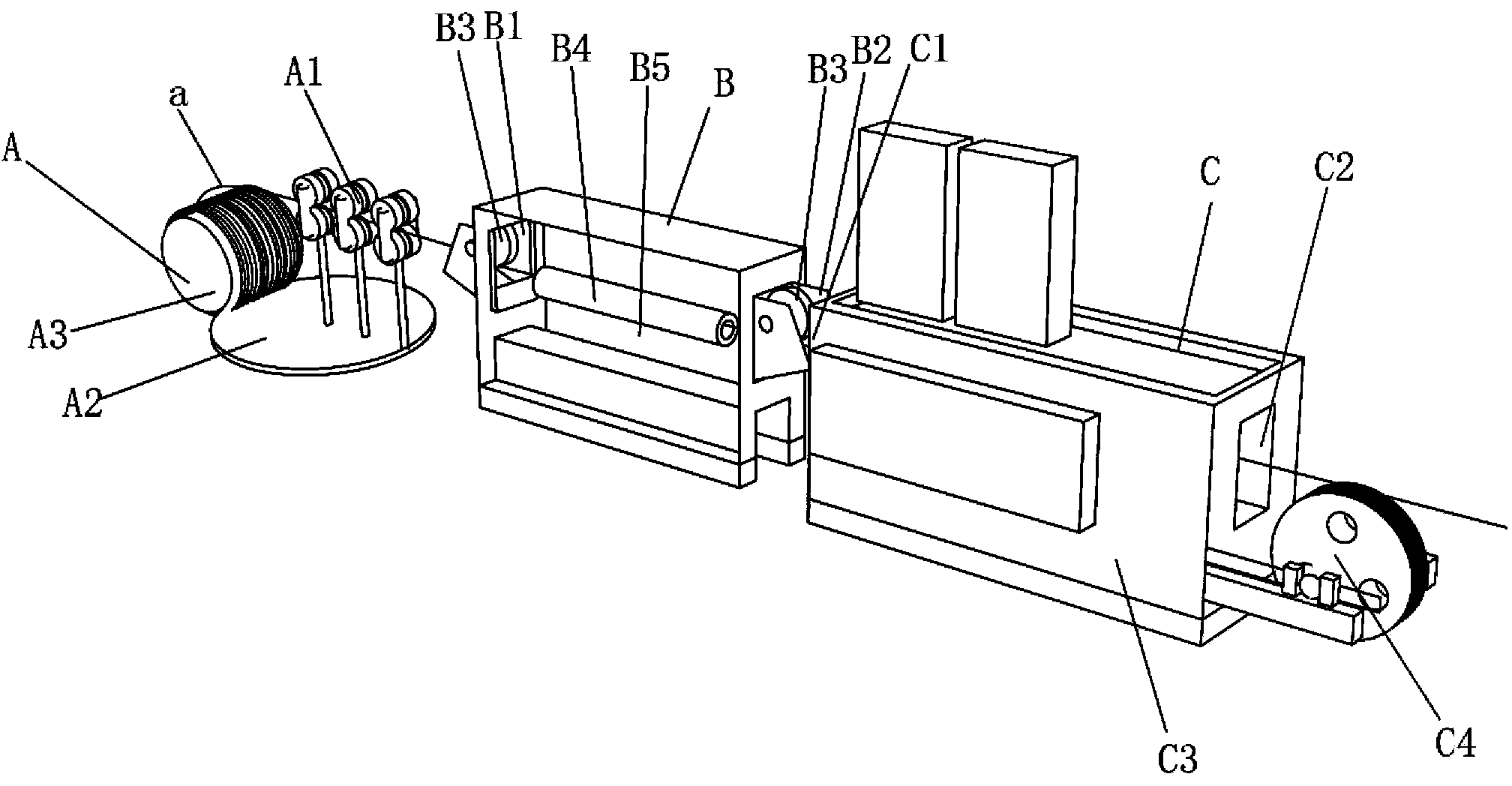

[0051] Such as figure 2 As shown, the metal wire rod straightening device A includes a metal wire rod holder A3, the metal wire rod is wound on the metal wire rod holder A3, and a plurality of sets of metal rods are arranged on the side of the metal wire rod holder A3. The pair of rollers A1, the metal wire rod creel A3 and the metal pair of rollers A1 are set on the supporting platform A2, and the metal wire rod becomes a thick-diameter wire a after being straightened b...

Embodiment 2

[0065] In this embodiment, the difference from Embodiment 1 is that the bottom of the cooling water pool I5 is inclined 30 degrees to the metal wire collection equipment. The rest of the working principles are the same as in Embodiment 1.

[0066] In addition, since the bottom surface angle of the cooling water pool I5 belongs to the category easily understood by those skilled in the art, no detailed description will be given here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com